Polycarbonate/polyester alloy and preparation method and application thereof

A technology of polycarbonate and polyester alloy, which is applied in the field of polymer materials, can solve the problems of reducing the thermal deformation temperature of materials, high requirements for molding technology, and warping and deformation of parts, so as to achieve increased compatibility, excellent electrical characteristics, Dimensional stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] The present invention also provides the above-mentioned preparation method of polycarbonate / polyester alloy, comprising the following steps:

[0083] The bisphenol A polycarbonate, polyester resin, compatibilizer, transesterification inhibitor and light diffusing agent are mixed and extruded.

[0084] In one embodiment, the extrusion temperature is 260°C-300°C.

[0085] Preferably, the preparation method of the polycarbonate / polyester alloy includes the following steps:

[0086] The bisphenol A polycarbonate, polyester resin, compatibilizer, transesterification inhibitor and light diffusing agent were mixed in a high-speed mixer for 10 minutes, and then melted and extruded.

[0087] The present invention also provides applications of the above polycarbonate / polyester alloys. The technical solution is as follows:

[0088] A light diffusing plate, the preparation raw materials of which include the above-mentioned polycarbonate / polyester alloy; or the polycarbonate / poly...

Embodiment 1

[0092] This embodiment provides a polycarbonate / polyester alloy and a preparation method thereof.

[0093] (1) In this embodiment, the polycarbonate / polyester alloy is prepared from the following raw materials by mass percentage:

[0094] Bisphenol A polycarbonate 76.6%,

[0095] PET resin 20%,

[0096] Compatibilizer 2%,

[0097] Transesterification inhibitor 0.5%,

[0098] Antioxidant 0.3%,

[0099] Light diffusing agent 0.6%;

[0100] The light-diffusing agent in this embodiment is Taiwan Changxing organosilicon light-diffusing agent, and the refractive index is 1.43. The refractive index of PET resin is 1.58, the glass transition temperature is 80°C, and the molecular weight is about 30,000 g / mol; the molecular weight of bisphenol A polycarbonate is about 30,000 g / mol.

[0101] (2) The preparation method is as follows:

[0102] The bisphenol A polycarbonate, PET resin, compatibilizer, transesterification inhibitor, antioxidant and light diffusing agent were mixed in...

Embodiment 2

[0104] This embodiment provides a polycarbonate / polyester alloy and a preparation method thereof.

[0105] (1) In this embodiment, the polycarbonate / polyester alloy is prepared from the following raw materials by mass percentage:

[0106] Bisphenol A polycarbonate 71.6%,

[0107] PETG resin 25%,

[0108] Compatibilizer 2%,

[0109] Transesterification inhibitor 0.5%,

[0110] Antioxidant 0.3%,

[0111] Light diffusing agent 0.6%;

[0112] The light-diffusing agent in this embodiment is Taiwan Changxing organosilicon light-diffusing agent, and the refractive index is 1.43. The refractive index of PETG resin is 1.58, the glass transition temperature is 85°C, and the molecular weight is about 30,000 g / mol; the molecular weight of bisphenol A polycarbonate is about 30,000 g / mol.

[0113] (2) The preparation method is as follows:

[0114] The bisphenol A polycarbonate, PETG resin, compatibilizer, transesterification inhibitor, antioxidant and light diffusing agent were mixed...

PUM

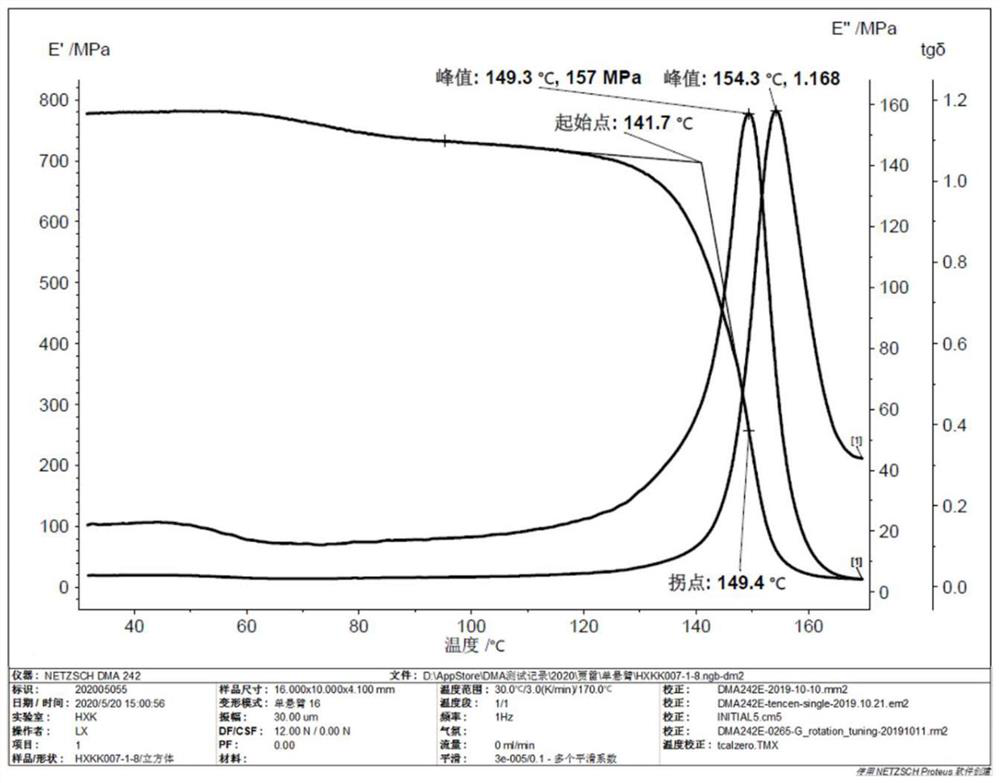

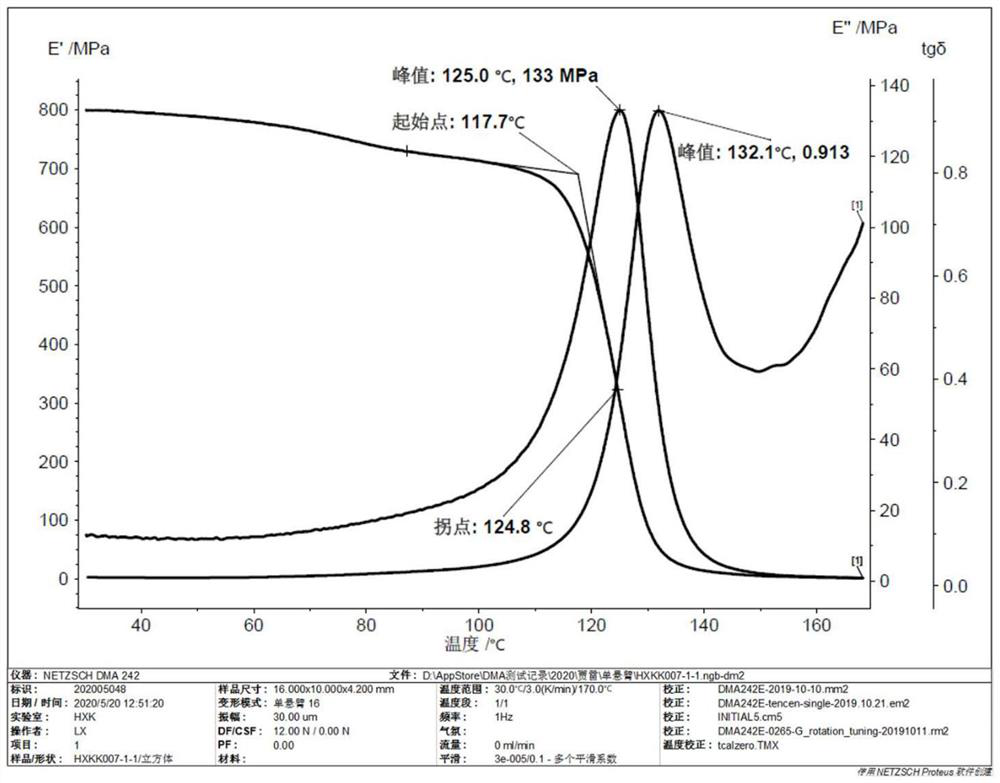

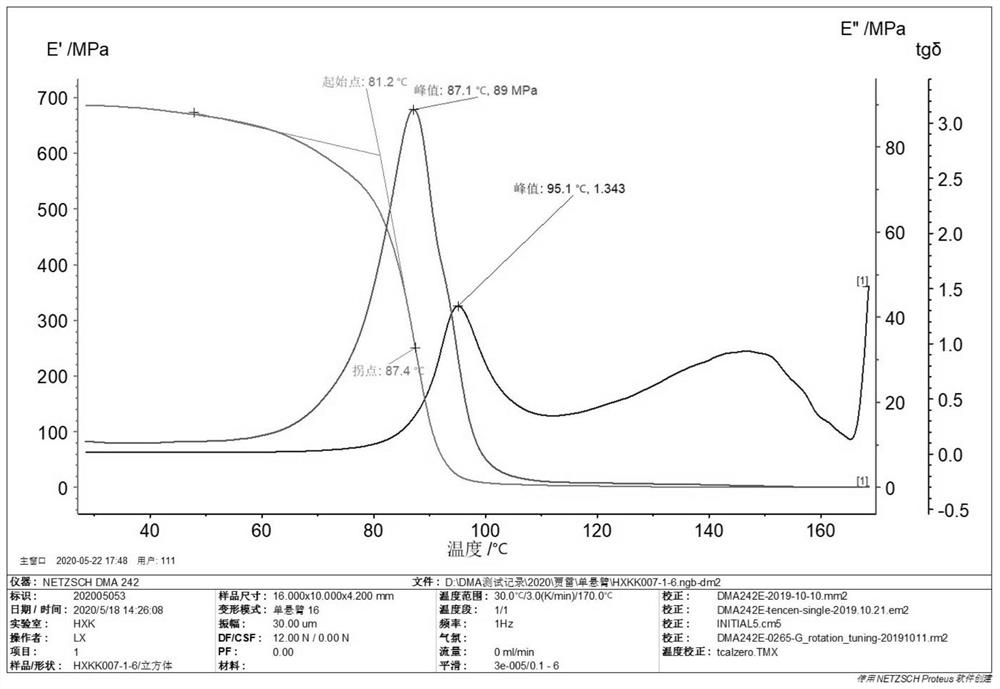

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com