Dye composition as well as preparation method and application thereof

A dye composition and a technology for yellow dyes, applied in the field of dyes, can solve the problems of poor color fastness to rubbing, color fastness to washing, poor color fastness to alkali and perspiration, a large difference in compatibility, affecting the color light of fabrics, and the like. The cloth surface is neat, the fabric style and feel are excellent, and the compatibility is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: the preparation of dye composition

[0038] A dye composition, in parts by weight, comprising 2 parts of yellow dye, 30 parts of red dye, and 68 parts of blue dye;

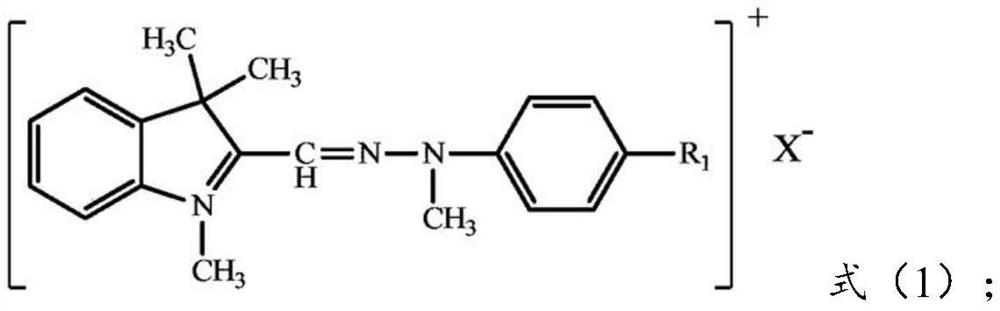

[0039] The structural formula of yellow dye is:

[0040]

[0041] Among them, R 1 is -H, X is Cl;

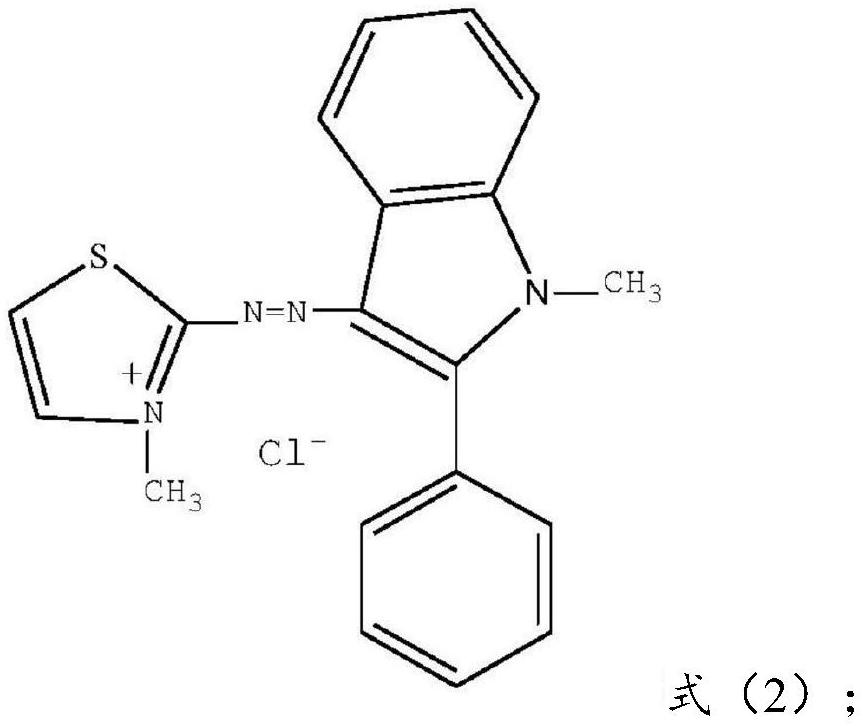

[0042] The structural formula of red dye is:

[0043]

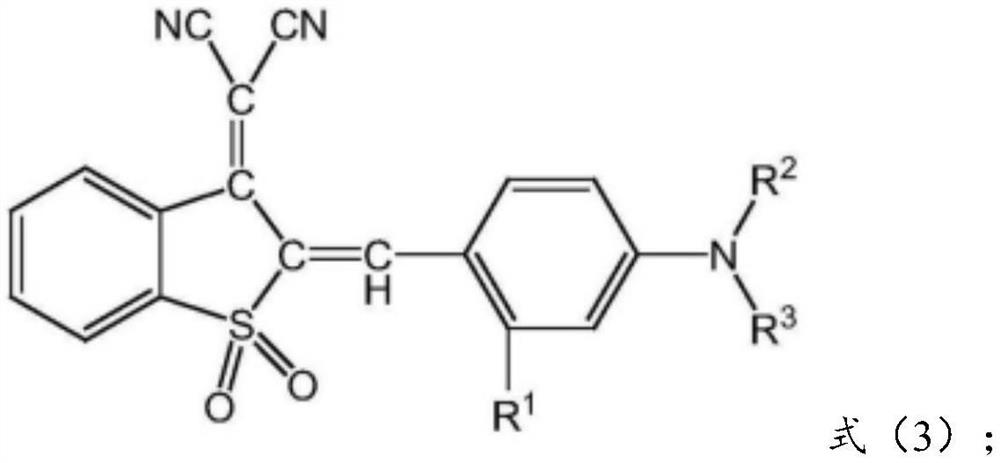

[0044] The structural formula of blue dye is:

[0045]

[0046] Among them, R 1 for -CH 3 , R 2 for -CH 3 , R 3 for -CH 2 CH 2 OCOCH 3 .

[0047] A preparation method of a dye composition, comprising the following steps:

[0048] The components are mixed and ground to prepare a dye composition, and the mesh number of the ground dye composition is 100-120 mesh.

Embodiment 2

[0049] Embodiment 2: the preparation of dye composition

[0050] A dye composition, in parts by weight, comprising 25 parts of yellow dye, 25 parts of red dye, and 50 parts of blue dye;

[0051] The structural formula of yellow dye is:

[0052]

[0053] Among them, R 1 for -CH 2 CH 3 , X is Cl;

[0054] The structural formula of red dye is:

[0055]

[0056] The structural formula of blue dye is:

[0057]

[0058] Among them, R 1 for-NHCOCH 3 , R 2 for -CH3 , R 3 for -CH 2 COOCH 3 .

[0059] A preparation method of a dye composition, comprising the following steps:

[0060] The components are mixed and ground to prepare a dye composition, and the mesh number of the ground dye composition is 150-160 mesh.

Embodiment 3

[0061] Embodiment 3: the preparation of dye composition

[0062] A dye composition, in parts by weight, comprising 35 parts of yellow dye, 5 parts of red dye, and 60 parts of blue dye;

[0063] The structural formula of yellow dye is:

[0064]

[0065] Among them, R 1 is -H, X is Cl;

[0066] The structural formula of red dye is:

[0067]

[0068] The structural formula of blue dye is:

[0069]

[0070] Among them, R 1 for -H,R 2 for -CH 2 CH 3 , R 3 for -CH 2 CH 2 COOCH 3 .

[0071] A preparation method of a dye composition, comprising the following steps:

[0072] The components are mixed and ground to prepare a dye composition, and the mesh number of the ground dye composition is 150-160 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com