Modification method of cellulose fiber fabric and salt-free dyeing method

A technology of cellulose fibers and fabrics, applied in the field of chemical modification of cellulose materials and protein materials and their blended fabrics, can solve the problems of difficult dye liquor wastewater treatment, low dyeing rate and color fixation rate, and damage to the ecological environment. Achieve high dye utilization rate, improve affinity, and high dyeing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Modified formula:

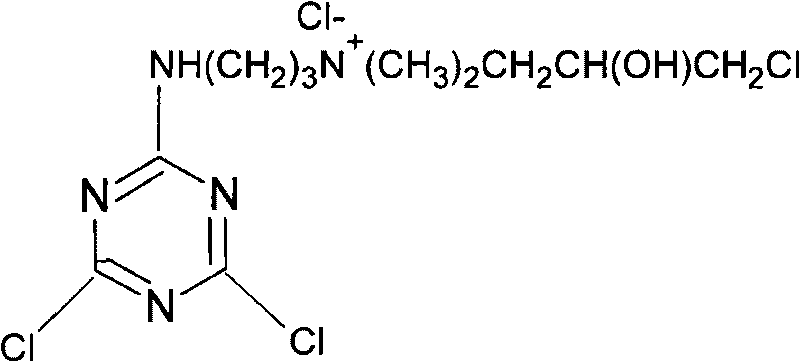

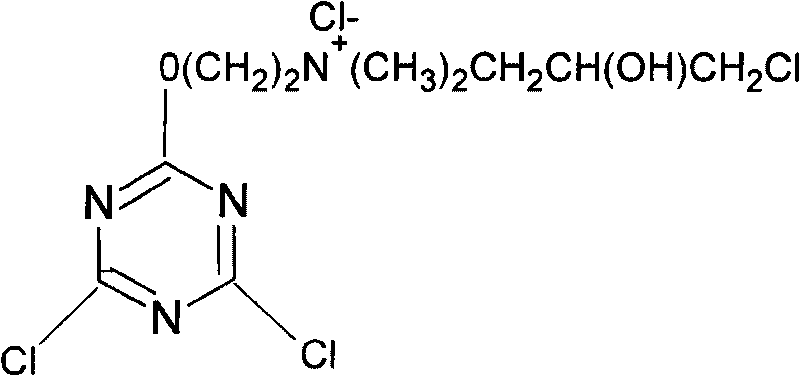

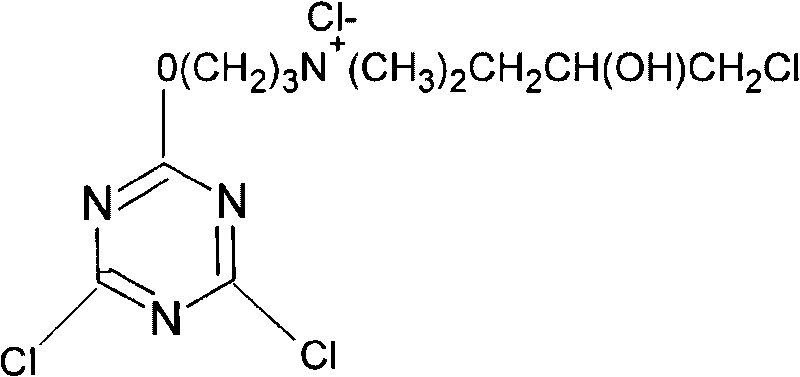

[0050] 2-[2-Hydroxy-3-chloropropyl]-dimethylaminopropylamino-4,6-dichlorotriazine ammonium chloride 0.5-10% (mass percentage, the same below)

[0051] Sodium hydroxide 0.1-8%,

[0052] Penetrant JFC 0.01-1%,

[0053] The remainder is water;

[0054] Modification treatment method: modification in ordinary dyeing machine;

[0055]Put the prepared solution above into the dyeing machine, and put the pre-treated cotton fabric into the dyeing machine. At a temperature of 40°C, it was operated continuously for 200 minutes. Cool down to 40°C and wash the fabric fully with water.

Embodiment 2

[0057] Modified formula:

[0058] 2-[2-Hydroxy-3-chloropropyl]-dimethylaminopropylamino-4,6-dichlorotriazine ammonium chloride 0.5-10% (mass percentage, the same below)

[0059] Sodium hydroxide 0.1-8%,

[0060] Penetrant JFC 0.01-1%,

[0061] The remainder is water;

[0062] Modification treatment process: modification in ordinary dyeing machine;

[0063] Put the prepared solution above into the dyeing machine, and put the pre-treated cotton fabric into the dyeing machine. At a temperature of 60°C, it was operated continuously for 120 minutes. Cool down to 40°C and wash the fabric fully with water.

Embodiment 3

[0065] Modified formula:

[0066] 2-[2-Hydroxy-3-chloropropyl]-dimethylaminopropylamino-4,6-dichlorotriazine ammonium chloride 0.5-10% (mass percentage, the same below)

[0067] Sodium hydroxide 0.1-8%,

[0068] Penetrant JFC 0.01-1%,

[0069] The remainder is water;

[0070] Modification treatment method: modification in ordinary dyeing machine;

[0071] Put the prepared solution above into the dyeing machine, and put the pre-treated cotton fabric into the dyeing machine. At a temperature of 70°C, it was operated continuously for 60 minutes. Cool down to 40°C and wash the fabric fully with water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com