Medical degradable multilayer polymer/graphene film material and preparation method thereof

A technology of graphene film and degradable polymer, which is applied in the field of biodegradable material preparation, can solve the problems that the mechanical strength and degradation time of materials cannot be adjusted according to actual needs, so as to achieve controllable degradation time, realize mechanical strength, and inhibit infiltration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

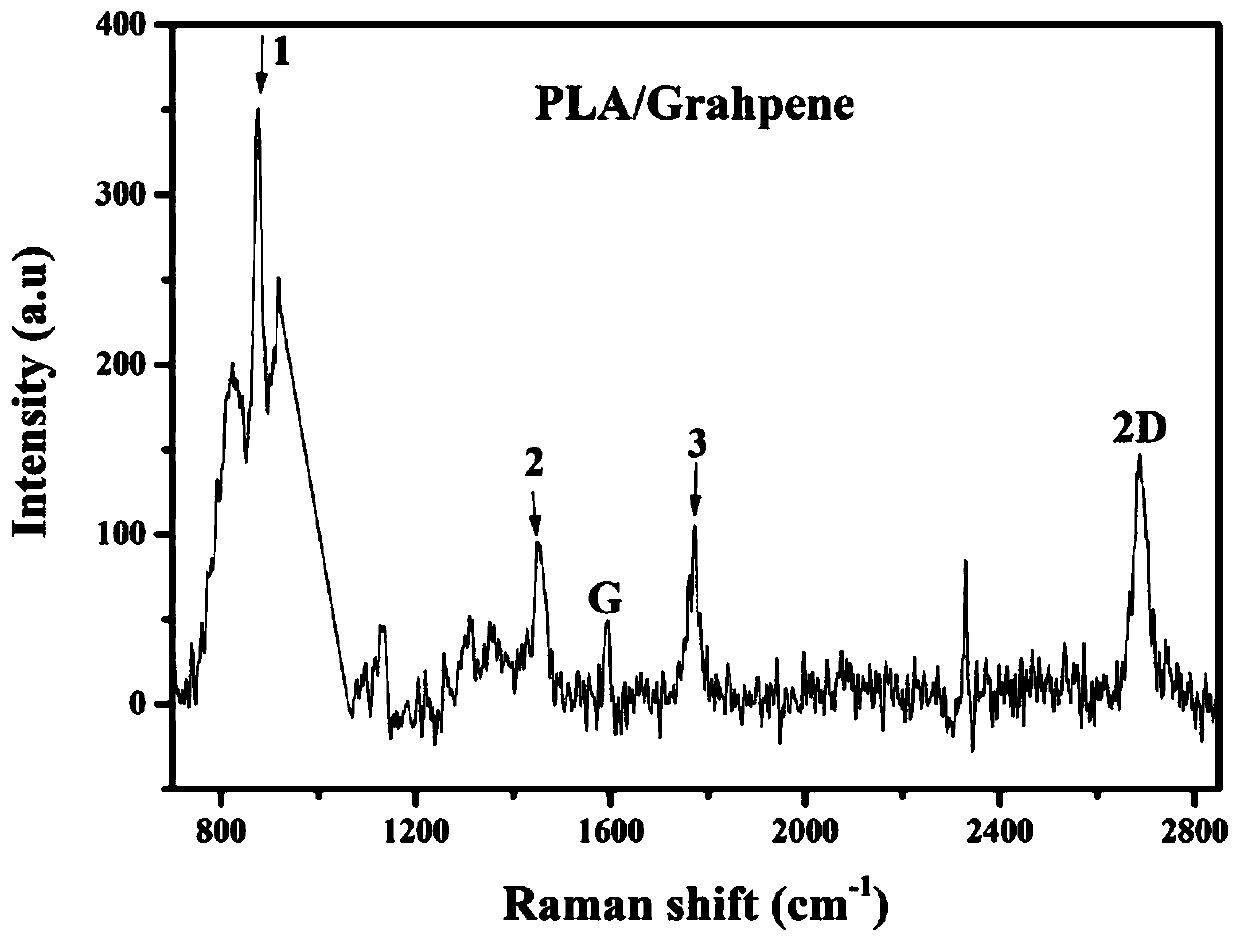

[0029] (1) Spin-coat 10mg / mL polylactic acid (PLA) solution onto the graphene / copper sheet with graphene at 3000rpm, and the spin-coating time is 30s; then etch the copper sheet in ammonium persulfate solution, at room temperature, The copper sheet was etched for 24 hours to obtain the PLA / graphene film.

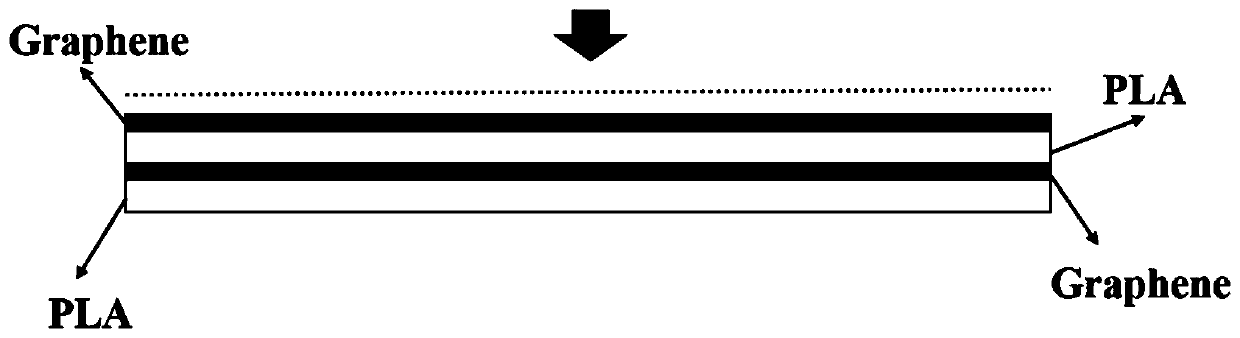

[0030] 2) Transfer the PLA / graphene film to the surface of the graphene / copper sheet, make the PLA side stick to the side of the graphene / copper sheet with graphene, let it dry naturally for 24 hours, and then etch the copper sheet in ammonium persulfate solution, A graphene / PLA / graphene film is obtained.

[0031] 3) On the prepared graphene / PLA / graphene film, ① spin coating or casting PLA solution to prepare a degradable polymer film ② transfer the obtained product to the surface of the graphene / copper substrate, so that the PLA side and the graphene / The graphene side of the copper sheet substrate is bonded, and the copper sheet is removed by etching; repeat ① and ② continu...

Embodiment 2

[0034] (1) Spin-coat 50mg / mL polylactic acid (PLA) solution onto the graphene / copper sheet with graphene at 4000rpm, and the spin-coating time is 50s; then etch the copper sheet in ammonium persulfate solution, at room temperature, The copper sheet was etched for 6h to obtain the PLA / graphene film.

[0035] 2) Transfer the PLA / graphene film to the surface of the graphene / copper sheet, make the PLA side stick to the side of the graphene / copper sheet with graphene, let it dry naturally for 12 hours, and then etch the copper sheet in ammonium persulfate solution, A graphene / PLA / graphene film is obtained.

[0036] 3) On the prepared graphene / PLA / graphene film, ① spin coating or casting PLA solution to prepare a degradable polymer film ② transfer the obtained product to the surface of the graphene / copper substrate, so that the PLA side and the graphene / The graphene side of the copper sheet substrate is bonded, and the copper sheet is removed by etching; repeat ① and ② continuousl...

Embodiment 3

[0039] (1) Spin-coat 25mg / mL polylactic acid (PLA) solution onto the graphene / copper sheet with graphene at 3500rpm, and the spin-coating time is 40s; then etch the copper sheet in ammonium persulfate solution, at room temperature, The copper sheet was etched for 12 hours to obtain a PLA / graphene film.

[0040] 2) Transfer the PLA / graphene film to the surface of the graphene / copper sheet, make the PLA side stick to the side of the graphene / copper sheet with graphene, let it dry naturally for 18 hours, and then etch the copper sheet in ammonium persulfate solution, A graphene / PLA / graphene film is obtained.

[0041] 3) On the prepared graphene / PLA / graphene film, ① spin coating or casting PLA solution to prepare a degradable polymer film ② transfer the obtained product to the surface of the graphene / copper substrate, so that the PLA side and the graphene / The graphene side of the copper sheet substrate is bonded, and the copper sheet is removed by etching; repeat ① and ② continu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com