Method for promoting pigment dyeing by using cellulase

A cellulase and paint dyeing technology, applied in the field of textile printing and dyeing, can solve problems such as environmental pollution, increased dyeing process, and damage to the natural and excellent properties of cotton fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Use the following process to light and thin pure cotton fabric (100g / m 2 ) for paint dyeing:

[0013] (1) Utilize cellulase to process fabric in dyeing machine, technological condition is as follows: the dosage of cellulase is 1% owf, temperature 55 ℃, pH5.2, time 30min, bath ratio 1: 20; Take it out and dehydrate it with a centrifuge until the liquid-carrying rate is 90%, and then dry it in an oven at 100°C;

[0014] (2) Dyeing the dried fabric, the process conditions are as follows: anionic paint red 3% owf, temperature 55°C, pH 7.0, time 70min, bath ratio 1: 10; color fixing treatment after dyeing, process The conditions are as follows: anionic binder 10g / L, temperature 80°C, time 20min; finally, the fabric is centrifugally dehydrated to 90% liquid-carrying rate, dried at 100°C, and baked at 150°C for 5min.

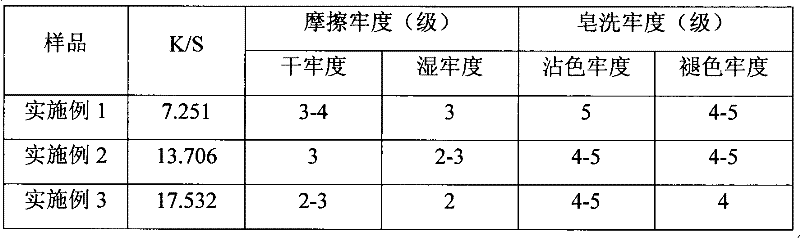

[0015] Test the color depth K / S value and color fastness of the above-mentioned paint dyed fabrics, the results are shown in Table 1.

Embodiment 2

[0017] Use the following process to medium-thick pure cotton fabric (180g / m 2 ) for paint dyeing:

[0018] (1) Use cellulase to treat the fabric in the dyeing machine, the process conditions are as follows: cellulase 3% owf, temperature 55 ° C, pH 5.4, time 40min, bath ratio 1: 20; after completion, the fabric is taken out and used The centrifuge dehydrates to 90% liquid, and then dries the fabric in an oven at 100°C;

[0019] (2) The fabric after drying is carried out paint dyeing, and process condition is as follows: anionic paint yellow 8%, temperature 55 ℃, pH7.0, time 80min, bath ratio 1: 10; Carry out fixation treatment after dyeing, process condition As follows: anionic binder 30g / L, temperature 80°C, time 30min; finally, the fabric is centrifuged and dehydrated to a liquid-carrying rate of 90%, dried at 100°C, and baked at 150°C for 8 minutes.

[0020] Test the color depth K / S value and color fastness of the above-mentioned paint dyed fabrics, the results are shown i...

Embodiment 3

[0022] Adopt the following process to thick heavy cotton fabric (250g / m 2 ) for paint dyeing:

[0023] (1) Use cellulase to treat the fabric in the dyeing machine, the process conditions are as follows: cellulase 5% owf, temperature 55 ° C, pH 5.2, time 40min, bath ratio 1: 20; after completion, the fabric is taken out and used The centrifuge dehydrates to 95% liquid, and then dries the fabric in an oven at 100°C;

[0024] (2) The fabric after drying is carried out paint dyeing, and technological condition is as follows: anionic paint blue 15%owf, temperature 55 ℃, pH7.0, time 80min, bath ratio 1: 10; Carry out fixation treatment after dyeing, process The conditions are as follows: anionic binder 50g / L, temperature 80°C, time 30min; finally, the fabric is centrifugally dehydrated to 90% liquid, dried at 100°C, and baked at 150°C for 10min.

[0025] Test the color depth K / S value and color fastness of the above-mentioned paint dyed fabrics, the results are shown in Table 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com