Preparation method and application of high-tenacity foam material

A foam material and high toughness technology, applied in the field of preparation of foam core materials, can solve problems such as brittle large surface pulverization, affecting the application range, etc., achieve the effect of reducing thermal deformation temperature and increasing elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

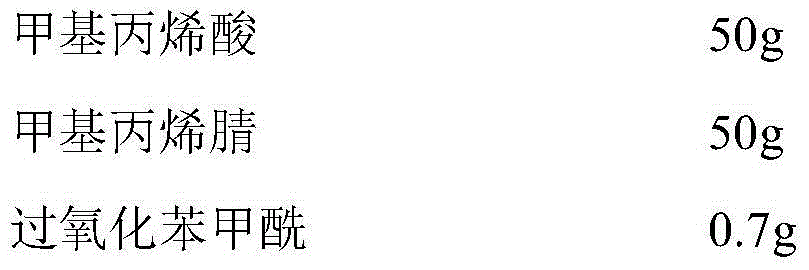

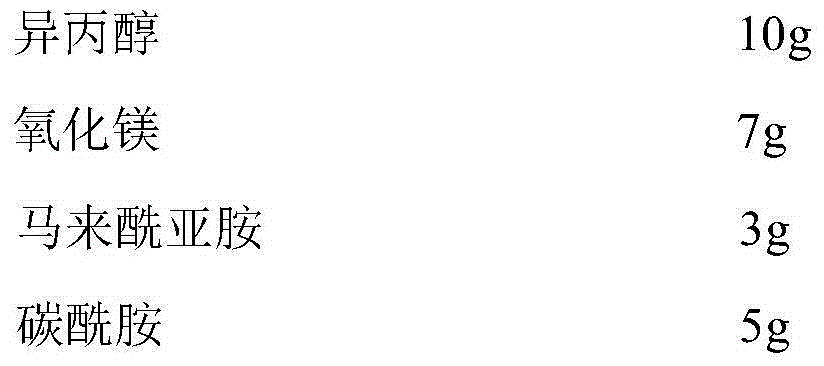

[0018] Raw material ratio is:

[0019] 50g of methacrylic acid, 50g of methacrylonitrile, 10g of silicone rubber core-shell toughened CSR composite resin, 7g of magnesium oxide, 10g of mixed blowing agent (isopropanol:formamide=1:1), initiator mixture (peroxide Benzoyl: talc = 1:3) 0.7g, maleimide 3g, carboxamide 5g.

[0020] The operation steps are:

[0021] Step 1, the two glass plates are sealed with a rubber strip to form a mold cavity;

[0022] Step 2, according to the above formula, mix methacrylic acid, methacrylonitrile and silicone rubber core-shell toughened CSR composite resin, and add magnesium oxide to it to completely dissolve the magnesium oxide;

[0023] Step 3, then add the mixed foaming agent, initiator mixture, maleimide and carbonamide, stir, mix evenly, and inject into the mold cavity;

[0024] Step 4, polymerizing for 50 hours at a temperature of 45°C in a water bath to form a foam precursor copolymerized plate;

[0025] Step 5: Preheat the foam precu...

Embodiment 2

[0029] The ratio of raw materials is: 40g of methacrylic acid, 40g of methacrylonitrile, 1g of silicone rubber core-shell toughened CSR composite resin, 3g of magnesium oxide, 5g of mixed foaming agent (isopropanol: formamide = 1:1), initiator Agent mixture (benzoyl peroxide: talc = 1:3) 0.1 g, maleimide 0.5 g, carboxamide 0.3 g.

[0030] Operation steps are identical with embodiment 1.

[0031] Test result: the high tenacity polymethacrylimide foam material that this embodiment makes, density 65Kg / m 3 , the tensile strength is 2.5MPa, the elongation at break is 5%, and the heat distortion temperature is 189°C.

Embodiment 3

[0033] 60g of methacrylic acid, 60g of methacrylonitrile, 20g of silicone rubber core-shell toughened CSR composite resin, 7g of magnesium oxide, 16g of mixed blowing agent (isopropanol:formamide=1:1), initiator mixture (peroxide Benzoyl: talc = 1:3) 1g, maleimide 3g, carboxamide 10g.

[0034] Operation steps are identical with embodiment 1.

[0035] Test result: the high tenacity polymethacrylimide foam material that this embodiment makes, density 60Kg / m 3 , the tensile strength is 2.2MPa, the elongation at break is 4.5%, and the heat distortion temperature is 189°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com