Leather processing agent

A technology of leather treatment agent and emulsifier, which is applied in the fields of leather surface treatment, small hide/big hide/leather/fur treatment, tanning treatment, etc. Layer phenomenon, uniform feel, excellent fineness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

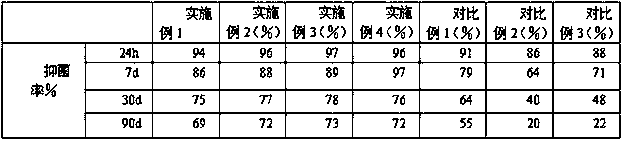

Examples

Embodiment 1

[0020] A leather treatment agent, comprising the following components by weight percentage: 25% sodium polyacrylate, 1% tripolyethylene glycol monododecyl ether, 1% sodium tripolyphosphate, 1% silver-loaded activated carbon and silver-loaded zeolite, 1% % nano titanium dioxide, 11% modified rapeseed oil, 25% amphoteric acrylic retanning agent, 35% water. The dosage ratio of silver-loaded activated carbon and silver-loaded zeolite is 1:1.

[0021] The preparation method of the above-mentioned modified rapeseed oil is as follows: add yeast to the rapeseed oil, heat up at a heating rate of 5°C / min after fully mixing, keep warm and mix for 2min after the temperature rises to 178-185°C, and then heat at 10°C / min Cool down at a cooling rate of 1 min. After the temperature drops to 28-35°C, keep it warm for 30 minutes and pass through a 400-mesh sieve. Then add cationic polyacrylamide, mix thoroughly and let stand for 1 hour, then increase the temperature at a rate of 10°C / min. Rais...

Embodiment 2

[0024] A kind of leather treatment agent, similar to Example 1, the difference is that it comprises the following components in weight percentage: 30% sodium polyacrylate, 3% emulsifier, 3% sodium tripolyphosphate, 3% silver-loaded thing, 3% Nano titanium dioxide, 10% modified rapeseed oil, 20% amphoteric acrylic retanning agent, 28% water.

[0025] The emulsifier is tripolyethylene glycol monododecyl ether.

[0026] The silver-loaded substance is silver-loaded activated carbon and silver-loaded zeolite. The dosage ratio of silver-loaded activated carbon and silver-loaded zeolite is 1:1.

Embodiment 3

[0028] A kind of leather treatment agent, and embodiment 2 is similar, and difference is, comprises the component of following percentage by weight: 31% sodium polyacrylate, 3% emulsifying agent, 2% sodium tripolyphosphate, 2% silver-loaded thing, 2% Nano titanium dioxide, 10% modified rapeseed oil, 20% amphoteric acrylic retanning agent, 30% water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com