Transparent biaxially oriented polyamide embossed film and preparation method thereof

A polyamide film and two-way stretching technology, which is applied in the field of nylon packaging film, can solve the problems of large temperature and humidity dimensional change rate and high water absorption, so as to prevent large temperature and humidity dimensional change rate, maintain embossed texture, and improve glass quality. The effect of transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

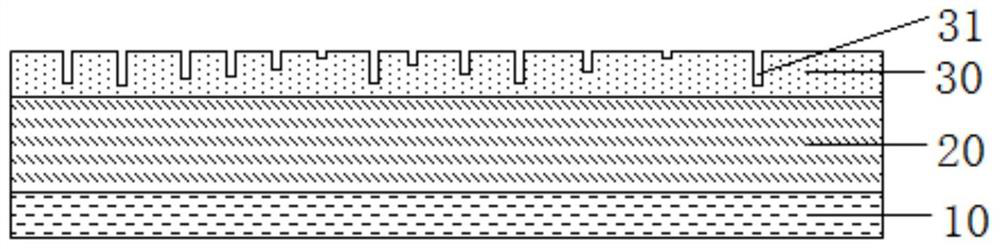

[0029] A kind of transparent biaxially stretched polyamide embossed film of the present embodiment, as figure 1 , from top to bottom are sequentially arranged as an upper surface layer 30, a core layer 20 and a lower surface layer 10;

[0030] The upper surface layer 30 is an embossed layer consisting of 98% nylon 12, 1.0% opening agent and 1.0% slippery agent; the core layer 20 is composed of 95% PA6 and 5.0% PA6I; the The lower surface layer 10 is composed of 93% PA6, 5.0% PA6I, 1.0% anti-blocking agent and 1.0% slip agent.

[0031] The slip agent is composed of erucamide and oleamide.

[0032] The antiblocking agent consists of silicon dioxide.

[0033] The preparation method of the embossed film of the present embodiment is as follows:

[0034] Step a: Mix nylon 12, anti-blocking agent and smoothing agent according to the proportion of the upper surface layer 30, melt blend, extrude, and granulate through a twin-screw extruder to obtain an embossed layer masterbatch;

...

Embodiment 2

[0043] The difference between embodiment 2 and embodiment 1 is:

[0044] The upper surface layer is an embossed layer, which is composed of 99% nylon 12, 0.5% opening agent and 0.5% slippery agent; the described core layer is composed of 96% PA6 and 4.0% PA6I; the described The lower surface layer is composed of 95% PA6, 4.0% PA6I, 0.5% opening agent and 0.5% slip agent.

[0045] The slip agent is composed of erucamide and oleamide.

[0046] The anti-blocking agent is composed of silicon dioxide.

[0047] Prepared by the method of Example 1, wherein the temperature of the embossing roller is 50° C., the pressure of the embossing roller is 1.5 MPa, and the speed is 200 m / min.

[0048] The total thickness of the embossed film is 15 microns; the thickness of the upper surface layer accounts for 33.3% of the total thickness; the thickness of the core layer accounts for 50.0% of the total thickness; the thickness of the lower surface layer accounts for 16.7% of the total thicknes...

Embodiment 3

[0050] The difference between embodiment 3 and embodiment 1 is:

[0051]The upper surface layer is an embossed layer consisting of 99.5% nylon 12 and 0.5% slip agent; the core layer is composed of 97% PA6 and 3.0% PA6I; the lower surface layer is composed of 96% PA6, 3.0% PA6I, 0.5% opening agent and 0.5% slip agent.

[0052] The slip agent is composed of erucamide and oleamide.

[0053] Prepared by the method of Example 1, the temperature of the embossing roller is 50° C., the pressure of the embossing roller is 1.5 MPa, and the speed is 200 m / min.

[0054] The total thickness of the embossed film is 15 microns; the thickness of the upper surface layer accounts for 33.3% of the total thickness; the thickness of the core layer accounts for 50.0% of the total thickness; the thickness of the lower surface layer accounts for 16.7% of the total thickness %; the deepest depth of the embossing is 80% of the thickness of the upper surface layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com