Assembly of multiple handling devices connected with each other for items and method for operating such an assembly

A technology for operating devices and articles, applied in the types of packaging articles, packaging, wrapping paper, etc., can solve the problems of use that cannot create value, high area consumption in the transmission section, machine wear and other problems, and reduce the number of driving devices and energy consumption. , the effect of reducing structural expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following detailed description of a number of possible embodiments of the invention is provided by way of non-limiting examples only, and reference is made to the accompanying drawings. In this case, identical components have essentially the same reference numerals and some have not been explained more than once.

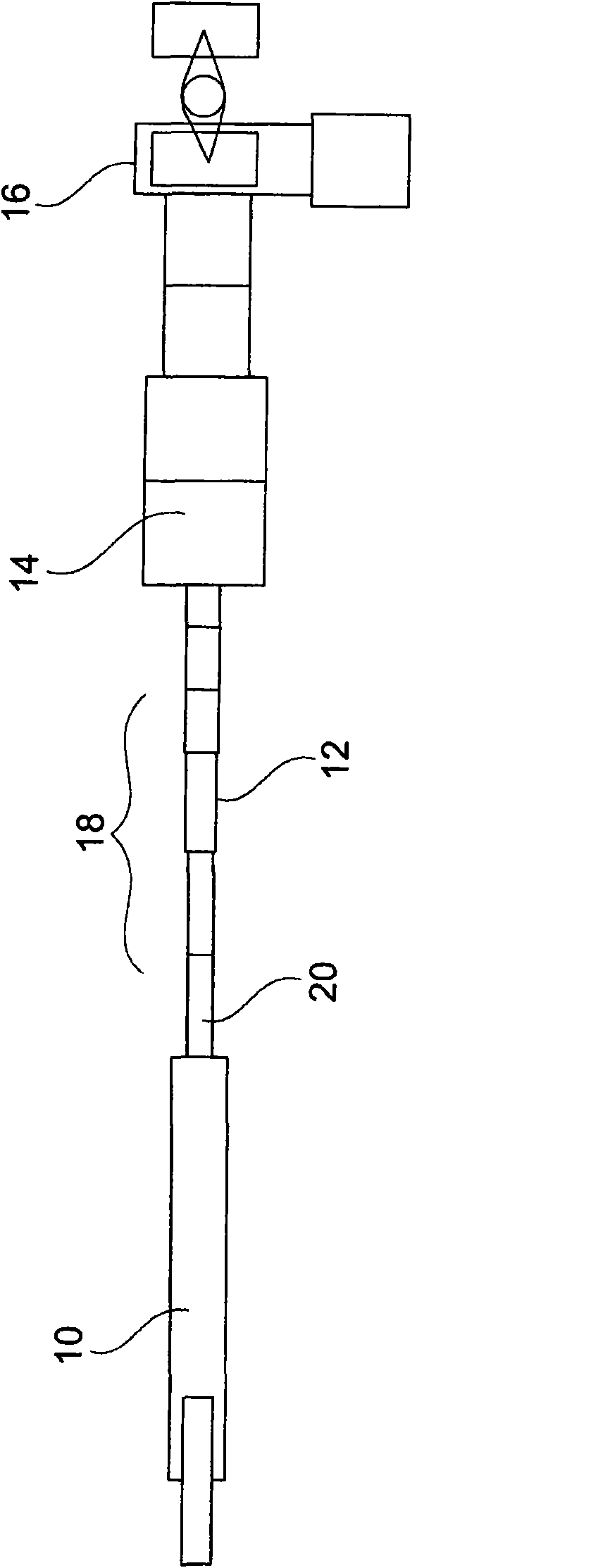

[0040] combine Figures 1 to 6 Various variants and possibilities are shown, in which a so-called drying section in a packaging plant is realized with a very compact machine arrangement. figure 1 The systems shown in the Figures 2 to 4 The essential part for the invention of the supplementary transfer zone without guardrails and without accumulation capability is then illustrated in conjunction with the remaining machine components. in accordance with figure 1 The system comprises a so-called single-pass packaging machine 10 comprising a lamination module as well as a shrinking tunnel. Furthermore, a transfer section 12 can be seen which leads from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com