Multi-functional polycarbonate modified material and preparation method thereof

A technology of polycarbonate and modified materials, applied in the field of multifunctional polycarbonate modified materials and their preparation, can solve the problems of high cost, single excellent performance, can not meet the long-term outdoor use, etc., and achieves low cost and high resistance. The effect of low temperature impact performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Raw material formula (mass ratio, parts): powdery PC resin (load 1200g, temperature 300°C when MFR=5.0g / 10min) 80, powdery PC-co-PDMS resin (load 1200g, temperature 300°C when MFR=10.0g / 10min, PDMS content 40wt%) 20, potassium perfluorobutane sulfonate flame retardant (purity 99.8%, particle size 0.5 μ m) 0.1, ultraviolet light absorber UV 5411 0.3, antioxidant B900 0.1, lubricant 0.2, Dibenzoyl peroxide 0.1, antioxidant B215 0.1.

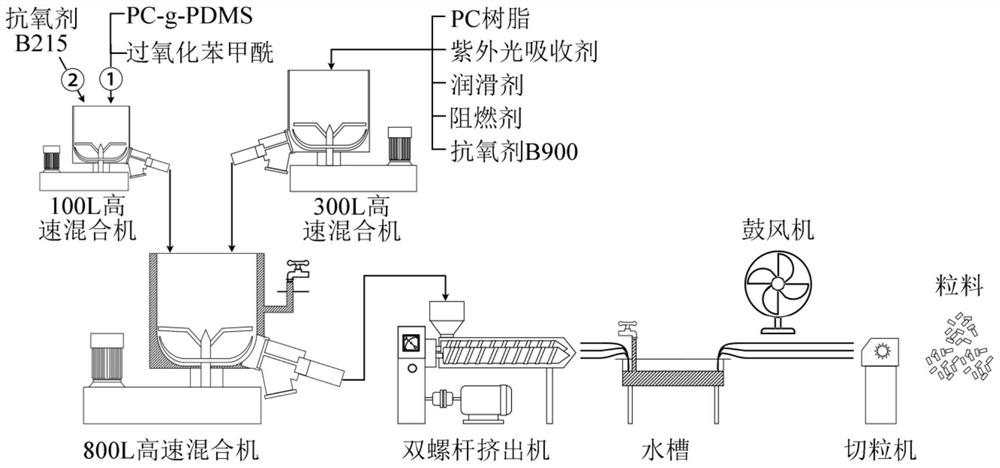

[0039] Preparation Process:

[0040]Preparation of polycarbonate / polydimethylsiloxane copolymer mixture: First, add PC-co-PDMS and benzoyl peroxide in a 100-liter high-speed mixer under the condition of a stable temperature control of 90 ° C, and replace with nitrogen Among them, the air is 5 minutes; then the rotation speed is at a low speed (below 500rpm) and stirred for 1 minute, and the high-speed stirring is started (that is, above 1000rpm for 3 minutes) to rapidly raise the temperature to 110°C and keep the temperature constant; then...

Embodiment 2

[0046] Raw material formula (mass ratio, parts): powdery PC resin (load 1200g, temperature 300 ℃ when MFR = 10.0g / 10min) 75, powdery PC-co-PDMS resin (load 1200g, temperature 300 ℃ when MFR = 10.0g / 10min, PDMS content 30wt%) 25, potassium perfluorobutane sulfonate flame retardant (purity 99.8%, particle size 1μm) 0.08, ultraviolet light absorber UV 234 0.5, antioxidant B900 0.3, lubricant 0.1, over Dibenzoyl oxide 0.05, antioxidant B215 0.05.

[0047] Preparation Process:

[0048] Preparation of the mixture of polycarbonate / polydimethylsiloxane copolymer: First, add PC-co-PDMS and benzoyl peroxide in a 100-liter high-speed mixer under the condition that the temperature can be stably controlled at 95°C, and replace with nitrogen Among them, the air is 5 minutes; then the rotation speed is at a low speed (below 500rpm) and stirred for 1 minute, and the high-speed stirring is started (that is, above 1000rpm) for 3 minutes to quickly raise the temperature to 115°C and keep the t...

Embodiment 3

[0054] Raw material formula (mass ratio, parts): powdery PC resin (load 1200g, temperature 300 ℃ when MFR = 15.0g / 10min) 70, powdery PC-co-PDMS resin (load 1200g, temperature 300 ℃ when MFR = 6.0g / 10min, PDMS content 25wt%) 30, potassium perfluorobutanesulfonate flame retardant (purity 99.8%, particle size 1.5μm) 0.09, ultraviolet light absorber UV 5411 0.3, UV 2340.2, antioxidant B900 0.2, lubrication agent 0.15, dibenzoyl peroxide 0.15, antioxidant B215 0.1.

[0055] Preparation Process:

[0056] Preparation of polycarbonate / polydimethylsiloxane copolymer mixture: First, add PC-co-PDMS and benzoyl peroxide to a 100-liter high-speed mixer under the condition of a stable temperature of 85 ° C, and replace with nitrogen Among them, the air is 5 minutes; then the rotation speed is at a low speed (below 500rpm) and stirred for 1 minute, and the high-speed stirring is started (that is, above 1000rpm for 3 minutes) to quickly raise the temperature to 105°C and keep the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com