Method for preparing temperature regulation textile by sol-gel technology

A gel technology and fabric technology, applied in the direction of fabric surface trimming, heating/cooling fabric, textile material processing, etc., can solve the problems of limiting the temperature regulation effect of phase change materials, unfavorable application of textile fabrics, increasing safety hazards, etc. Low production cost, low price, and the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

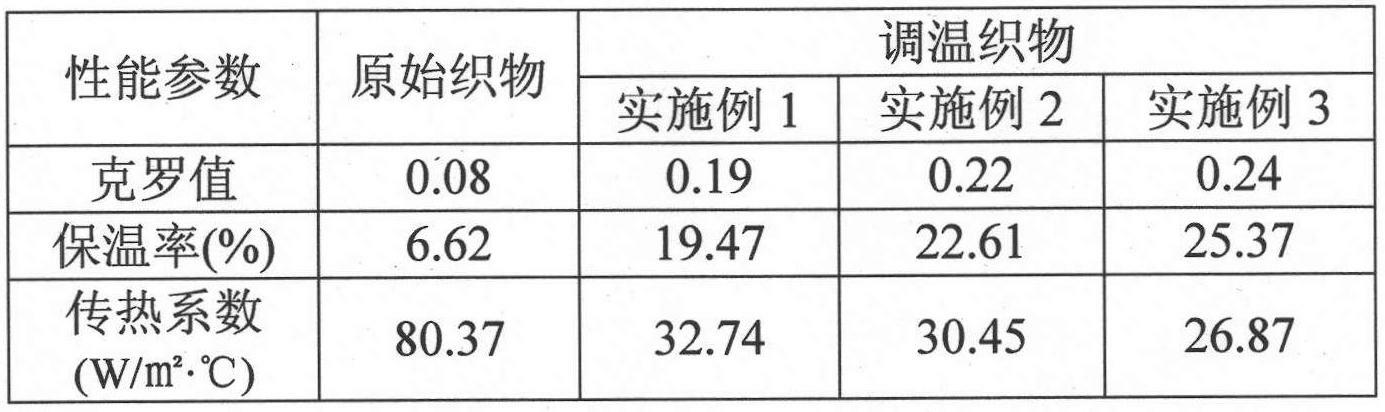

Embodiment 1

[0023] Step 1: Dissolve 7g of tetraethyl orthosilicate in a mixture of 14.3g of ethanol and 15g of water under mechanical stirring at 400 rpm, adjust the pH value to 2.6 with hydrochloric acid, and stir for 3 hours to form a stable and uniform Ethyl orthosilicate liquid preparation;

[0024] Step 2: Add 6g of paraffin, 37.8g of water and 13g of emulsifier into a high-speed emulsifier, and emulsify for 30 minutes at 10,000 rpm to form a stable and uniform paraffin core emulsion;

[0025] Step 3: Under mechanical stirring at 60°C and 400 rpm, slowly add the tetraethyl orthosilicate solution obtained in the first step to the paraffin core emulsion obtained in the second step, and then add 10g of acrylic latex , prepared into a phase-change microcapsule finishing liquid, and stirred evenly for 2 hours.

Embodiment 2

[0027] Step 1: Dissolve 5g of tetraethyl orthosilicate in a mixture of 11g of ethanol and 11g of water under mechanical stirring at 400 rpm, adjust the pH value to 2.6 with hydrochloric acid, and stir for 3 hours to form a stable and uniform Ethyl silicate liquid preparation;

[0028] Step 2: Add 5g of paraffin, 29g of water and 10g of emulsifier into a high-speed emulsifier, and emulsify for 30 minutes at 10,000 rpm to form a stable and uniform paraffin core emulsion;

[0029] Step 3: Under mechanical stirring at 60°C and 400 rpm, slowly add the tetraethyl orthosilicate solution obtained in the first step to the paraffin core emulsion obtained in the second step, and then add 8g of acrylic latex , prepared into a phase-change microcapsule finishing liquid, and stirred evenly for 2 hours.

Embodiment 3

[0031] Step 1: Dissolve 10g of tetraethyl orthosilicate in a mixture of 26g of ethanol and 24g of water under mechanical stirring at 400 rpm, adjust the pH to 3.1 with hydrochloric acid, and stir for 3 hours to form a stable and uniform Ethyl silicate liquid preparation;

[0032] Step 2: Add 13g of paraffin, 68g of water and 24g of emulsifier into a high-speed emulsifier, and emulsify for 30 minutes at 10,000 rpm to form a stable and uniform paraffin core emulsion;

[0033] Step 3: Under mechanical stirring at 60°C and 400 rpm, slowly add the tetraethyl orthosilicate solution obtained in the first step to the paraffin core emulsion obtained in the second step, and then add 19g of acrylic latex , prepared into a phase-change microcapsule finishing liquid, and stirred evenly for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com