Disperse dye composition and application thereof

A technology of disperse dyes and compositions, applied in the directions of organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of large energy consumption and environmental pollution, soaping and reduction cleaning are carried out under alkaline conditions, etc., to save energy and water consumption, outstanding color fastness performance, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Mix 100 grams of component I of formula (I-1), 200 grams of multifunctional leveling agent SE with 750 grams of water, grind and disperse, and dry to obtain the finished product. The dye can provide fabric uniformity and fastness performance Good orange.

Embodiment 2

[0056] Component A containing 50 grams of formula (I-1), 50 grams of formula (I-2), and 100 grams of multifunctional leveling agent SE are mixed with 750 grams of water, ground and dispersed, and dried to obtain the finished product. The dye can provide fabric uniformity and good fastness properties of orange.

Embodiment 3~36

[0058] According to the method described in Example 1, the difference is that the structure and weight ratio of component I, component II, component III, and component IV and auxiliary agents in Table 1 are used to make a slurry after adding water and blending, grinding Disperse, dry, and make a finished product, thereby providing the desired uniform and fast color tone to the fabric.

[0059] Table 1: Composition and corresponding hue of different disperse dye compositions

[0060]

[0061]

[0062] 2. Application of the disperse dye composition of the present invention

[0063] 2.1. Applied to polyester dyeing process:

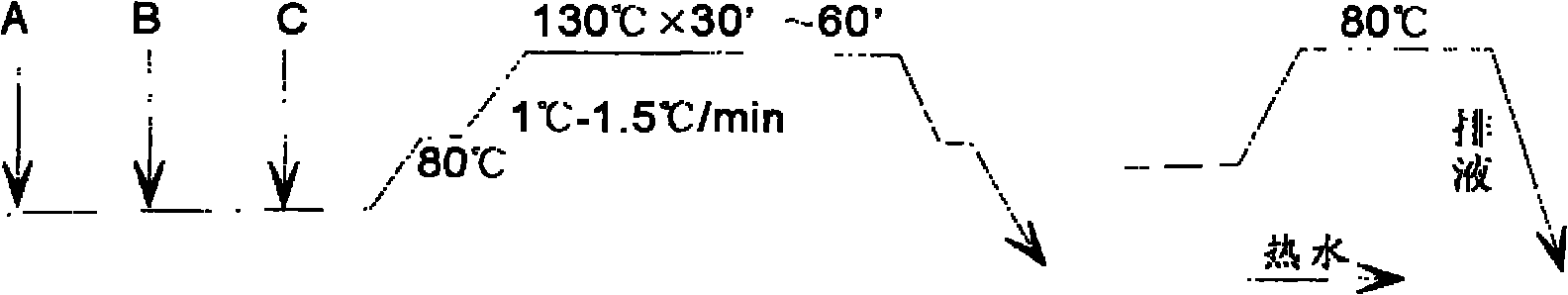

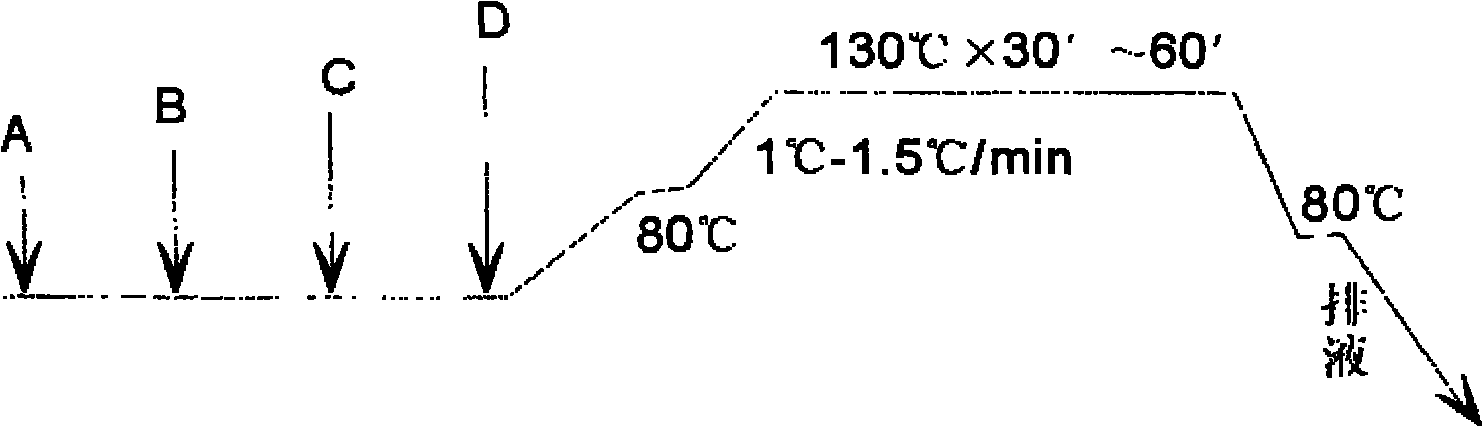

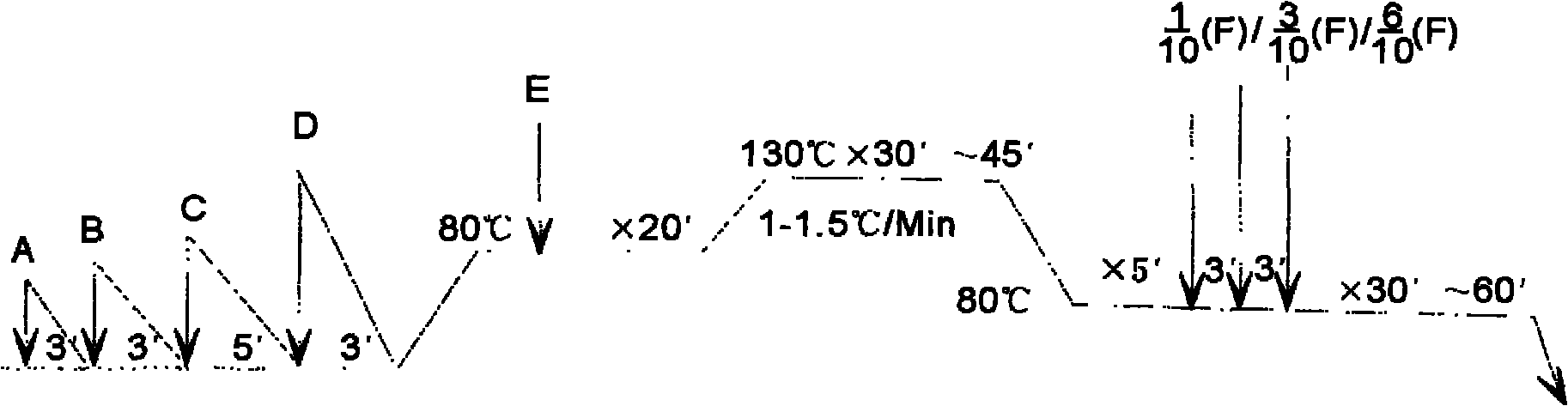

[0064] Dyeing process route such as figure 1 Shown: Measure the standard water level, put 100 grams of all polyester fabric at room temperature, then add 0.5-2g / L of the special additive of the present invention, then adjust the pH to about 7-11, run for more than 3 minutes, and then add the present invention The disperse dye prepared in Example 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com