Patents

Literature

48results about How to "Low heat distortion temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

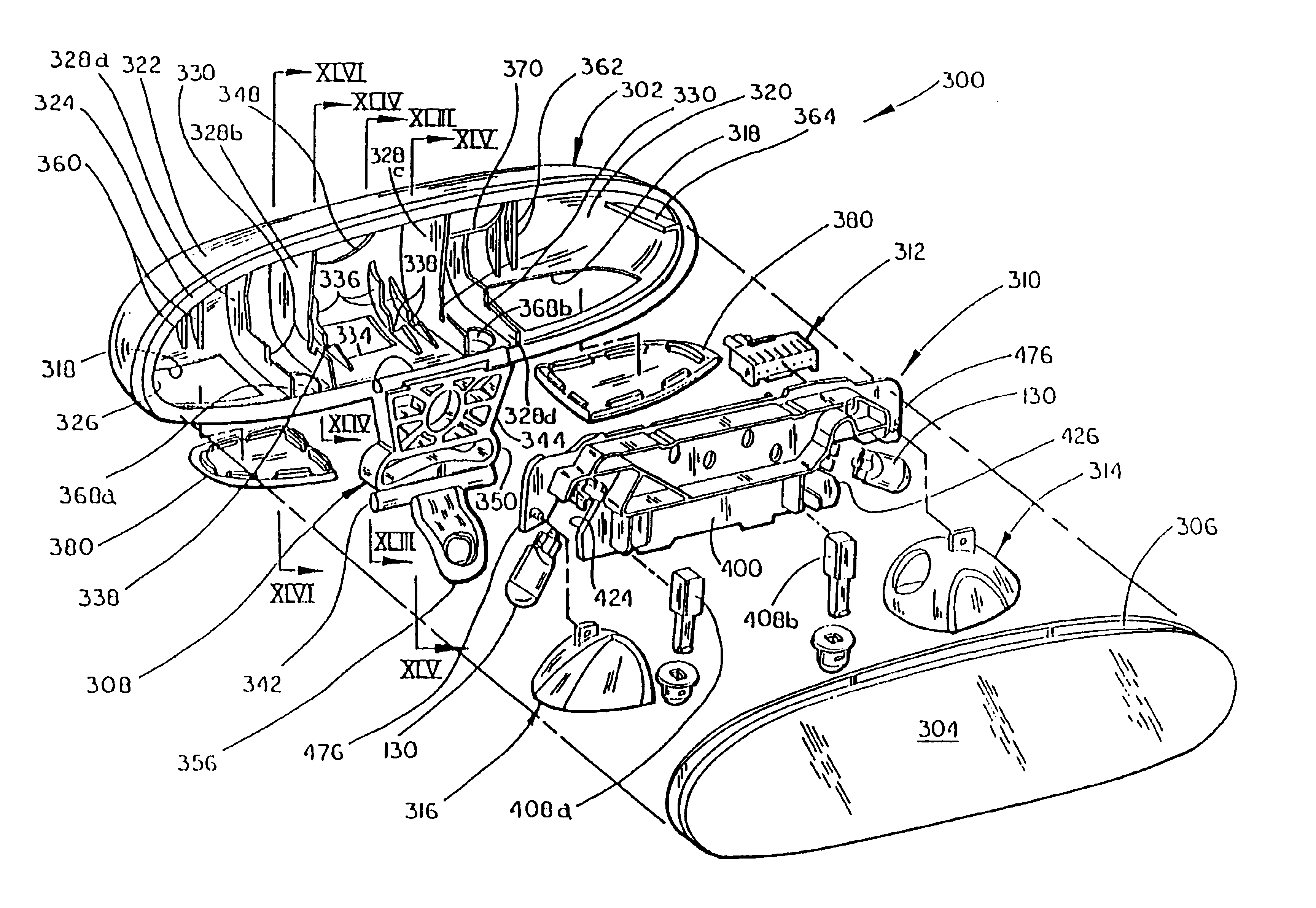

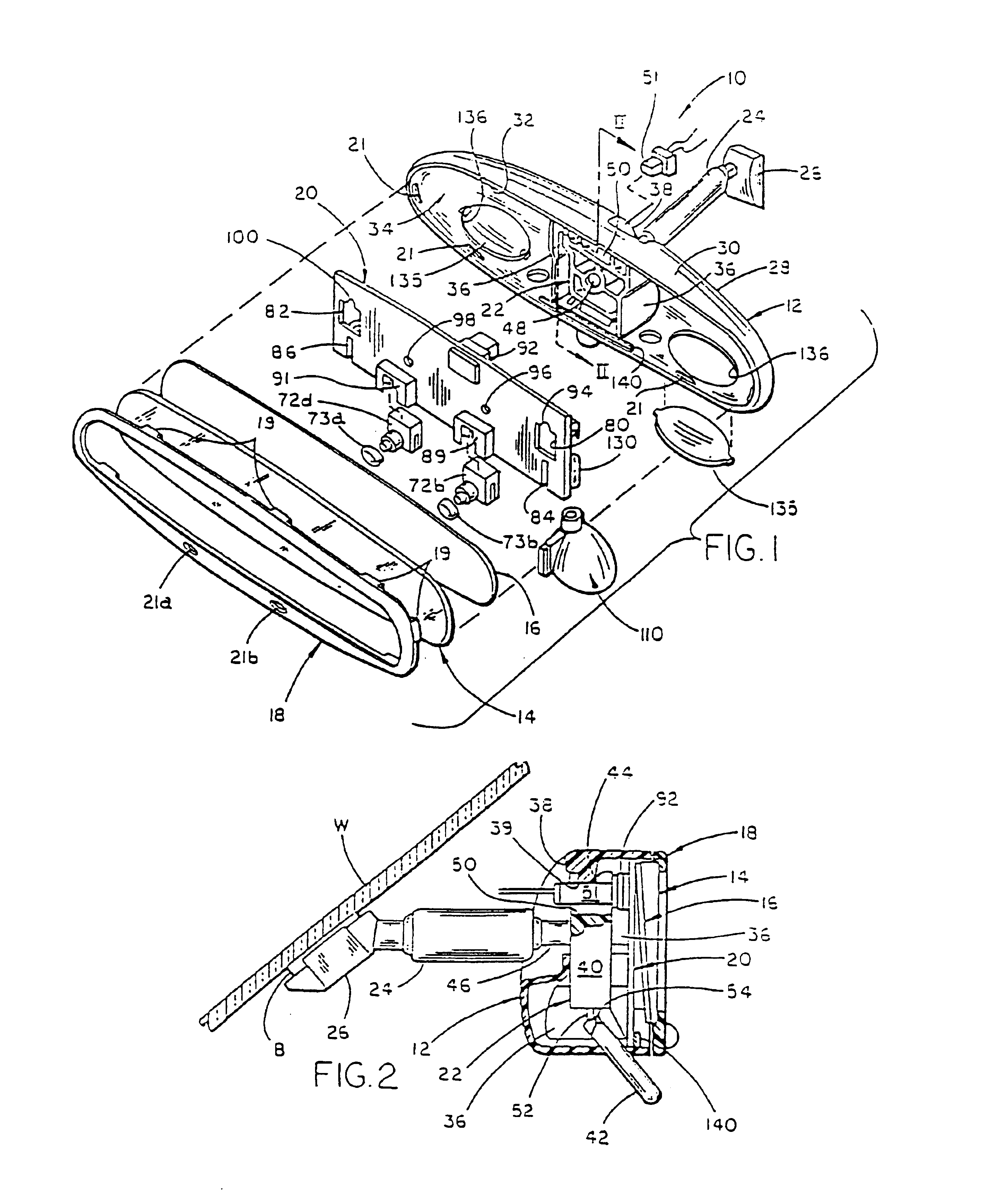

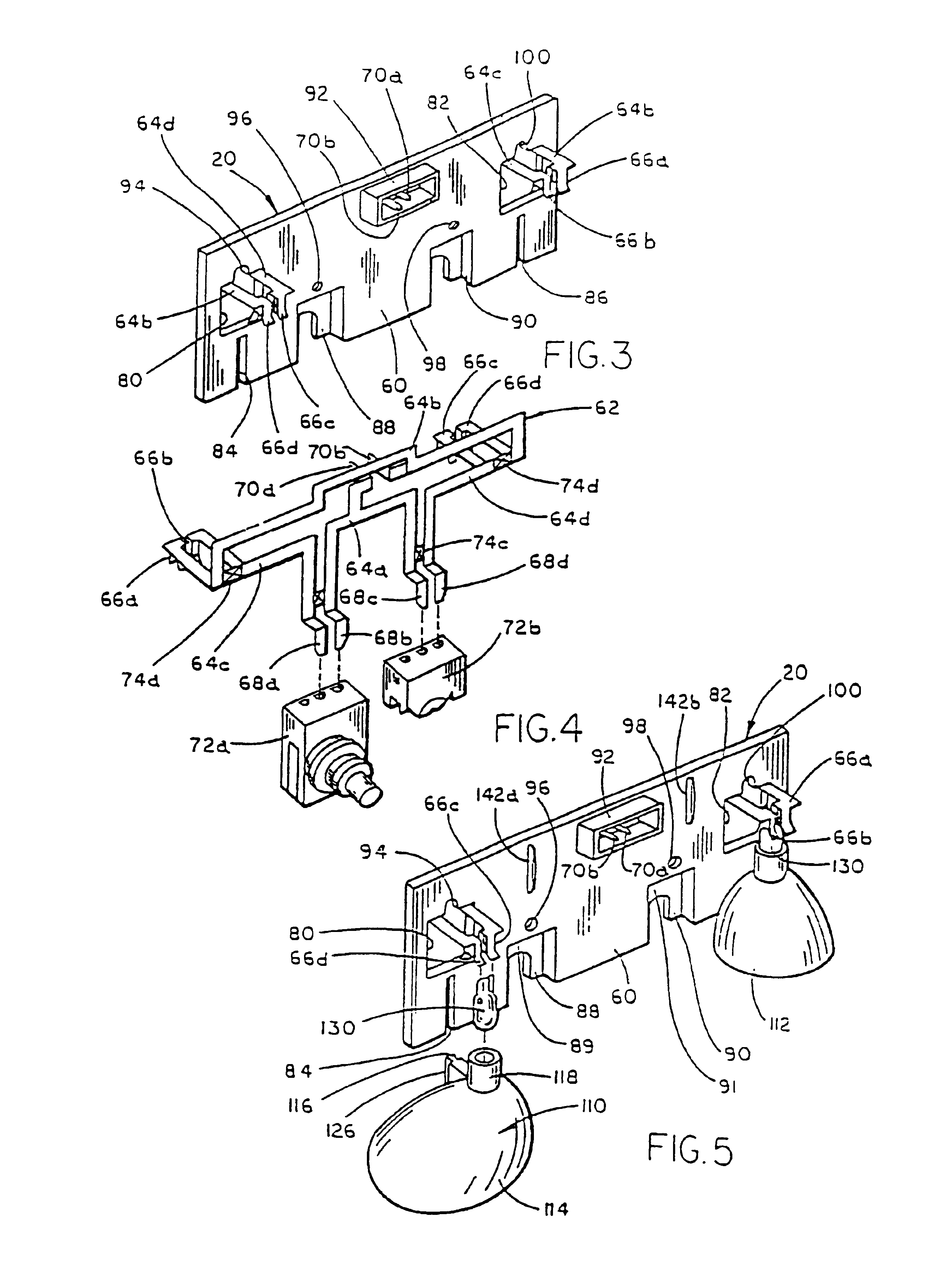

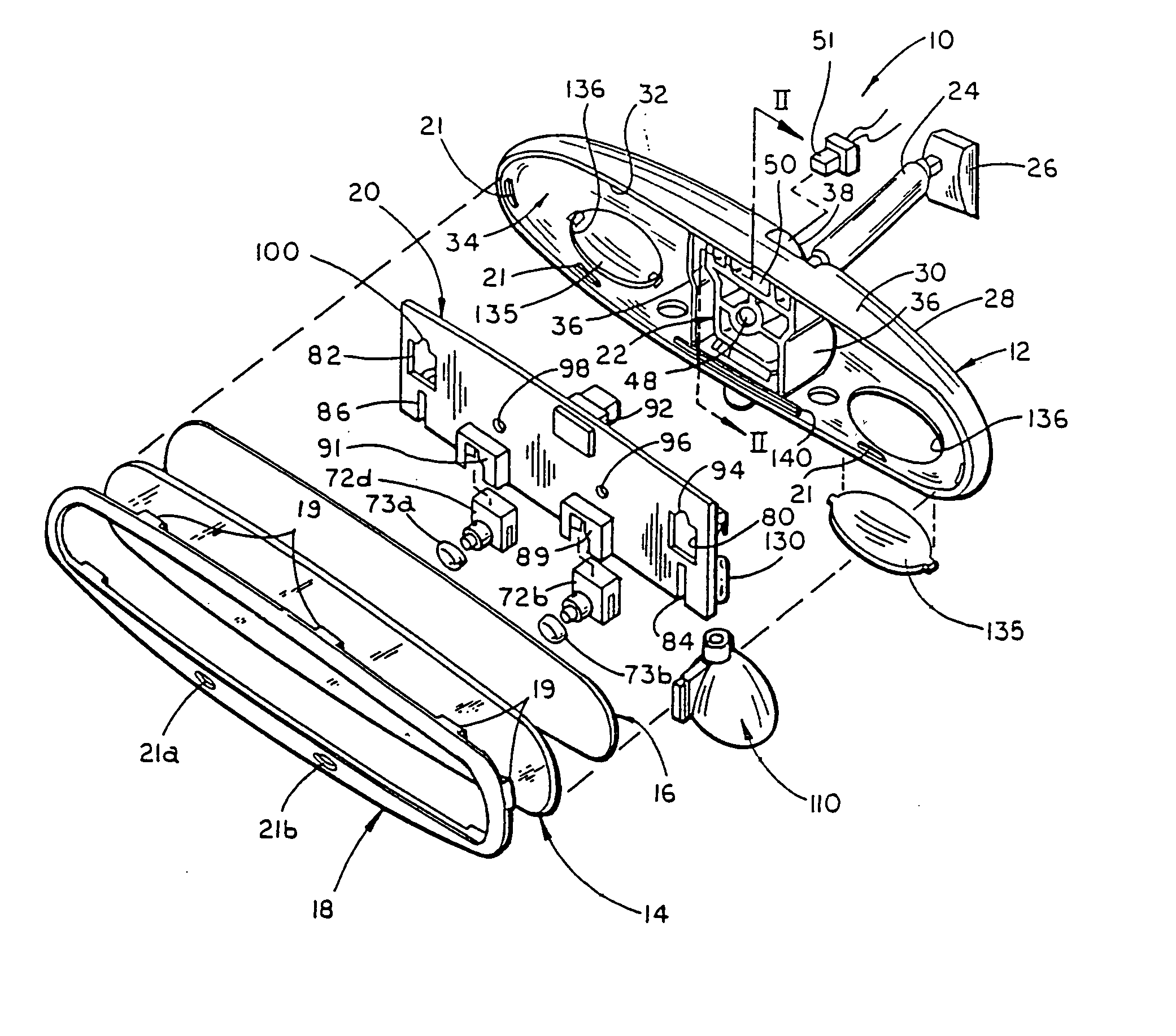

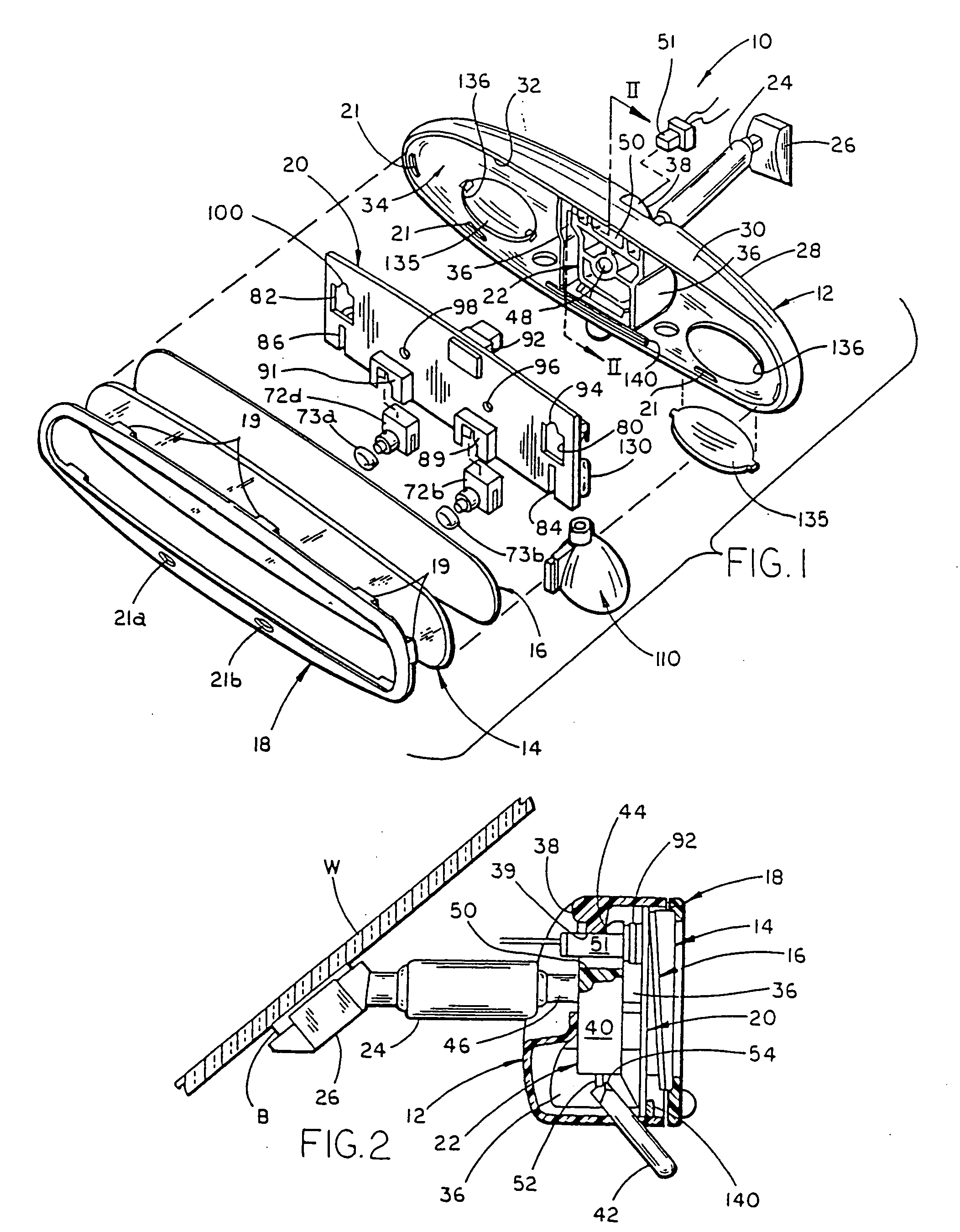

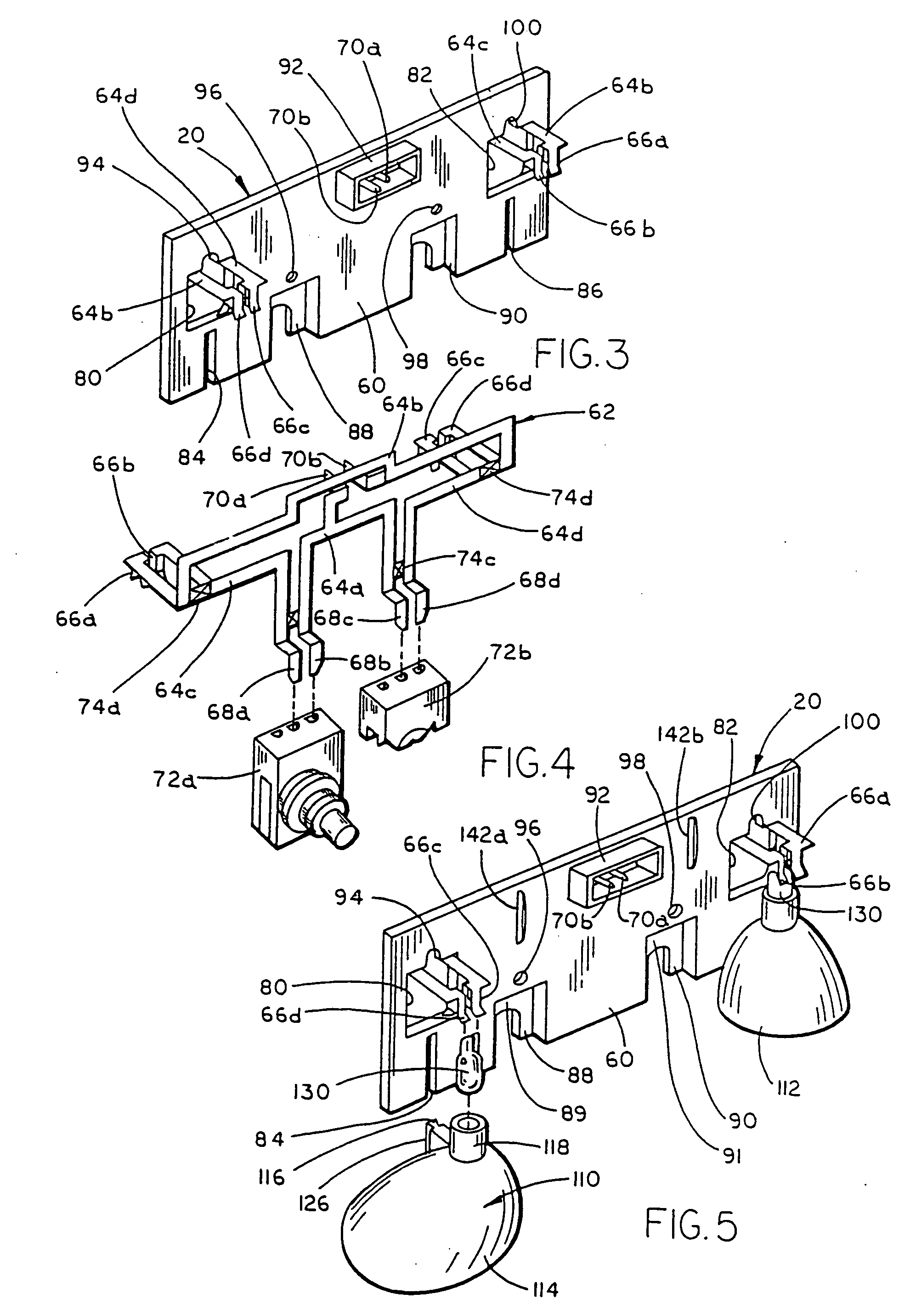

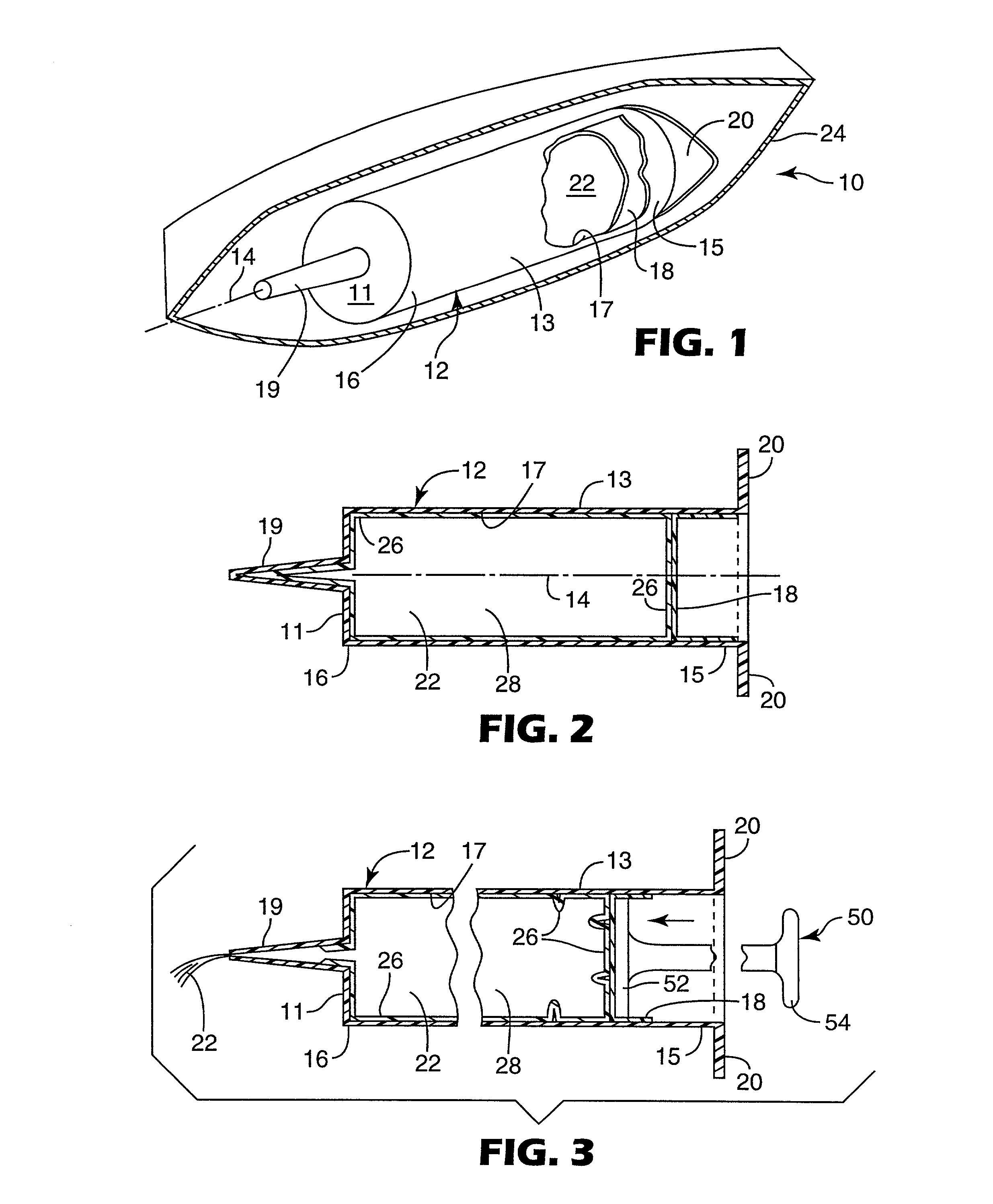

Modular rearview mirror assembly

InactiveUS6877888B2Increased durabilityImprove reliabilityLighting elementsClosed circuit television systemsPolymer resinElectrical devices

An interior rearview mirror assembly for vehicles incorporates a reflective mirror element for viewing by a user of the mirror assembly, a lip formed from moldable polymeric resin selected to expand sufficiently when heated to allow snap in insertion of the reflective mirror element while the lip is warm and flexable, a carrier located to the rear of the reflective element such that the carrier is closer to a windshield of the vehicle than the mirror element when the mirror element is mounted in the vehicle, at least one electrical accessory, and an electrical connector adapted to receive a connector from the vehicle electrical system with the electrical accessory connected to the electrical connector. Preferably, the electrical accessory is supported by the carrier and is selected from a variety of electrical devices, lamps, lights, sensors and the like.

Owner:DONNELLY CORP

Non-halogen flame-retardant polypropylene composite material and preparation thereof

InactiveCN101412830AImprove flame retardant performanceImprove mechanical propertiesFlexural modulusAcrylonitrile

The invention provides a halogen-free flame-retardant polypropylene composite material, which is characterized by consisting of the following raw materials in weight portion: 82.5 to 12 portions of polypropylene, 0.3 to 2 portions of heat stabilizer, 0.2 to 1 portion of processing aid, 1 to 10 portions of toughening agent, 10 to 40 portions of flame retardant, 1 to 5 portions of glass fiber compatibilizer and 5 to 30 portions of glass fiber. The invention also provides a method for preparing the material. The material has the flame retardancy up to 1.6mm V0, the tensile strength higher than or equal to 50 MPa, the flexural modulus higher than or equal to 3,000 MPa, the notched impact strength more than or equal to 8KJ / m<2>, the shrinkage between 4 and 6 per thousand, the heat distortion temperature higher than or equal to 140 DEG C, as well as the other technical indexes up to or exceeding the standard of flame-retardant acrylonitrile-butadiene-styrene copolymer materials. As the material uses the phosphorus-nitrogen flame retardant containing no halogen, the flame-retardant effect of the material completely reaches UL94-V0 grade.

Owner:SHANGHAI KINGFA SCI & TECH +1

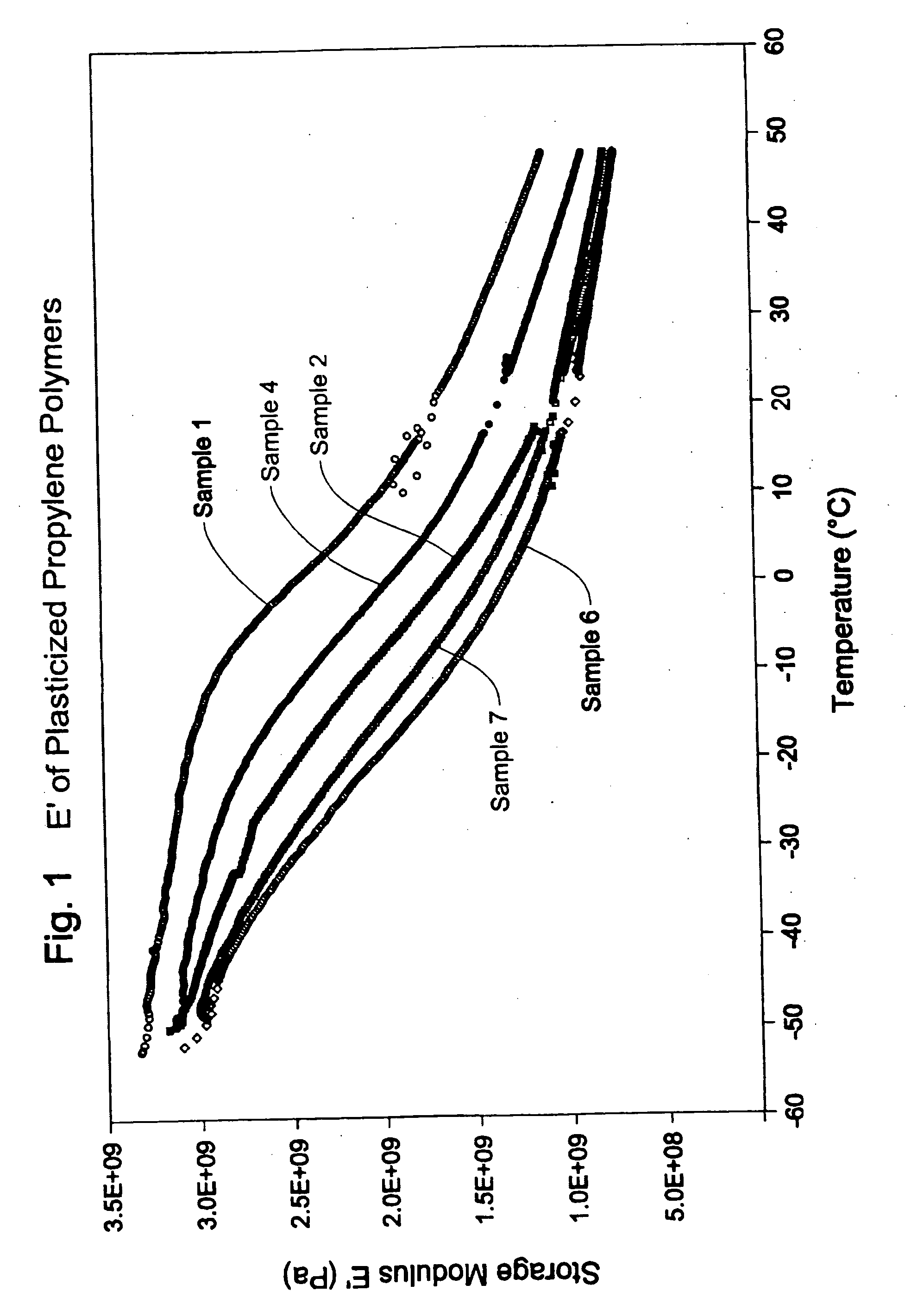

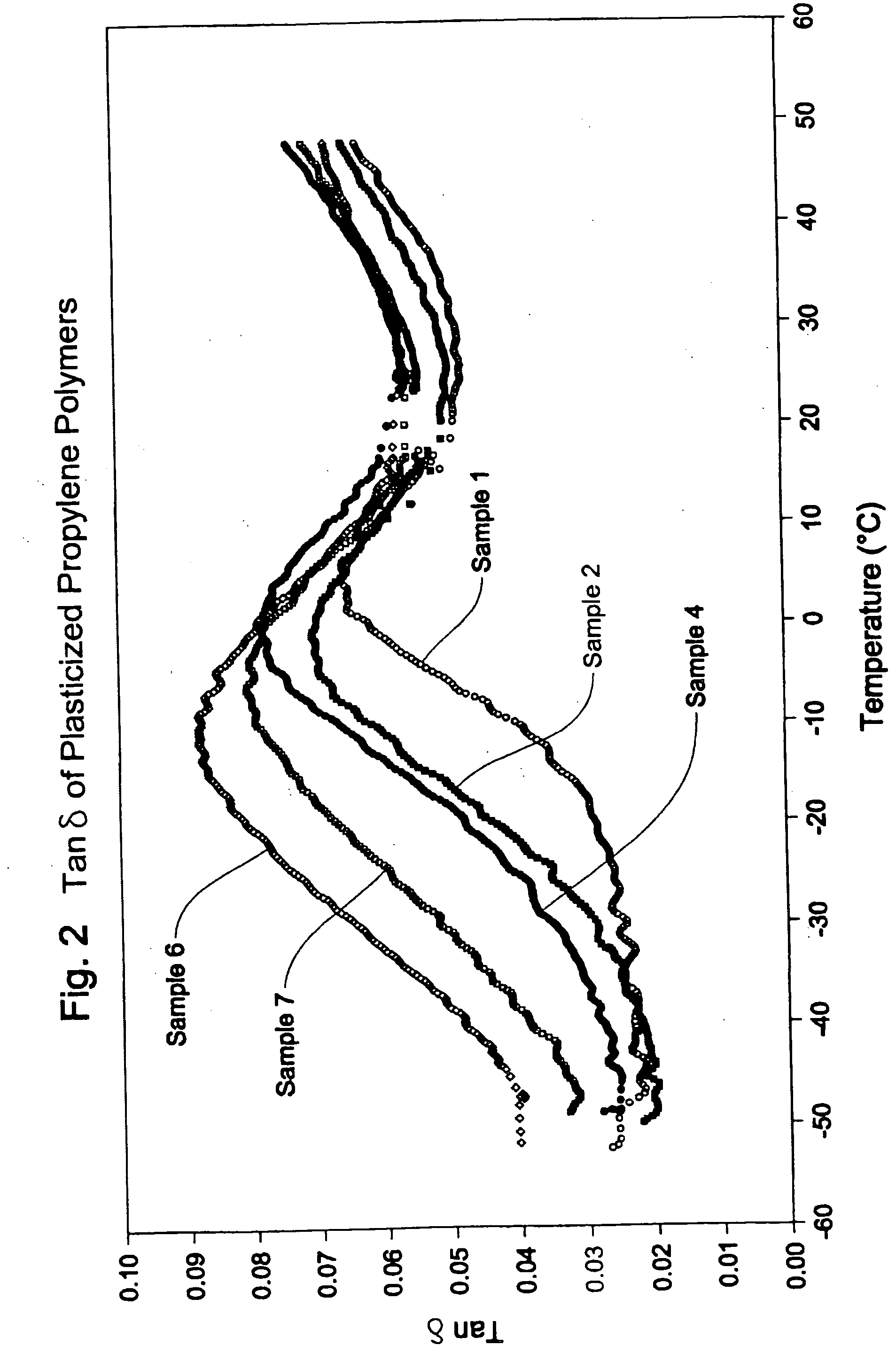

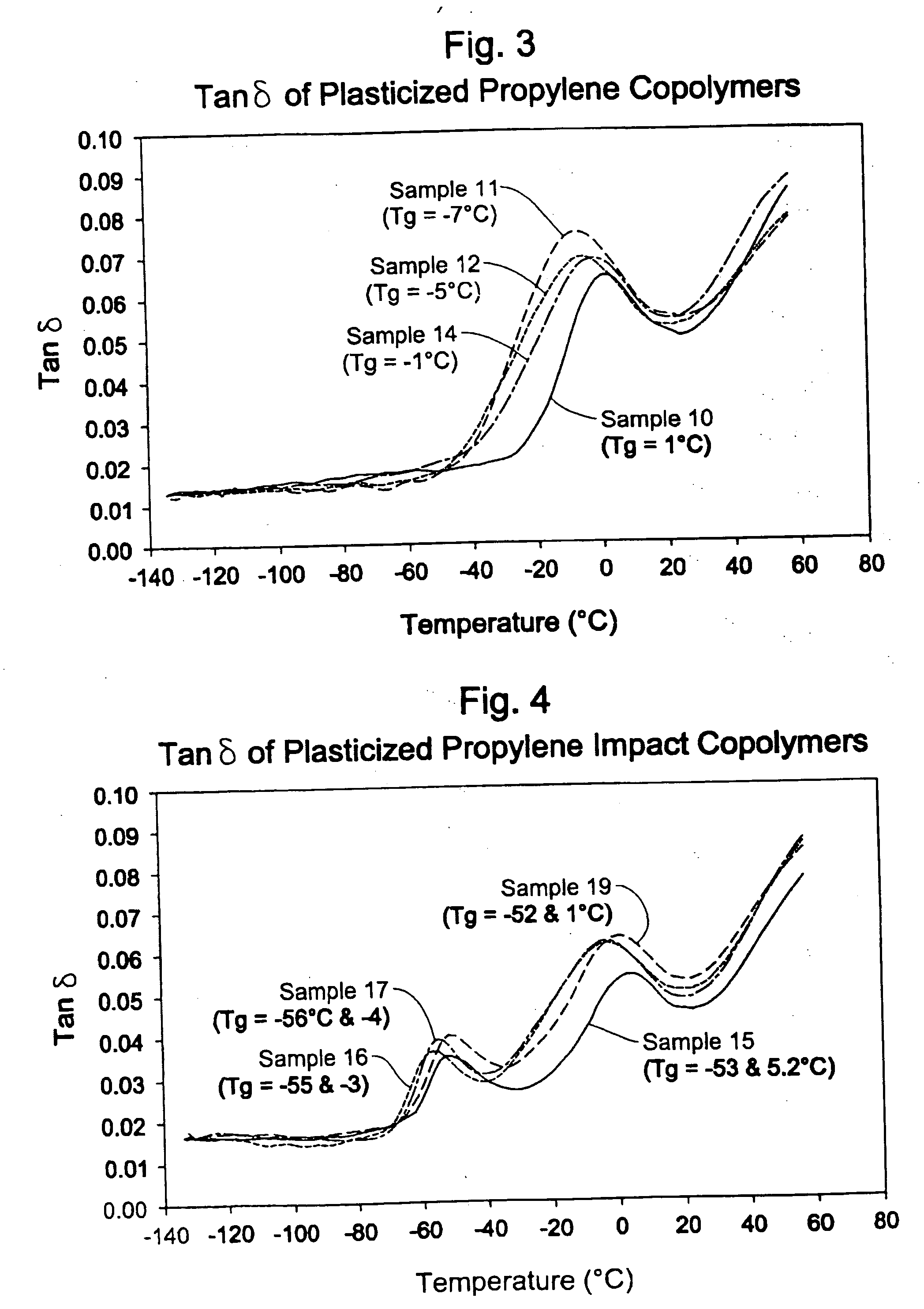

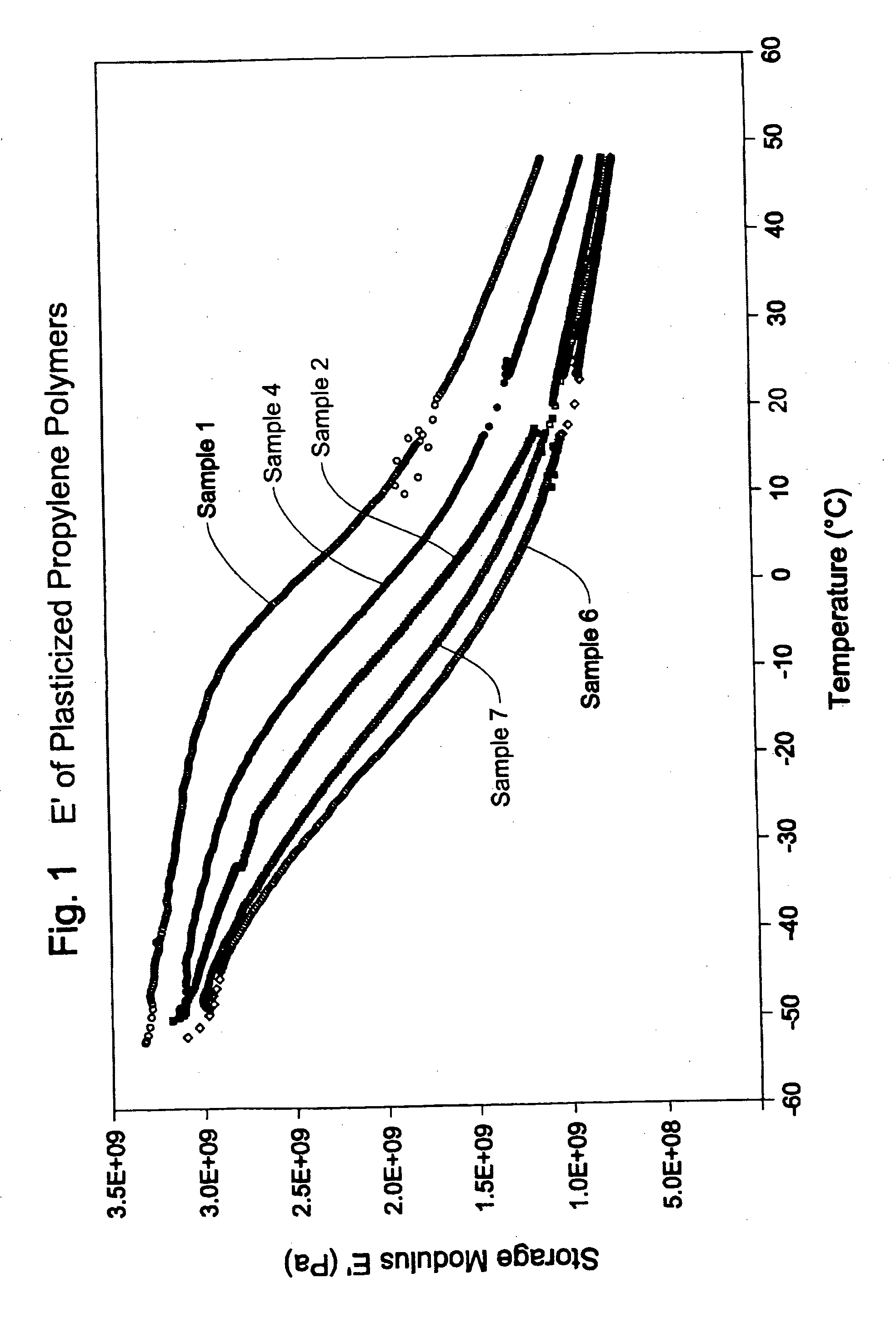

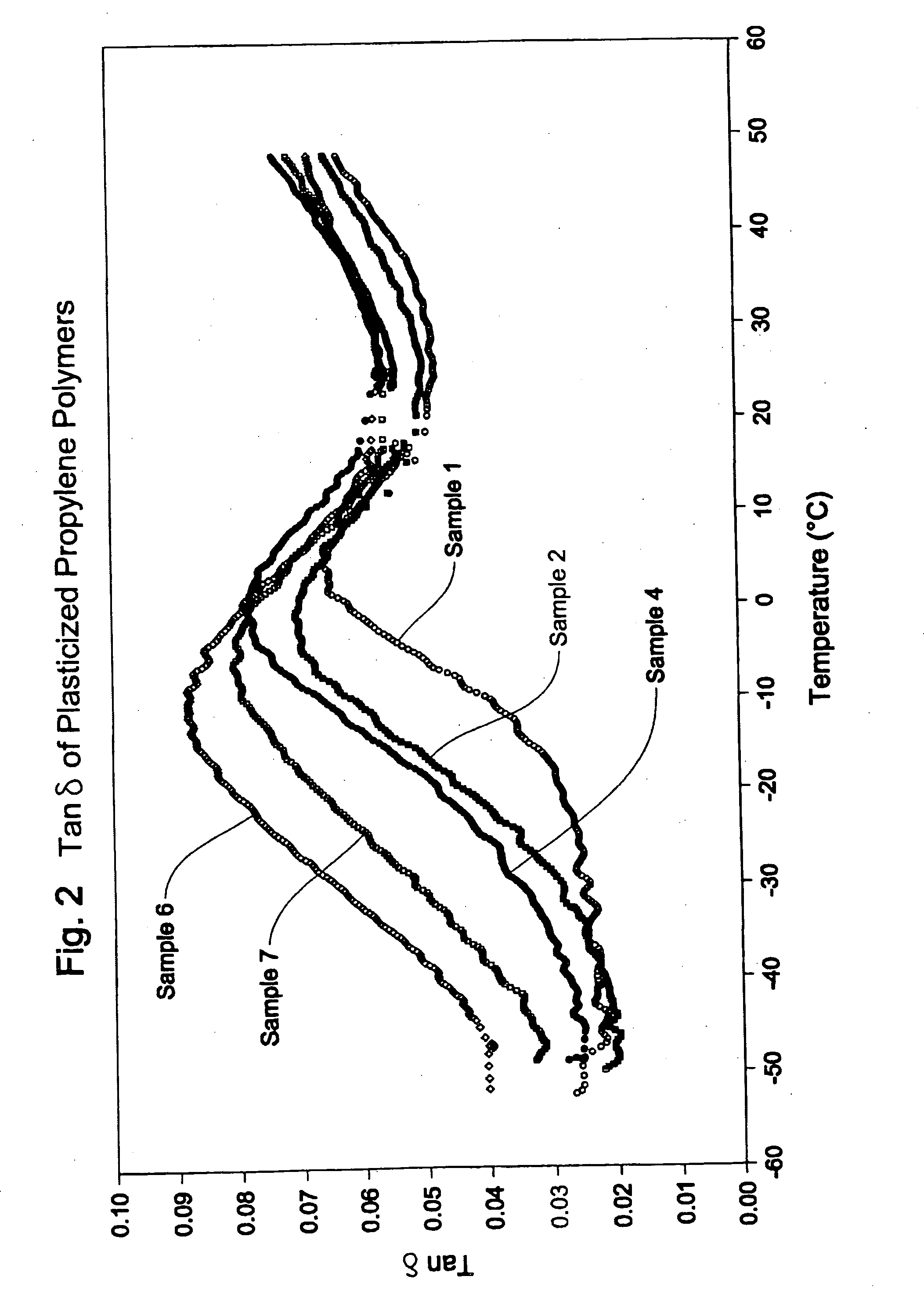

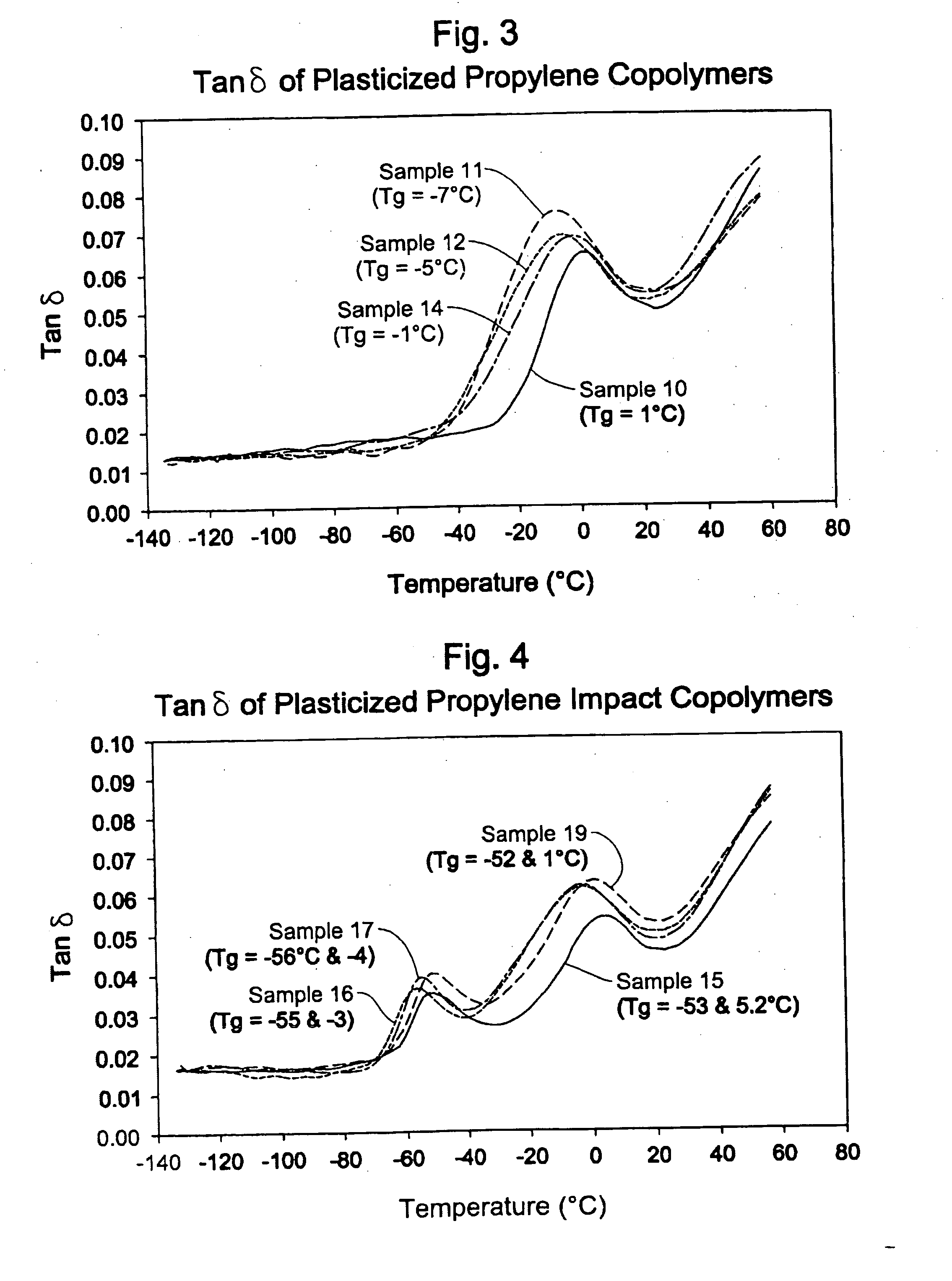

Plasticized polyolefin compositions

InactiveUS20060189763A1Facilitate complianceImprove toughnessGranular deliveryWoven fabricsPolyolefinPolymer science

The present invention relates to plasticized polyolefin compositions comprising a polyolefin and a non-functionalized hydrocarbon plasticizer.

Owner:EXXONMOBIL CHEM PAT INC

Plasticized polyolefin compositions

Owner:EXXONMOBIL CHEM PAT INC

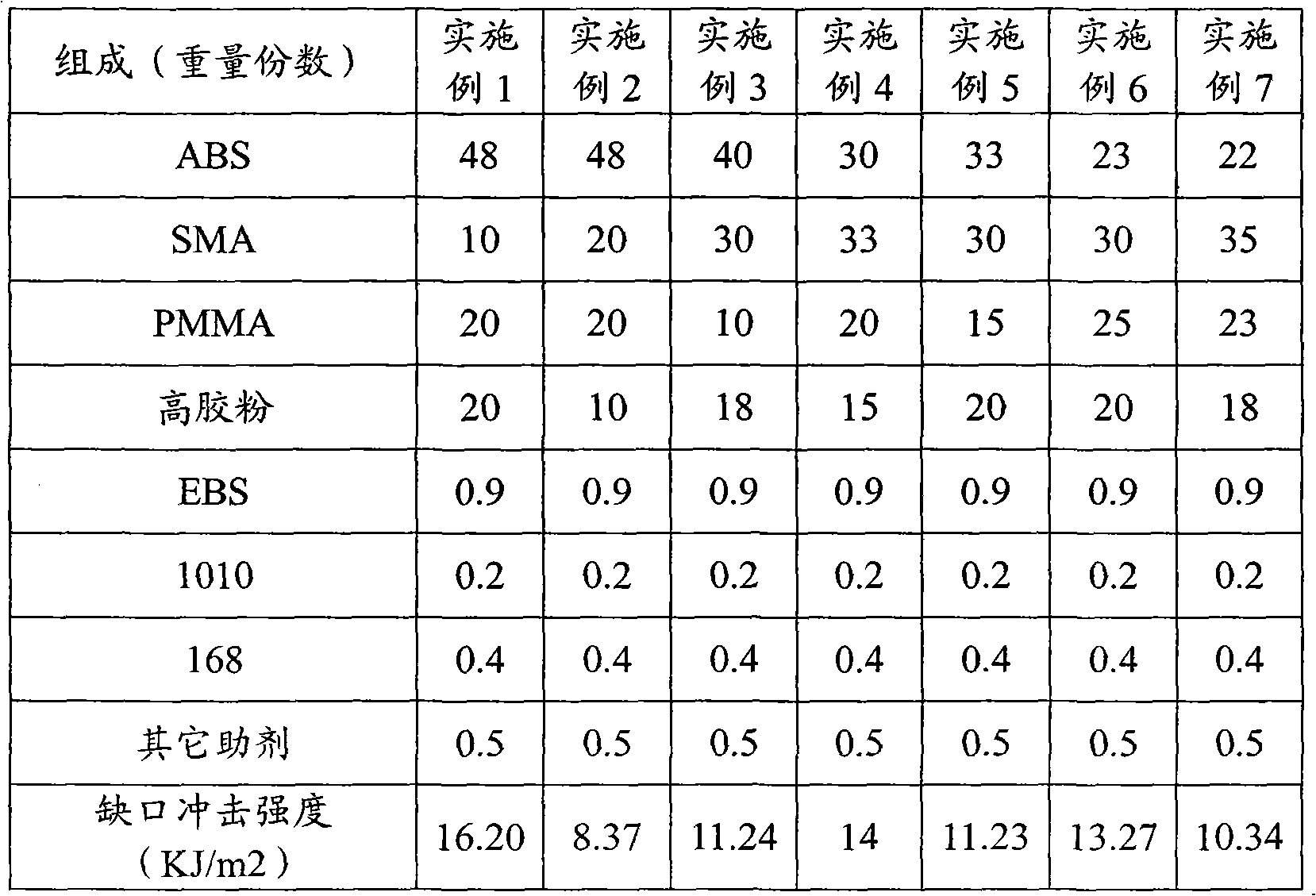

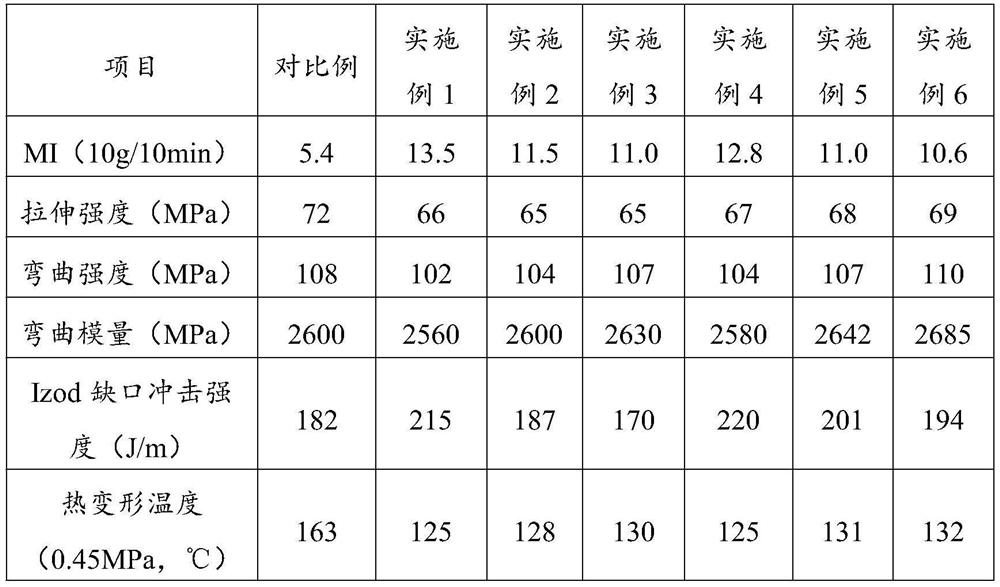

Heat-resisting ABS modified material and preparation method thereof for plating

ActiveCN101768320AImprove heat resistance of ABSImproves flow and flexural strengthPolybutyl methacrylateFlexural strength

The invention discloses a heat-resisting ABS modified material and a preparation method thereof for plating; the heat-resisting ABS modified material for plating is prepared by raw materials of acrylonitrile-butadiene-styrene copolymer (ABS), styrene-maleic anhydride copolymer (SMA), poly methyl methacrylate (PMMA), toughened rubber powder, antioxidant, a dispersing agent and other additives; the preparation method includes that: the raw materials are mixed and fed to a double-screw extruder for granulation, so as to obtain end products. The ABS modified material not only has high deformation temperature (HDT), but also has good plating effect, better impact toughness and flexural strength, and is applicable to parts requiring heat resistance and baking finish treatment.

Owner:徐东

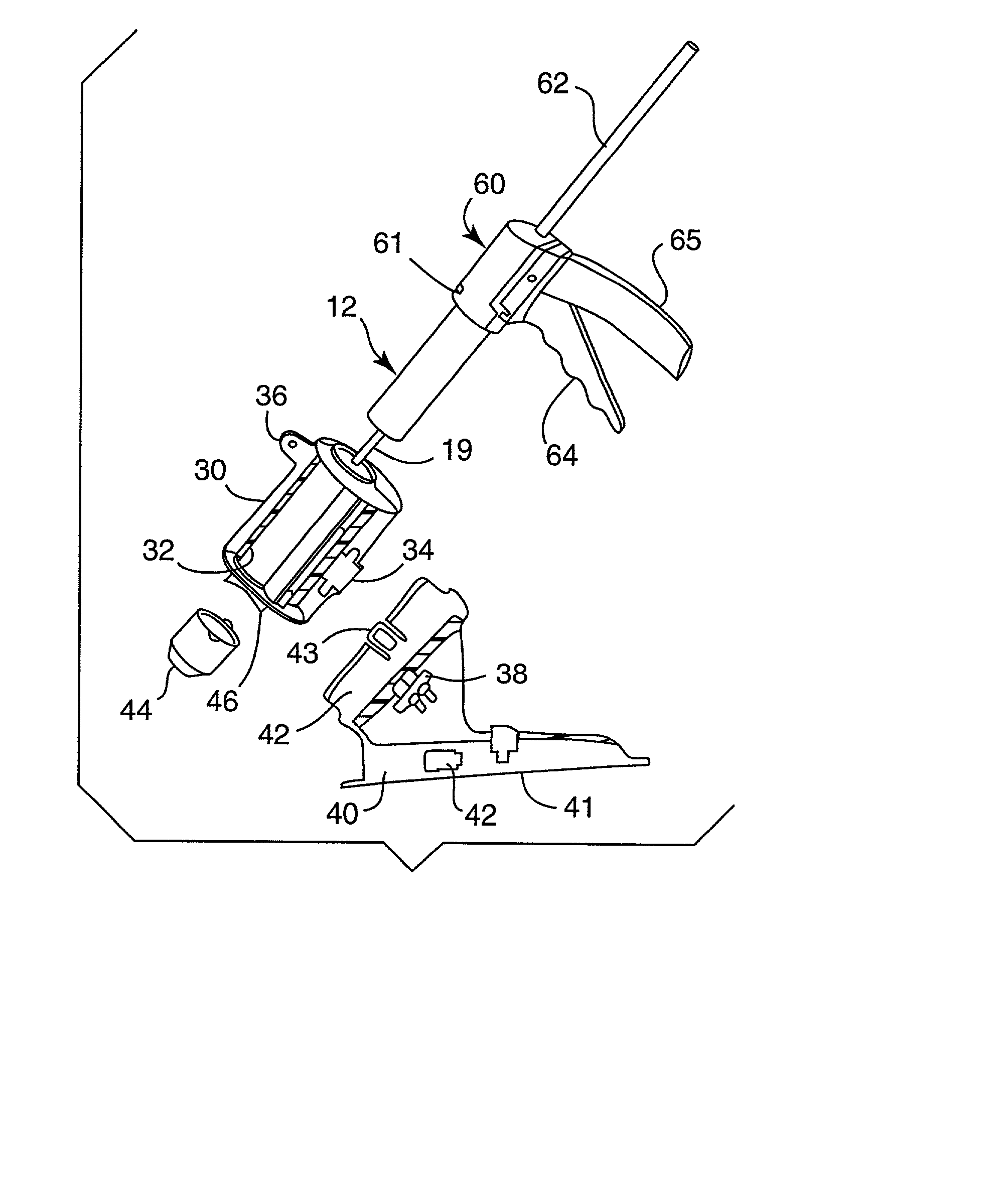

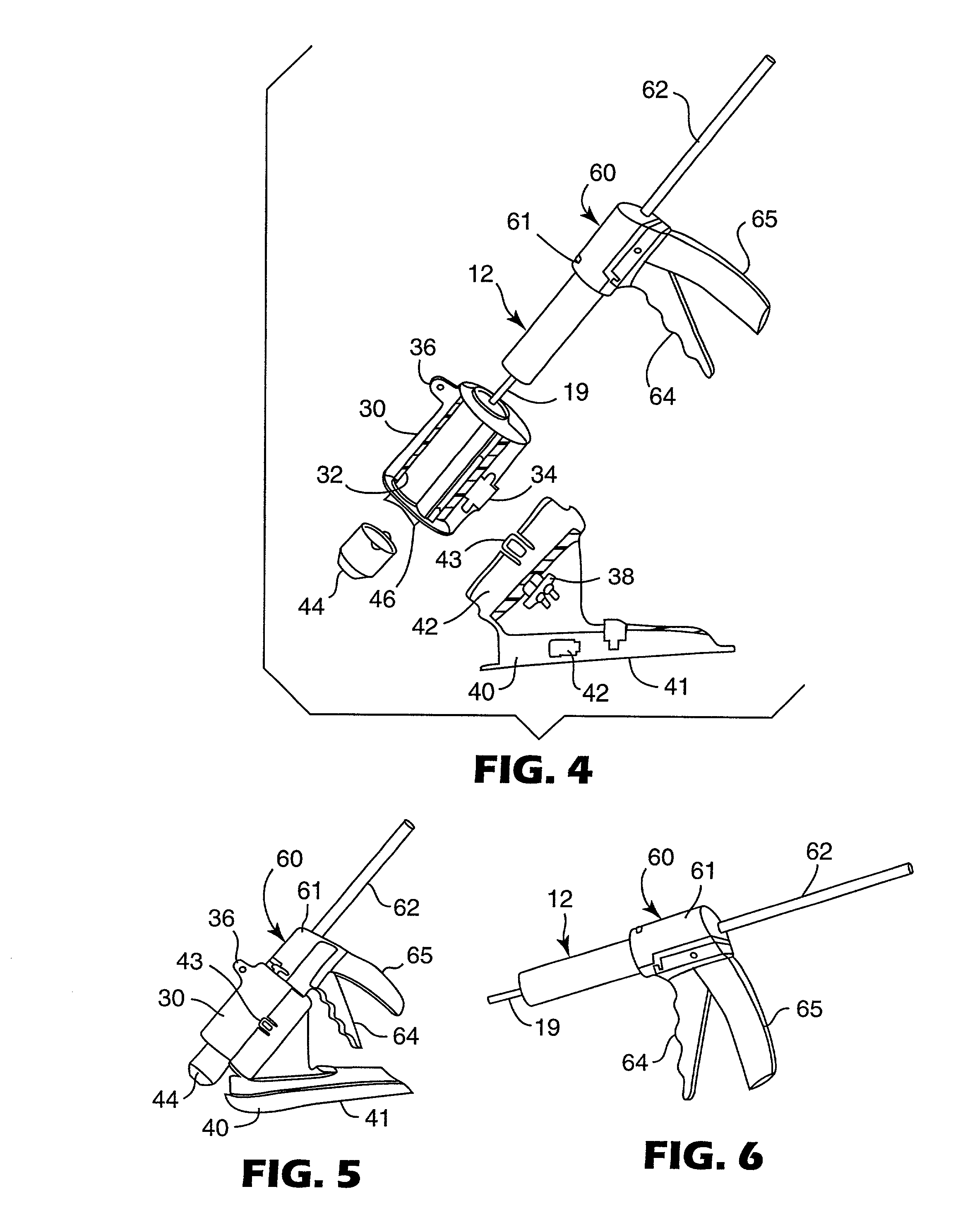

Modular rearview mirror assembly

InactiveUS20050141230A1Easy to prepareIncreased durabilityClosed circuit television systemsOptical signallingDriver/operatorDisplay device

An interior rearview mirror system for a vehicle comprises an interior rearview mirror assembly having a reflective mirror element. The reflective element may be a variable reflectance reflective element having a reflectivity which is variable in accordance with a voltage applied thereto or a prismatic reflective element. The reflective element has a field of view rearward of the vehicle when the interior mirror assembly is attached at a portion of the interior of the vehicle. The interior mirror assembly includes at least one pivot element enabling a driver of the vehicle to adjust the rearward field of view of the reflective element to that driver's desired setting, and the interior mirror assembly has a mirror support having a mounting portion for attaching the mirror assembly to a portion of the interior of the vehicle and the mirror support includes at least one pivot element. The interior rearview mirror assembly has a directional information display that displays directional information preferably derived from a geographic positioning system or from a magneto-responsive sensor.

Owner:DONNELLY CORP

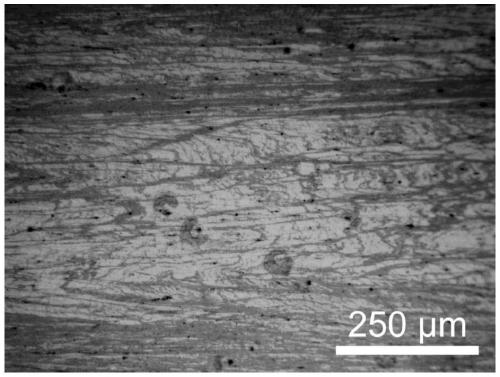

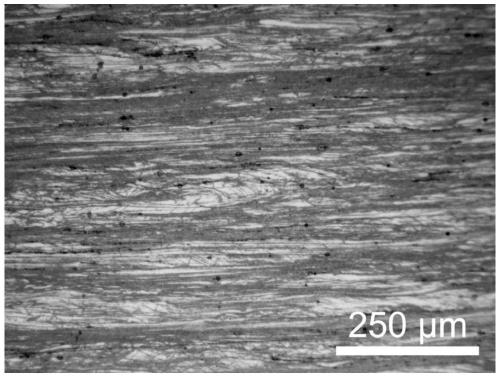

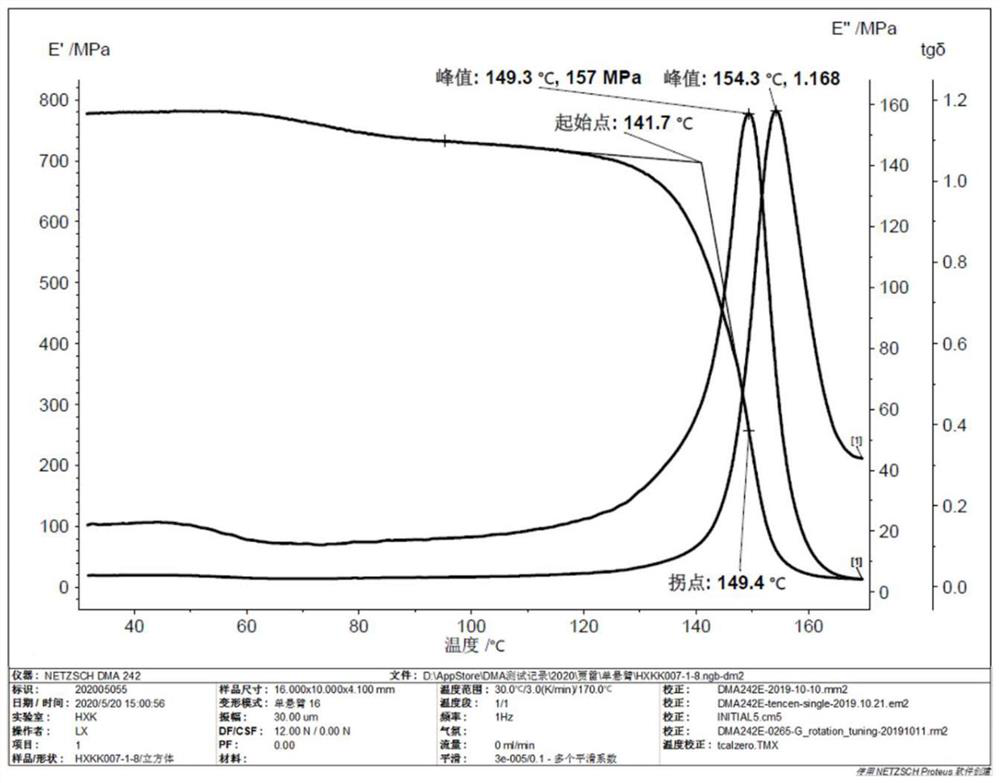

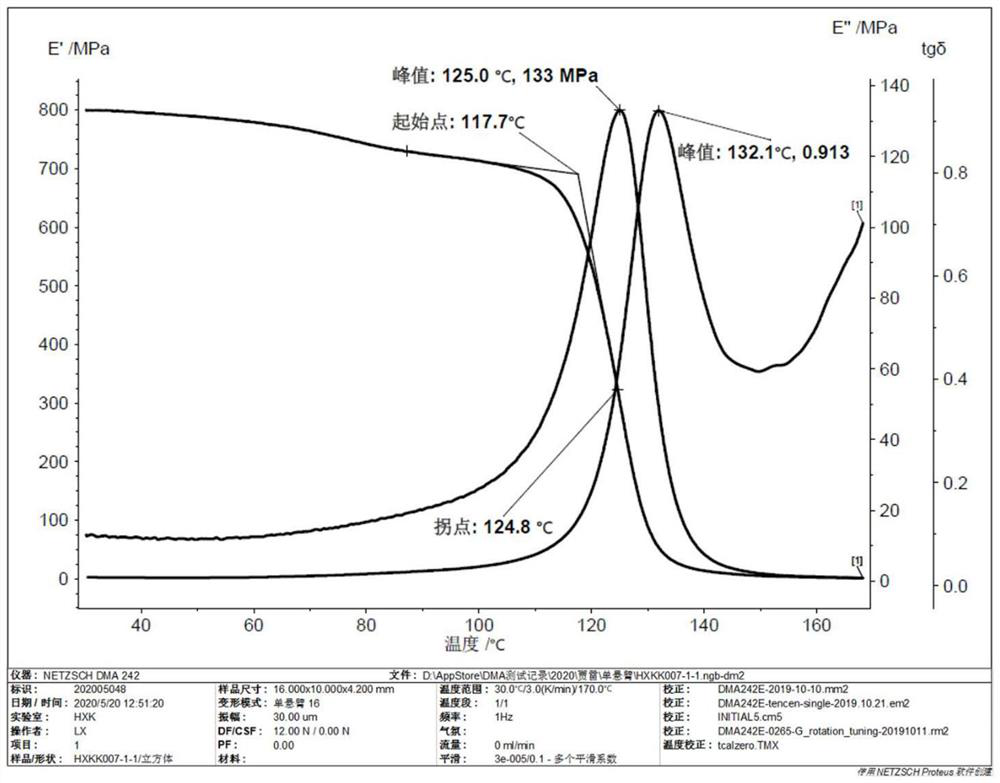

Mg-Mn wrought magnesium alloy and preparation method thereof

The invention provides a Mg-Mn wrought magnesium alloy and a preparation method thereof and belongs to the field of magnesium alloy design. The Mg-Mn wrought magnesium alloy comprises the following raw material components in percentage by mass: 0.2-5.0% of industrial pure manganese and the balance of industrial pure magnesium and inevitable impurities. The preparation method comprises the following steps: firstly melting magnesium, then adding magnesium-manganese intermediate alloy, stirring and refining and then pouring into an ingot, subsequently carrying out homogenizing heat treatment on the ingot, and extruding, so that corresponding extruded section is obtained. According to the invention, cheap magnesium manganese intermediate alloy is utilized, novel wrought magnesium alloy with good strength and toughness is prepared, compared with the currently widely used commercial magnesium alloy, the wrought magnesium alloy section is low in cost (compared with AZ31 magnesium alloy, cost can be greatly saved in a Mg-Mn (calculated according to Mn content in 1.0wt%) binary wrought magnesium alloy), heat distortion temperature of the alloy is low, the novel wrought magnesium alloy has excellent moulding and processing performances, and strength and toughness of the novel wrought magnesium alloy are obviously better than those of the traditional commercial AZ31 magnesium alloy.

Owner:CHONGQING UNIV

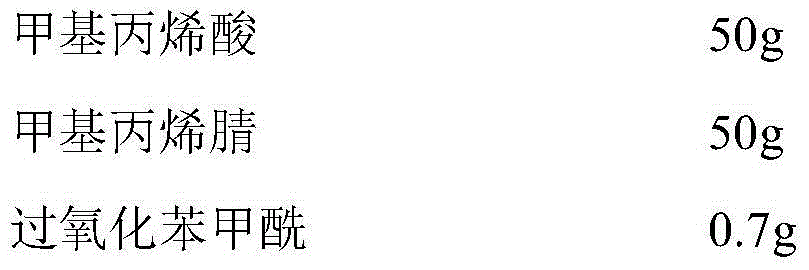

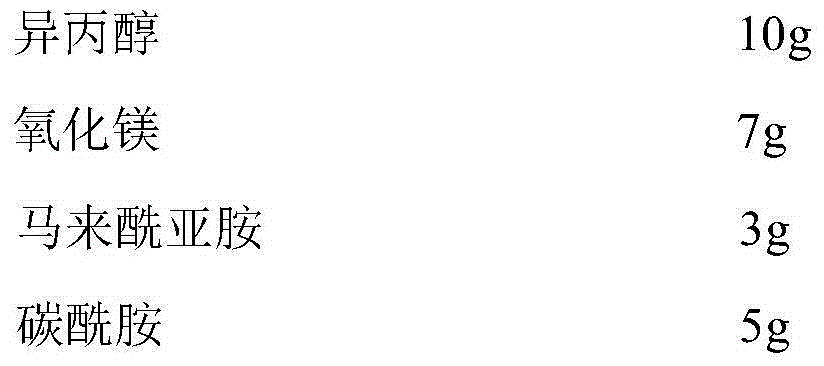

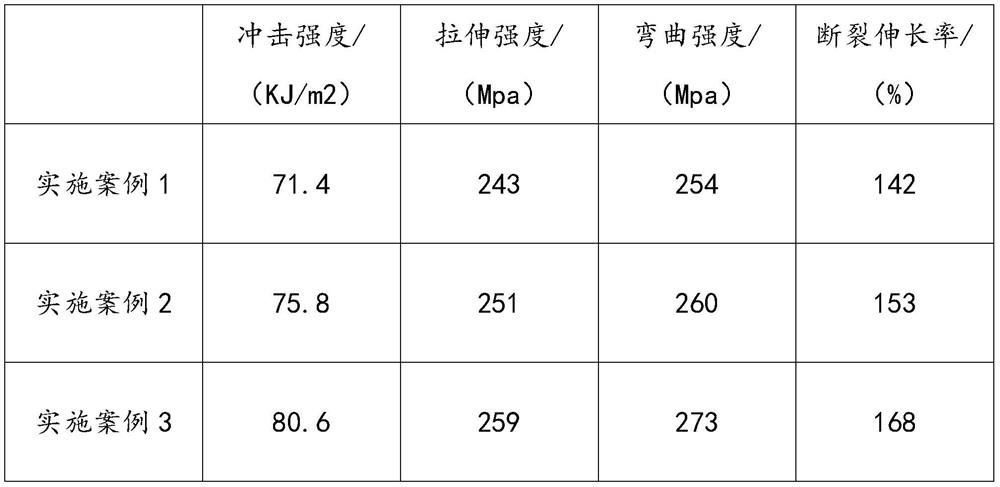

Preparation method and application of high-tenacity foam material

ActiveCN104945553AHigh elongation at breakLow heat distortion temperatureHeat deflection temperatureFoaming agent

The invention discloses a preparation method of a high-tenacity foam material. The method includes the steps that 1, two glass plates are sealed through rubber strips to form a mold cavity; 2, methacrylic acid, methacrylonitrile and core-shell rubber are mixed, and magnesium oxide is added into the mixture and completely dissolved; 3, a mixed foaming agent, an initiating agent mixture, maleimide and carbamide are added, stirred and mixed evenly to be injected into the mold cavity; 4, a polymerization reaction is performed for 40 h-60 h under the bath temperature of 30 DEG C-50 DEG C to form a foam presoma copolymer board; 5, the foam presoma copolymer board is placed under the temperature of 130 DEG C-180 DEG C to be preheated for 2 h-5 h, foamed for 30 min-90 min under the temperature of 180 DEG C-230 DEG C and then subjected to heat treatment for 1 h-3 h under the temperature of 130 DEG C-180 DEG C, and then the high-tenacity foam material can be obtained. By the adoption of the core-shell rubber tenacity-increasing PMI foam material, the breaking elongation of PMI foams can be effectively increased, but the heat deformation temperature is not obviously decreased. A new means is provided for studying the PMI foam material and improving performance.

Owner:句容市育达实业投资有限公司

Combination for storing and applying heat softenable moisture curable materials

InactiveUS20020130143A1Inexpensive to useEconomical to useOpening closed containersBottle/container closureEngineeringDegree Fahrenheit

A combination for use in storing and applying moisture curable materials which includes (1) a container assembly with a tubular wall of moisture vapor transmissive polymeric material having an inner surface defining a chamber and a plunger within the tubular wall adapted to move along the wall toward an outlet end in sealing engagement with an inner surface of the wall; (2) a moisture curable material within the chamber which is solid at normal room temperature, is softenable to a suitable viscosity for application of less than 30,000 centipoise when heated to a temperature in the range of about 140 to 230 degrees Fahrenheit or 60 to 110 degrees Centigrade, and has little adhesion to the wall, even when said adhesive is moisture cured; and (3) an envelope of moisture impermeable material around the container assembly.

Owner:3M INNOVATIVE PROPERTIES CO

Polyphenylene ether resin composition and method of preparing the same

The invention relates to a polyphenylene oxide resin composition, which contains polyphenylene oxide resin and elastomer, wherein, the composition also contains polystyrene. The elastomer is a polymer which is grafted with bulky oxazoline on polymer with rubber characteristics; the polymer with rubber characteristics is segmented copolymer polymerized of aromatic compound with one or two conjugated vinyl compounds or ethylene propylene diene rubber grafted with ethylene methyl acrylate. The invention also relates to a preparation method of the composition. The composition of the invention has good flexibility, great tensile strength and great elongation at break under tearing strength.

Owner:BYD CO LTD

High-tenacity anti-aging modified PVC insulation cable material

InactiveCN104356533AGood oil resistanceImprove aging resistancePlastic/resin/waxes insulatorsSodium stearateHydroxystearic Acid

The invention discloses a high-tenacity anti-aging modified PVC insulation cable material composed of polyvinyl chloride, acrylonitrile-butadiene rubber, chlorinated polyethylene, ABS, sodium stearate modified nano calcium carbonate, calcined kaolin, dicumyl peroxide, hydroxystearic acid, palmitic acid amide, stearic acid pentaerythritol ester, THAM, adipic acid calcium, maleic anhydride, epoxy linoleic acid pentaerythritol ester, magnesium oxide and zinc oxide. The high tenacity anti-aging modified PVC insulation cable material has the advantages of excellent tenacity, strong aging resistance and superior insulating property; an insulated cable made of the high tenacity anti-aging modified PVC insulation cable material has the advantages of overall performance and long service life.

Owner:ANHUI CONSTANT CRYSTAL CABLE GROUP

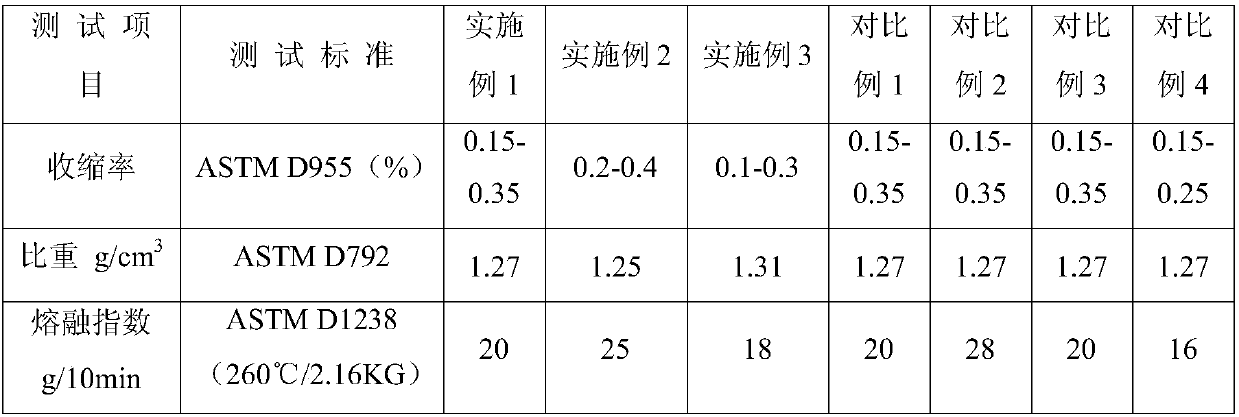

Polyamide 6 modified material for additive manufacturing, and preparation method thereof

InactiveCN107778846ASimple processGood modification effectAdditive manufacturing apparatusPolyamideGlass fiber

The invention relates to the field of additive manufacturing consumables, and discloses a polyamide 6 modified material for additive manufacturing, and a preparation method thereof. The polyamide 6 modified material comprises, by mass, 62-78% of polyamide 6 (PA6), 8-15% of glass fibers, 8-20% of a toughener, 5-10% of a compatibilizer, 0.3-2% of an antioxidant and 0.2-1% of a fiber glass exposure inhibitor. The preparation method has a simple process, and has the following remarkable modification effects: 1, the glass fibers and the toughener are added, so the mechanical strength and the toughness of the prepared polyamide 6 modified material are obviously improved, and the strengthening and toughening effects are remarkable; 2, the preferable glass fiber exposure inhibitor is added, so thefree fluidity of the material is improved, and the processing performances are improved, thereby the surface glossiness of the material is high; 3, the material has a lower shrinkage rate and a higher thermal deformation temperature than traditional nylon materials; and 4, printing verifies that silks are smoothly produced from nozzles during 3D printing, and the material has the advantages of low warping, high precision and good appearance quality, and is very suitable for producing consumables for FDM additive manufacturing.

Owner:四川鑫达企业集团有限公司

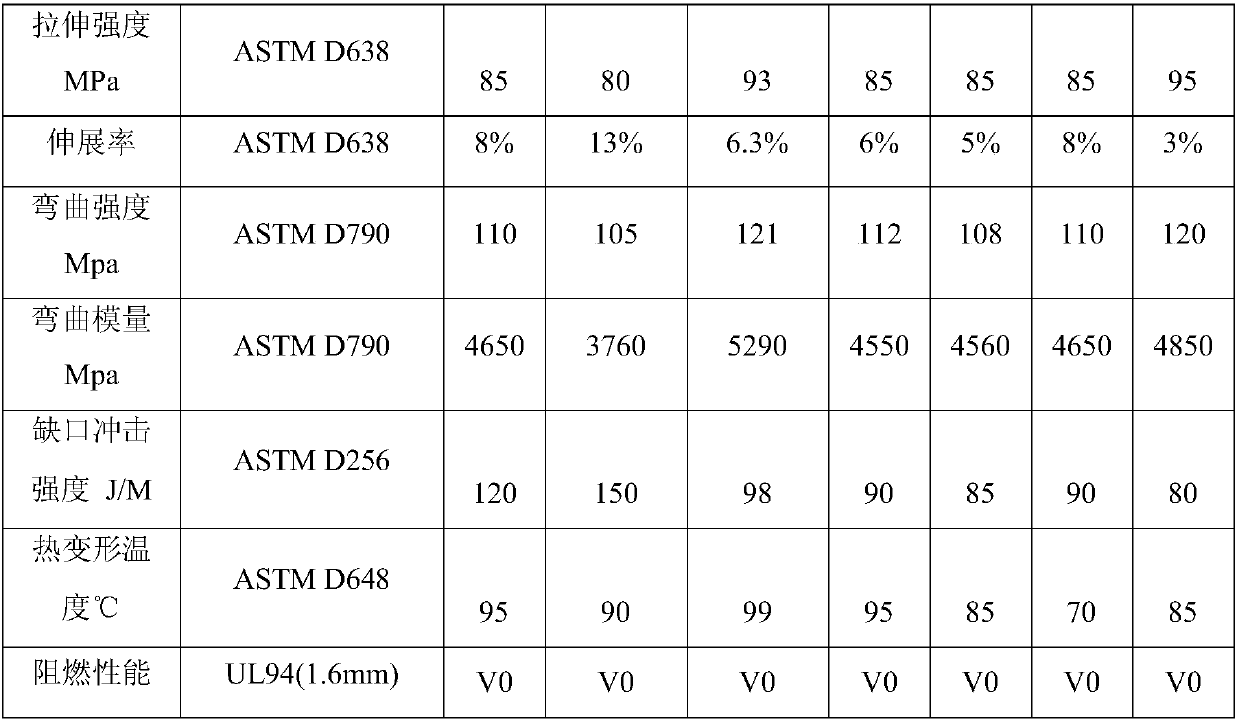

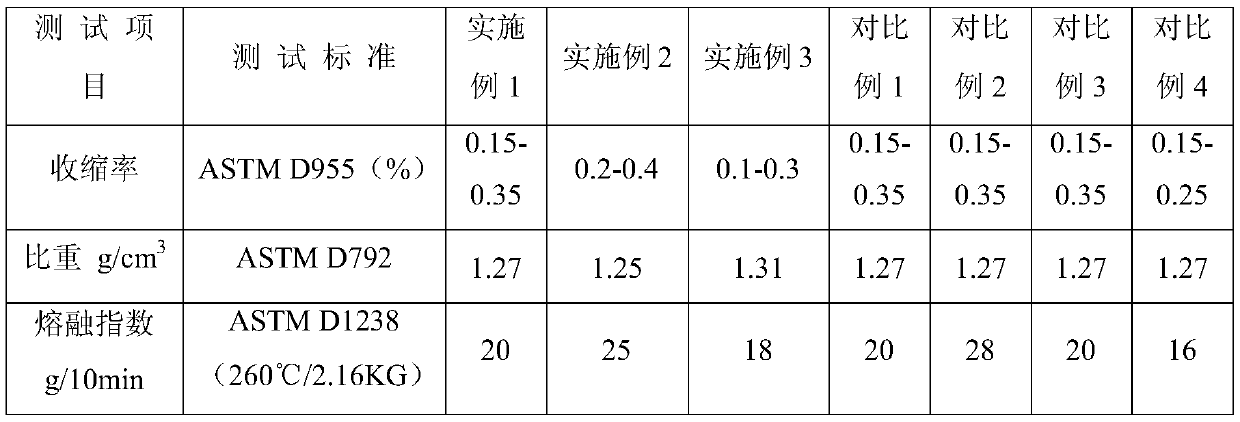

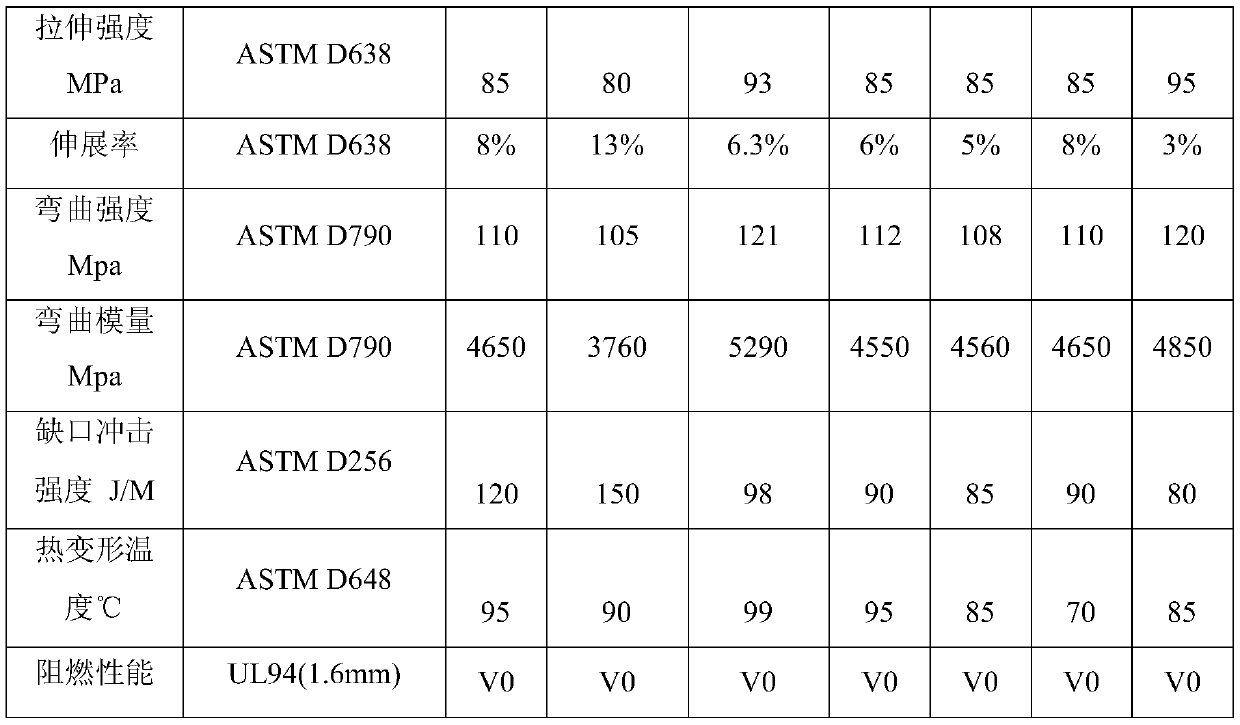

Halogen-free flame-retardant highlight mineral fiber enhanced PC/ABS composite material and preparation method thereof

ActiveCN107674397AImprove mechanical propertiesLow heat distortion temperatureFiberMetallic materials

The invention discloses a halogen-free flame-retardant highlight mineral fiber enhanced PC / ABS composite material and a preparation method thereof. The halogen-free flame-retardant highlight mineral fiber enhanced PC / ABS composite material comprises the following components in parts by weight: 35 to 55 parts of PC, 5 to 10 parts of ABS, 0.1 to 0.3 part of a sesquialter silicon flame retardant, 6 to 12 parts of an organic phosphorus flame retardant, 0.1 to 0.3 part of an anti-drip agent, 2.0 to 5.0 parts of a compatilizer, 2 to 5 parts of a toughening agent, 0.1 to 1 part of a stabilizer, 10 to25 parts of mineral fiber material, 0.3 to 1 part of a coupling agent and 0.3 to 0.6 part of a floating fiber leakage preventing agent. The prepared composite material can completely replace a metalmaterial in the aspect of performance, realizes a macromolecular material with highlight effect through the common mold temperature machine and provides more choices for industrial design.

Owner:安徽科高新材料有限公司

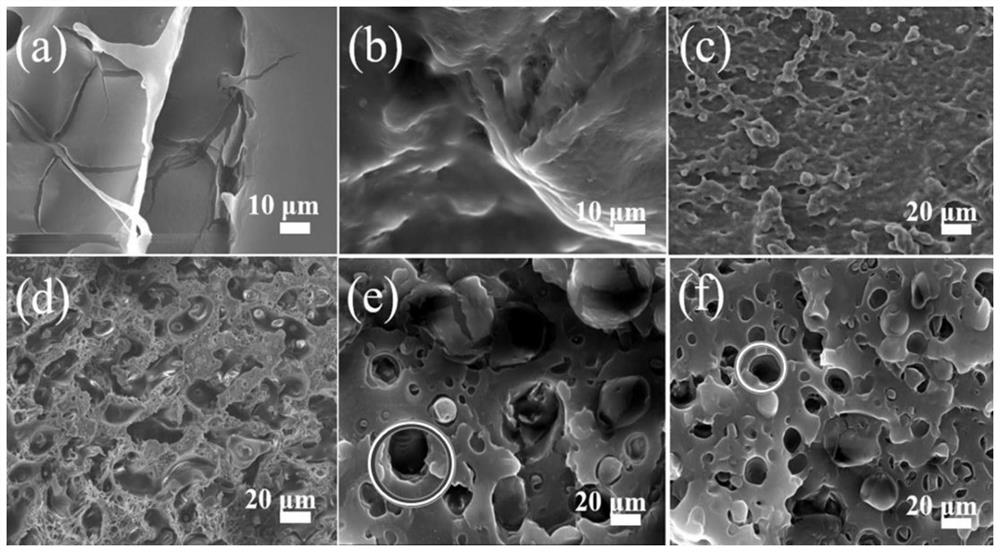

Toughened polylactic acid composite material and preparation method thereof

ActiveCN111647256AImprove performanceReduce intensityPolyethylene terephthalate glycolThermal deformation

The invention discloses a toughened polylactic acid composite material and a preparation method thereof, and the toughened polylactic acid composite material comprises the following raw materials by weight: 20-80 parts of polylactic acid (PLA), 20-80 parts of polyethylene terephthalate-1,4-cyclohexanedimethanol ester (PCTG), 0-9 parts of a compatilizer, 0-5 parts of a toughening agent, and 0.1-0.5part of an antioxidant; wherein the polylactic acid comprises L-lactic acid and D-lactic acid; the average molecular weight is 207 kDa; the relative density ranges from 1.20-1.30 g / cm3; and the melting temperature is 200-220 DEG C. The toughened polylactic acid composite material has excellent comprehensive properties, effectively improves the compatibility of PLA and PCTG, greatly enhances the notch impact strength and toughness, enhances the thermal deformation temperature, and can be industrially applied to some specific packaging materials and container materials.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

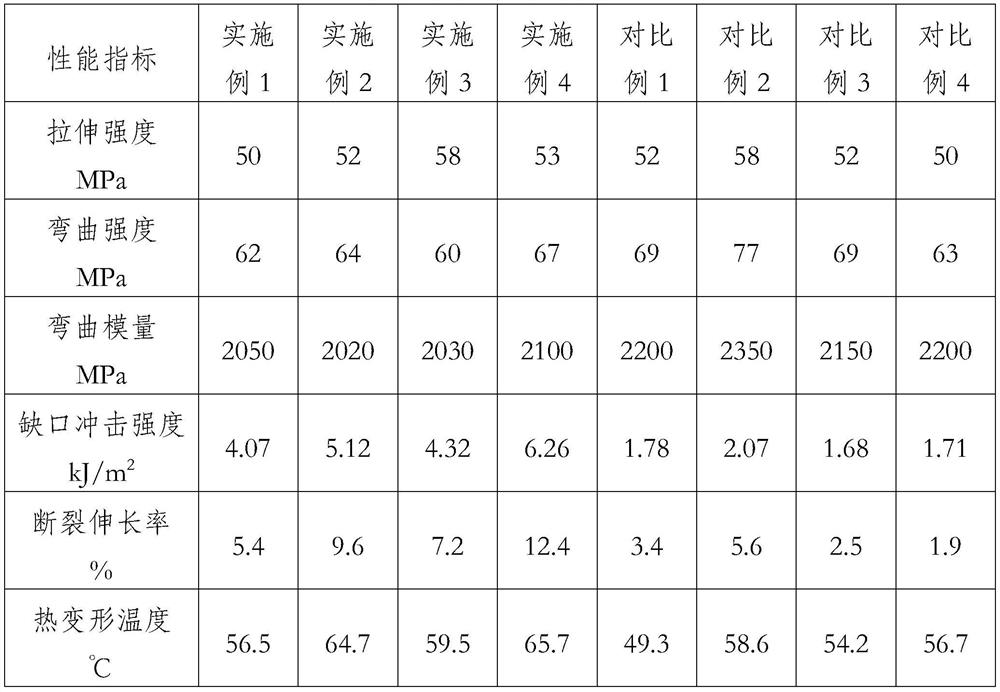

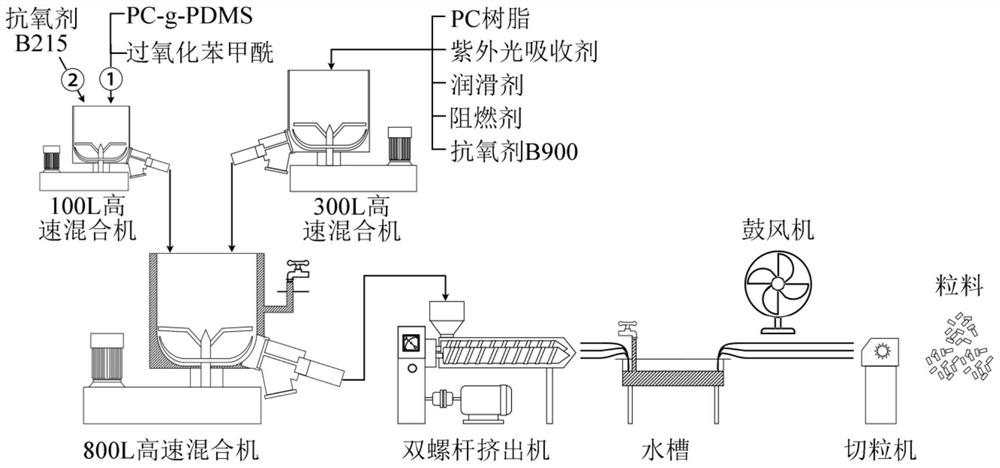

Multi-functional polycarbonate modified material and preparation method thereof

The invention discloses a multi-functional polycarbonate modified material which has the advantages of transparency, flame retardance, weather resistance and high and low temperature impact resistance, and can meet the requirements of high-end electronic and electrical products in certain outdoor specific harsh occasions. The multi-functional polycarbonate modified material is prepared from the following raw materials in parts by mass: 60 to 80 parts of polycarbonate, 20 to 40 parts of a mixture of polycarbonate / polydimethylsiloxane copolymer, 0.08 to 0.1 parts of a flame retardant, 0.3 to 0.5 parts of an ultraviolet light absorber, 0.1 to 0.3 parts of an antioxidant B900 and 0.1 to 0.2 parts of a lubricant.

Owner:NANJING UNIV OF TECH +1

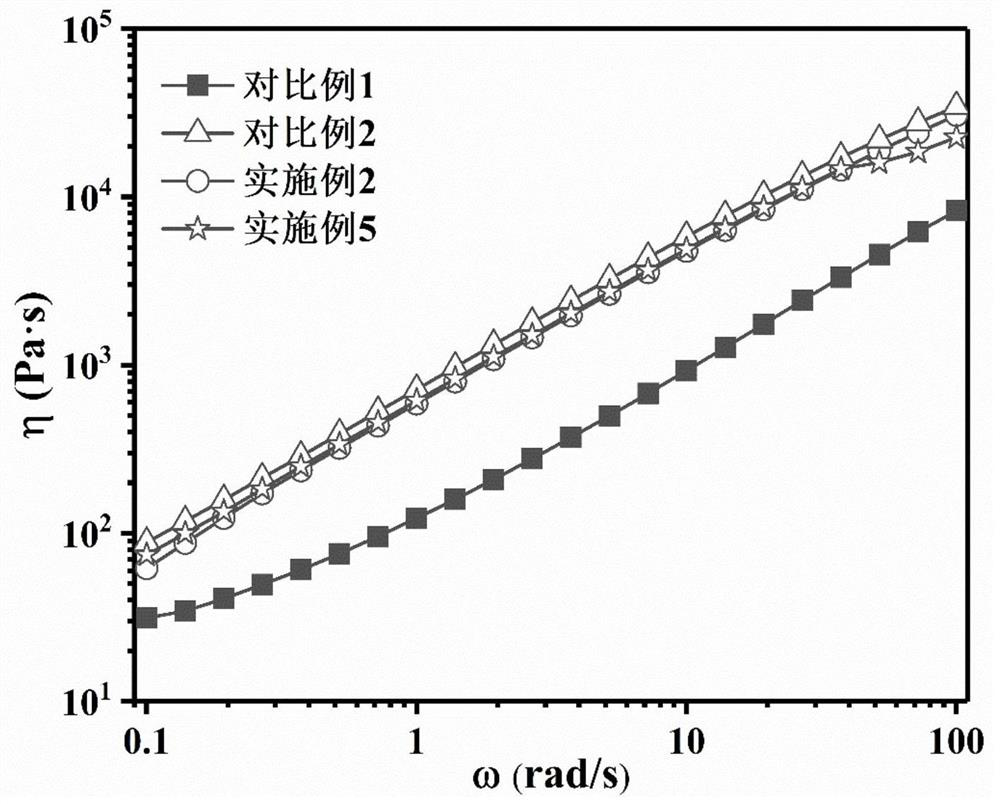

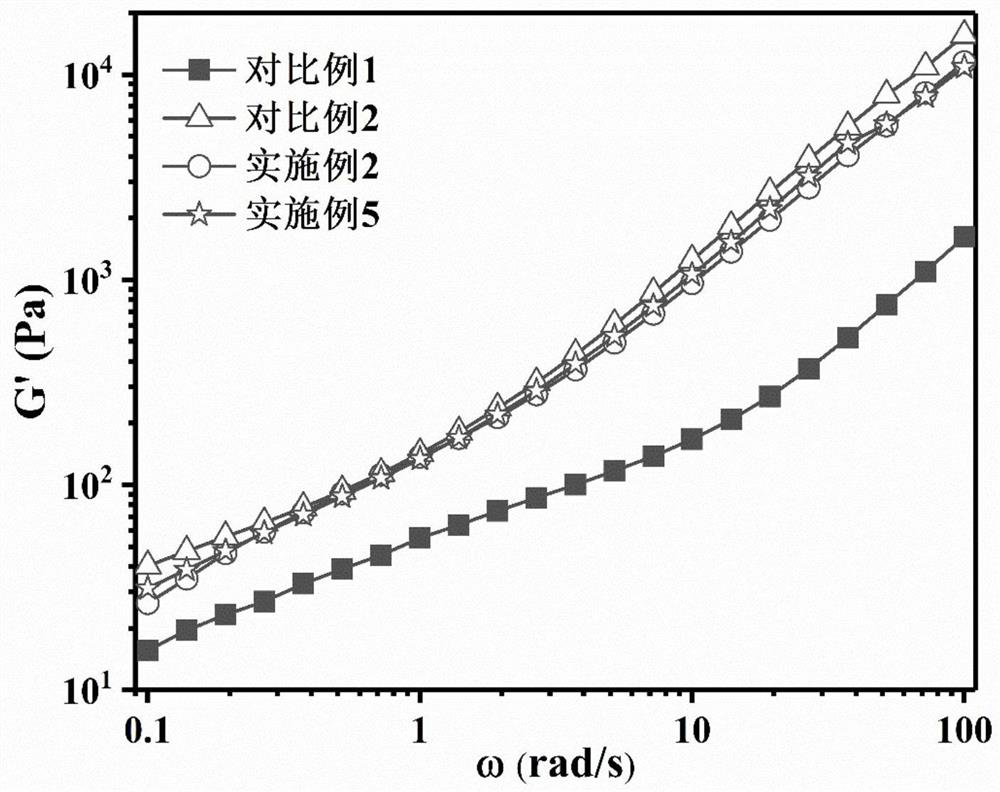

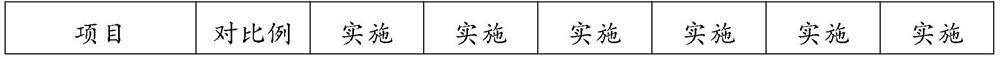

Polyphenyl ether resin composition and preparation method thereof, and wire duct and preparation method thereof

The invention provides a polyphenyl ether resin composition and a preparation method thereof, and a wire duct and a preparation method thereof, and relates to the technical field of composite materialextrusion molding. The polyphenyl ether resin composition provided by the invention comprises the following preparation raw materials in parts by weight: 50 to 75 parts of polyphenyl ether resin, 10to 30 parts of polystyrene resin, 4 to 10 parts of a toughening agent, 1 to 3 parts of polyolefin, 5 to 15 parts of a flame retardant, 1 to 5 parts of a smoke suppressant, 0 to 5 parts of an inorganicmicro-nano filler, 0 to 1 part of a lubricant, 0 to 0.5 part of a main antioxidant, and 0 to 0.5 part of an auxiliary antioxidant. The polyphenyl ether resin composition provided by the invention hasexcellent flame retardancy and high temperature resistance, is relatively low in smoke density during combustion, has high impact toughness and scratch resistance, and is suitable for an extrusion molding process of the wire duct and use in an extreme environment.

Owner:湖南恒屹新材料有限公司 +1

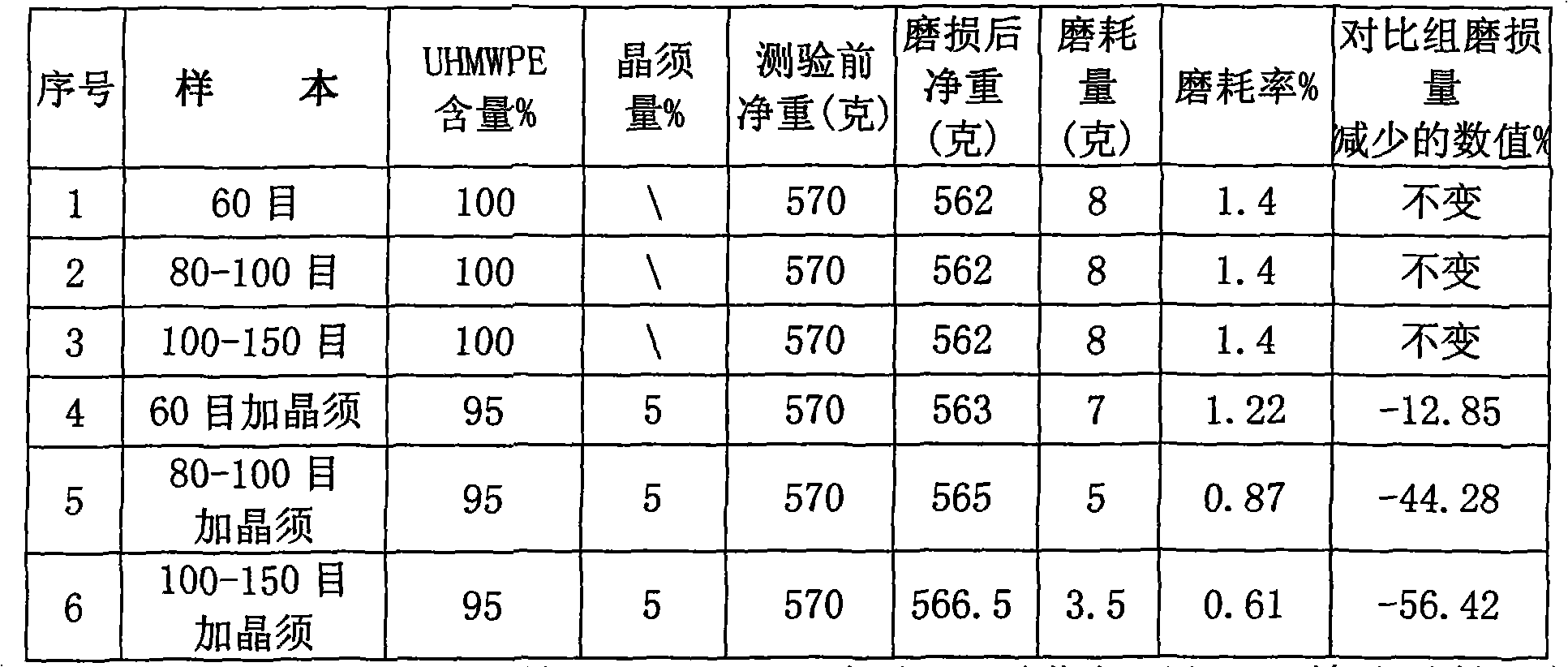

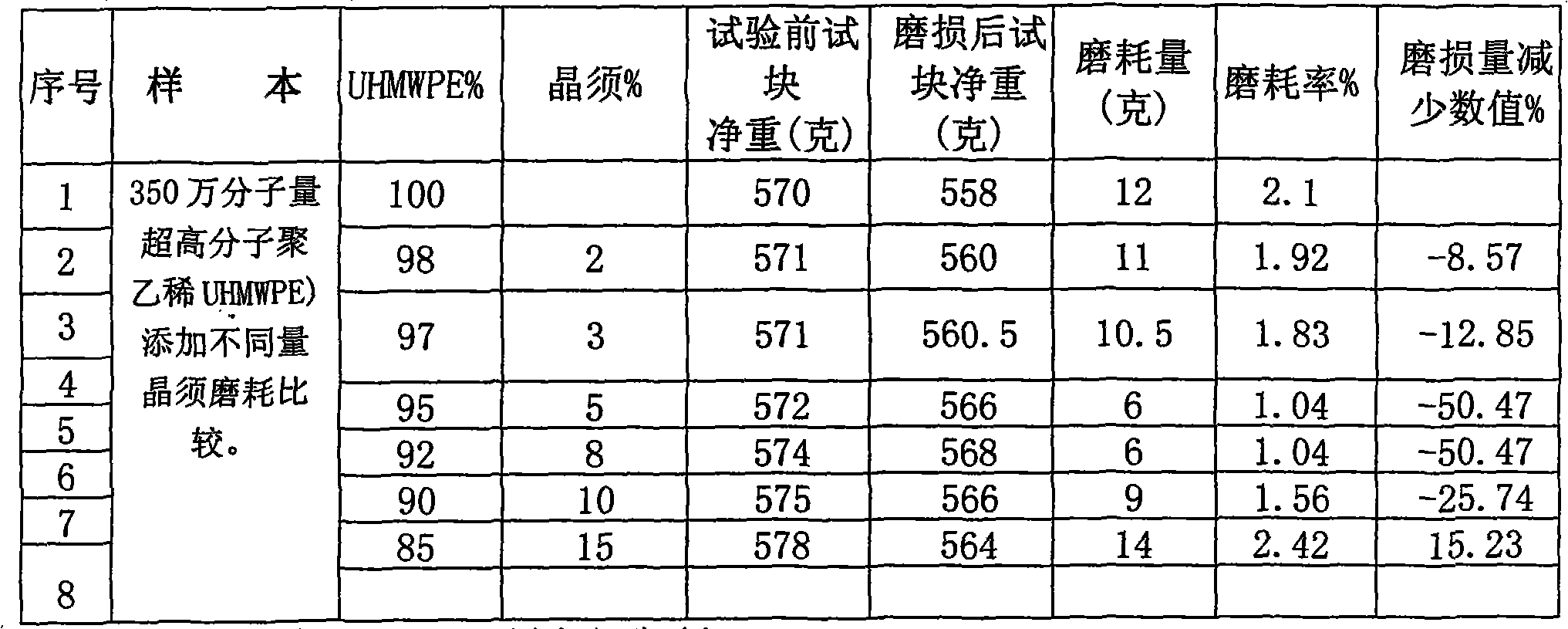

Modified ultra-high molecular weight polyethylene (UHMWPE) and application thereof on centrifugal pump

InactiveCN101857688AImprove mechanical stabilityImprove yieldPump componentsPumpsPolymer scienceThermal expansion

The invention relates to a modified ultra-high molecular weight polyethylene (UHMWPE) that is characterized by being prepared by mixing 85 to 98 wt% of ultra-high molecular weight polyethylene with the molecular weight (measured by viscosimetry) of 1.5 to 5 millions and 2 to 15 wt% of potassium carbonate whisker processed by a coupling agent. The invention not only greatly improves the abrasion resistance of the UHMWPE, but also has the comprehensive effects of raising of use temperature, reduction of coefficient of thermal expansion and improvement of melting performance, processing and molding performance, production efficiency and product quality; and in particular, the invention is suitable for anti-corrosive and wear-resisting centrifugal pumps.

Owner:宜兴市宙斯泵业有限公司

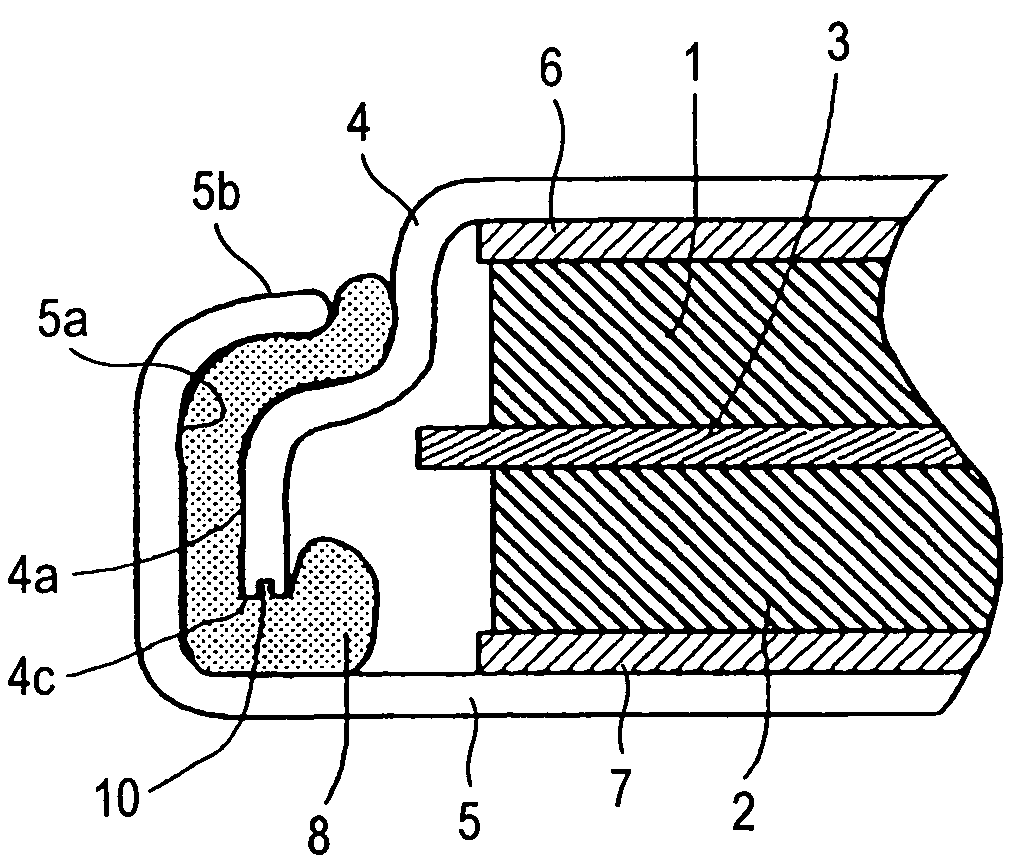

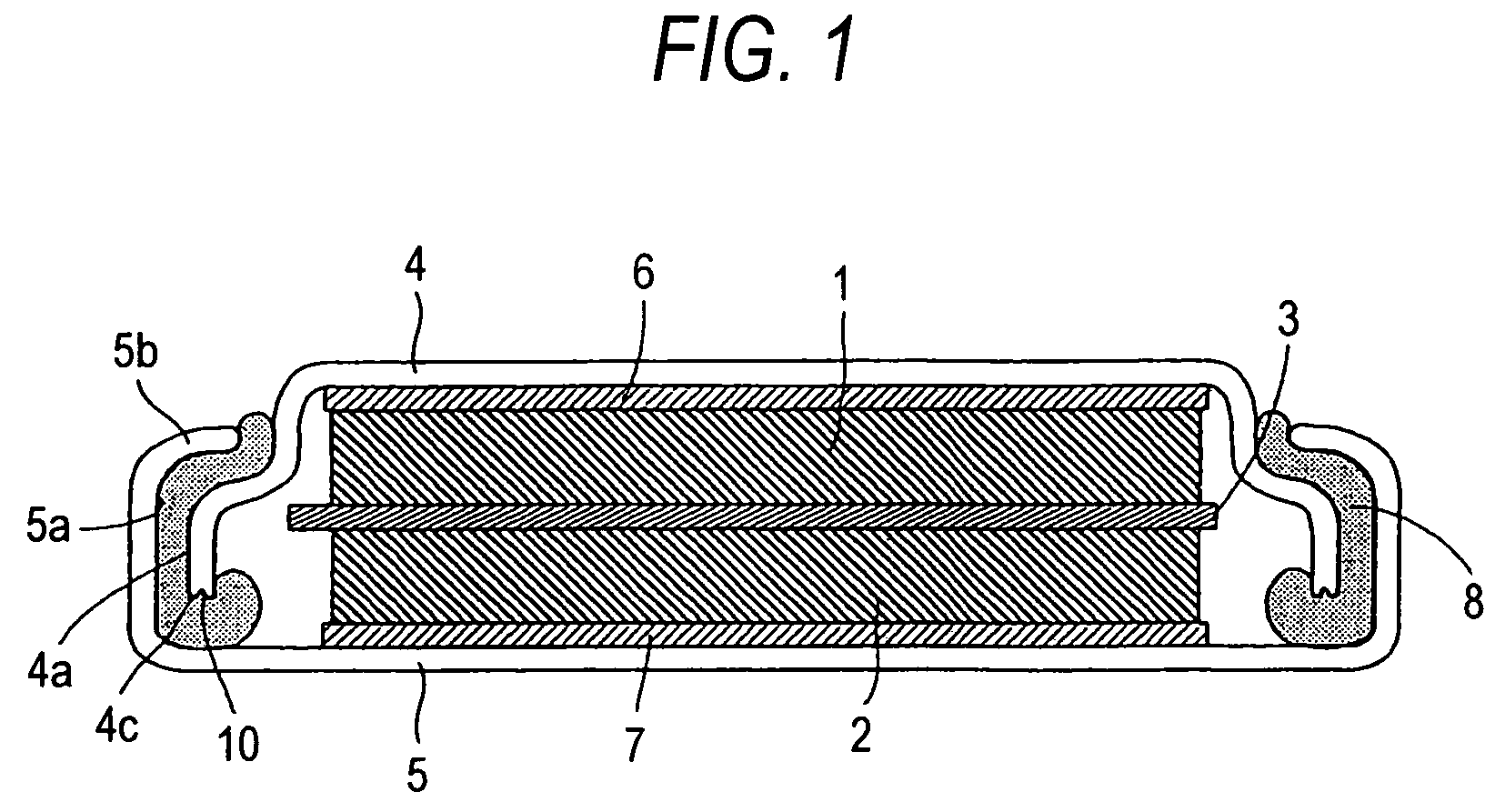

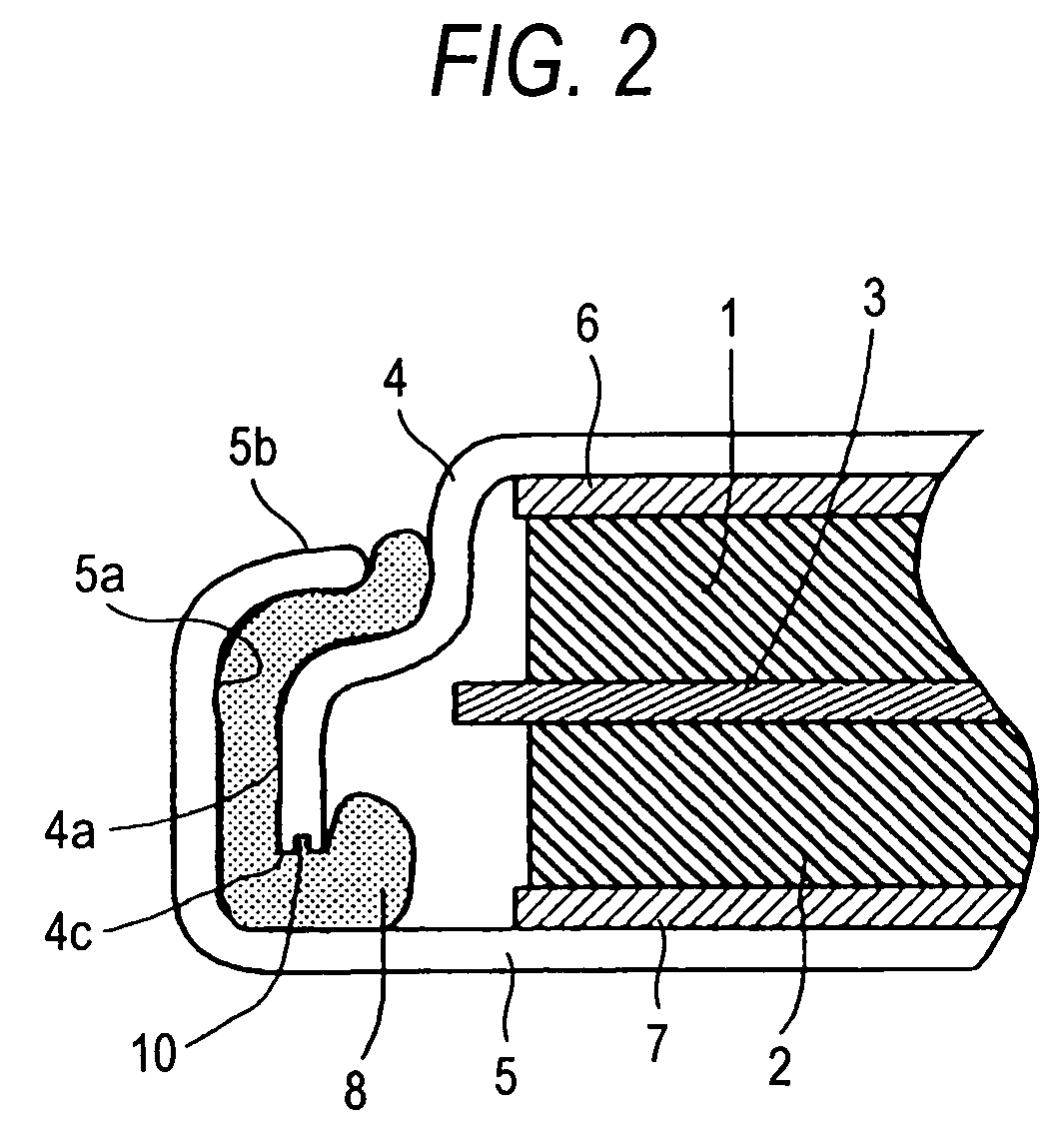

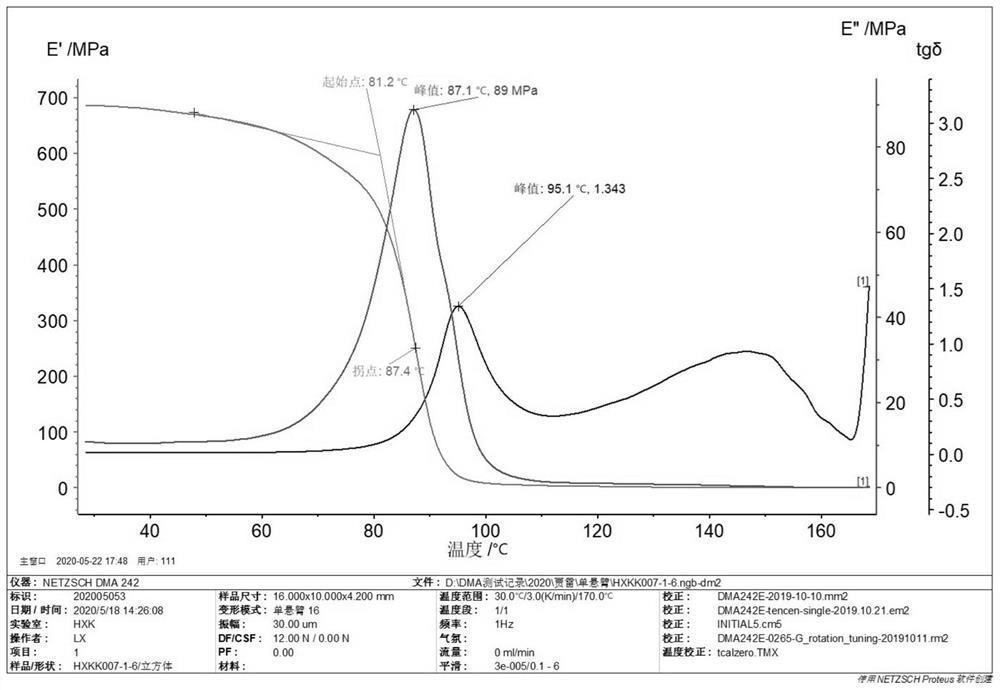

Electric double layer capacitor

ActiveUS7317608B2Improve heat resistanceLarge coefficientHybrid capacitor electrodesDouble layer capacitorsPolyether ether ketoneBiomedical engineering

An electric double layer capacitor including a separator, a pair of polarizing electrodes disposed opposite to each other with the separator interposed therebetween, an electrolytic solution impregnated in a pair of the polarizing electrodes and the separator, an exterior cover and an exterior case for accommodating the separator, a pair of the polarizing electrodes, and the electrolytic solution, and a gasket disposed between the outer circumferential part of the exterior cover and the inner circumferential part of the exterior case, the storage space formed by the exterior case and the exterior cover being hermetically sealed by inwardly bending the opening tip portion of the exterior case, is characterized in that no folded-back part is provided at the outer circumferential part of the exterior cover, and the gasket is polyether ether ketone.

Owner:FDK CORP

Polycarbonate/polyester alloy as well as preparation method and application thereof

ActiveCN112226061AAvoid degradationLow heat distortion temperatureTrans esterificationHeat deflection temperature

The invention relates to a polycarbonate / polyester alloy as well as a preparation method and application thereof. The alloy is prepared from the following raw materials in percentage by mass: 60%-85%of bisphenol A polycarbonate, 12%-35% of polyester resin with the refractive index of 1.5+ / -0.1 and the glass-transition temperature of from 60 DEG C to 100 DEG C, 1%-5% of a compatilizer, 0.1%-5% ofan ester exchange inhibitor and 0.1%-3% of a light diffusion agent with the refractive index of 1.35-1.49, wherein the polyester resin is selected from PET resin and / or PETG resin. Due to the existence of a low-Tg polyester chain, the thermal deformation temperature of the alloy is reduced by 15-45 DEG C, and the alloy is beneficial to processing and is not easy to warp; by adding a transesterification inhibitor and the compatilizer, the alloy inherits the transparency of bisphenol A type PC and keeps high light transmittance; and by adding a light diffusion agent, the haze of the alloy can beimproved.

Owner:GUANGZHOU HUAXINKE ENTERPRISE

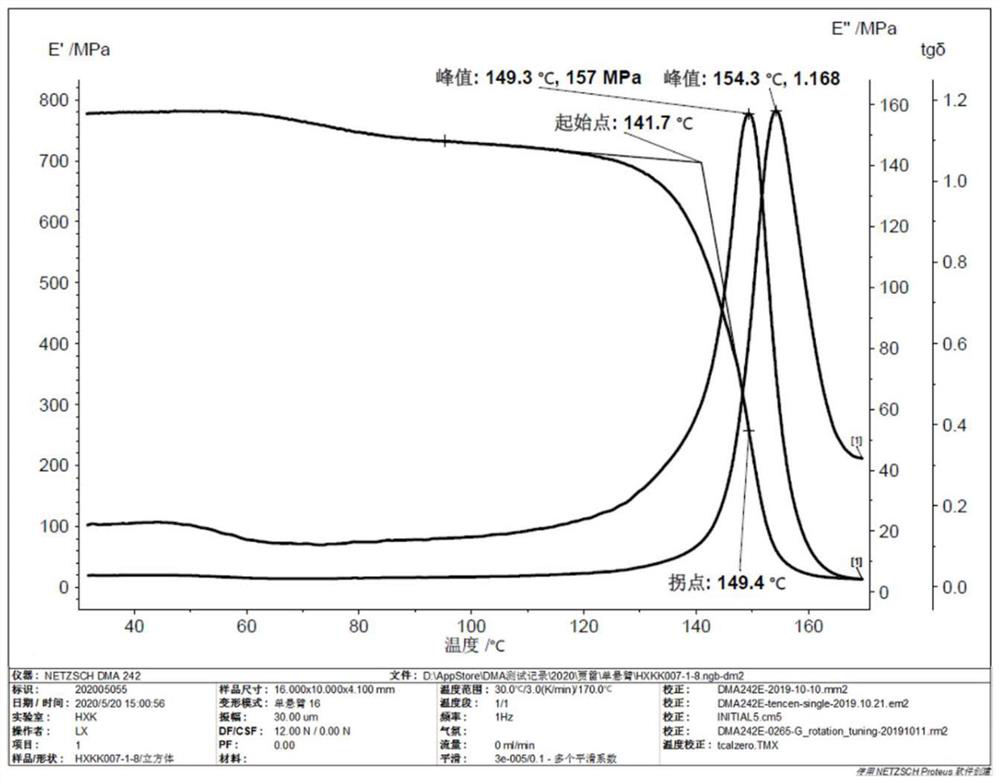

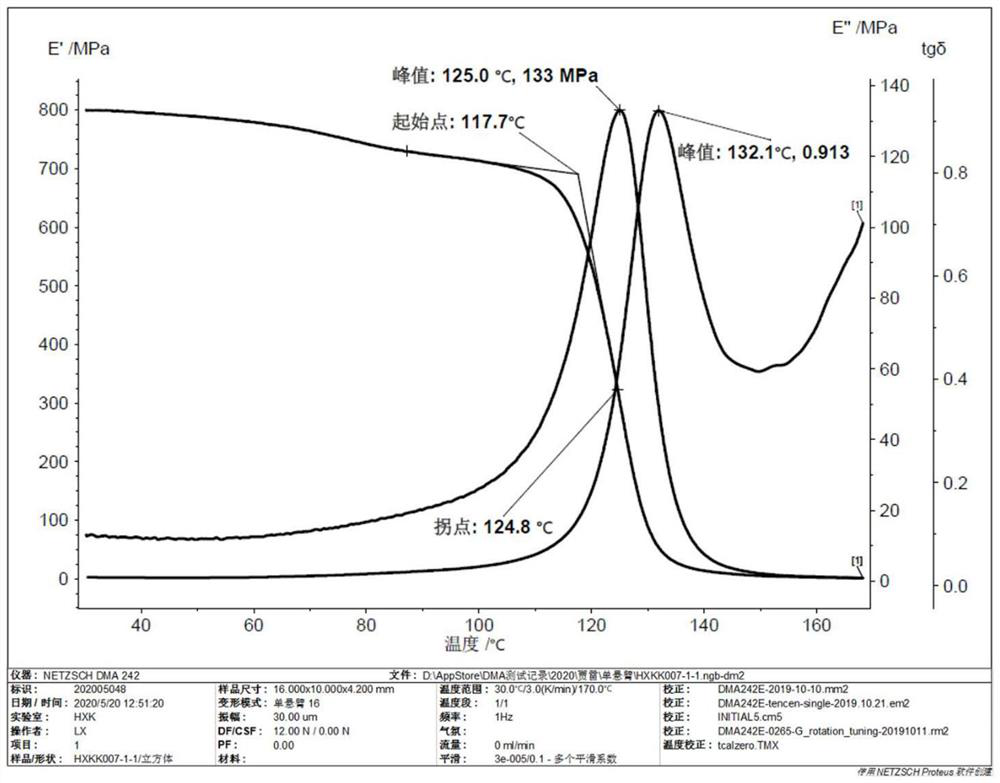

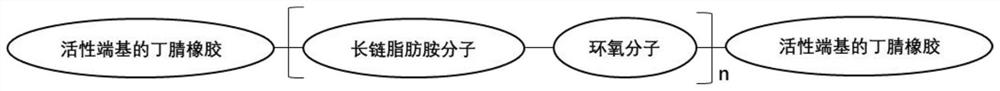

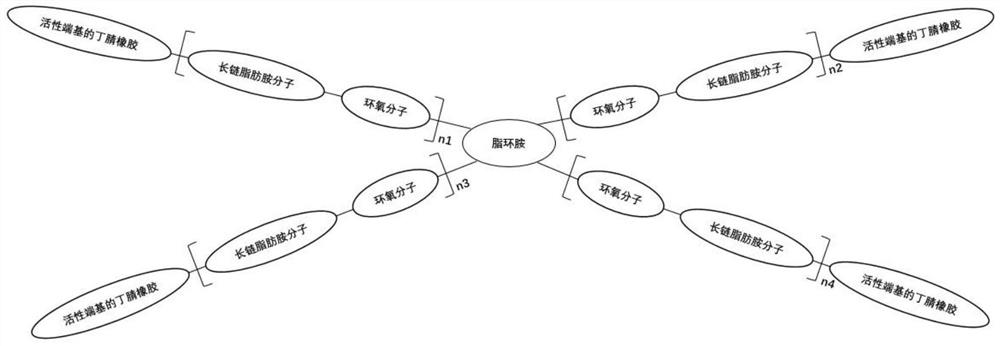

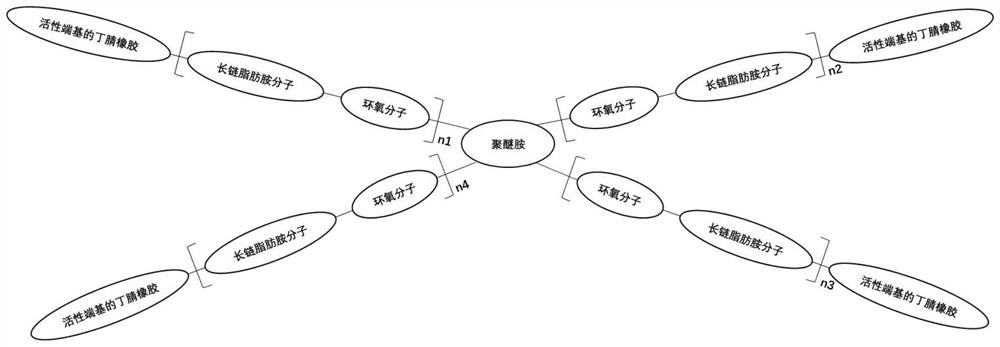

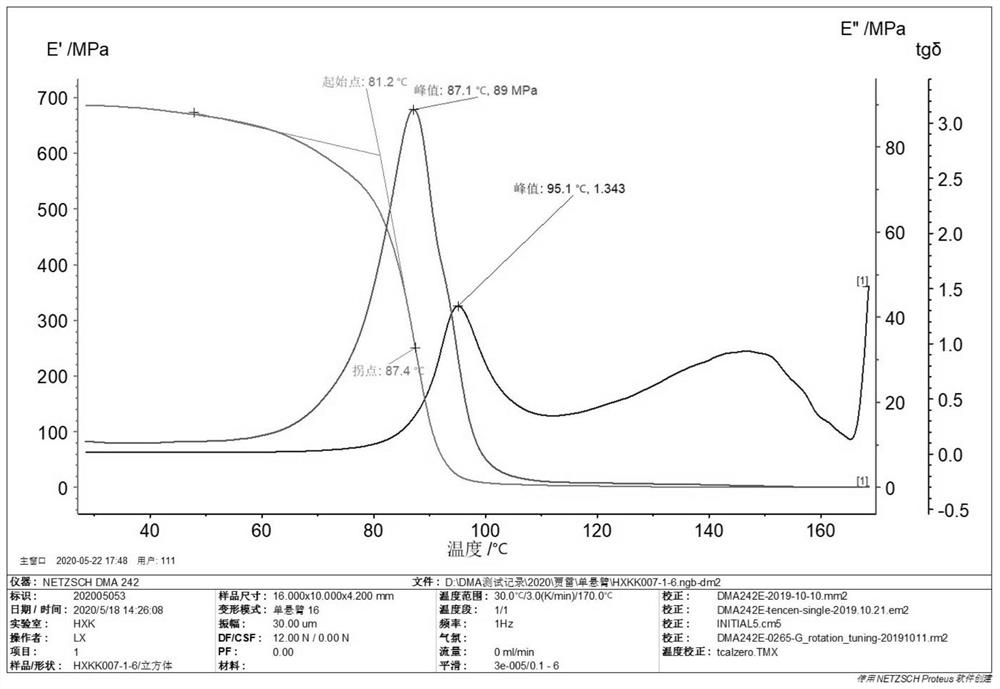

Normal-temperature curing epoxy resin-based vitrimer adhesive and preparation method thereof

ActiveCN113337234ALow heat distortion temperatureImproves flexibility and impact resistanceMacromolecular adhesive additivesRubber derivative adhesivesTensile fractureCarboxylic group

The invention discloses a normal-temperature curing epoxy resin-based vitrimer adhesive, which is prepared by mixing a component A epoxy resin and a component B epoxy curing agent according to a weight ratio of 1:(0.80-1.20), the component A comprises the following components in parts by weight: 100 parts of bisphenol A type epoxy resin, 5-15 parts of bisphenol F type epoxy resin, 5-20 parts of a reactive diluent and 0.5-20 parts of epoxy-terminated liquid nitrile rubber, the component B comprises the following components in parts by weight: 55-70 parts of an amine curing agent, 15-30 parts of a toughening agent and 15-25 parts of a curing accelerator, the amine curing agent is a mixture of a long-chain aliphatic amine curing agent, an alicyclic amine curing agent and a polyether amine curing agent, and the toughening agentis amino-terminated, carboxyl-terminated or hydroxyl-terminated liquid nitrile rubber or any mixture thereof. The adhesive provided by the invention has the characteristics of high bonding strength, large tensile fracture elongation, small elastic modulus, good low-temperature flexibility and strong impact resistance, can be repeatedly fused within the temperature range of 80-200 DEG C, is high in plasticity and good in weldability, and has a shape memory function.

Owner:WUHAN UNIV OF TECH +1

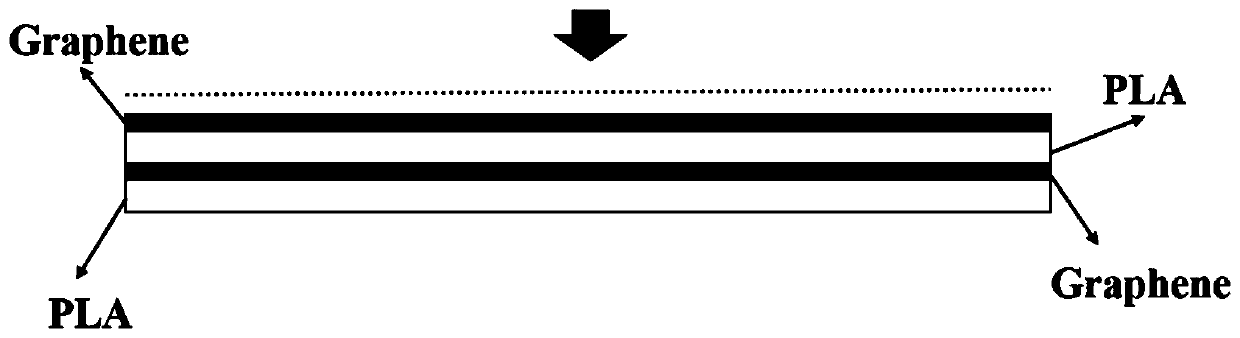

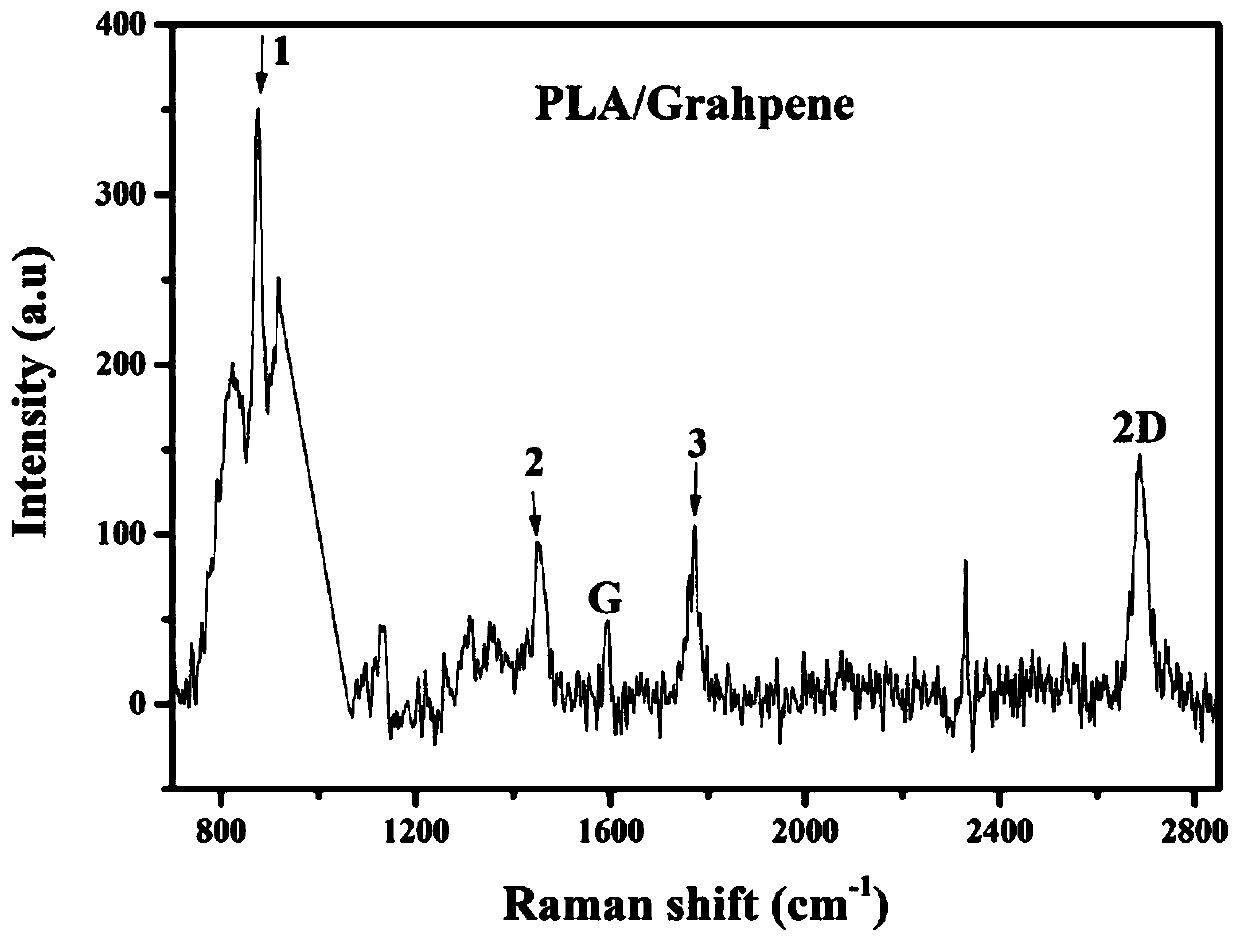

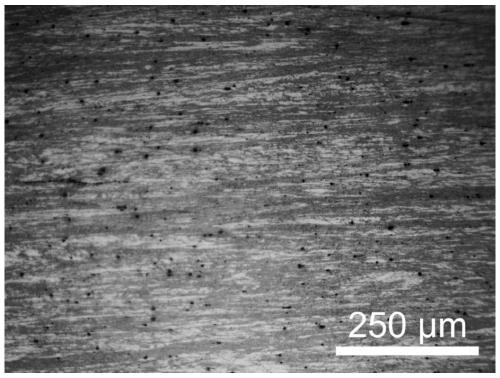

Medical degradable multilayer polymer/graphene film material and preparation method thereof

ActiveCN110327484AGood antibacterial functionPrevent infiltrationSuture equipmentsCoatingsPolymer scienceBiocompatibility Testing

The invention discloses a medical degradable multilayer polymer / graphene film material and a preparation method thereof. The method includes firstly attaching a biodegradable polymer to a single-layergraphene / Cu substrate by spin coating or casting; then removing Cu through etching to obtain polymer / single-layer graphene film; and laminating a plurality of layers of the polymer / single-layer graphene film to obtain the multilayer polymer / graphene film. The polymer is good in biocompatibility with graphene and is degradable in vivo, and the degradation time of the disclosed film material can beadjusted and controlled through controlling the number of layers of the polymer / graphene film. In addition, the multilayer polymer / graphene film has high mechanical strength, and is corrosion resistant and antibacterial. The preparation method is simple. The multilayer polymer / graphene film material is expected to be applied in clinical surgical suture supporting materials and surface modification of implants.

Owner:ZHEJIANG UNIV

Preparation method of microalloyed ultrahigh-strength magnesium alloy

ActiveCN113802039AImprove casting performanceHigh strengthRotary stirring mixersAlloy elementPlasticity

The invention discloses a preparation method of a microalloyed ultrahigh-strength magnesium alloy, and relates to a preparation method of a microalloyed magnesium alloy. The preparation method aims to solve the technical problems that an existing magnesium alloy material is too high in cost, and the strength and plasticity of the material are difficult to match well. In the preparation method, an Nd element is adopted as one of alloying elements of the magnesium alloy, a small quantity of a rare earth element Nd and an alloying element Zr are added into a traditional Mg-Zn binary alloy, after two-stage deformation heat treatment, microalloying is achieved, meanwhile, a good strengthening and toughening effect is achieved, it is ensured that the alloy has high strength and meanwhile still has acceptable plasticity, microalloying can also reduce the defects such as inclusion caused by alloying to the greatest extent, the cost is reduced, and the production efficiency is improved.

Owner:TAIYUAN UNIV OF TECH

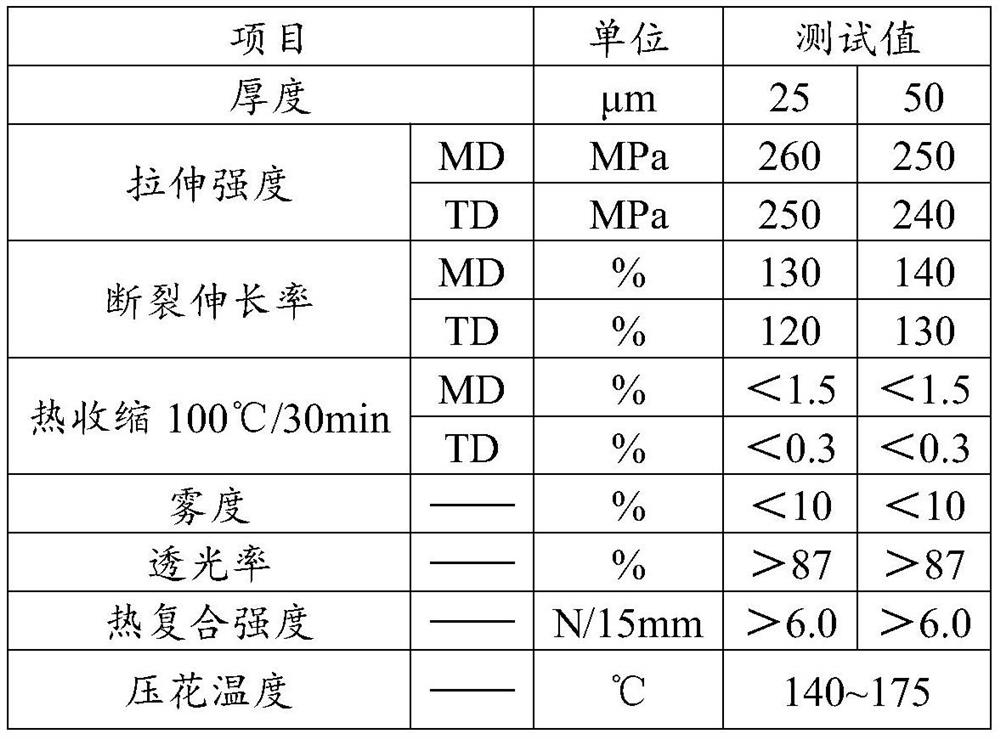

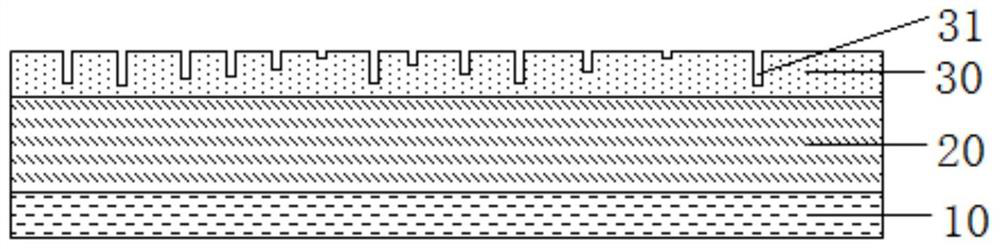

Biaxially-oriented knurling thermal composite polyester film and preparation method thereof

PendingCN114347618AEnvironmentally friendlyReduce crystallinitySynthetic resin layered productsFlat articlesPolyesterPolymer science

The invention relates to the technical field of polyester films, and provides a two-way stretching knurling thermal composite polyester film and a preparation method thereof. Through the design of the raw materials, the formula and the process, the upper surface layer of the polyester film has good thermal compounding property, the core layer has lower crystallinity and thermal deformation temperature, and the lower surface layer has lower crystallinity and thermal deformation temperature and good knurling property. The polyester film provided by the invention not only has good mechanical properties and optical properties of a polyester film, but also has the characteristics of thermal compounding and knurling, can be used as a knurling composite film of various plate products, is environment-friendly, can be used for replacing a PVC (Polyvinyl Chloride) knurling composite film, and has a wide market prospect.

Owner:杭州大东南高科新材料有限公司 +1

A kind of halogen-free flame-retardant high-gloss mineral fiber reinforced PC/ABS composite material and its preparation method

ActiveCN107674397BImprove mechanical propertiesLow heat distortion temperatureFiberOrganic phosphorus

The invention discloses a halogen-free flame-retardant highlight mineral fiber enhanced PC / ABS composite material and a preparation method thereof. The halogen-free flame-retardant highlight mineral fiber enhanced PC / ABS composite material comprises the following components in parts by weight: 35 to 55 parts of PC, 5 to 10 parts of ABS, 0.1 to 0.3 part of a sesquialter silicon flame retardant, 6 to 12 parts of an organic phosphorus flame retardant, 0.1 to 0.3 part of an anti-drip agent, 2.0 to 5.0 parts of a compatilizer, 2 to 5 parts of a toughening agent, 0.1 to 1 part of a stabilizer, 10 to25 parts of mineral fiber material, 0.3 to 1 part of a coupling agent and 0.3 to 0.6 part of a floating fiber leakage preventing agent. The prepared composite material can completely replace a metalmaterial in the aspect of performance, realizes a macromolecular material with highlight effect through the common mold temperature machine and provides more choices for industrial design.

Owner:安徽科高新材料有限公司

Preparation method for low-alloyed high-strength plastic magnesium alloy material

ActiveCN111304471ALow costEvenly distributedMetal-working apparatusSolid solution strengtheningThermal treatment

The invention discloses a preparation method for a low-alloyed high-strength plastic magnesium alloy material, and relates to a preparation method for a magnesium alloy material, and aims to solve thetechnical problems that an existing magnesium alloy material is too high in cost, cannot simultaneously guarantee strength and plasticity, and is great in high-temperature deformation energy consumption. A way of combining low alloying with low-temperature upsetting and squeezing deformation thermal treatment can be adopted to improve mechanical property of a magnesium alloy. Low-content zinc andyttrium can be added, so that solution strengthening and grain refining effect is generated in a magnesium matrix; the solution strengthening and grain refining effect is combined with the low-temperature upsetting and squeezing deformation thermal treatment, so that the magnesium alloy can generate more diffuse precipitated phases while grain refining is generated in a deformation process, and the generated diffuse strengthening effect guarantees that strength and plasticity of the magnesium alloy material are greatly improved. Low-content alloy elements are added, and low-temperature upsetting and squeezing thermal treatment is adopted, so that processes are simplified, production cost can be greatly reduced, and market competitiveness of the alloy is improved. The preparation method isused for preparing the magnesium alloy.

Owner:TAIYUAN UNIV OF TECH

Polycarbonate/polyester alloy and preparation method and application thereof

The present invention relates to a polycarbonate / polyester alloy and its preparation method and application. The alloy is prepared from raw materials including the following mass percentages: 60%-85% bisphenol A polycarbonate, 1.5±0.1 refractive index, and 12%-12%-polyester resin with a glass transition temperature of 60°C-100°C 35%, compatibilizer 1%-5%, transesterification inhibitor 0.1%-5%, light diffusing agent with refractive index of 1.35-1.49 0.1%-3%; the polyester resin is selected from PET resin and / or PETG resin. The existence of low Tg polyester chain reduces the thermal deformation temperature of the alloy by 15-45℃, which is beneficial to processing and is not easy to warp; and the addition of transesterification inhibitor and compatibilizer synergistically makes the alloy inherit the transparency of bisphenol A-type PC and maintain high light transmittance; the addition of light diffusing agent can improve the haze of the alloy.

Owner:GUANGZHOU HUAXINKE ENTERPRISE

High-strength MPP cable protection pipe

The invention relates to the technical field of cable protection pipes, in particular to a high-strength MPP cable protection pipe which comprises MPP resin masterbatch, low-density polyethylene resin masterbatch, a composite base material, modified acrylic resin, a cross-linking agent, an antioxidant, a flame retardant, an ultraviolet light absorber and a plasticizer, and the high-strength MPP cable protection pipe comprises, by weight, 200 to 240 parts of the MPP resin masterbatch, 100 to 150 parts of the low-density polyethylene resin masterbatch, 80 to 100 parts of the composite base material, 50 to 80 parts of the modified acrylic resin, 10 to 15 parts of the cross-linking agent, 10 to 15 parts of the antioxidant, 5 to 8 parts of the flame retardant, 5 to 9 parts of the ultraviolet absorbent and 10 to 15 parts of the plasticizer. The MPP cable protection pipe can effectively solve the problem that the existing MPP cable protection pipes cannot completely adapt to environments with high requirements in strength and toughness, so that the application range of the MPP cable protection pipes is relatively small.

Owner:桐庐富力电力器材有限公司

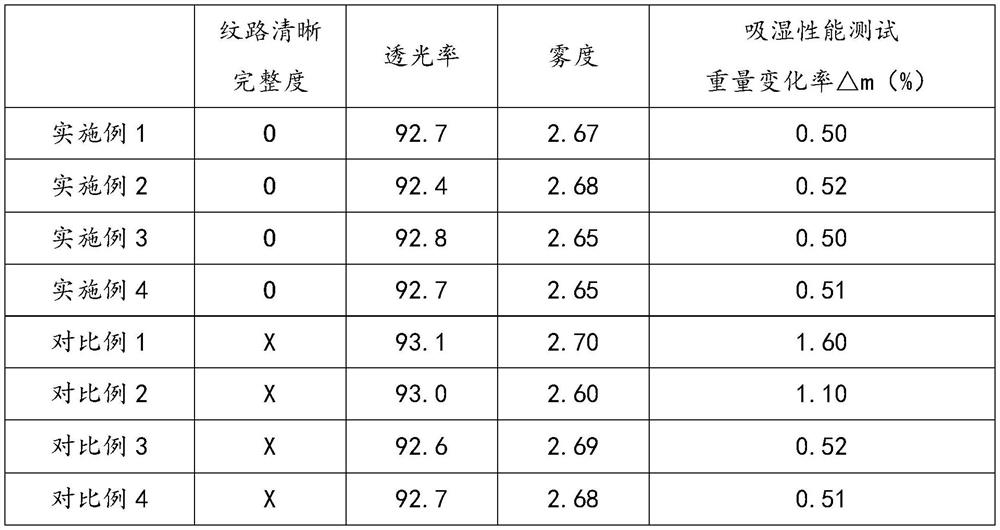

Transparent biaxially oriented polyamide embossed film and preparation method thereof

InactiveCN112477335AReduce the impactKeep clearSynthetic resin layered productsPolymer scienceNylon 12

The invention discloses a transparent biaxially oriented polyamide embossed film and a preparation method thereof. The transparent biaxially oriented polyamide embossed film sequentially comprises anembossed layer, a core layer and a lower surface layer, the embossed layer is composed of 98-99.5 wt% of nylon 12, 0-1 wt% of an anti-blocking agent and 0.5-1.0 wt% of a slipping agent. the core layeris composed of 95-97 wt% of PA6 and 3-5 wt% of PA6I; the lower surface layer is composed of 93-96 wt% of PA6, 3-5 wt% of PA6I, 0.5-1.0 wt% of an anti-blocking agent and 0.5-1.0 wt% of a slipping agent. The biaxially oriented polyamide embossed film obtained by adopting three-layer co-extrusion casting biaxial orientation and embossing through the embossing roller has the characteristics of clearlines, transparency, low hygroscopicity and the like, meanwhile, the product package is endowed with an obvious embossment stereoscopic impression, the artistic infection is enhanced, and the productis higher in end and has wide application value in the packaging field of foods and the like.

Owner:厦门长塑实业有限公司

Environment-friendly antibacterial polypropylene material special for sprayers and preparation method of material

The invention is applicable to the field of polypropylene materials, and particularly relates to an environment-friendly antibacterial polypropylene material special for sprayers. The material comprises the following components in parts by weight: 40-70 parts of wood pulp fiber treatment material which comprises a colloid adhesive, wood pulp fiber and quartz sand; 15-27 parts of a dispersant; 5-9parts of an antioxidant; 18-28 parts of rubber in which protein is added; and 80-120 parts of a polypropylene base material. Holes are densely distributed in the surface of the wood pulp fiber, afterquartz sand vibrates, disperses and enters, the advantages of high rigidity and high resilience matched with the wood pulp fiber are achieved by utilizing the colloid adhesive, namely, the wood pulp fiber treatment material can be recovered after the rigidity is damaged, and meanwhile, the effects of rubber and the polypropylene base material are combined, so that on the basis of high rigidity, quick restoring force is realized, and residual liquid materials are not easy to cause and bacteria are not easy to breed.

Owner:余姚市名邦喷雾包装有限公司

A kind of preparation method of composite material glued wood

ActiveCN109249491BIncreased bending stressHigh hardnessWood veneer joiningDomestic articlesThermal deformationCarbonization

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com