Heat-resisting ABS modified material and preparation method thereof for plating

A modified material and heat-resistant technology, which is applied in the field of heat-resistant ABS modified materials and its preparation, can solve the problems of little potential for improving heat resistance, poor surface gloss, and decreased impact strength, achieving good application prospects, Low cost and the effect of improving the heat resistance of ABS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

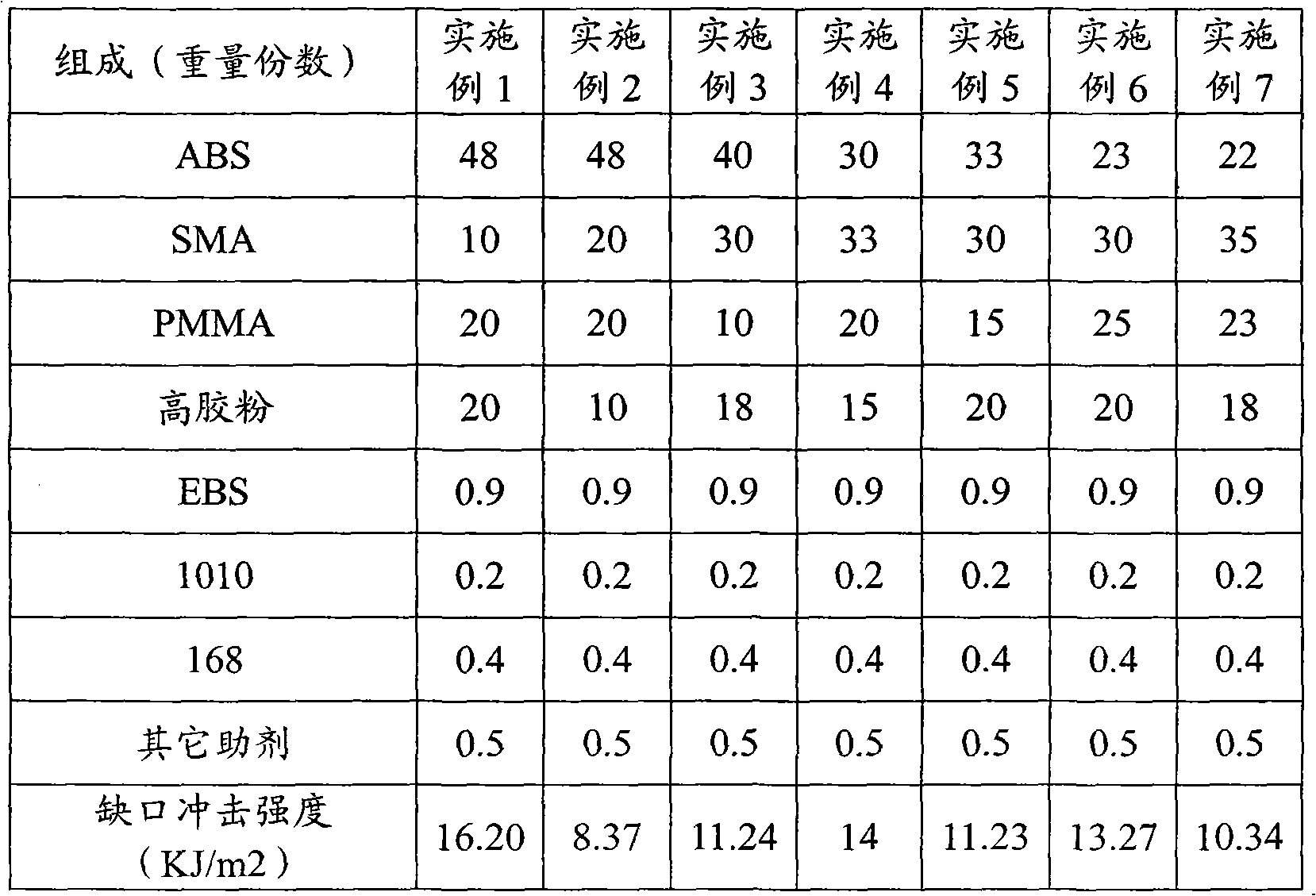

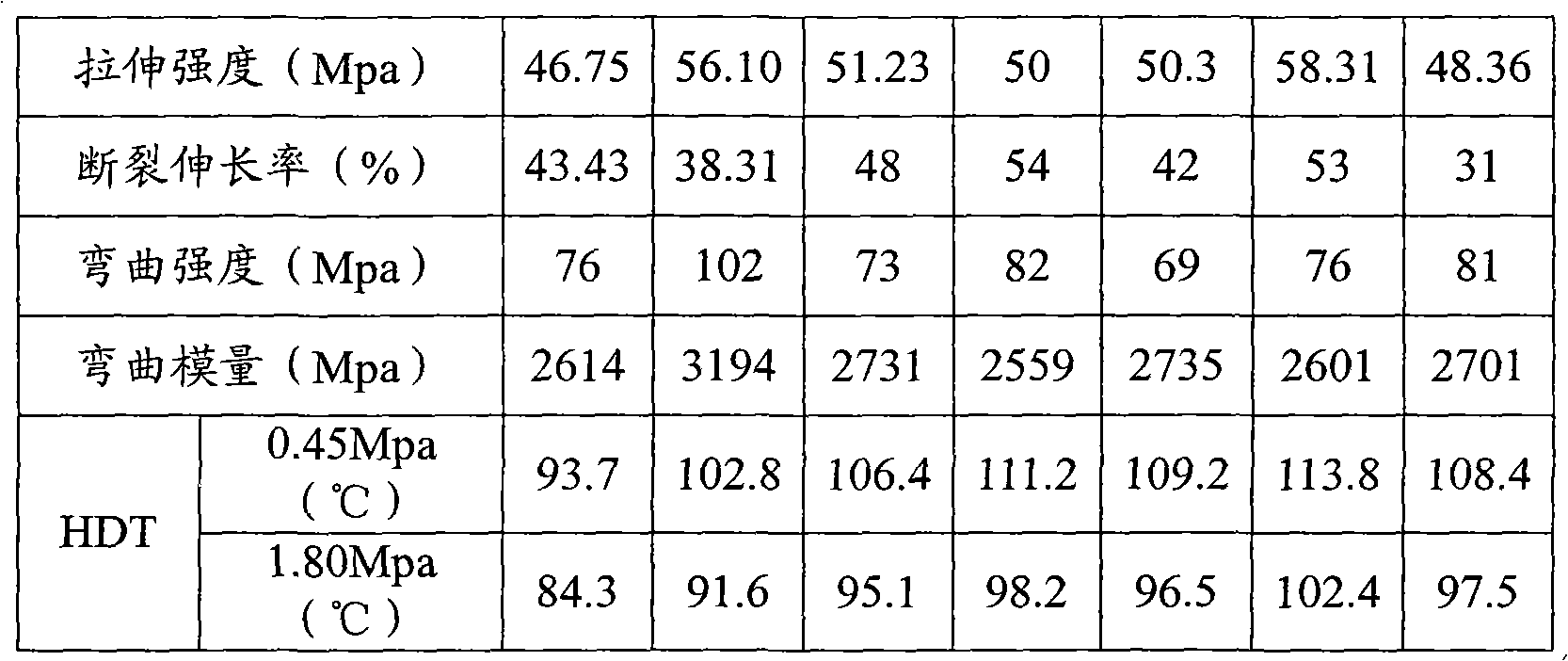

Embodiment 1

[0044] Example 1: A heat-resistant ABS modified material suitable for electroplating, made of the following raw materials in parts by weight: 48 parts of ABS, 10 parts of SMA, 20 parts of PMMA, 20 parts of high rubber powder, hindered phenolic antioxidant Agent 1010 and phosphite antioxidant 168 were 0.2 and 0.4 parts respectively, N, N'-ethylene bisstearamide 0.9 parts, and other additives including lubricants, heat stabilizers and ultraviolet light absorbers were 0.5 parts in total. share. Among them, in the ABS, the weight percentage of butadiene is 25%, the weight percentage of styrene is 55%, and the weight percentage of acrylonitrile is 20%. In SMA, the molar percentage of maleic anhydride is 18%, and described high rubber powder is the acrylonitrile-butadiene-styrene graft copolymer that heat stabilizer handles, and wherein the weight percentage of butadiene is 65% .

[0045] Preparation method: a: first dry polystyrene-butadiene-acrylonitrile and high-grade rubber po...

Embodiment 2

[0048] Example 2: A heat-resistant ABS modified material suitable for electroplating, made of the following raw materials in parts by weight: 48 parts of ABS, 20 parts of SMA, 20 parts of PMMA, 10 parts of high rubber powder, hindered phenolic antioxidant Agent 1010 and phosphite antioxidant 168 are 0.2 parts, 0.4 parts respectively, EBS 0.9 parts, and other additives include lubricants, heat stabilizers and ultraviolet light absorbers in total 0.5 parts, wherein the weight of butadiene in ABS The percentage content is 25%, the weight percentage content of styrene is 55%, and the weight percentage content of acrylonitrile is 20%. In SMA, the molar percentage of maleic anhydride is 18%, and described high rubber powder is the acrylonitrile-butadiene-styrene graft copolymer that heat stabilizer handles, and wherein the weight percentage of butadiene is 65% .

[0049] The preparation method is the same as in Example 1, and will not be repeated here.

Embodiment 3

[0050] Example 3: A heat-resistant ABS modified material suitable for electroplating is made of the following raw materials in parts by weight: 40 parts of ABS, 30 parts of SMA, 10 parts of PMMA, 18 parts of high-grade rubber powder, hindered phenolic antioxidant Agent 1010 and phosphite antioxidant 168 were 0.2 parts and 0.4 parts respectively, EBS was 0.9 parts, and other additives included lubricants, heat stabilizers and ultraviolet light absorbers at a total of 0.5 parts. Among them, in the ABS, the weight percentage of butadiene is 25%, the weight percentage of styrene is 55%, and the weight percentage of acrylonitrile is 20%. In SMA, the molar percentage of maleic anhydride is 18%, and described high rubber powder is the acrylonitrile-butadiene-styrene graft copolymer that heat stabilizer handles, and wherein the weight percentage of butadiene is 65% .

[0051] The preparation method is the same as in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com