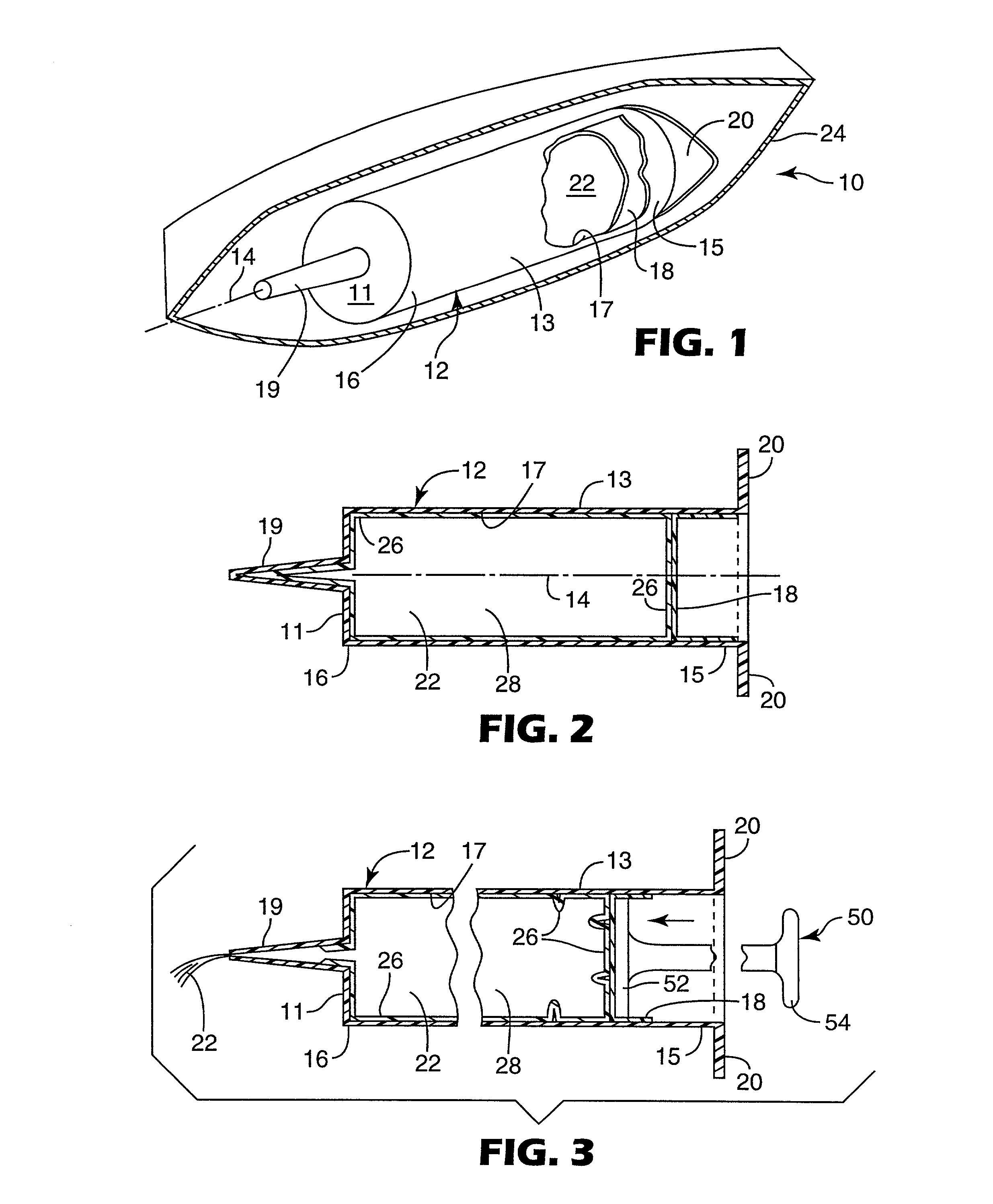

[0004] The present invention provides a combination and method for storing and applying moisture curable materials (e.g., adhesives, coatings or sealers) that is inexpensive and practical for use even if only occasional applications of the moisture curable materials are required over an extended period of time.

[0009] The tubular wall of moisture vapor transmissive polymeric material can be of a

polyolefin material such as

polyethylene or

polypropylene which are readily available, relatively inexpensive, and have low

surface energy or

critical surface tension (i.e., it appears that the

critical surface tension should be lower than about 35 dynes /

centimeter which is the

critical surface tension of ABS to which the moisture curable materials listed above will adhere quite strongly when moisture cured, but can be about 31 dynes /

centimeter which is the critical

surface tension of

polyethylene, or about 29 dynes /

centimeter which is the critical

surface tension of

polypropylene, to either of which those moisture curable materials have little adhesion when moisture cured).

Polyethylene or

polypropylene have relatively low Heat Deflection Temperatures under pressure which are reported in the Materials Selection chapter of

Machine Design

magazine's "Basics of Design

Engineering", June, 1994, the content whereof is hereby incorporated herein by reference. (e.g., under 64

pounds per square inch or 4.5 kilograms per

square centimeter pressure the

Heat Deflection Temperature (HDT) for

medium density polyethylene is about 120 to 165 degrees Fahrenheit or 49 to 74 degrees Centigrade, the

Heat Deflection Temperature for

high density polyethylene is about 140 to 190 degrees Fahrenheit or 60 to 88 degrees Centigrade, and the

Heat Deflection Temperature for unmodified polypropylene is about 200 to 250 degrees Fahrenheit or 93 to 121 degrees Centigrade). Such materials, however, can be suitable for use with the type of moisture curable material described above which softens to a suitable

viscosity for application when heated to a temperature in the range of about 140 to 230 degrees Fahrenheit or 60 to 110 degrees Centigrade, and preferably in the range of about 180 to 190 degrees Fahrenheit or 82 to 88 degrees Centigrade. Syringes molded of these materials having various capacities (e.g., 32 cubic centimeters) and which have at the outlet ends of their walls a transverse end wall from the center of which projects a outlet

nozzle are readily commercially available (e.g., from Plas-Pak Industries, Inc., Norwich, Conn.). Such a

syringe filled with the moisture curable material that is sealed within the removable envelope of moisture impermeable material can be stored for a long period of time (e.g., over 6 months at 90 degrees Fahrenheit or 32 degrees Centigrade and 90 percent

relative humidity).

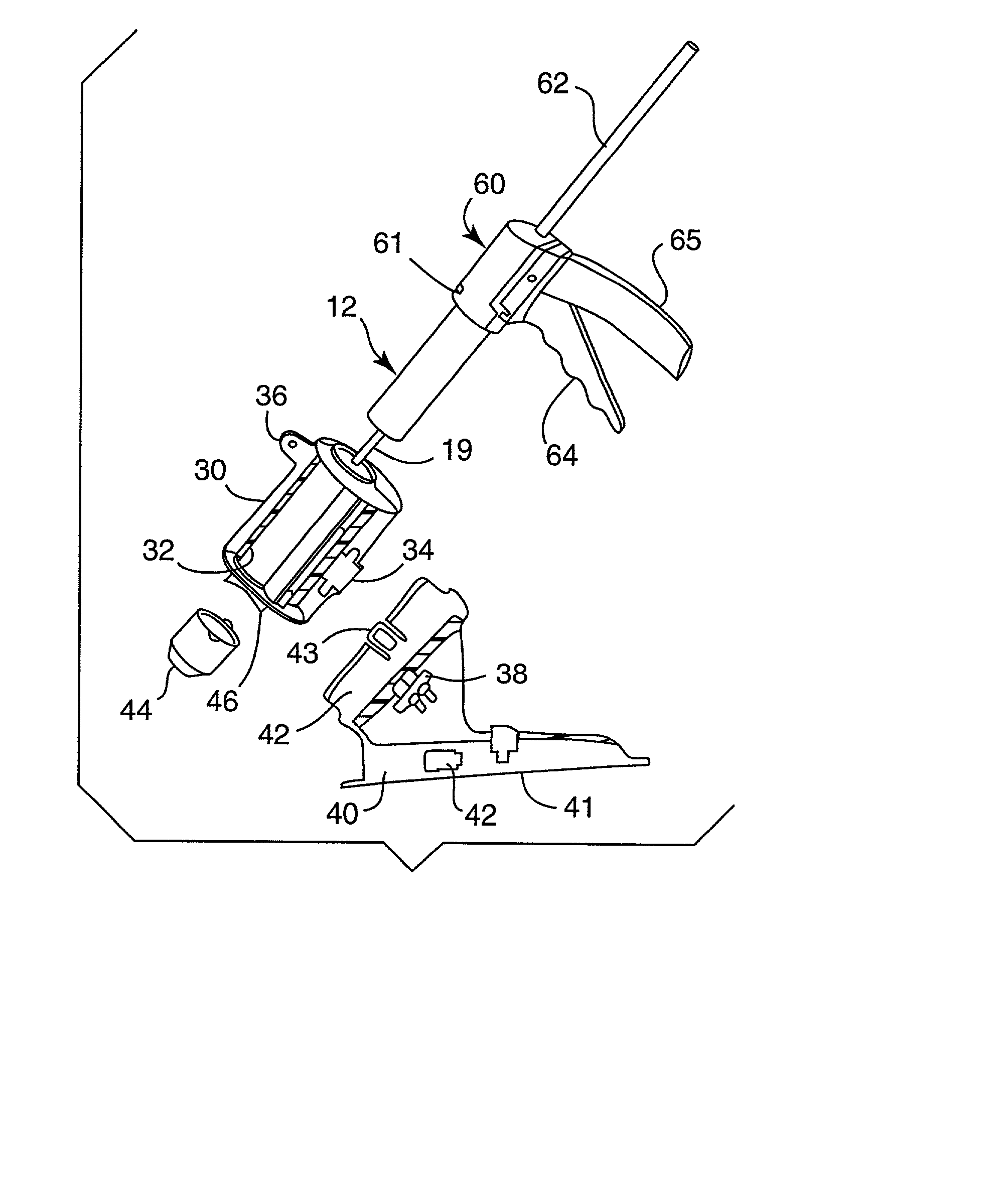

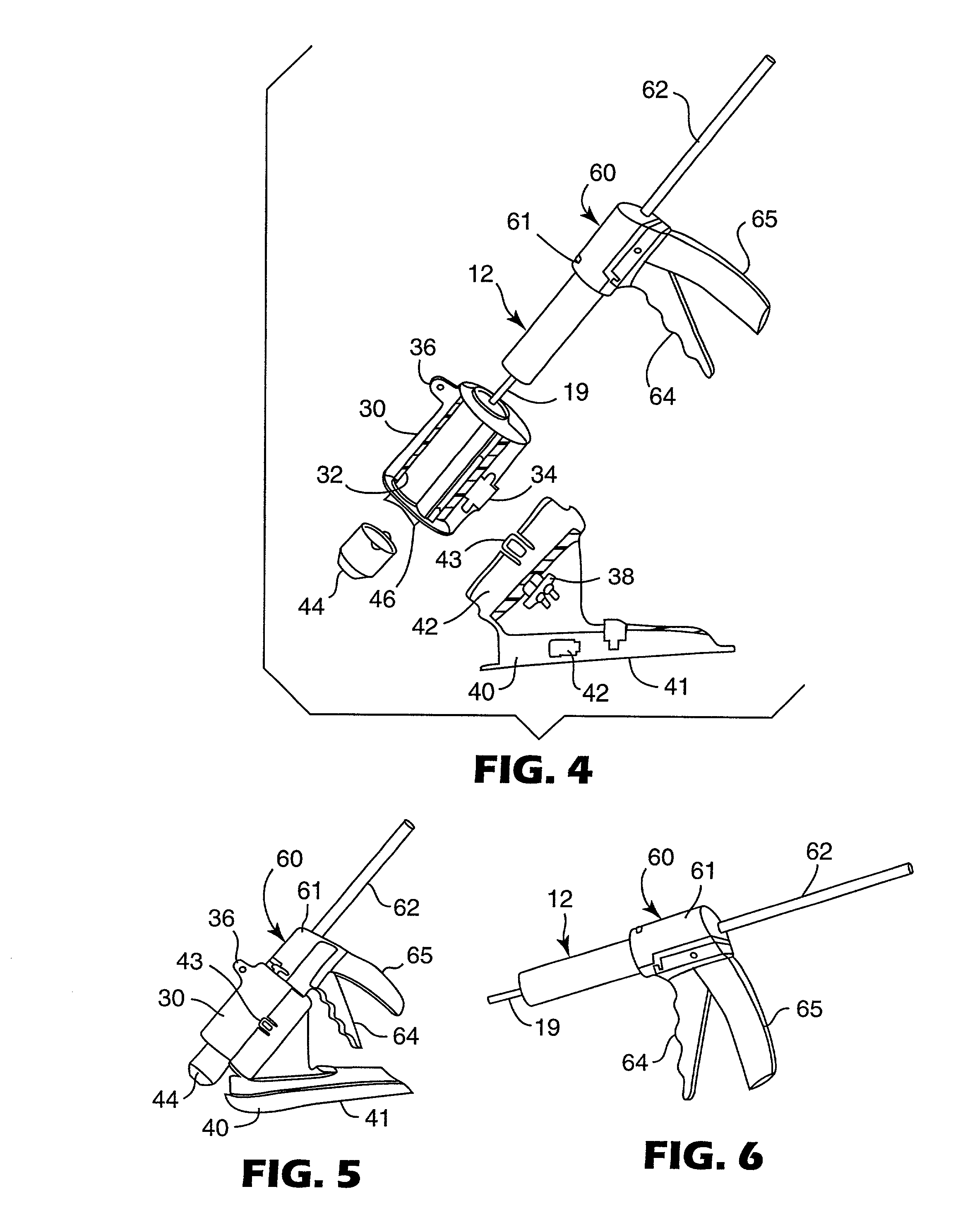

[0010] The means for receiving the container assembly after it is removed from the envelope of moisture impermeable material and for heating the moisture curable material in it to a suitable

viscosity for application can be an electrically heated cylindrical chamber adapted to closely receive the tubular wall of the container assembly. The container assembly can either be inserted into that chamber for a time sufficient to soften the moisture curable material and then removed from the chamber while the heated moisture curable material is applied, which facilitates manipulation of the container assembly or syringe during application of the moisture curable material; or the container assembly can remain in the heated chamber during application of the moisture curable material from an end portion of container assembly projecting from the chamber which insures that the moisture curable material will remain at the temperature needed for application over an extended period of time. If the container assembly remains in the heated chamber during application of the moisture curable material, that chamber can either be mounted at a fixed location, or can be moved with the container to a location at which the moisture curable material is to be applied. As an alternative to use of such a heated chamber, the container assembly can be heated by other means, such as by immersing the container assembly in boiling water, by the use of an oven, or otherwise.

Login to View More

Login to View More  Login to View More

Login to View More