Preparation method of condensed ring structure-containing crosslinker type isomeric crosslinked and modified recycling ABS (acrylonitrile-butadiene-styrene)

A technology of isomeric and condensed ring structure, applied in the field of isomeric cross-linking modified ABS and its preparation, can solve the problems of low elongation, low strength, poor heat resistance, etc., and achieve simple process operation. , Improve the heat resistance of ABS, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

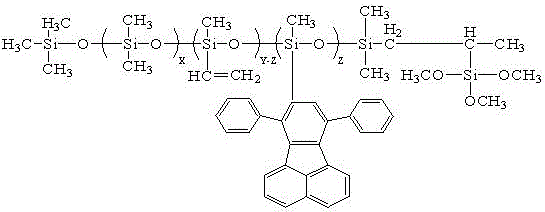

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with examples.

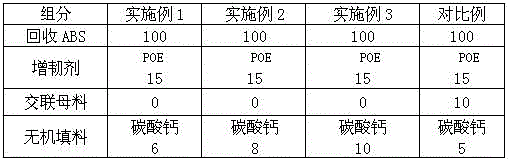

[0034] The weight distribution ratio of each component in Examples 1-3 and Comparative Examples is shown in Table 1. Weigh each component according to the proportion, mix it in a high-speed mixer for 5 minutes, and discharge the material. Put the raw material of the mixture into a twin-screw extruder to make the material. The temperature of the extruder is controlled between 180°C and 240°C. , the speed is 200r / min. Prepare the sample and test it according to the corresponding standard (see Table 2). The performance results are shown in Table 3.

[0035] Table 1: the formula composition (part) of embodiment 1-3 and comparative example

[0036]

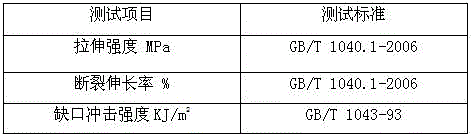

[0037] Table 2: Mechanical property test standard

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com