Nanometer material reinforced cotton fabric crease-resistant finishing liquid and application of crease-resistant finishing liquid

A nano-material, anti-wrinkle finishing technology, applied in the treatment of textile materials, fabric surface trimming, heating/cooling fabrics, etc., to achieve the effect of increasing energy consumption, strong adsorption capacity, wide application prospects and market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

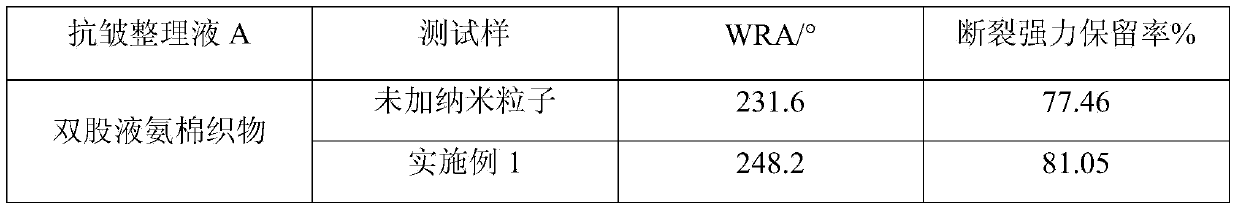

Embodiment 1

[0024] Plain double-strand liquid ammonia cotton fabric (100*70cm, 200.7g / m 2 ) in anti-wrinkle finishing solution A for 3 minutes, followed by double dipping and second rolling, with a liquid loading rate of 80-85%, baked at 100°C for 10 minutes, and then baked at 180°C for 1.5 minutes.

[0025] Anti-wrinkle finishing solution A contains: water-soluble POSS with a particle size of 1.5nm and a mass fraction of 2%, 6% MA-IA anti-wrinkle finishing agent with a mass fraction of 2%, sodium hypophosphite, potassium peroxodisulfate and triethanolamine, and the remaining The volume is 88.5% deionized water. Wherein the mol ratio of MA and IA is 1:1, the mol ratio of sodium hypophosphite and the sum of MA and IA is 1:1, potassium peroxodisulfate is 1.5% of the anti-wrinkle finishing agent quality, and triethanolamine is 1% of the finishing liquid quality 2%.

Embodiment 2

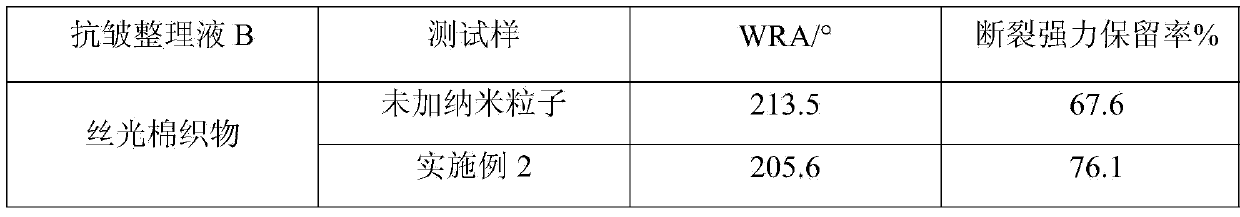

[0027] Soak the plain mercerized cotton fabric (133*72cm, 40s*40s) in anti-wrinkle finishing solution B for 5 minutes, then perform two dipping and two rolling, control the liquid retention rate at 80-85%, bake at 80°C for 3 minutes, and then bake at 180°C for 1.5 minutes. min.

[0028] Anti-wrinkle finishing solution B contains: SiO with a particle size of 30nm and a mass fraction of 1% 2 , the mass fraction is 3% of BTCA anti-wrinkle finishing agent and sodium hypophosphite, and the balance of 96% is deionized water. Among them, the molar ratio of sodium hypophosphite to BTCA is 1:1, and it can be fully dissolved by stirring.

Embodiment 3

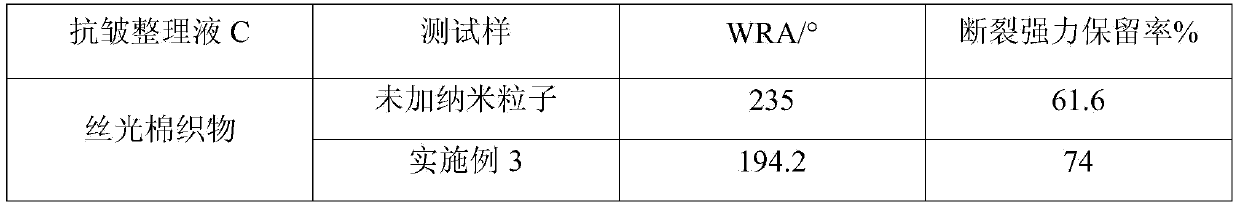

[0030] Soak the plain mercerized cotton fabric (133*72cm, 40s*40s) in anti-wrinkle finishing solution C for 5 minutes, then perform two dipping and two rolling, control the liquid retention rate at 80-85%, bake at 80°C for 3 minutes, then bake at 160°C for 3 minutes .

[0031] Anti-wrinkle finishing solution C contains: silk fibroin with a particle size of 193nm and a mass fraction of 4%, a glutaraldehyde anti-wrinkle finishing agent with a mass fraction of 10% and MgCl 2 ·6H 2 O, the balance 86% is deionized water. Among them, glutaraldehyde is a 25% aqueous solution, MgCl 2 ·6H 2 The molar ratio of O to glutaraldehyde is 1:2, and it can be fully dissolved by stirring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com