Patents

Literature

54 results about "Side-stick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A side-stick or sidestick controller is an aircraft control column (or joystick) that is located on the side console of the pilot, usually on the righthand side, or outboard on a two-seat flightdeck. Typically this is found in aircraft that are equipped with fly-by-wire control systems.

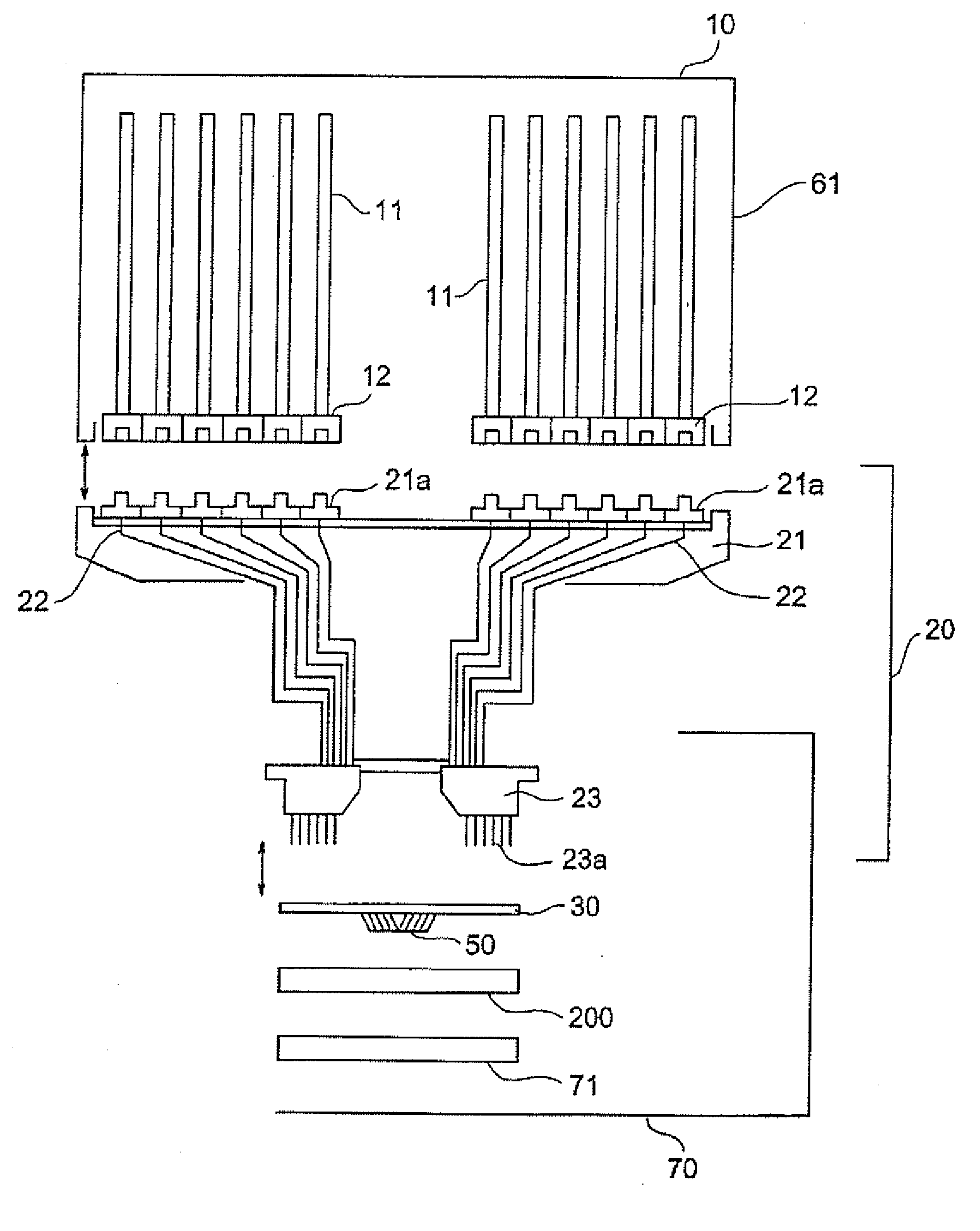

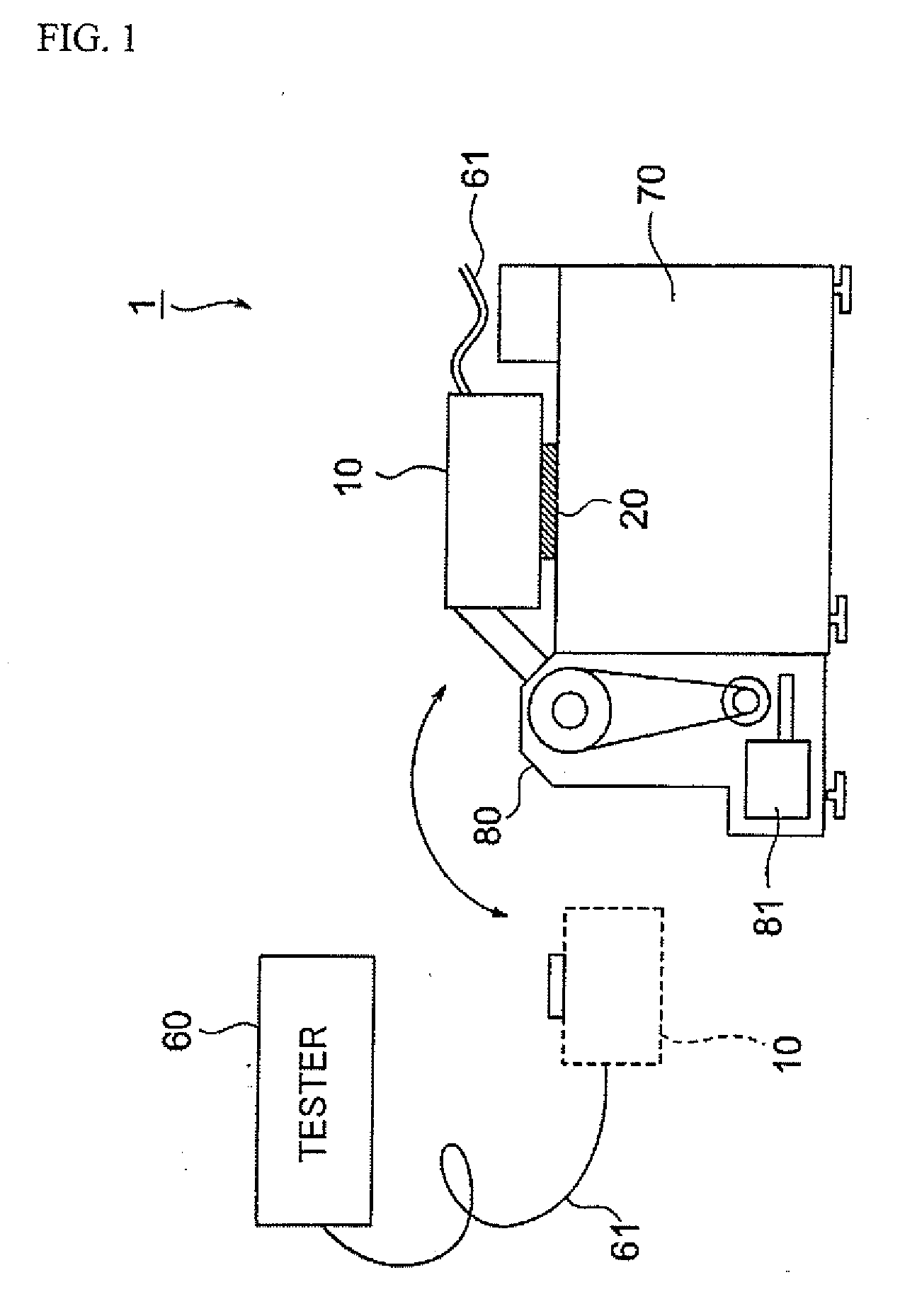

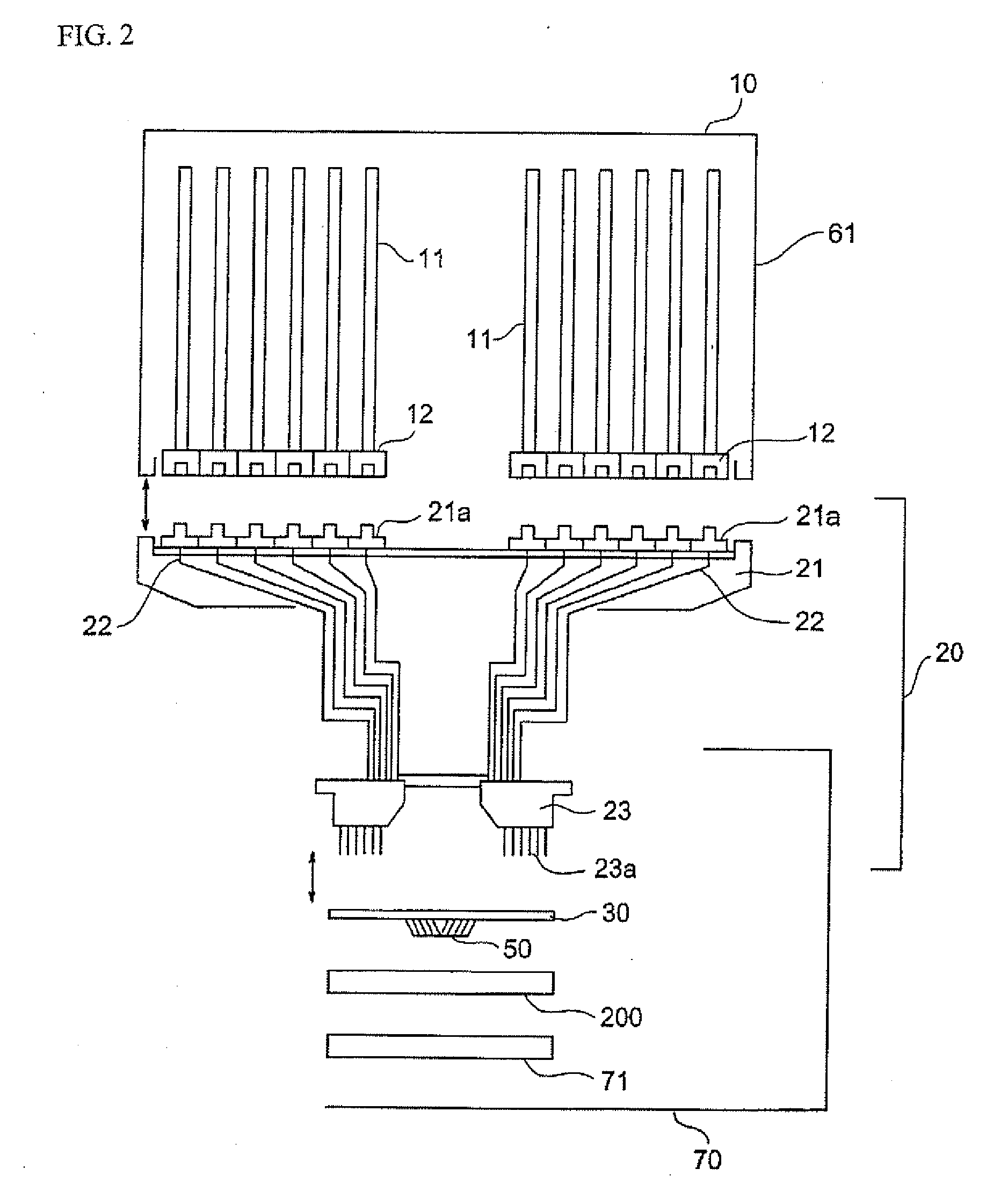

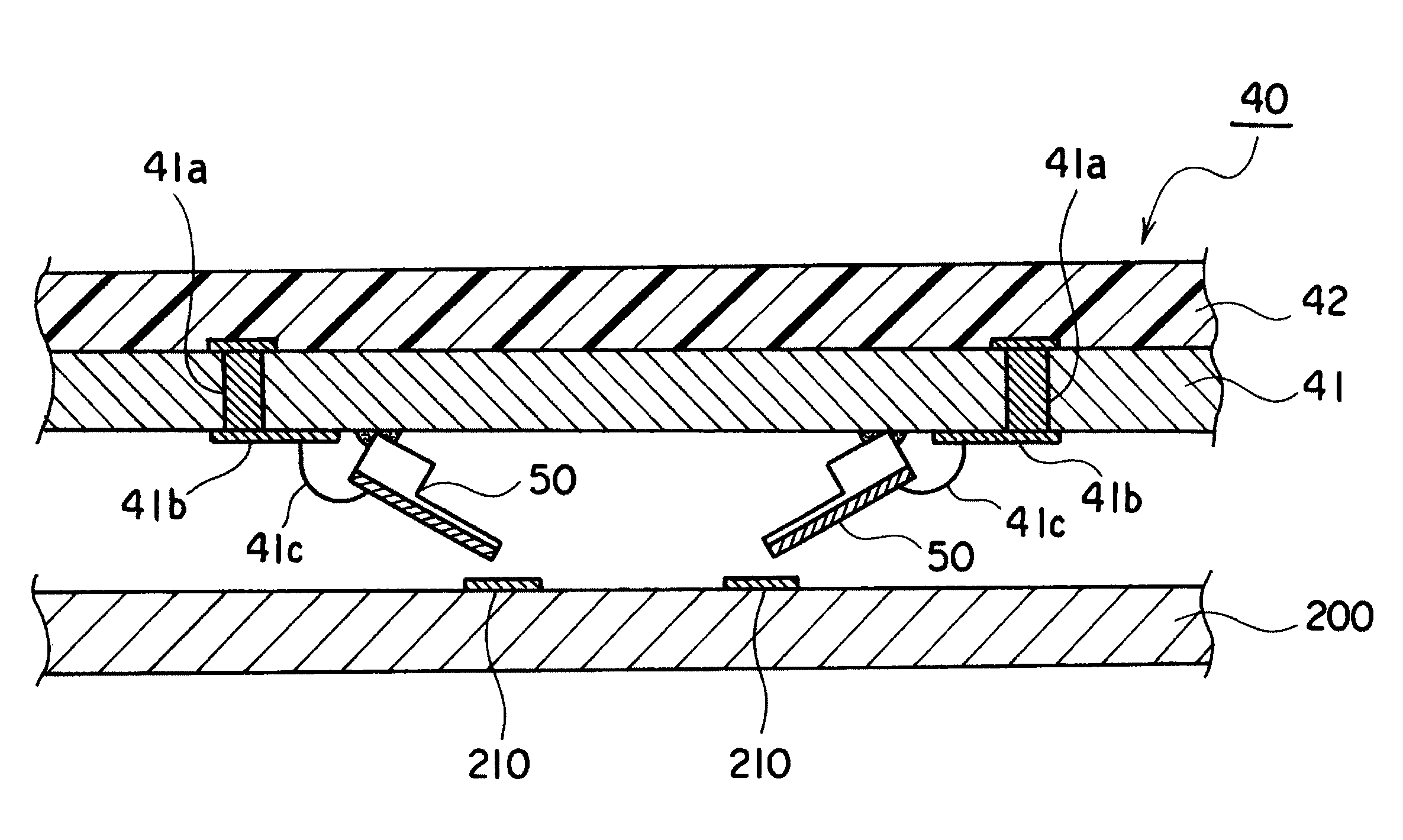

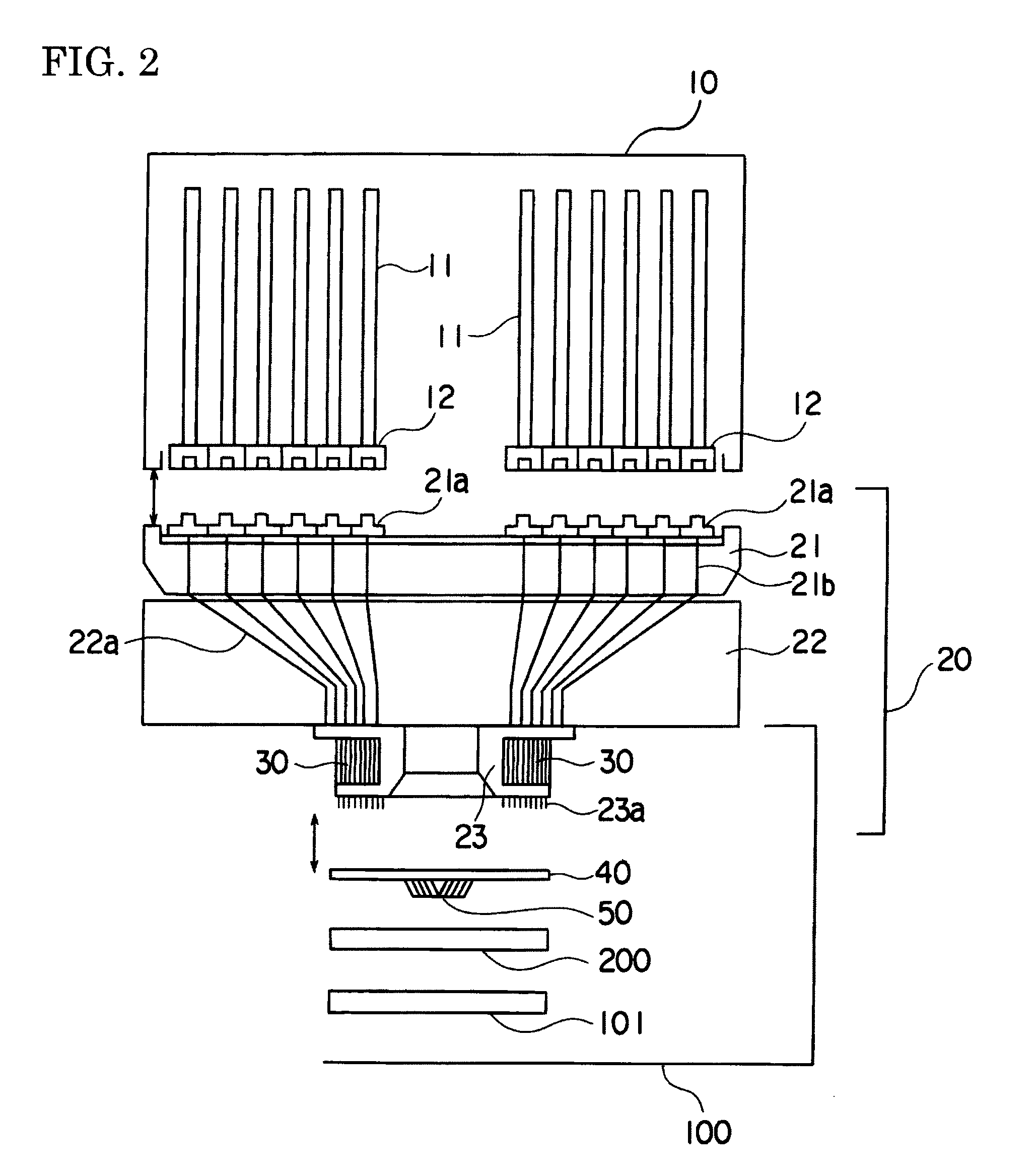

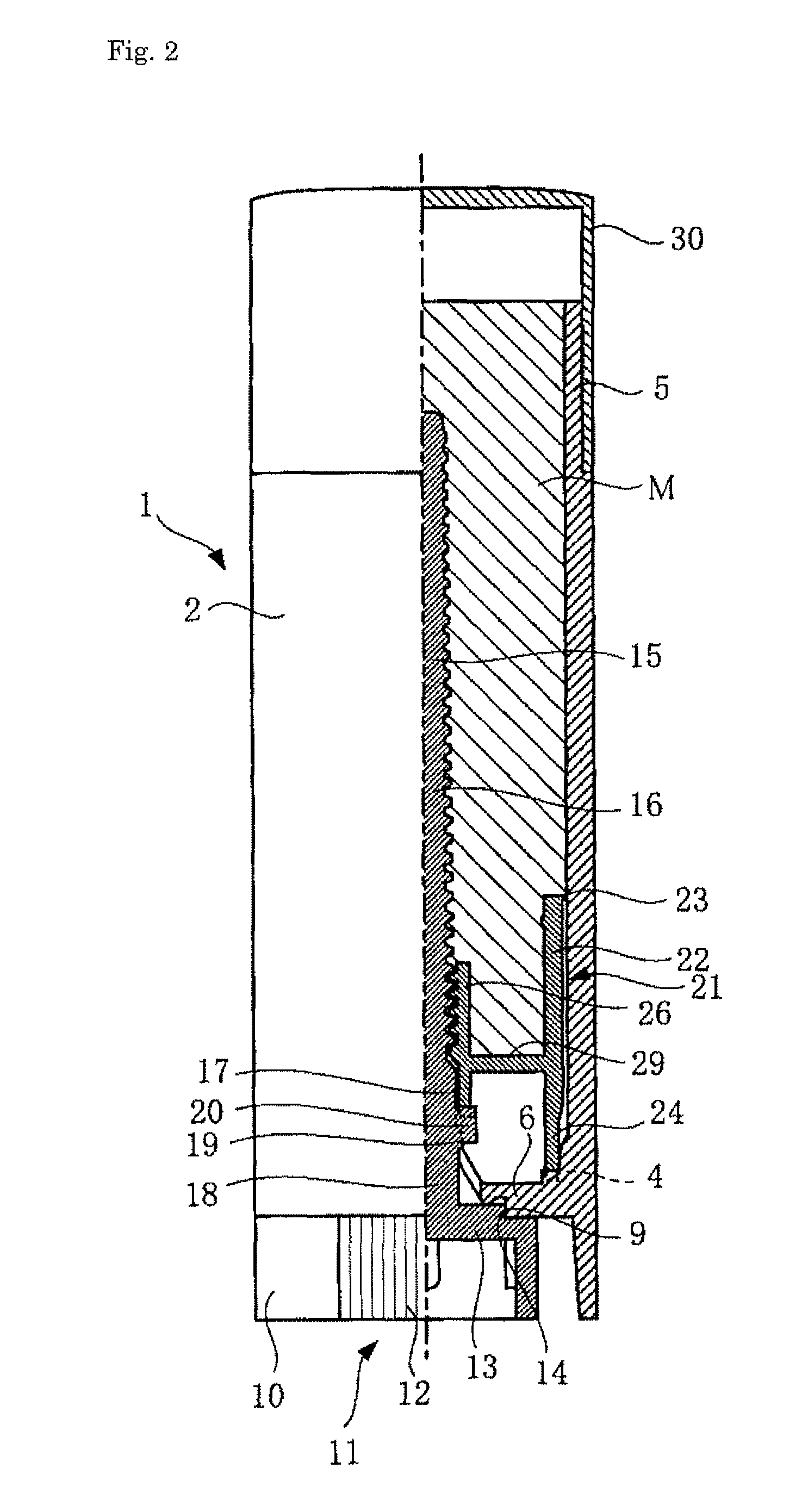

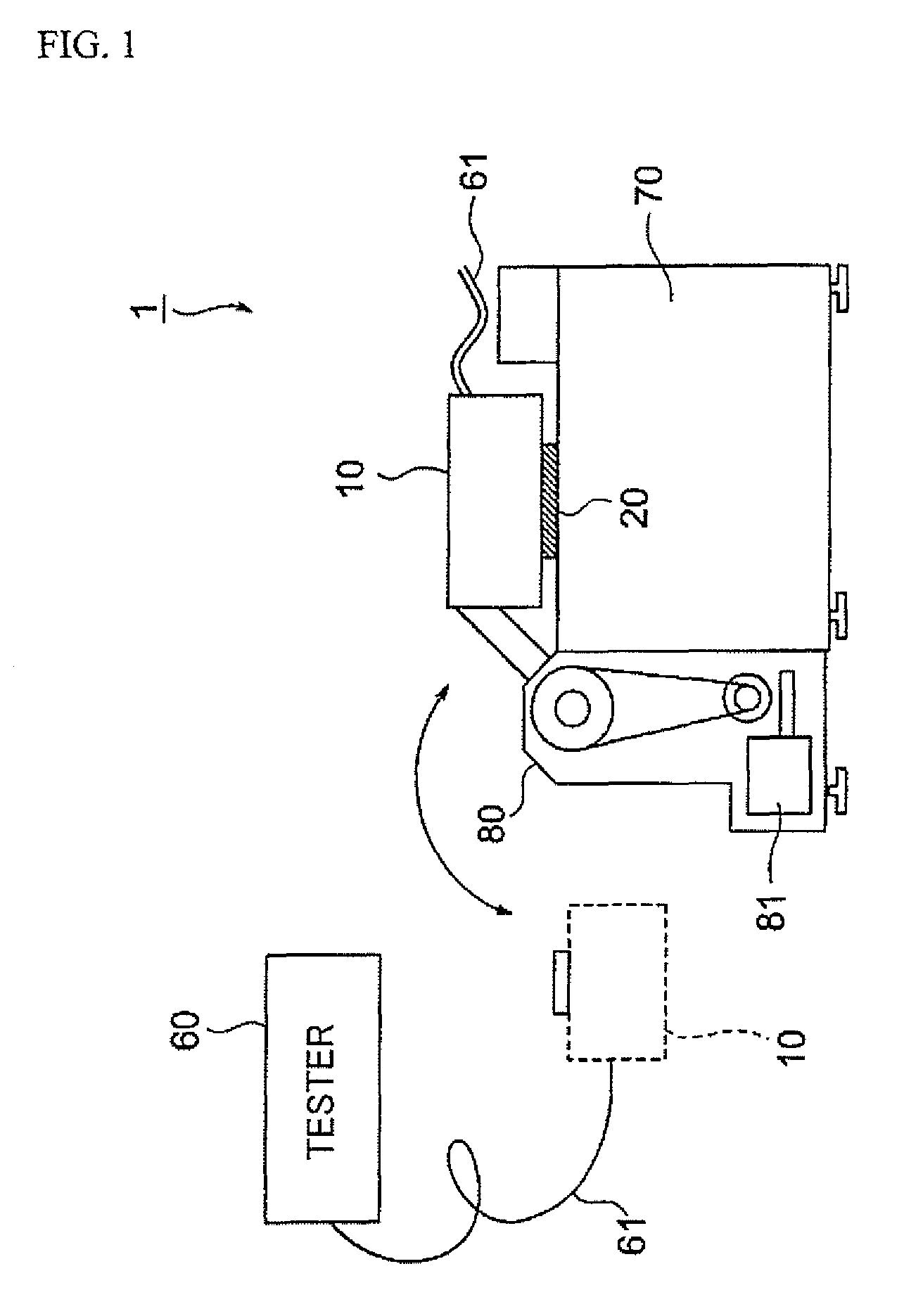

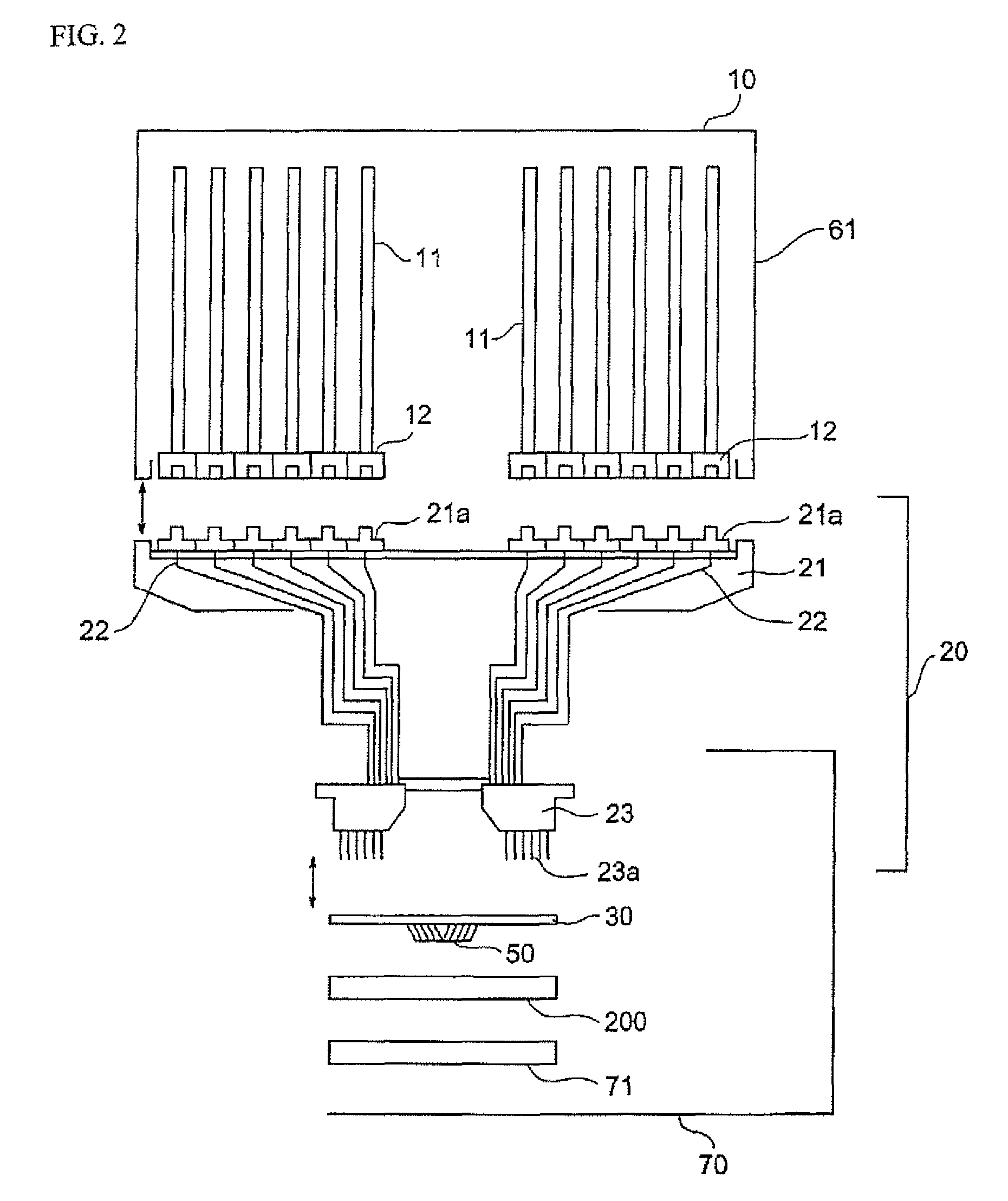

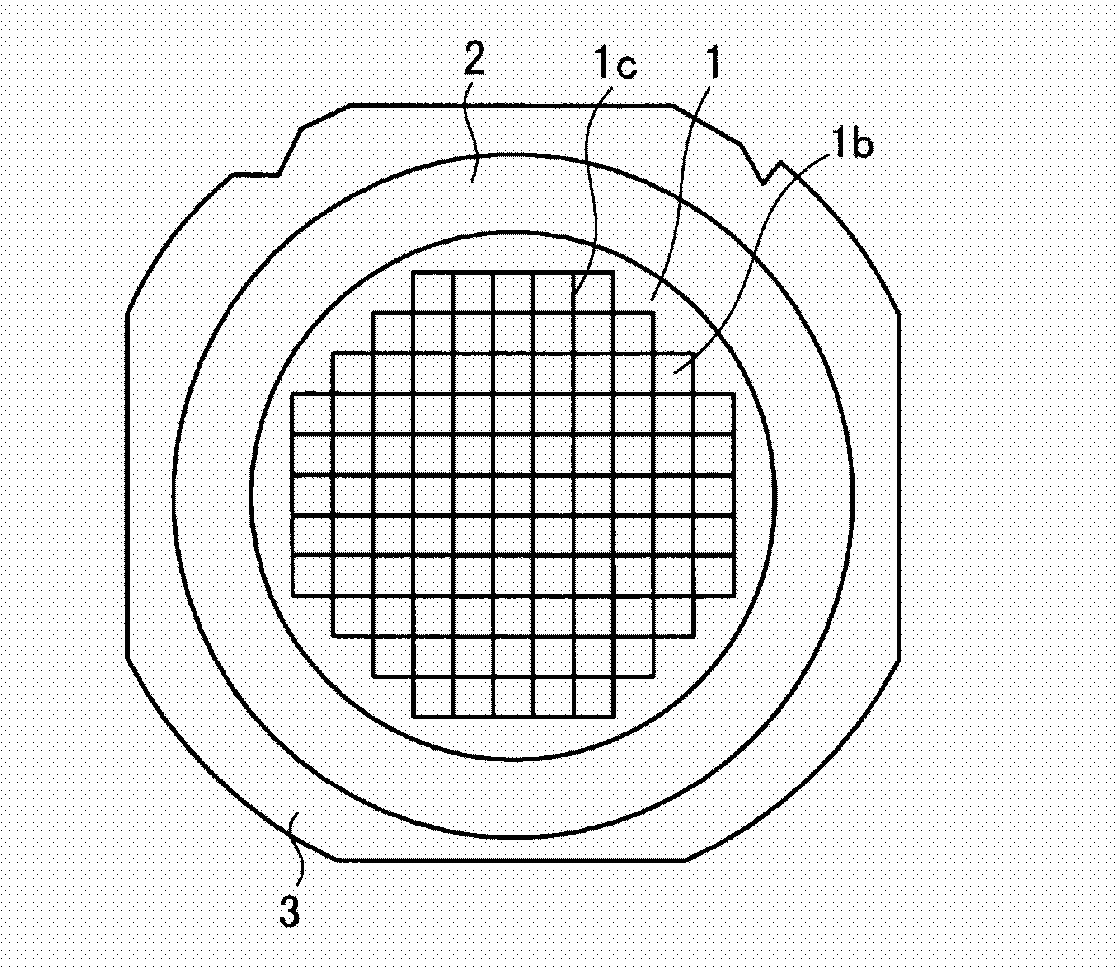

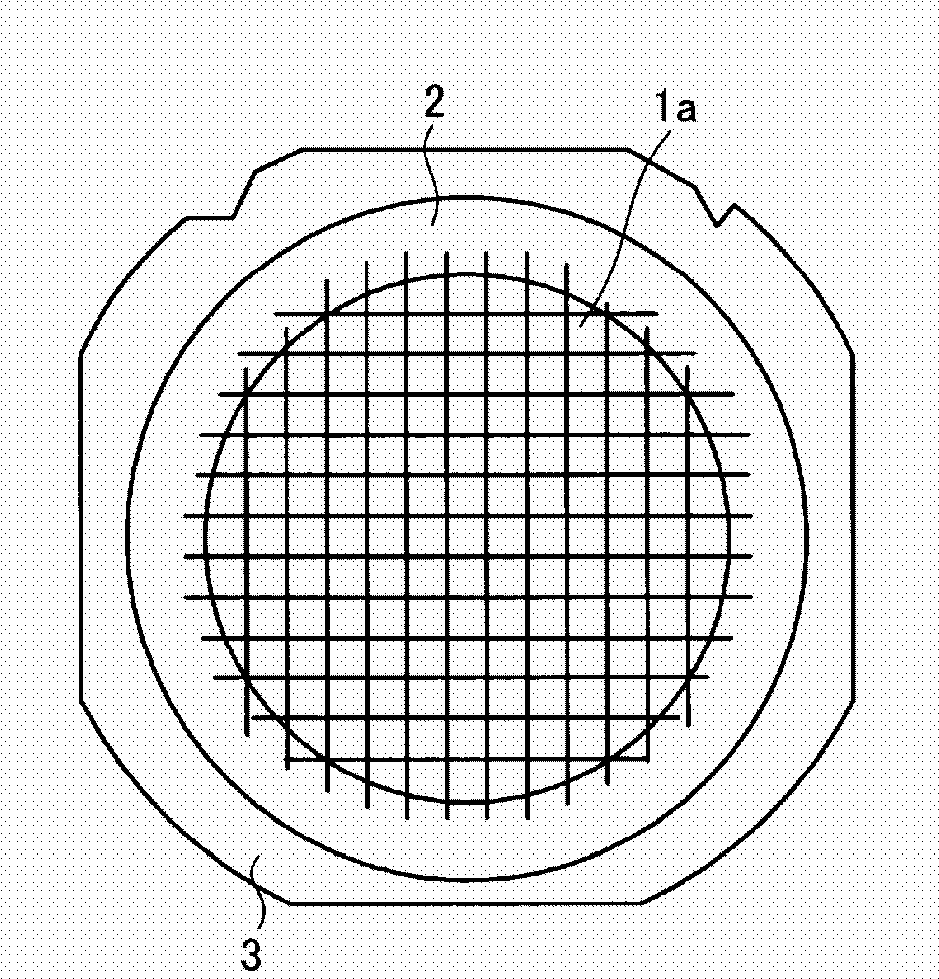

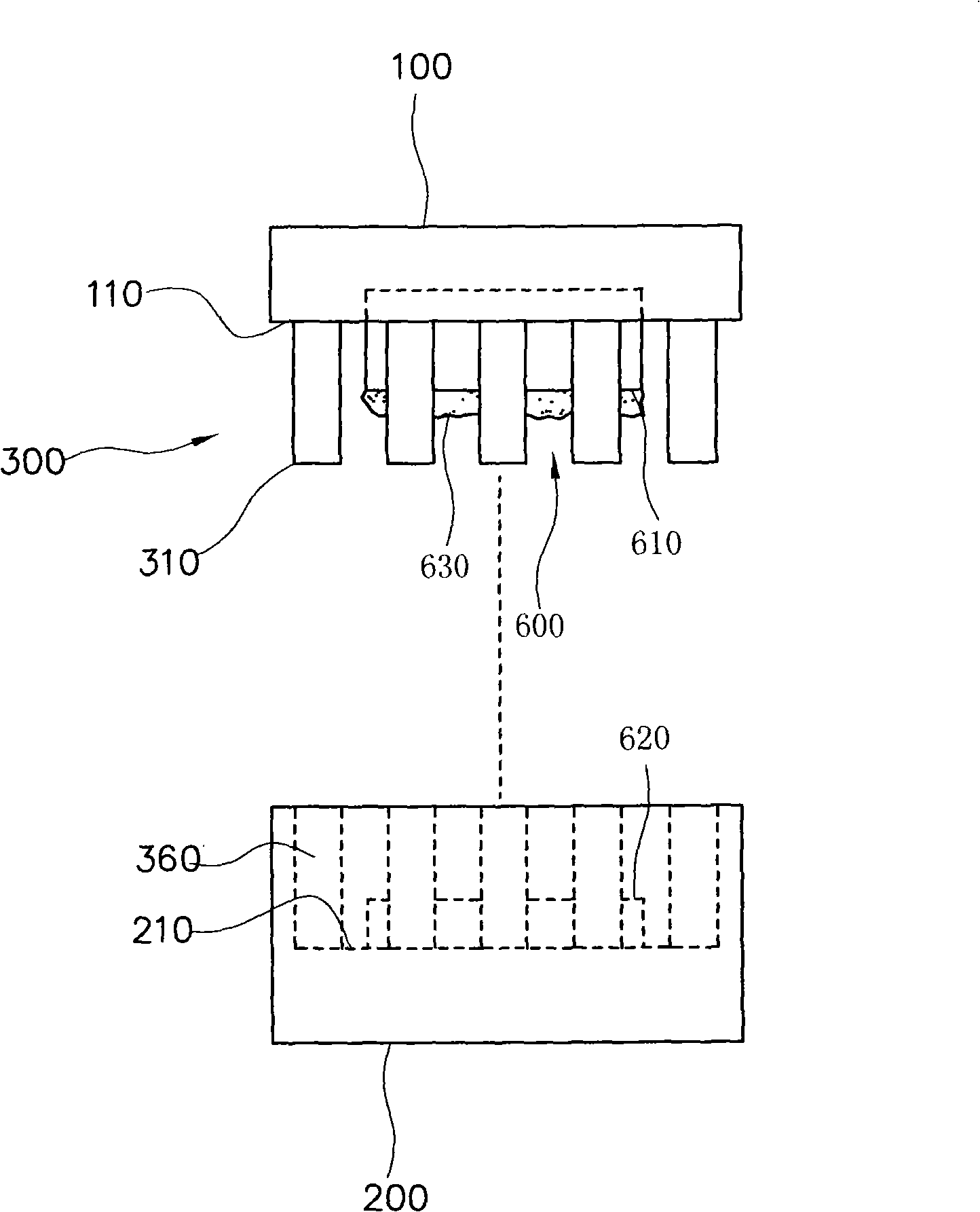

Contactor, contact structure provided with contactors, probe card, test apparatus, method of production of contact structure, and production apparatus of contact structure

InactiveUS20070013390A1Avoid contactSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsProbe cardContact pad

A probe card having a plurality of silicon finger contactors contacting pads provided on a tested semiconductor wafer and a probe board mounting the plurality of silicon finger contactors on its surface, wherein each silicon finger contactor has a base part on which a step difference is formed, a support part with a rear end side provided at the base part and with a front end side sticking out from the base part, and a conductive part formed on the surface of the support part, each silicon finger contactor mounted on the probe board so that an angle part of the step difference formed on the base part contacts the surface of the probe board.

Owner:ADVANTEST CORP

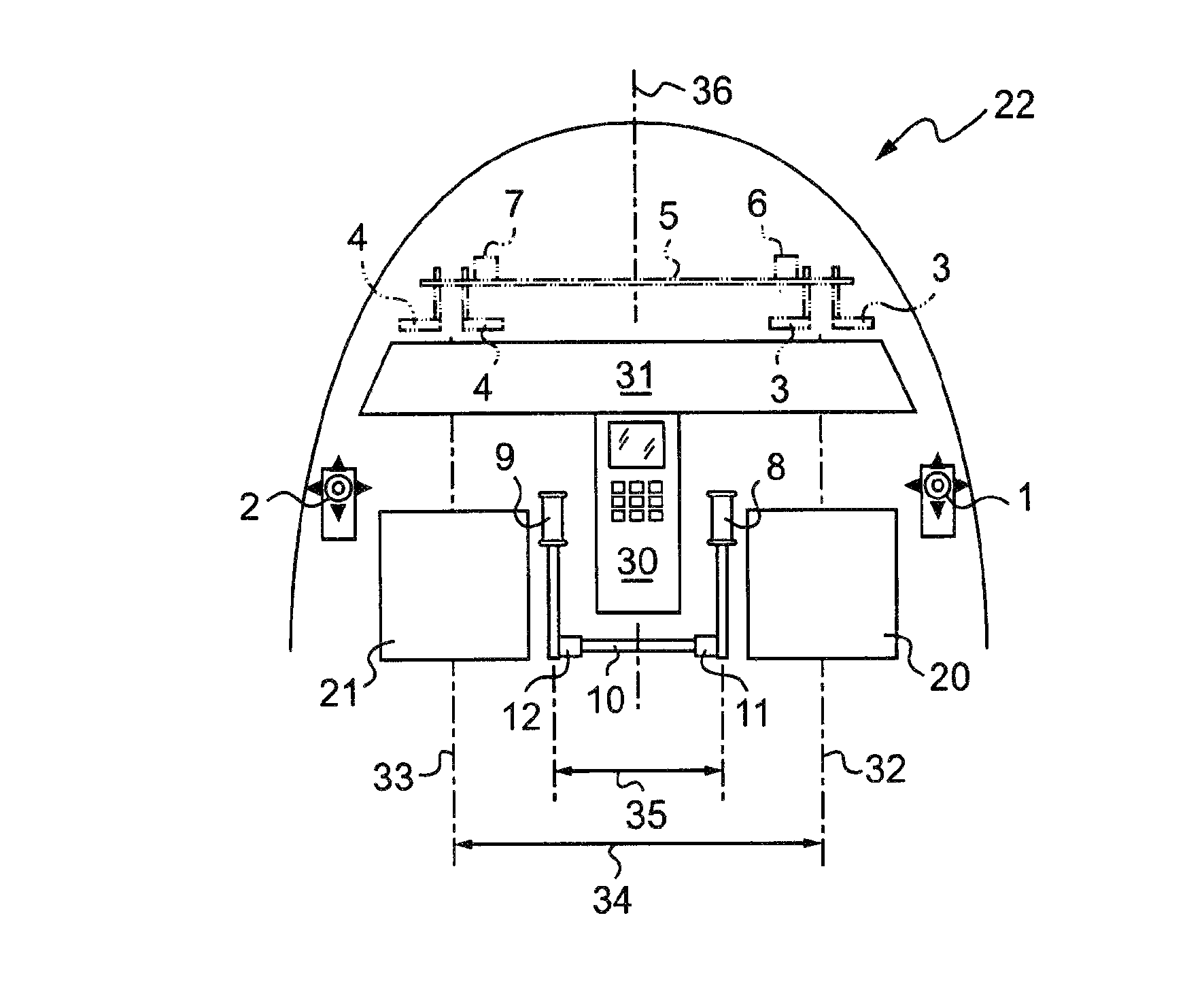

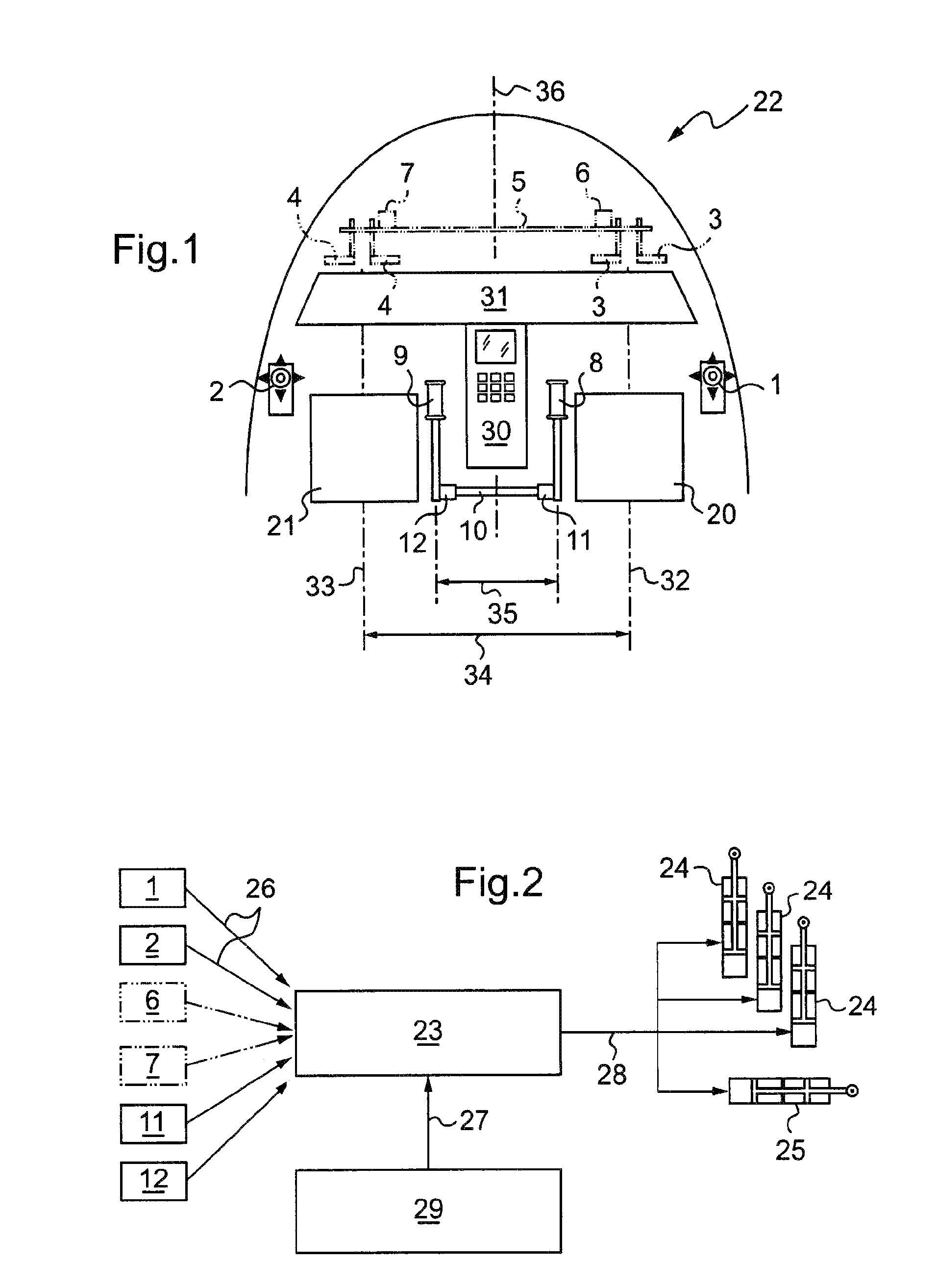

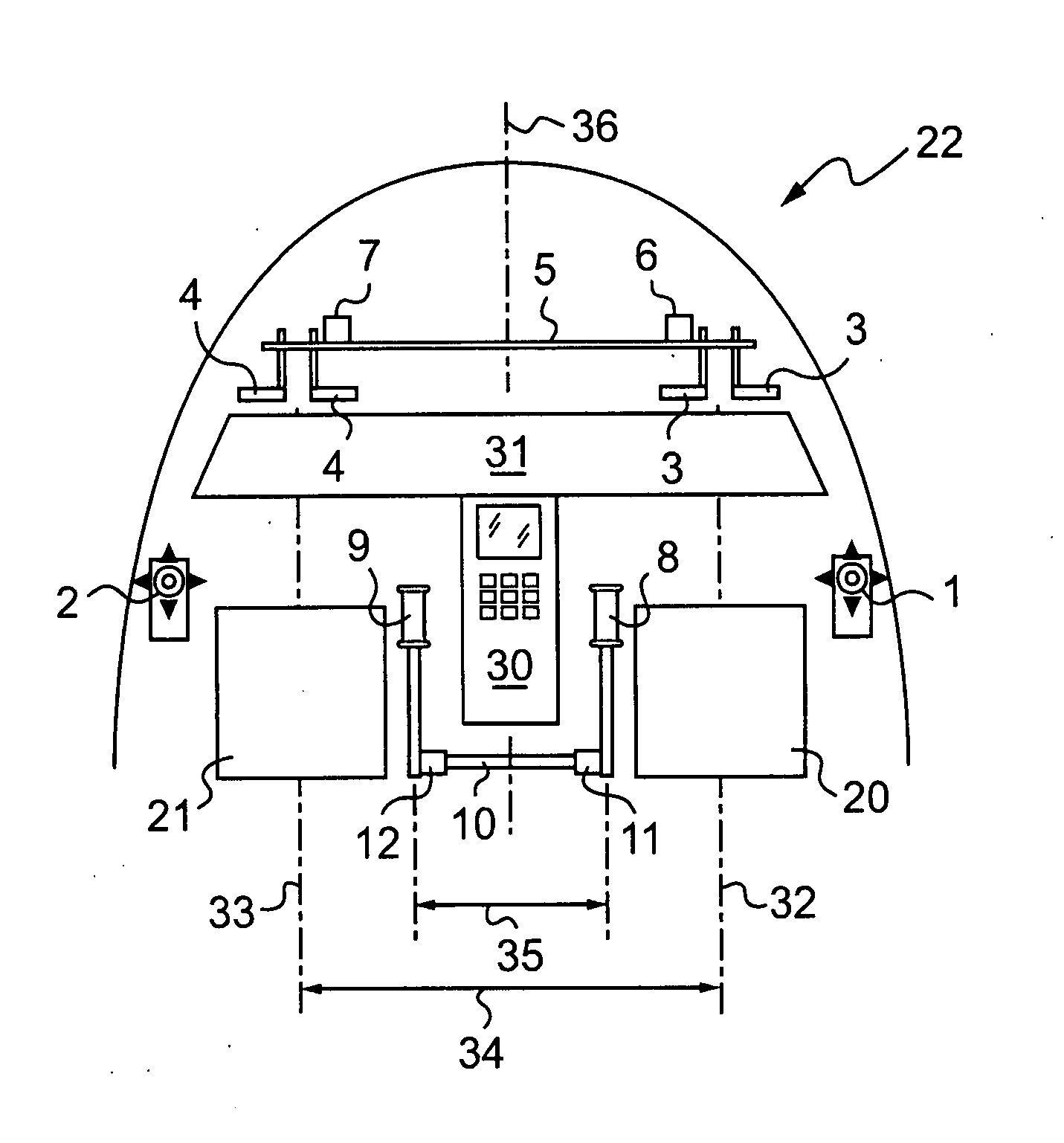

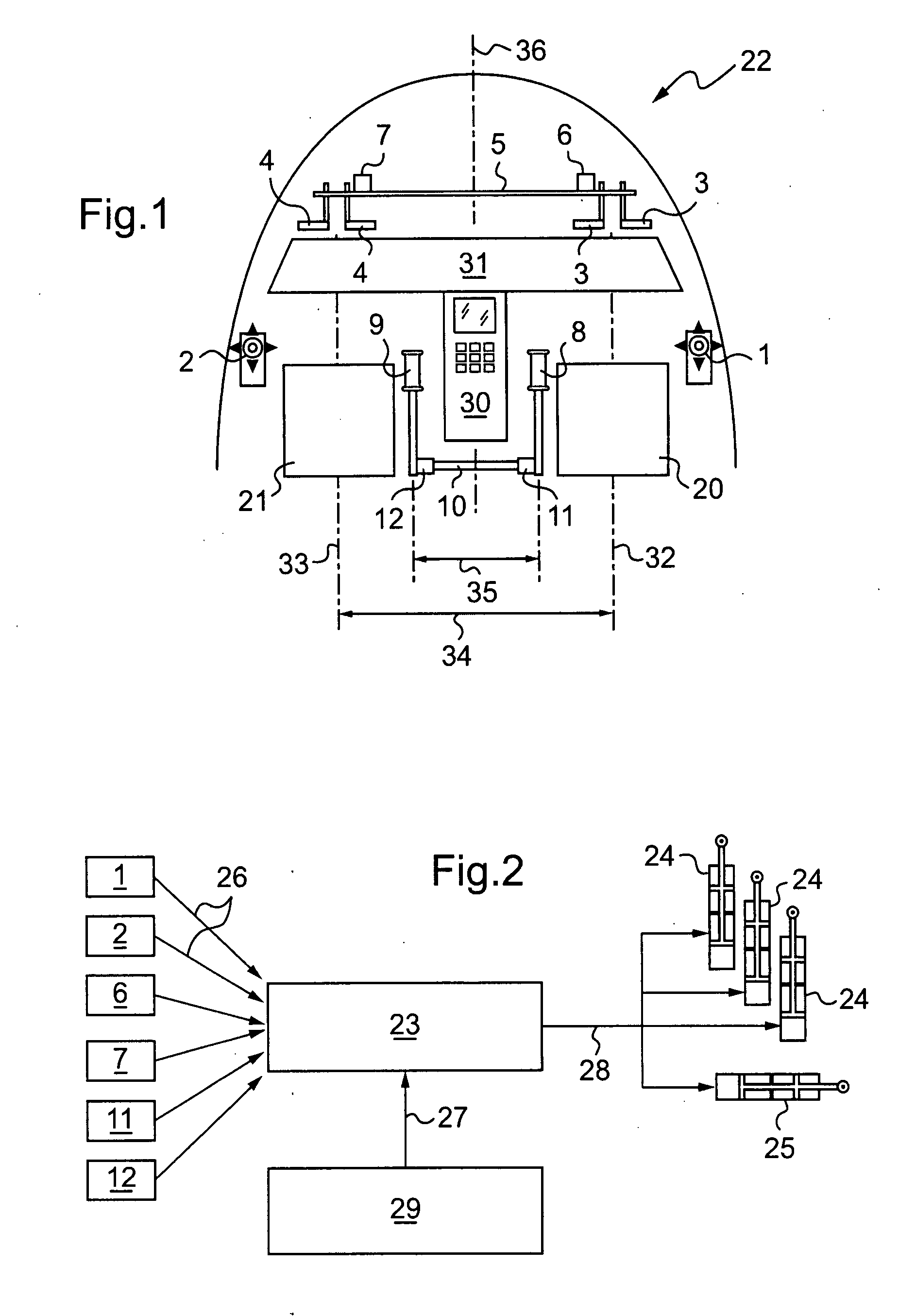

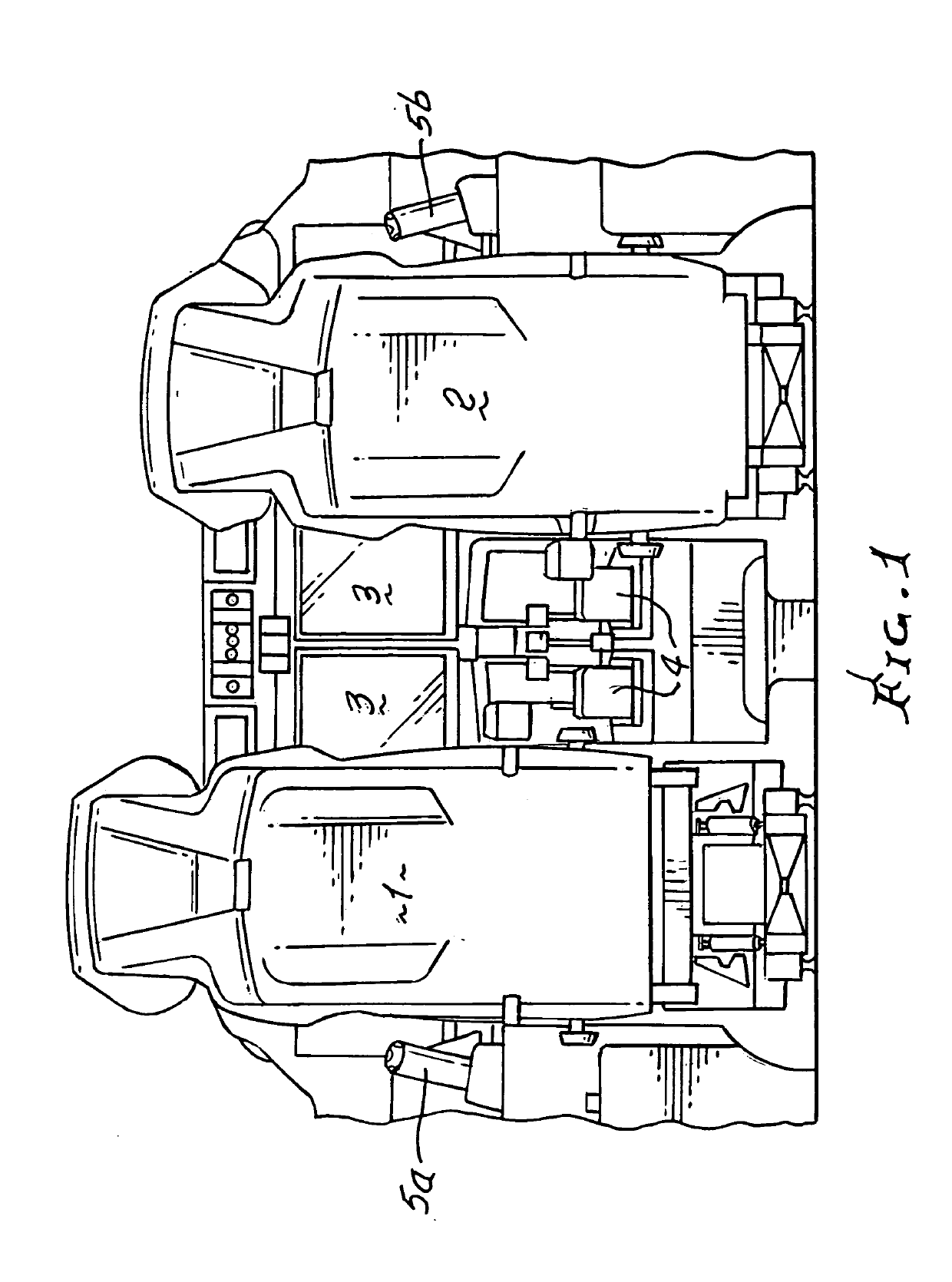

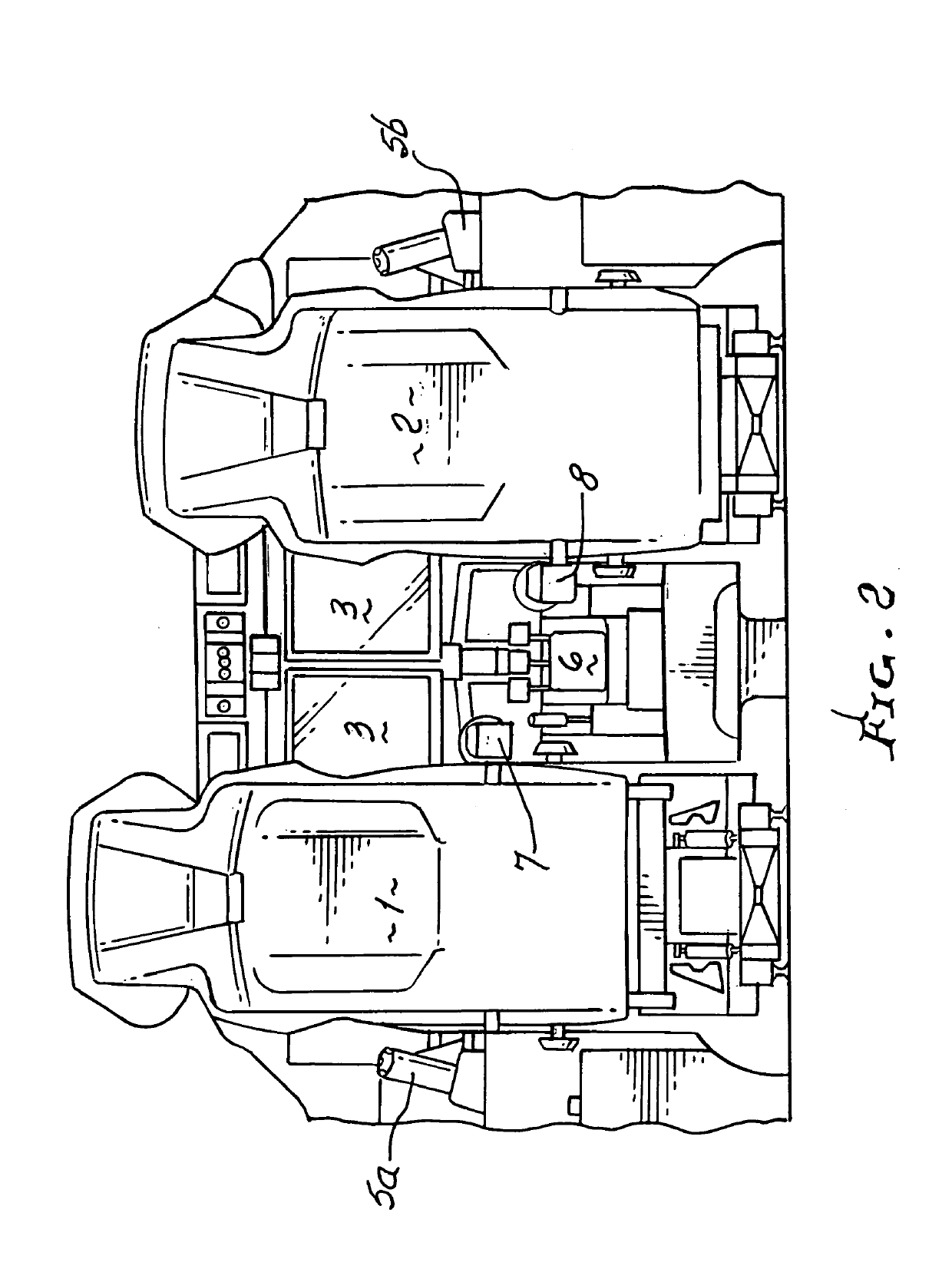

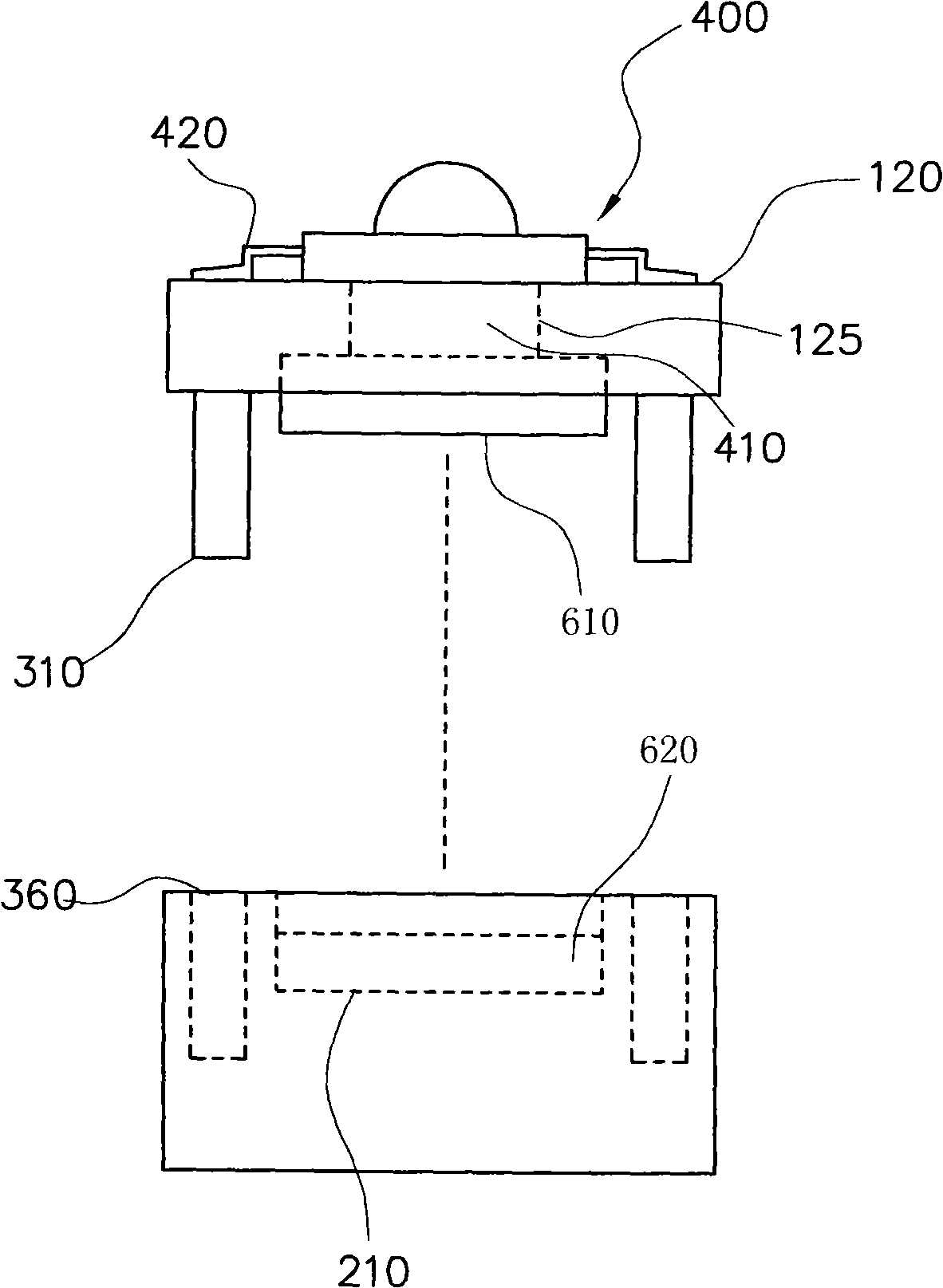

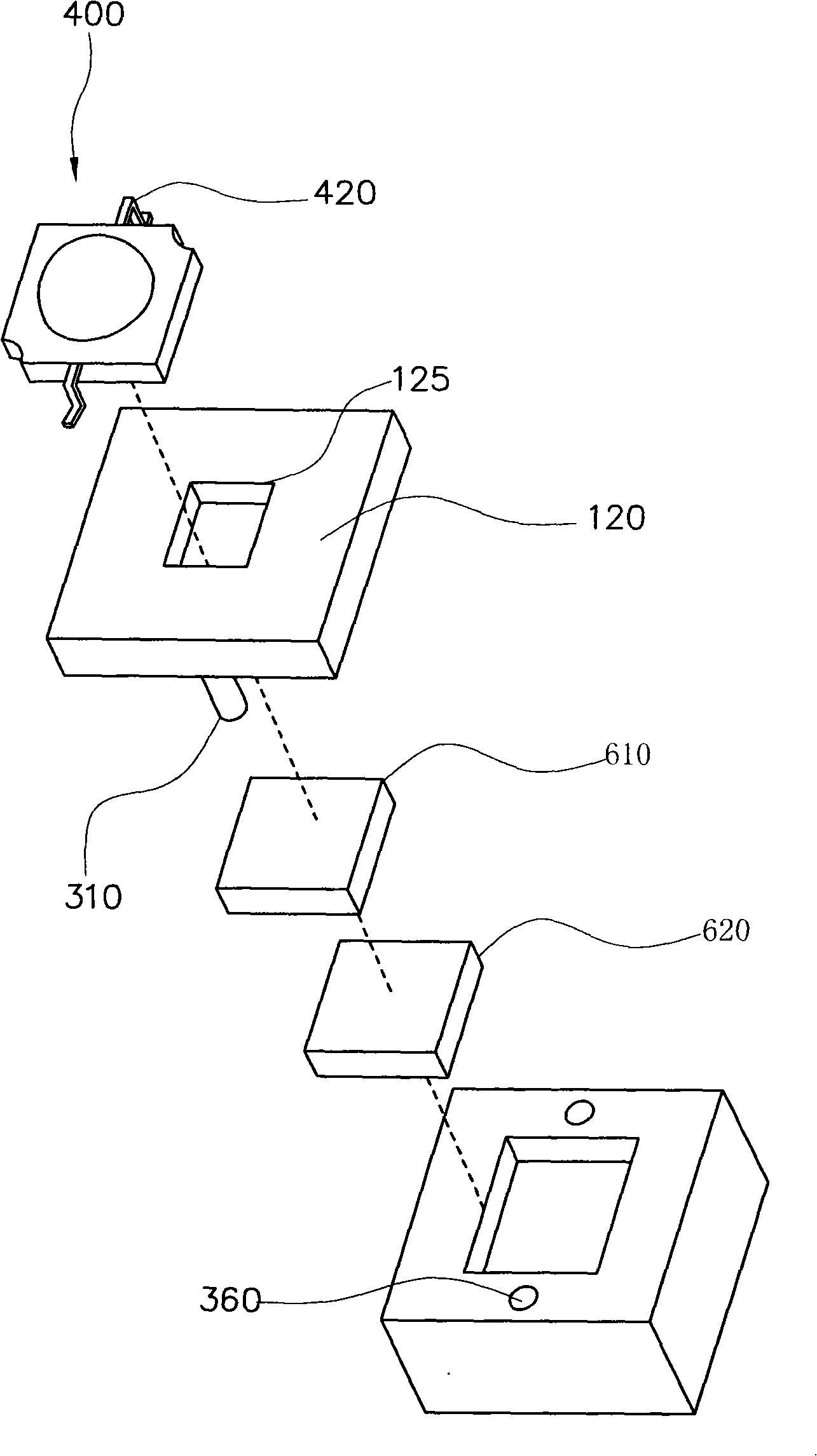

Flying control device for a rotorcraft

InactiveUS8052097B2Improve ergonomicsReduce weightManual control with multiple controlled membersActuated personallyFly controlFlight vehicle

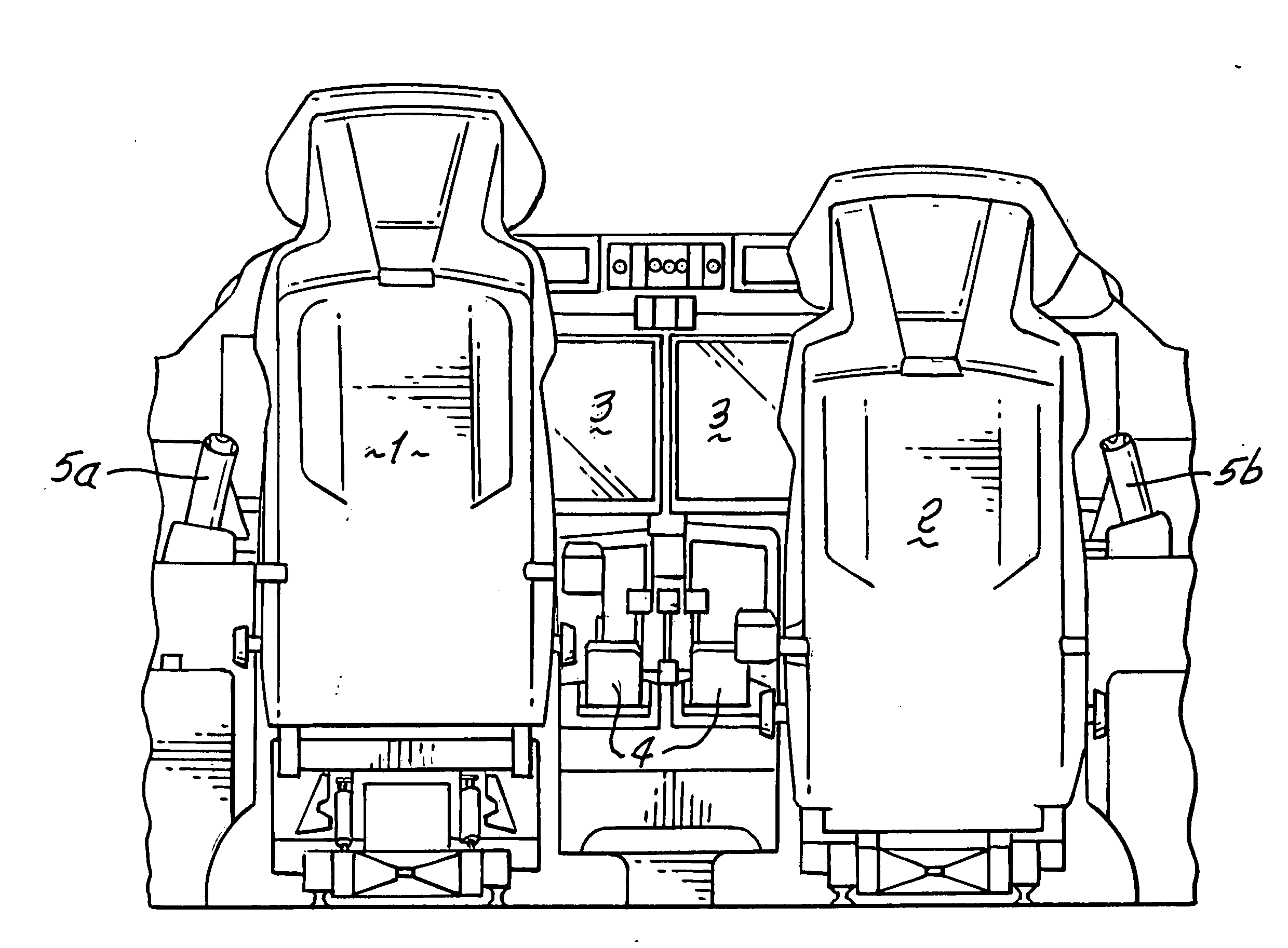

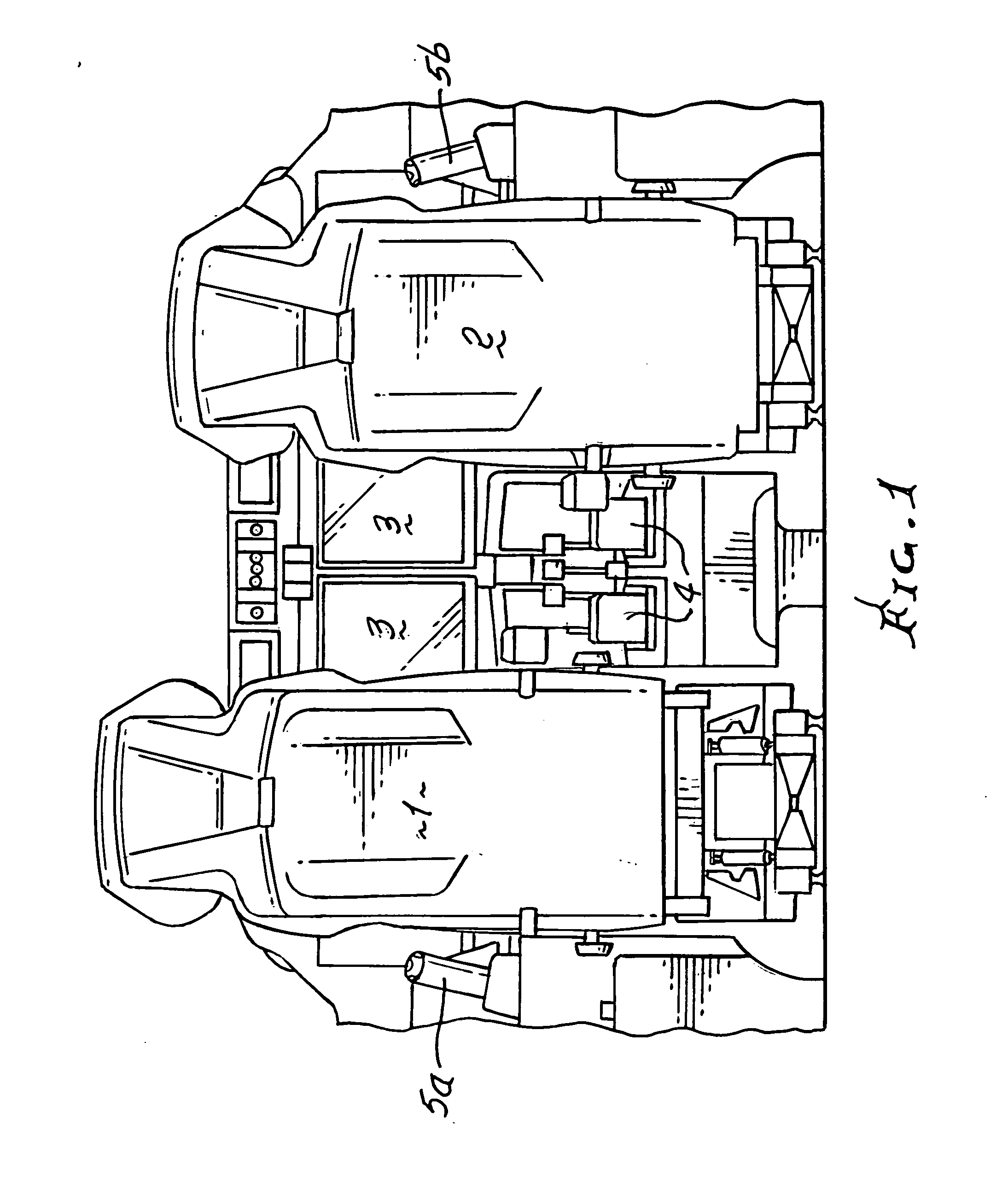

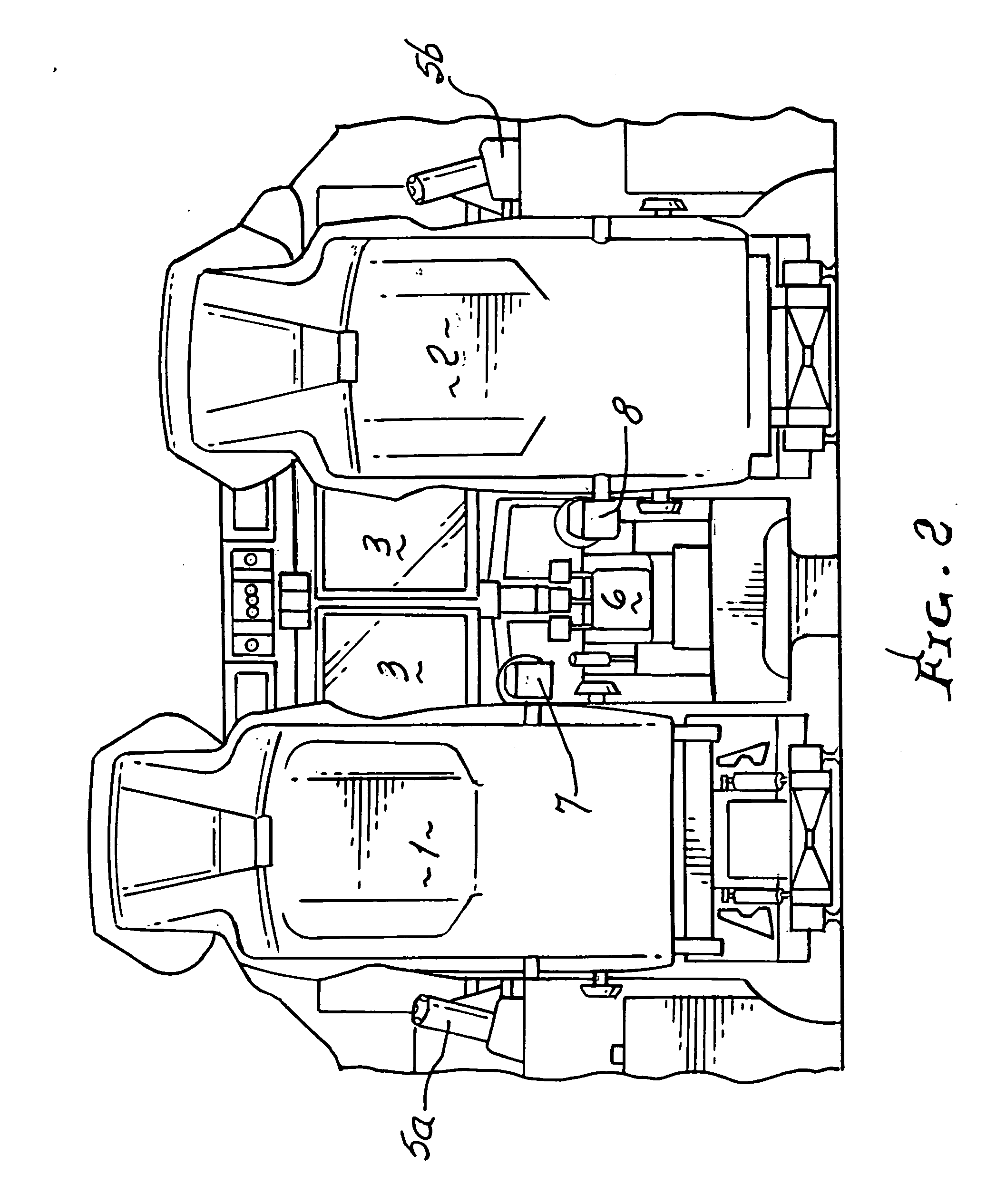

The invention relates to a rotorcraft cockpit having a left seat and a right seat placed side-by-side, a console extending between the seats, two side sticks, one situated to the right of the right seat and the other situated to the left of the left seat, enabling the pilot to control roll and pitch; a flight control system comprising sensors associated with the side sticks and a computer connected to the sensors serves to convert the orders applied by the pilot to the side sticks into signals for controlling actuators in order to vary roll and pitch; a piloting relationship integrated in the computer stabilizes the response of the rotorcraft in roll and in pitch when a side stick is actuated, and maintains the attitudes in roll and pitch at reference values when neither side stick is actuated.

Owner:EUROCOPTER

Contactor and method of production of contactor

InactiveUS20100102838A1Improve test accuracyContact member manufacturingElectrically conductive connectionsEngineeringMethods of production

Owner:ADVANTEST CORP

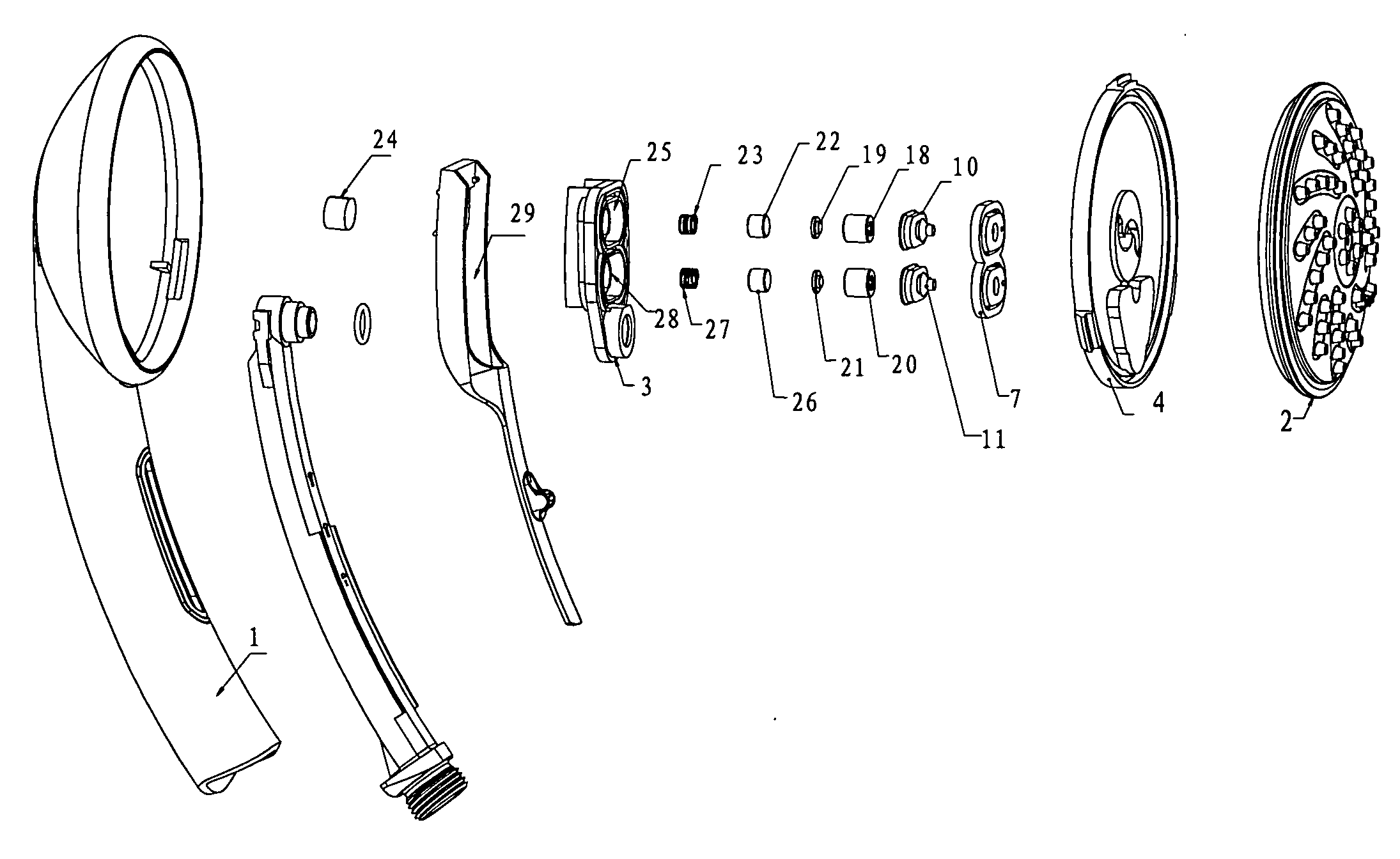

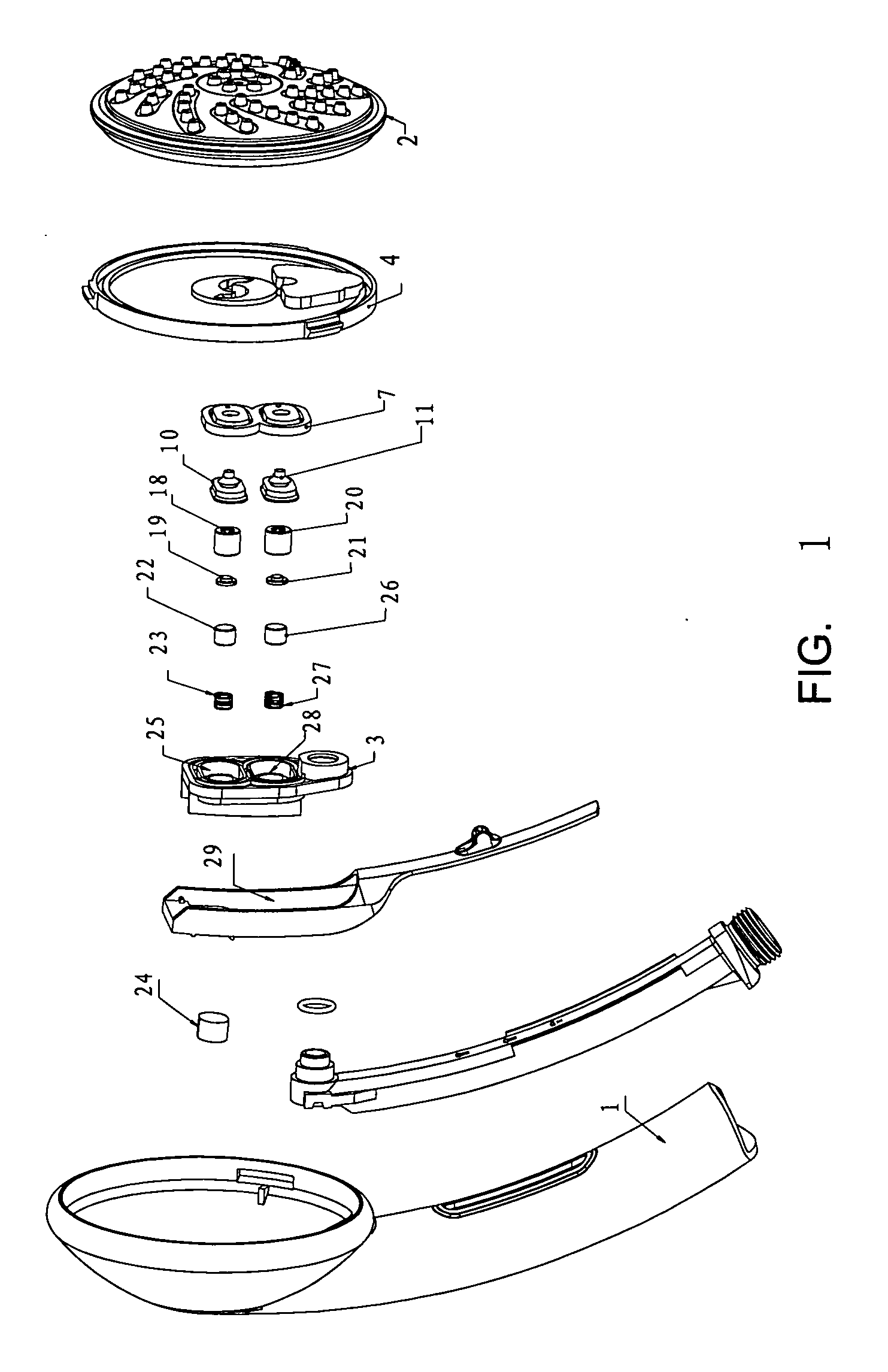

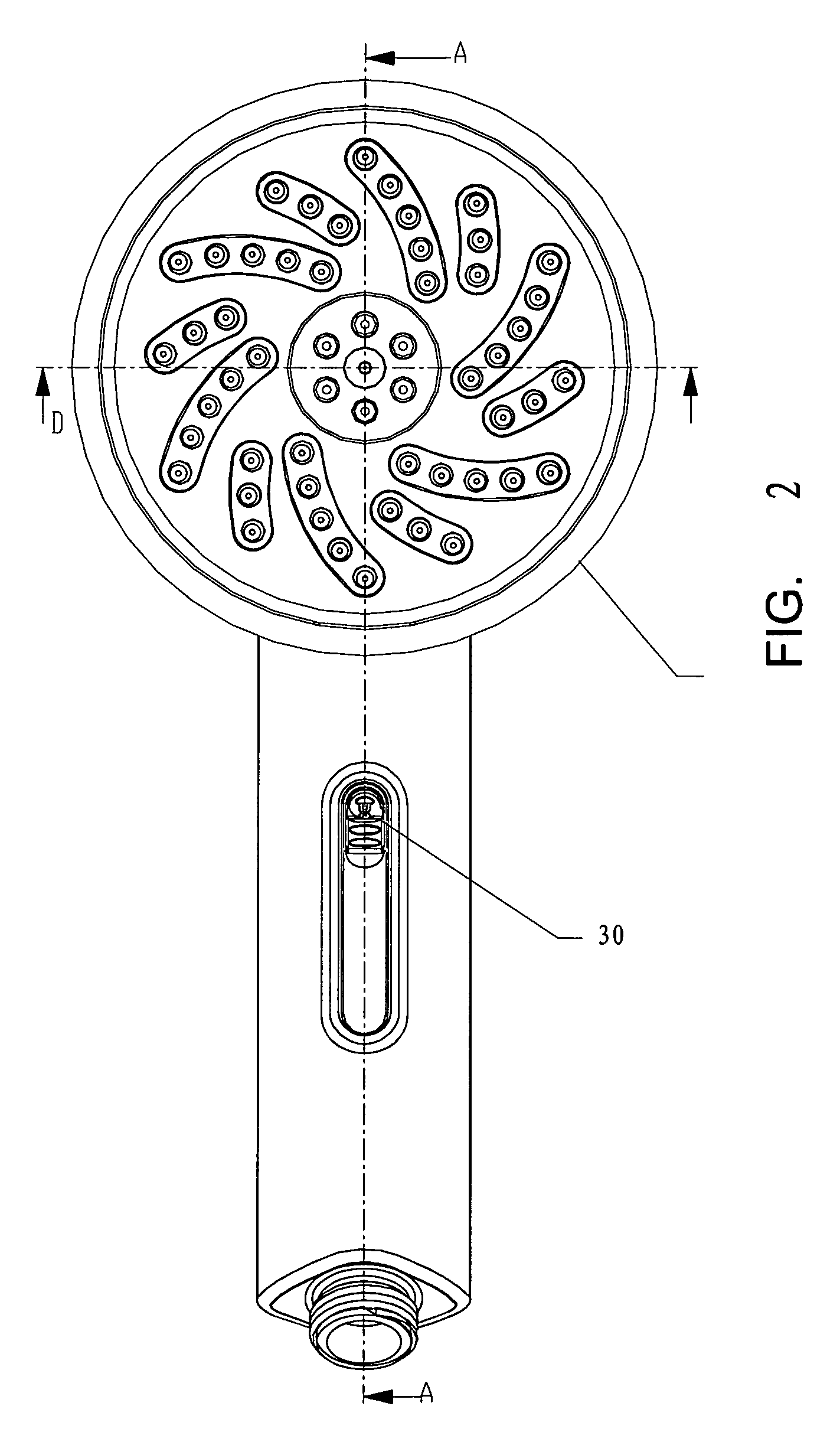

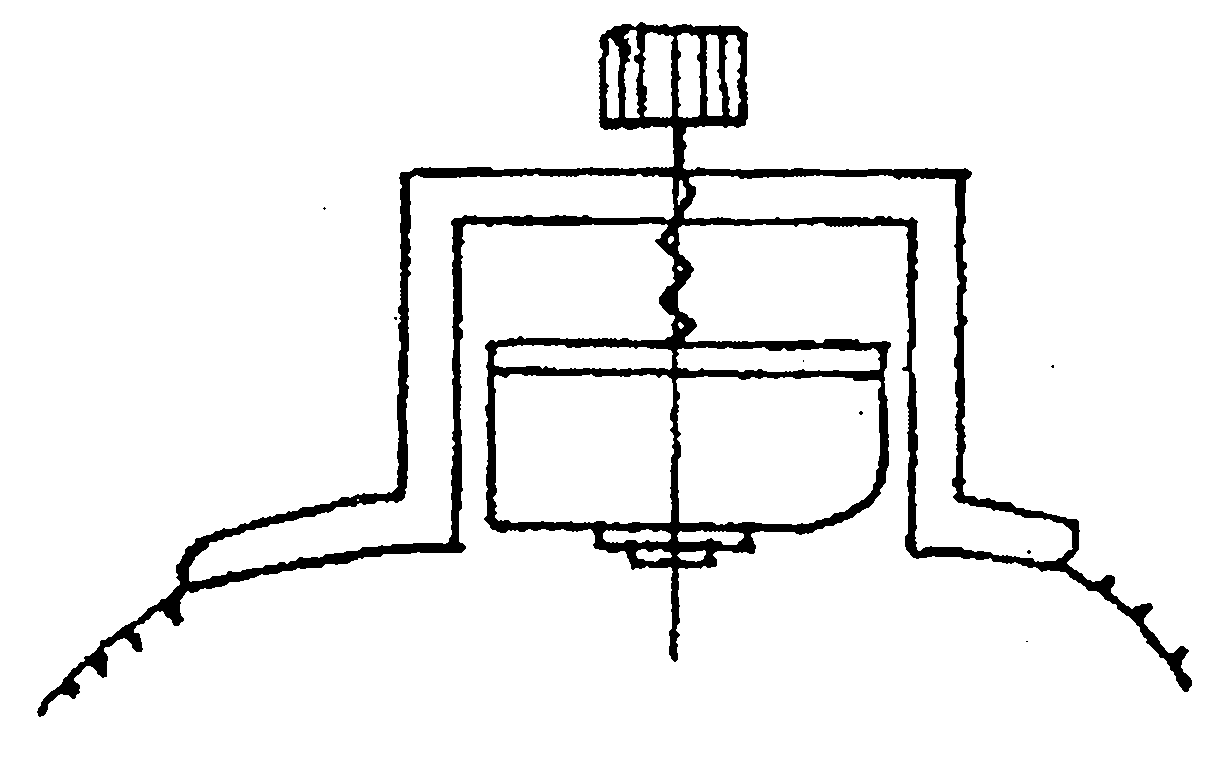

Water Outlet Control Device of Shower Spray Nozzle

InactiveUS20100301141A1Handle for easy operationEasy to operateOperating means/releasing devices for valvesBathsSpray nozzleWater flow

A mechanism of controlling water outflow of shower is provided in the casing of shower. The water outlet of the mechanism is aligned with the water outlet of shower. The mechanism of controlling water outflow comprises inner sealing shell, outer sealing shell, and an intermediate cavity defined between the inner sealing shell and the outer sealing shell. A water outflow cavity is formed between outer sealing shell and water outflow disc. The intermediate cavity communicates with intake channel of shower. The mechanism of controlling water outlet also comprises separating sealing pad inside the intermediate cavity, with one side sticked to the water outflow disc of outer sealing shell and the other side sticked to valve elements. The intermediate cavity comprises the inner cavity and outer cavity. The inner cavity communicates with water outflow cavity through the first small hole and with outer cavity through a through-hole. The intake channel communicates with outer cavity. The small hole matches with a mobile sealing pad that connects the button kit that controls the sealing pad to separate or contact the small hole. This invention can realize different effects of water outflow, easy operation handle and longer service life.

Owner:PAN YAOZHAO

Pulse diagnosis instrument

InactiveCN102018501AThe positioning process is visibleAccurate pulse positionCatheterDiagnostic recording/measuringSilica gelPulse diagnosis

The invention discloses a pulse diagnosis instrument, which comprises a positioning component independently fixed at the wrist of hand, wherein the positioning component is provided with a visible positioning window. The pulse diagnosis instrument further comprises a sensor component which is arranged on the positioning component, wherein a sensor probe of the sensor component is positioned in the positioning window after being assembled. The pulse diagnosis instrument has the advantages that: 1) the positioning process is visible and the positioning window is provided with marks, so the positioning is more accurate, 2) the positioning component is independently fixed at the wrist of hand and is fixed at the position opposite to the wrist, so as to prevent the measuring position from gearing caused by the rotation of the wrist, 3) the part of the positioning component fit with the hand is arc side stuck with a medical silica gel layer, and two arc-shaped elastic sheets can ensure the comfortableness and stability of the fixing between the positioning component and the wrist, and 4) a tension spring structure is used as a pulse pillow, which is prevented from being lost caused by separating from the base in using process, can freely rotate and realizes the convenient conversion of the pulse collection of left and right hands.

Owner:SHANGHAI DAOSHENG MEDICAL TECH

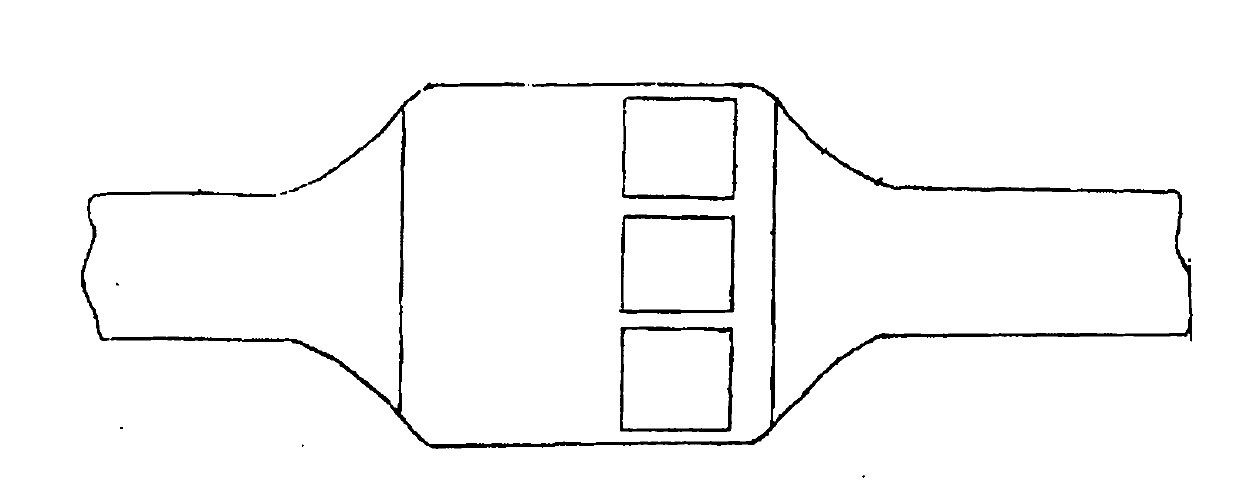

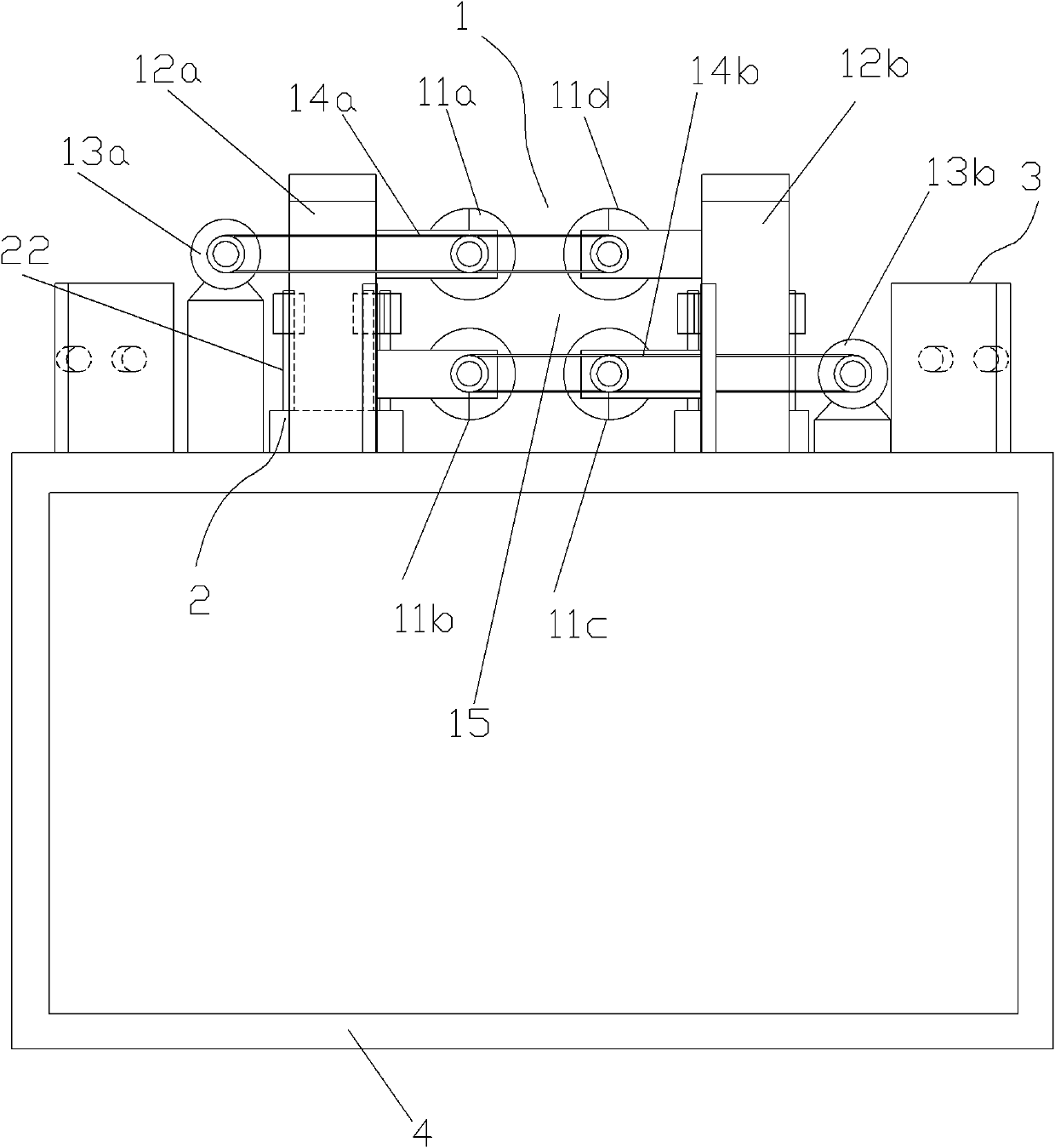

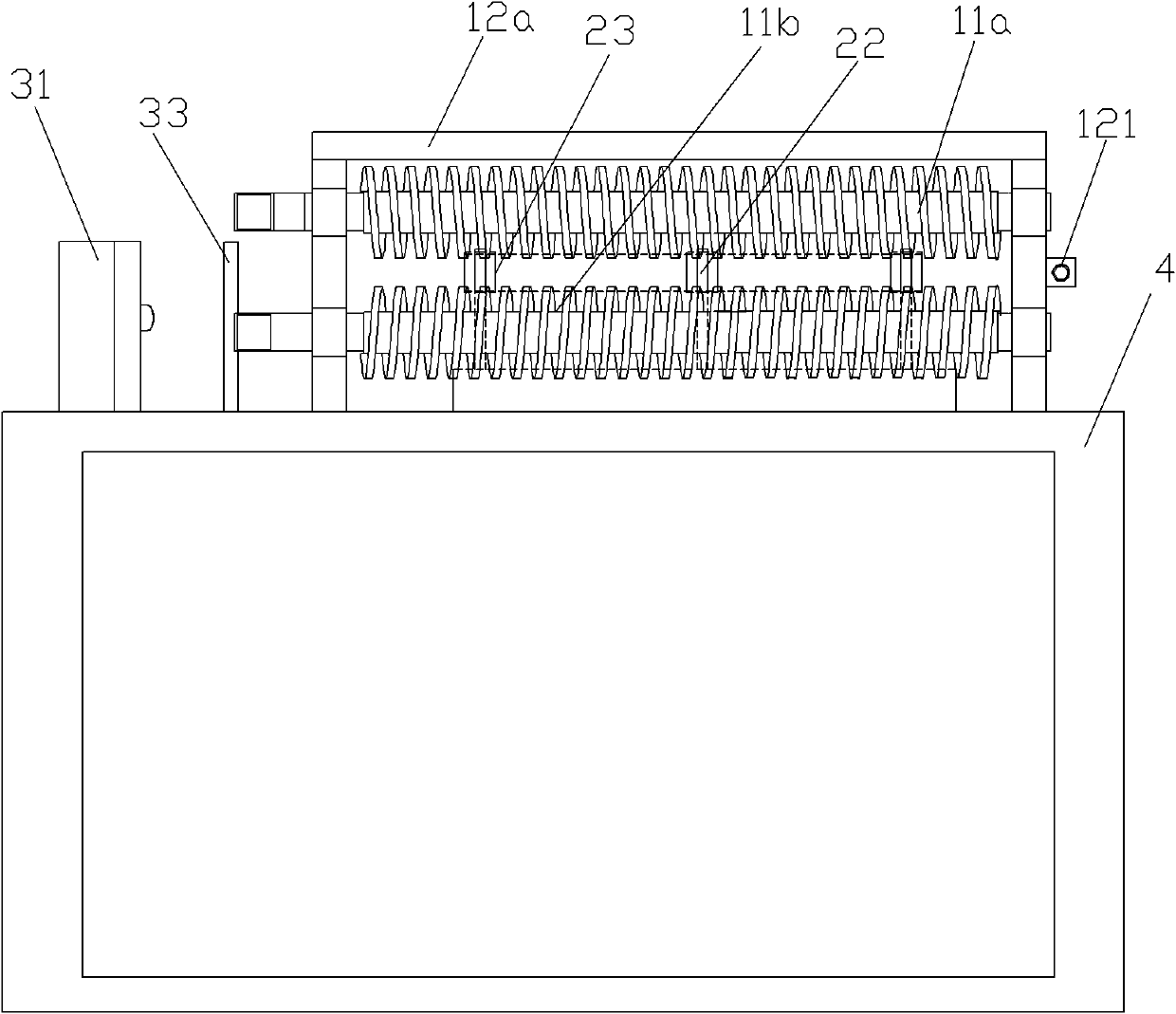

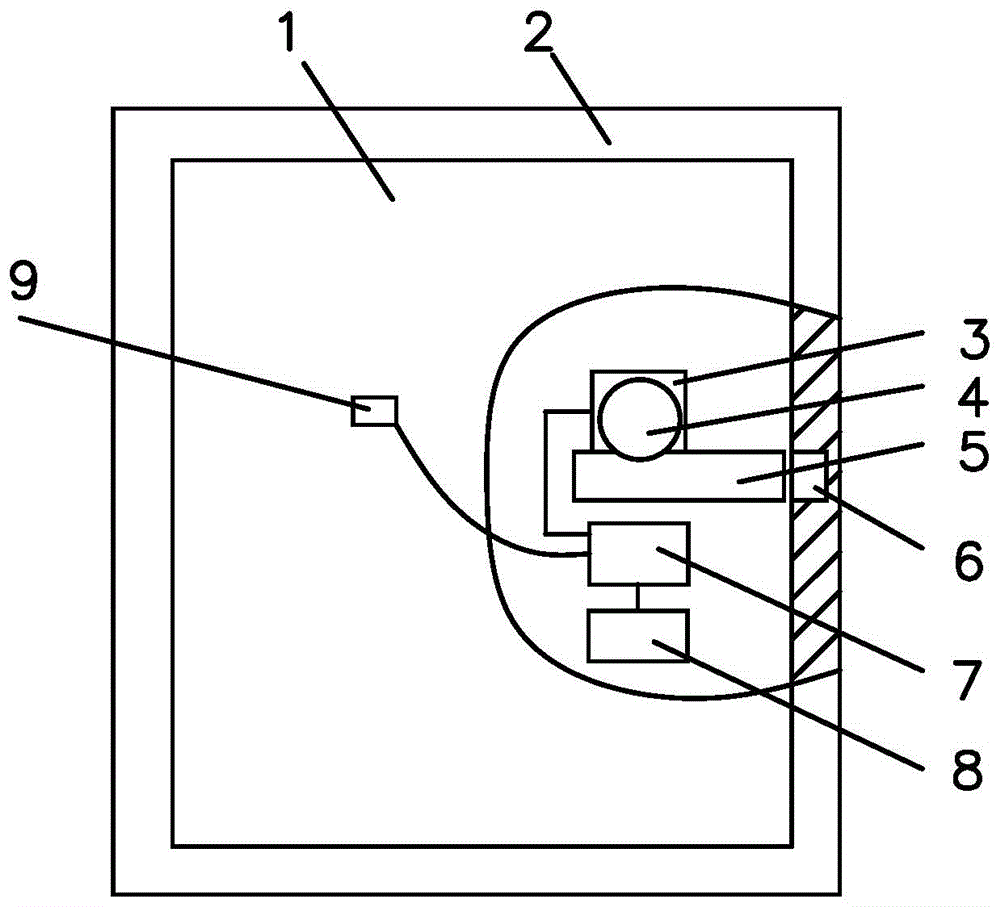

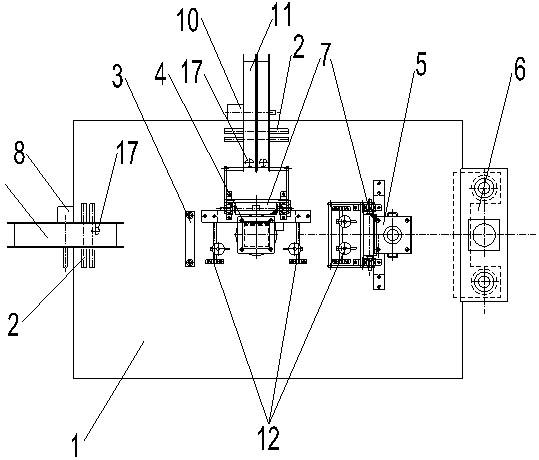

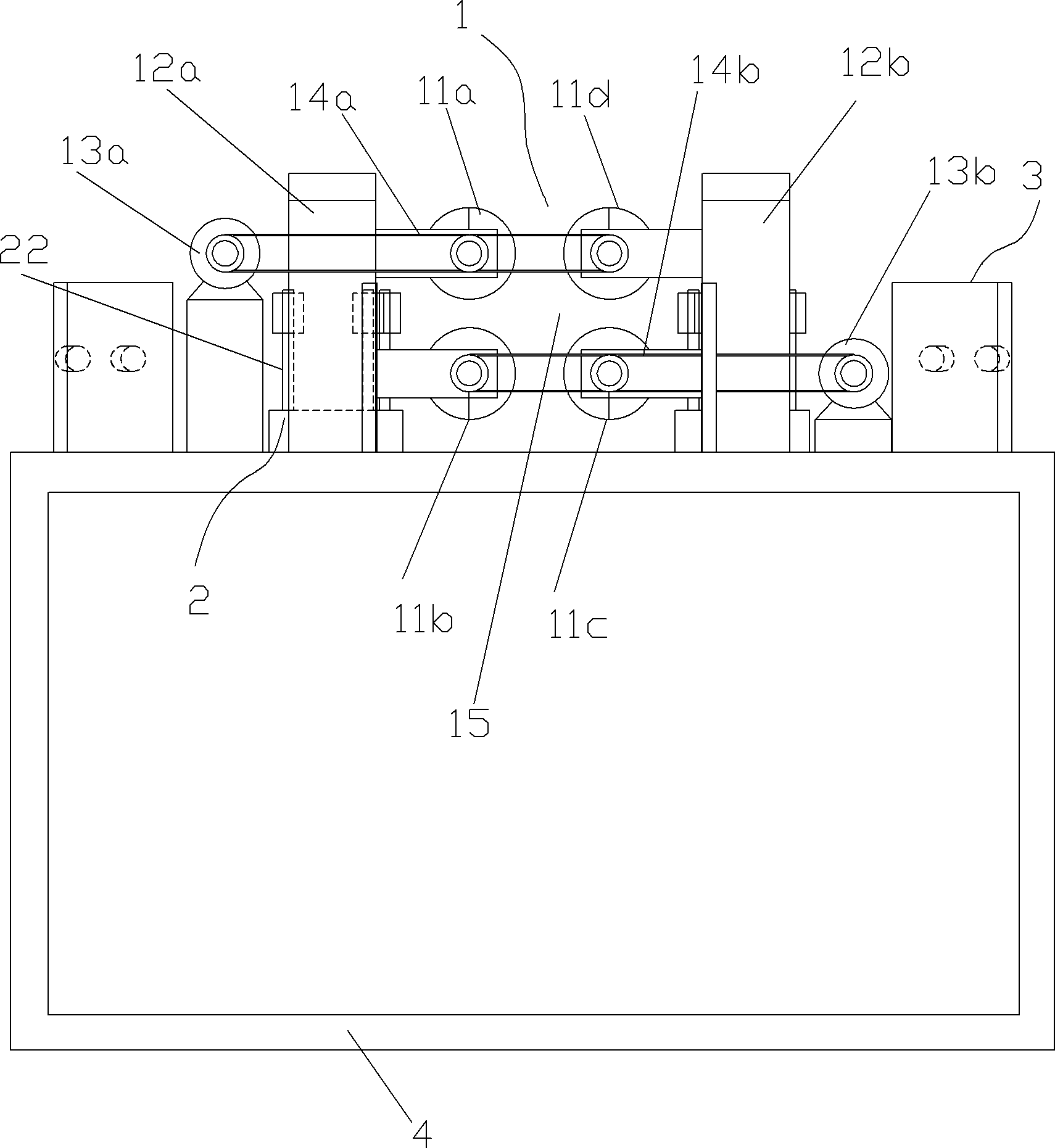

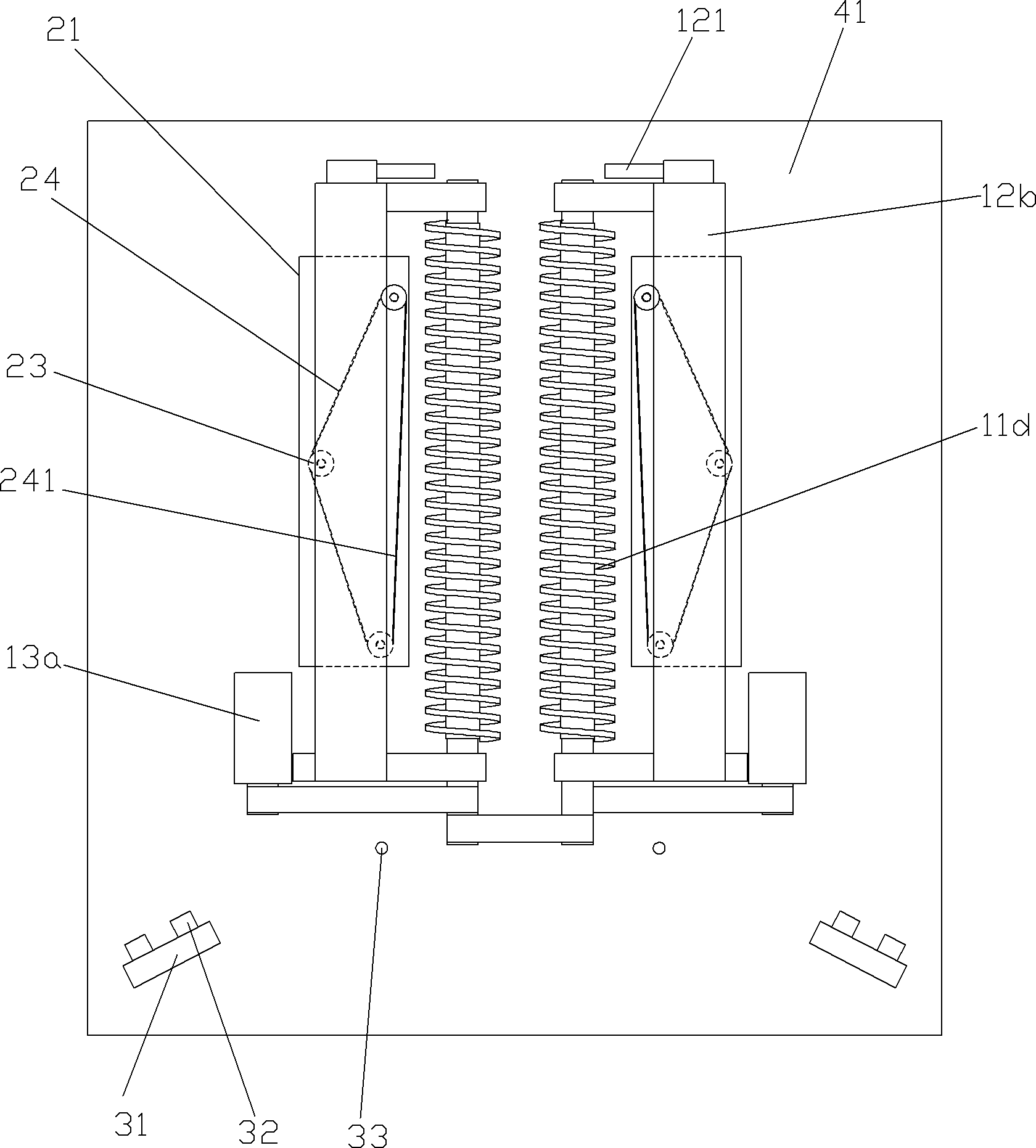

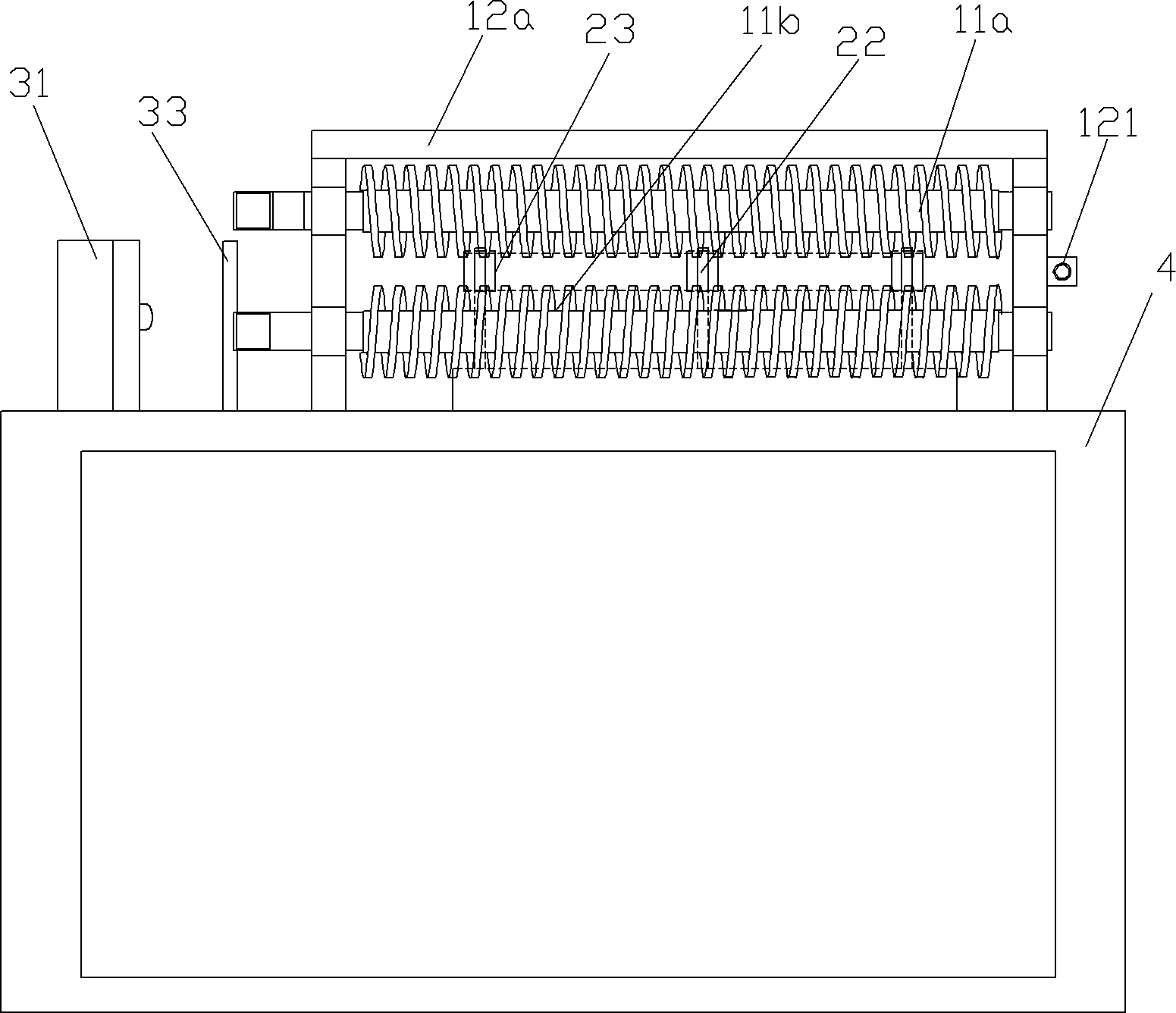

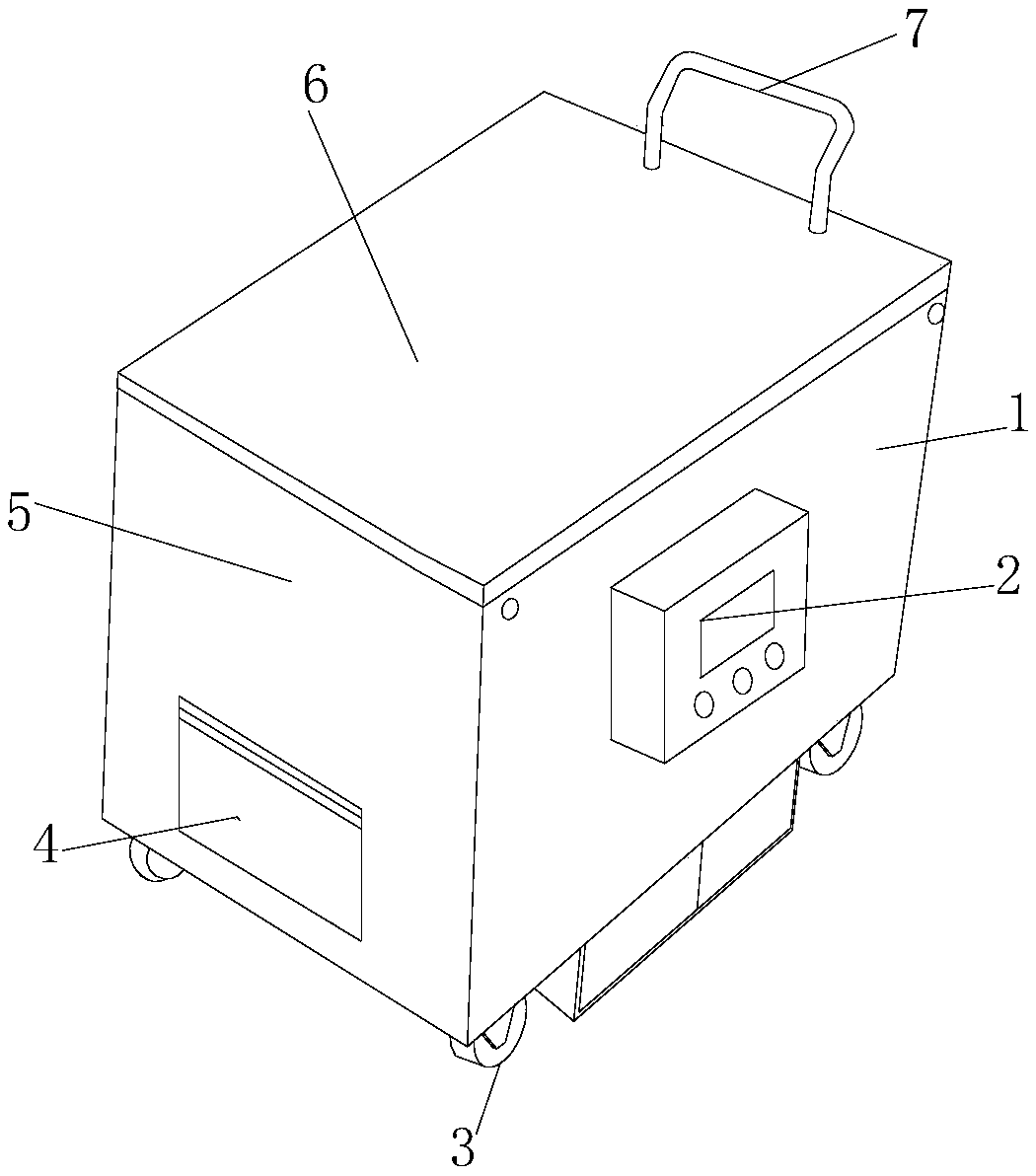

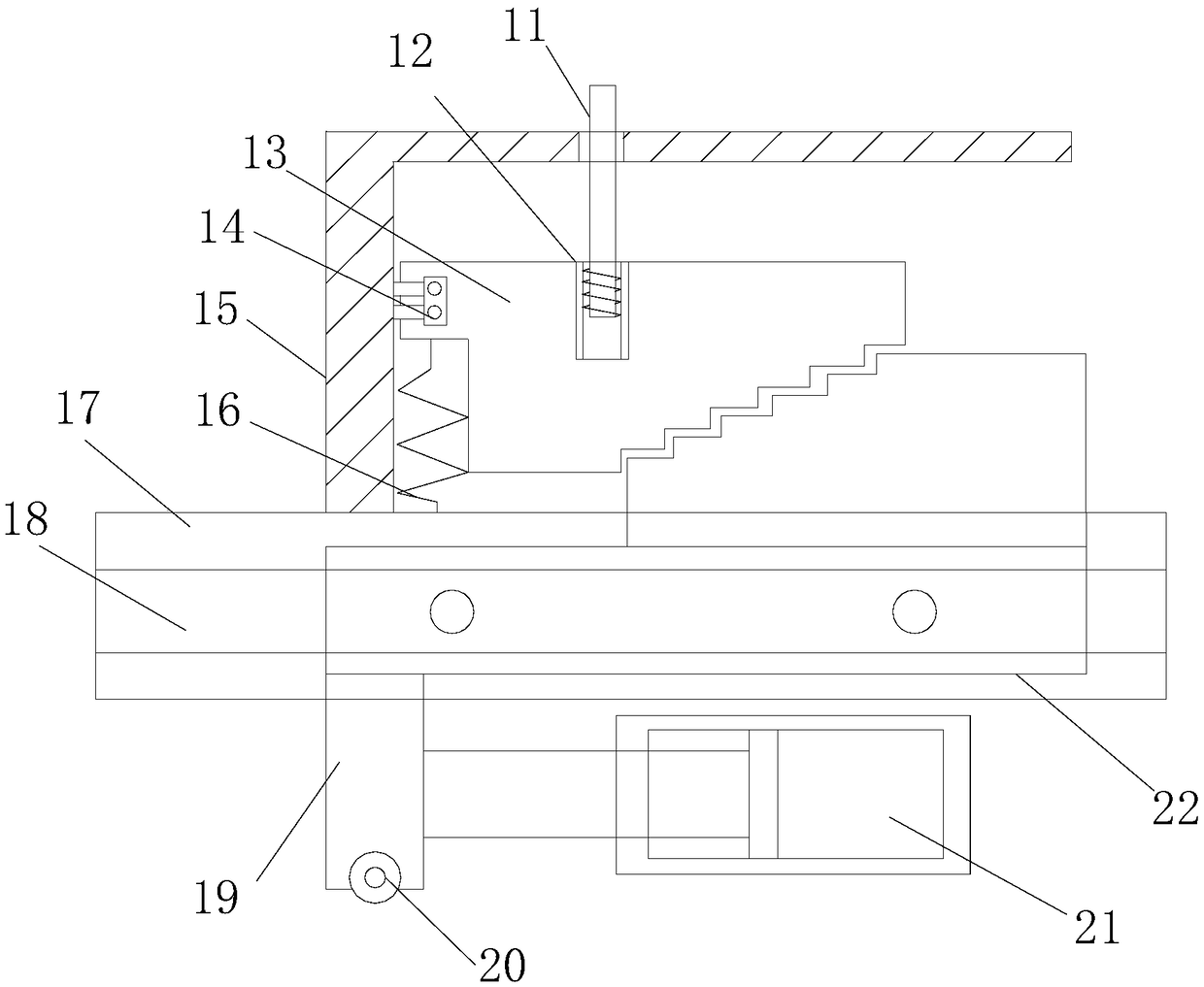

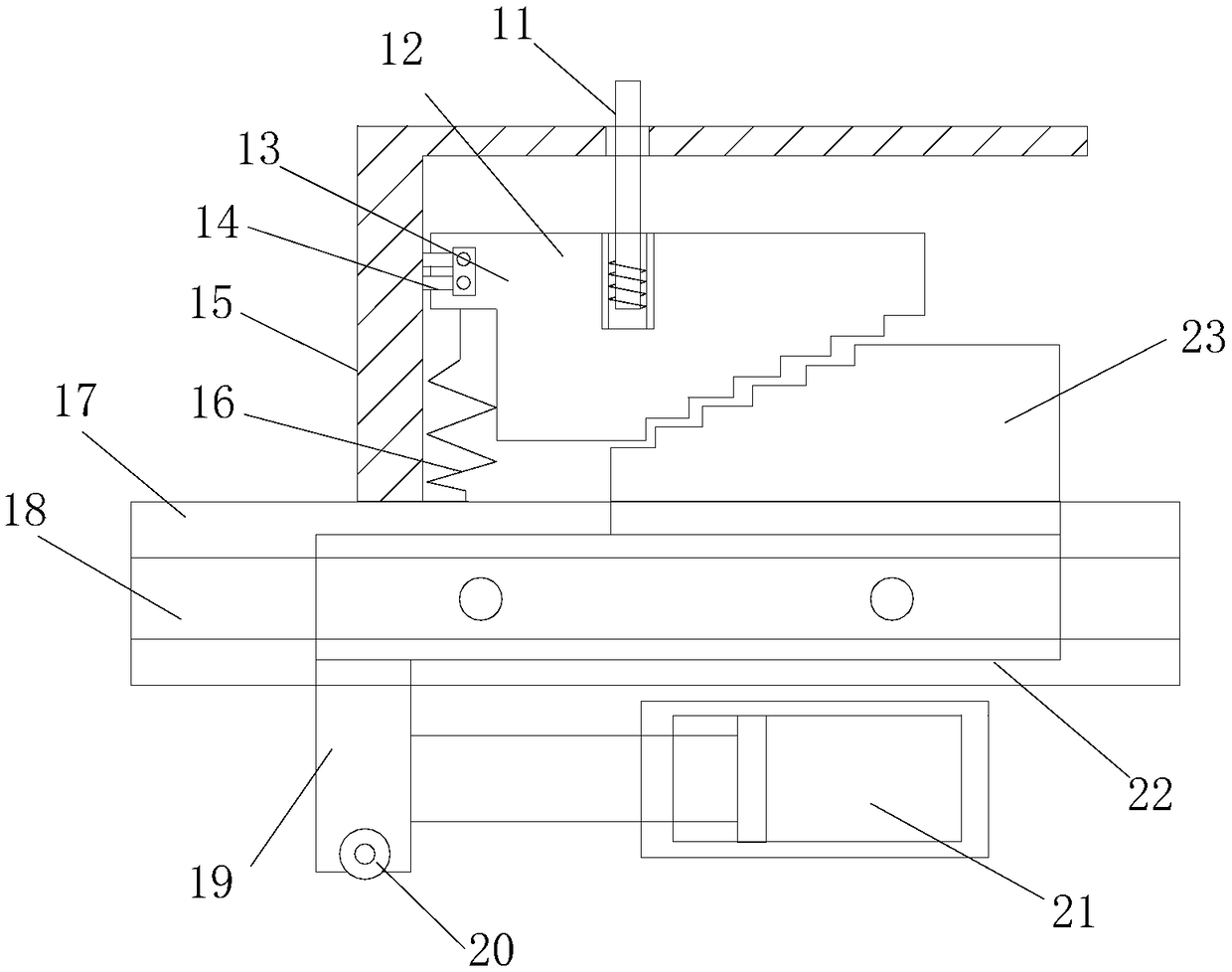

Automatic side-sticking equipment used during filter element production

ActiveCN102553351ALow costTo achieve the purpose of automatic weltingFiltration separationMiddle lineFilter material

The invention relates to automatic side-sticking equipment used during filter element production. The equipment at least comprises a filtering material spiral separating device and a paper tape pressing and sticking device, wherein the filtering material spiral separating device comprises four screw rods of which the radial cross sections are arranged in matrix; in the vertical direction, the two screw rods at the left are arranged on a first bracket, and the two screw rods at the right are arranged on a second bracket; in the horizontal direction, the two screw rods positioned above are synchronously driven by a first motor and a first synchronous driving mechanism, and the two screw rods positioned below are synchronously driven by a second motor and a second synchronous driving mechanism; filtering material passages in the axial direction of the screw rods are formed between the screw rods positioned above and the screw rods positioned below; and belt sections, close to the two sides of the filtering material passages, in the paper tape pressing and sticking device, deflect towards the middle lines of the filtering material passages along the conveying direction. Automatic side sticking between filtering materials and paper tapes is realized through the equipment; and the production efficiency and the accuracy of side sticking are greatly improved.

Owner:东莞市海莎过滤器有限公司 +1

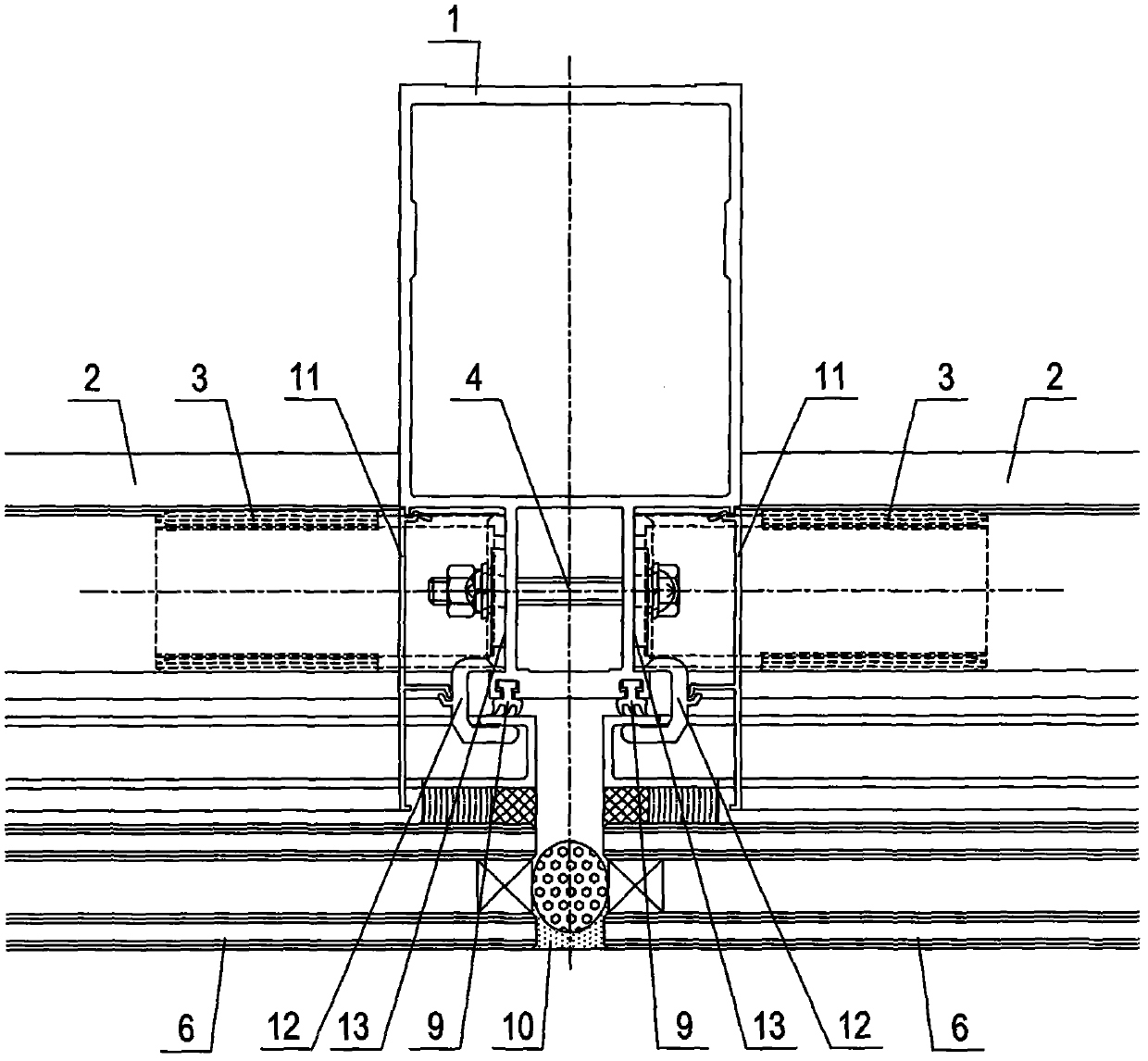

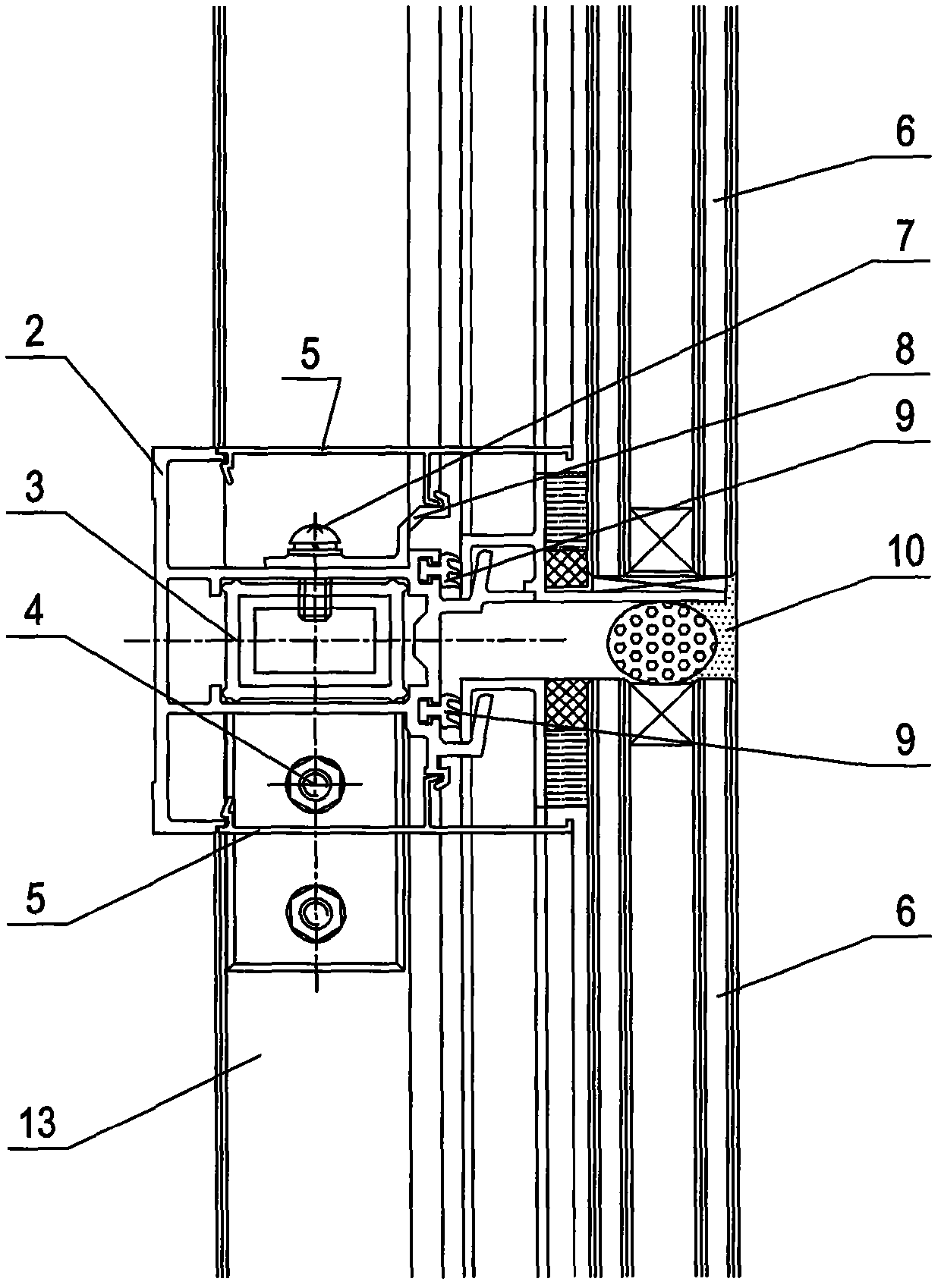

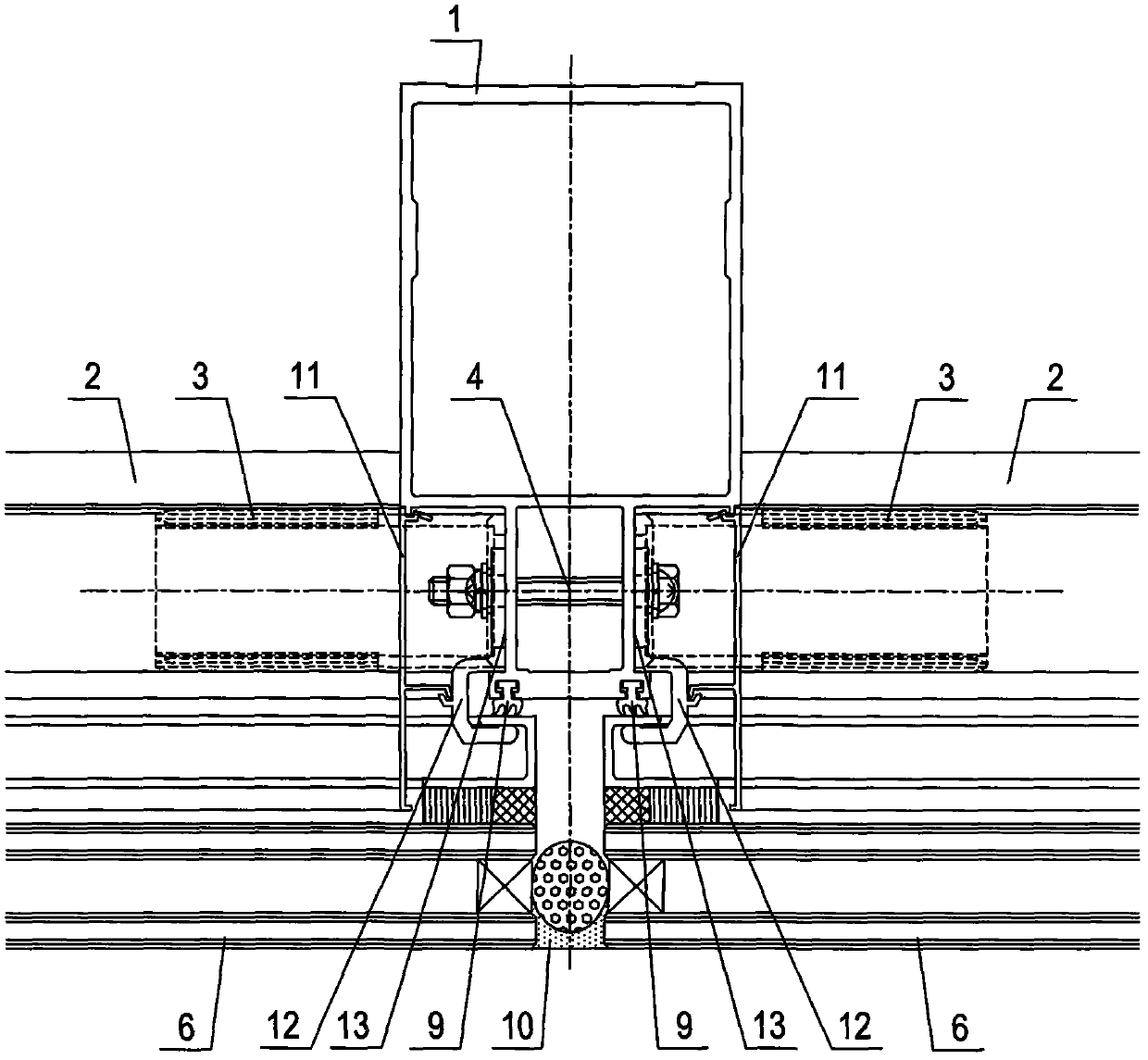

Device used for connecting curtain wall aluminum alloy cross beam with upright

The invention relates to a component type device used for connecting an curtain wall aluminum alloy cross beam with an aluminum alloy upright. The device mainly comprises the aluminum alloy upright, the aluminum alloy cross beam and an aluminum alloy bracket, wherein the aluminum alloy bracket is a right-angled component of which one side is inserted in the rectangular cavity of the aluminum alloy cross beam and the other side closely sticks to the limit groove of the aluminum alloy upright; one side of the the aluminum alloy bracket is the rectangular cavity which has two triangular edges on each of four sides; the head of the inserted side of the aluminum alloy bracket is a cone with a guiding function; and the other side sticking to the aluminum alloy upright is a flat rectangular hexahedron. The device of the invention has simple, compact and reasonable structure; and under the guidance of the cone with the guiding function, the aluminum alloy bracket can be conveniently inserted in the cavity of the aluminum alloy cross beam, then the aluminum alloy bracket is placed against the aluminum alloy upright and finally the cross beam is arranged on the upright by screwing up two bolts. The device is suitable for various component type curtain wall systems such as hidden frame curtain walls, semi-hidden frame curtain walls and exposed frame curtain walls.

Owner:无锡恒发幕墙工程有限公司

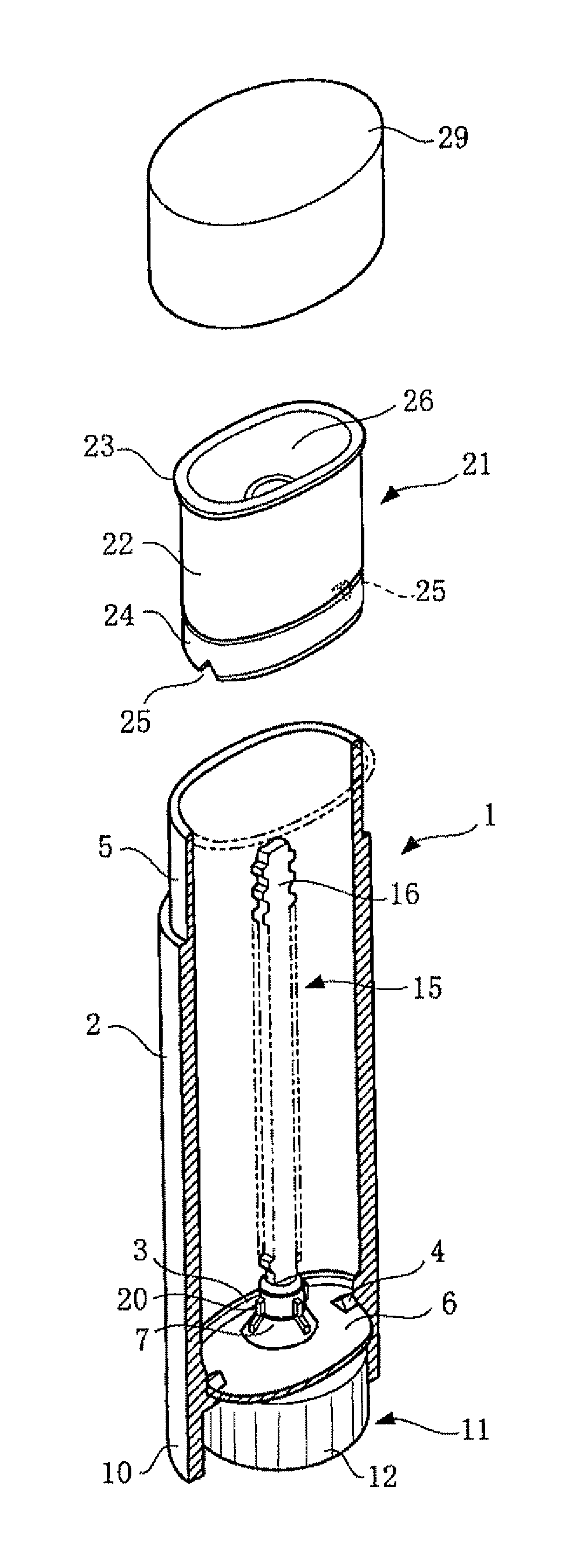

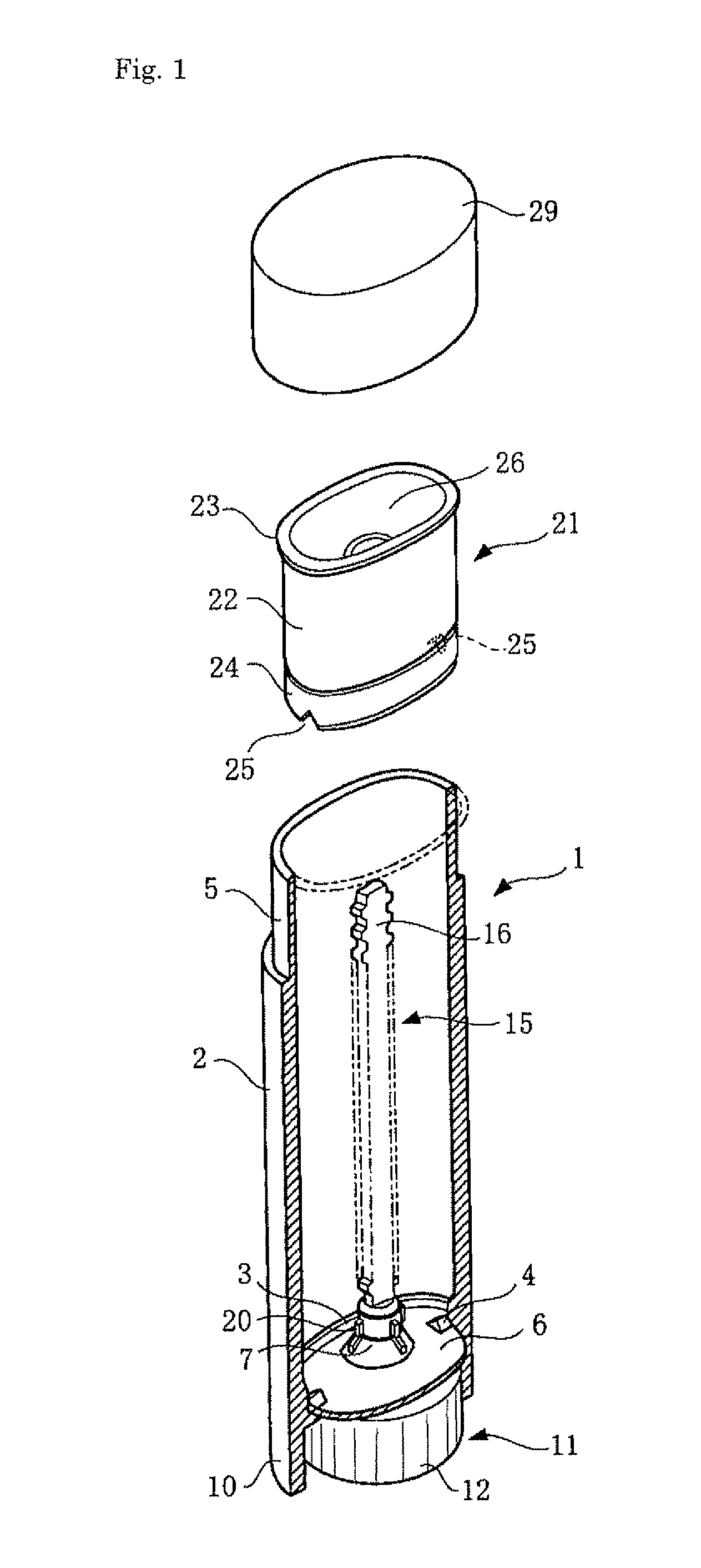

Twistable container for elevating a solid stick

InactiveUS8727651B2Reliable and stable sealLiquid surface applicatorsDispensing apparatusEngineeringStorage tube

An elevating container includes an elliptically shaped main tube, a non-circularly shaped moveable support unit which moves upwardly or downwardly along an inner surface of a storage tube of the main tube without rotating, and a driving unit fitted to the main tube to rotate in threaded engagement to the support unit without moving upwardly or downwardly. A seal section at the lower end of the inner peripheral surface of the storage tube and a sealing cylinder at the lower end of the support unit are air-tightly fitted to each other. In addition, positioning ribs are provided at the lower end of the storage tube, and positioning notches are provided at the lower end of the moveable support unit. When the positioning ribs and the positioning notches are engaged with each other, a circumferential misalignment between the main tube and the support unit is corrected.

Owner:ROHTO PHARM CO LTD +1

Contactor, contact structure provided with contactors, probe card, test apparatus, method of production of contact structure, and production apparatus of contact structure

InactiveUS7764152B2Avoid contactSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsContact padProbe card

A probe card having a plurality of silicon finger contactors contacting pads provided on a tested semiconductor wafer and a probe board mounting the plurality of silicon finger contactors on its surface, wherein each silicon finger contactor has a base part on which a step difference is formed, a support part with a rear end side provided at the base part and with a front end side sticking out from the base part, and a conductive part formed on the surface of the support part, each silicon finger contactor mounted on the probe board so that an angle part of the step difference formed on the base part contacts the surface of the probe board.

Owner:ADVANTEST CORP

Flying control device for a rotorcraft

ActiveUS20070235593A1Improve ergonomicsReduce weightManual control with multiple controlled membersActuated personallyFly controlFlight vehicle

The invention relates to a rotorcraft cockpit having a left seat and a right seat placed side-by-side, a console extending between the seats, two side sticks, one situated to the right of the right seat and the other situated to the left of the left seat, enabling the pilot to control roll and pitch; a flight control system comprising sensors associated with the side sticks and a computer connected to the sensors serves to convert the orders applied by the pilot to the side sticks into signals for controlling actuators in order to vary roll and pitch; a piloting relationship integrated in the computer stabilizes the response of the rotorcraft in roll and in pitch when a side stick is actuated, and maintains the attitudes in roll and pitch at reference values when neither side stick is actuated.

Owner:EUROCOPTER

Cockpit seat armrest avionics cursor control device

InactiveUS20160368593A1Stable supportEasy to reachVehicle seatsSeating arrangementsAviationFeature set

The invention concerns an improved CCD integration within pilot seat armrests, with benefits including ease and accuracy of CCD use, premium space savings on cockpit consoles, the ability to be retracted when not in use, always remaining within comfortable and easy reach of tall and short pilots alike and not interfering with other devices such as “side-stick” flight controls. The compactness and accuracy of use of the invention, its ability to be stowed, and its space-saving features set this CCD apart from existing CCDs and improve cockpit structure and pilot operation of aircraft that employ this invention.

Owner:AERION INTPROP MANAGEMENT CORP

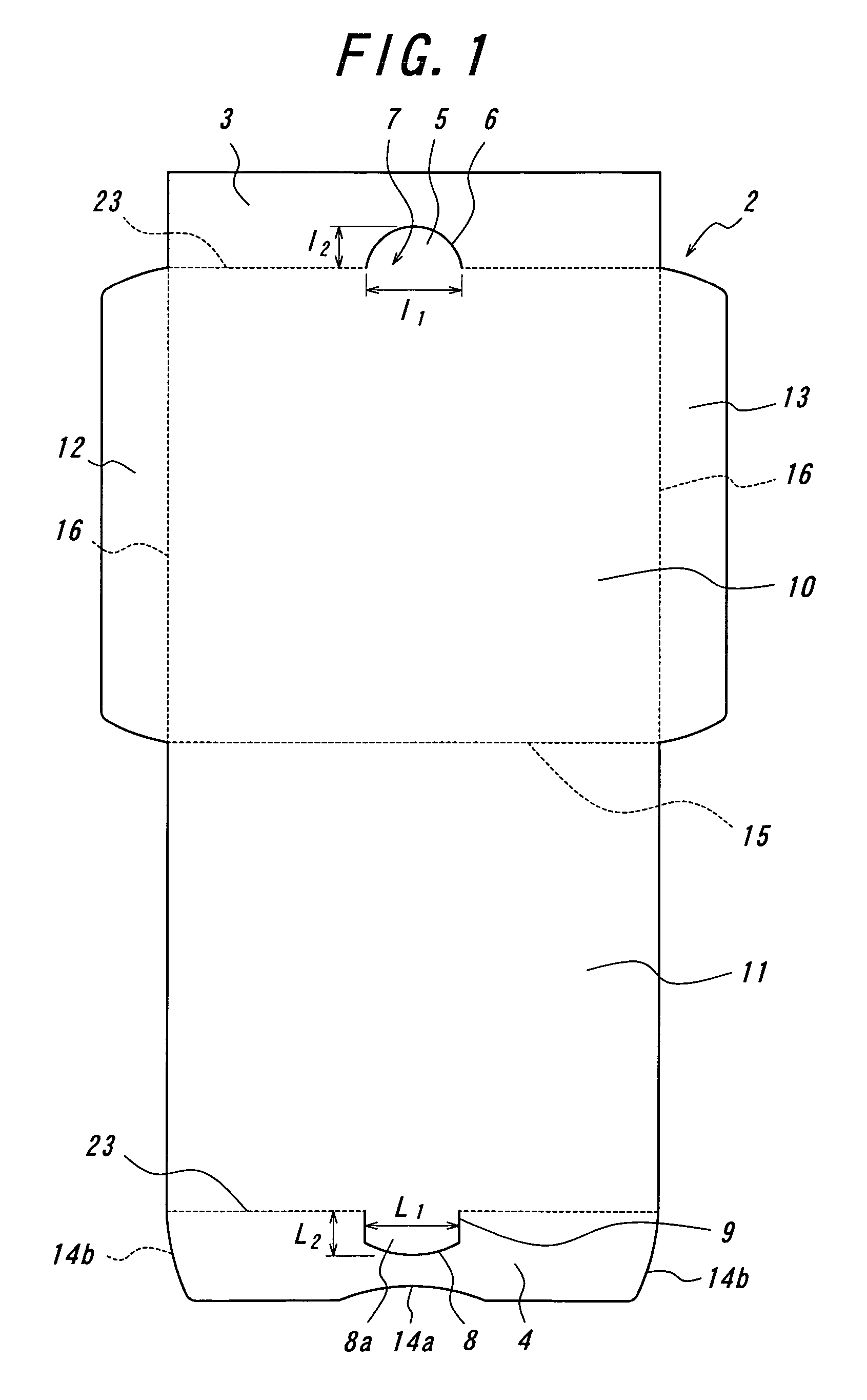

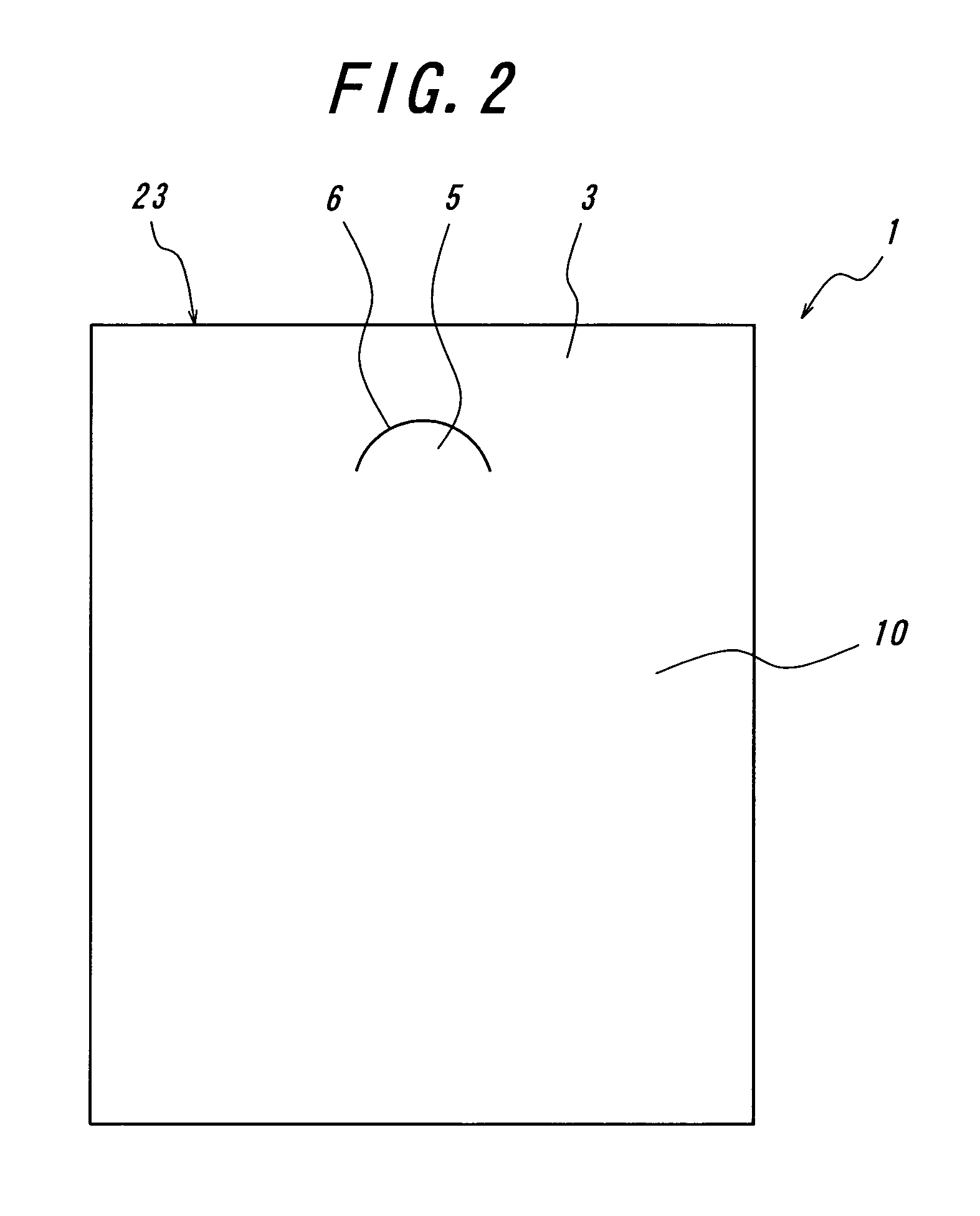

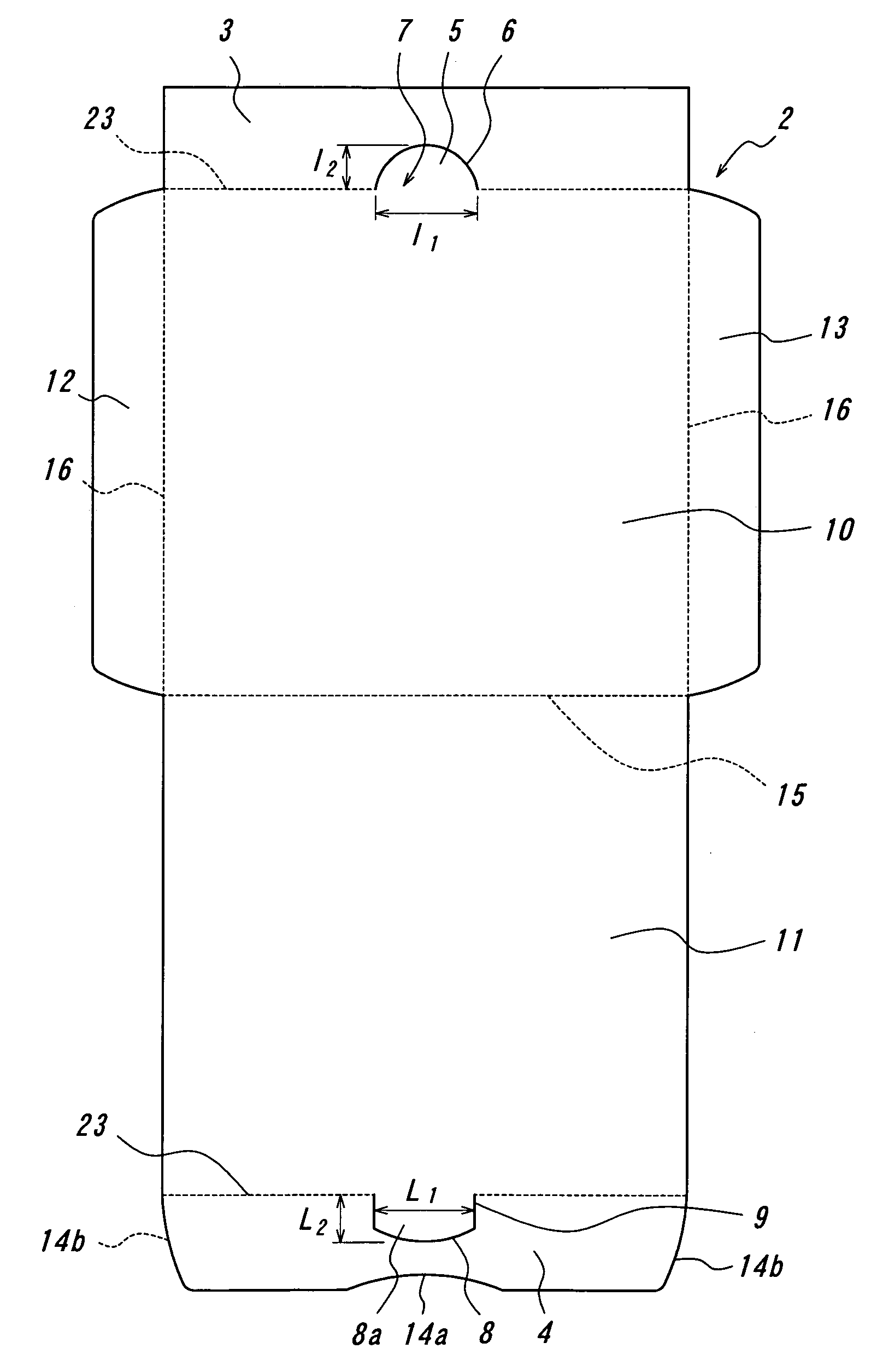

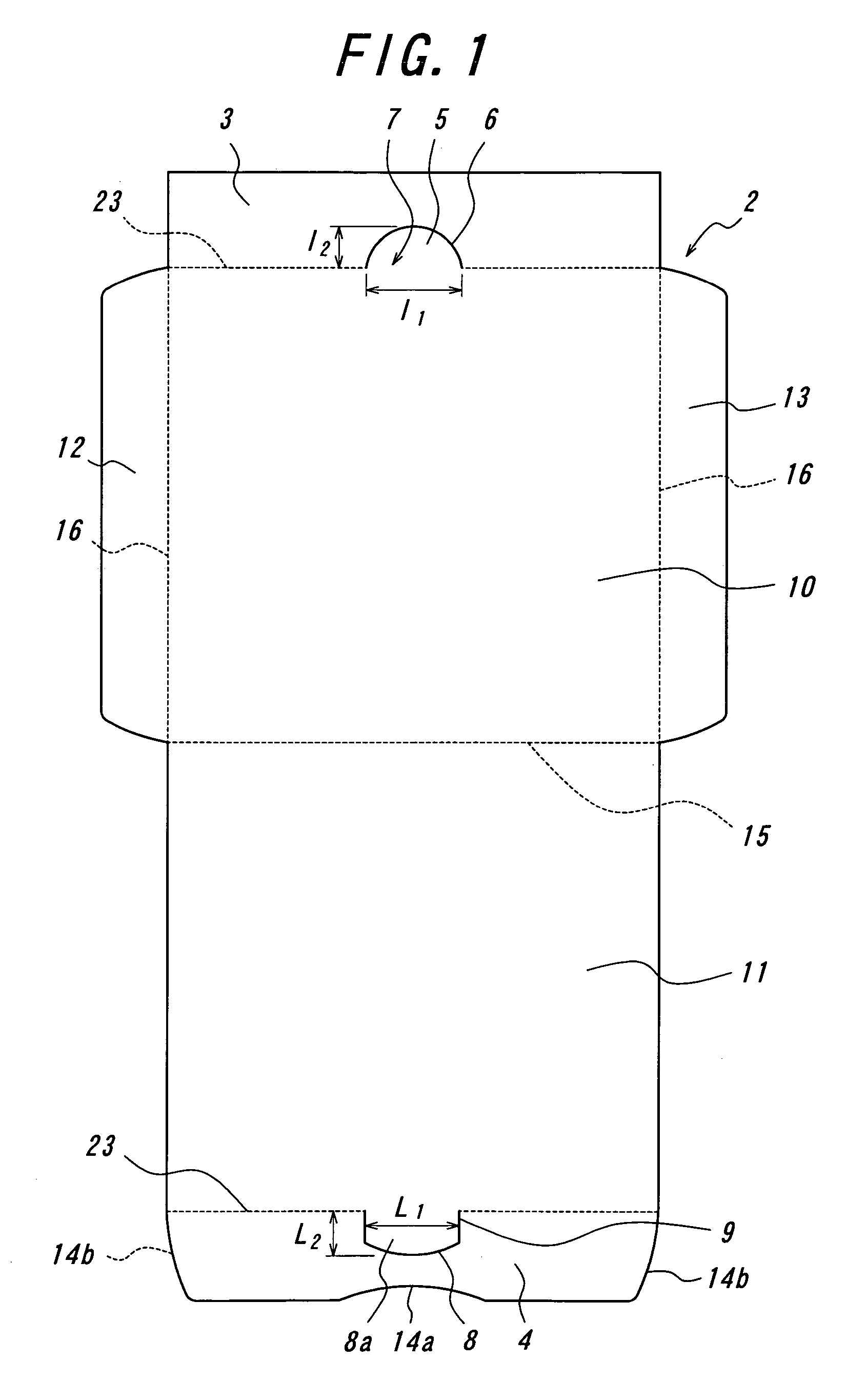

File wrapper for wrapping

InactiveUS7780001B2Reduce impactSimple processEnvelopesRecord information storagePulp and paper industrySlip sheet

A file wrapper for wrapping is provided. The file wrapper for wrapping comprises a file wrapper for wrapping comprising: a the cutting body, which comprises a unit piece of a covering paper and a backing paper of integral constitution that is bent to form a bag shape, sealing pieces provided to the covering paper and the backing paper, at the opening portion of the bag shape for inserting commodities, respectively, and side sticking pieces provided to the both sides portion of the covering paper. The one sealing piece is provided with a stopper of commodities after inserting them, and the other sealing piece is provided with the connecting piece inserted in the notch hole of the stopper and engaged thereto.

Owner:DAINICHI PRINTING

File wrapper for wrapping

InactiveUS20060108404A1Sufficiently fixedReduce loadEnvelopesRecord information storageSlip sheetPulp and paper industry

A file wrapper for wrapping is provided. The file wrapper for wrapping comprises a file wrapper for wrapping comprising: a die cutting body, which comprises a unit piece of a covering paper and a backing paper of integral constitution that is bent to form a bag shape, sealing pieces provided to the covering paper and the backing paper, at the opening portion of the bag shape for inserting commodities, respectively, and side sticking pieces provided to the both sides portion of the covering paper. The one sealing piece is provided with a stopper of commodities after inserting them, and the other sealing piece is provided with the connecting piece inserted in the notch hole of the stopper and engaged thereto.

Owner:DAINICHI PRINTING

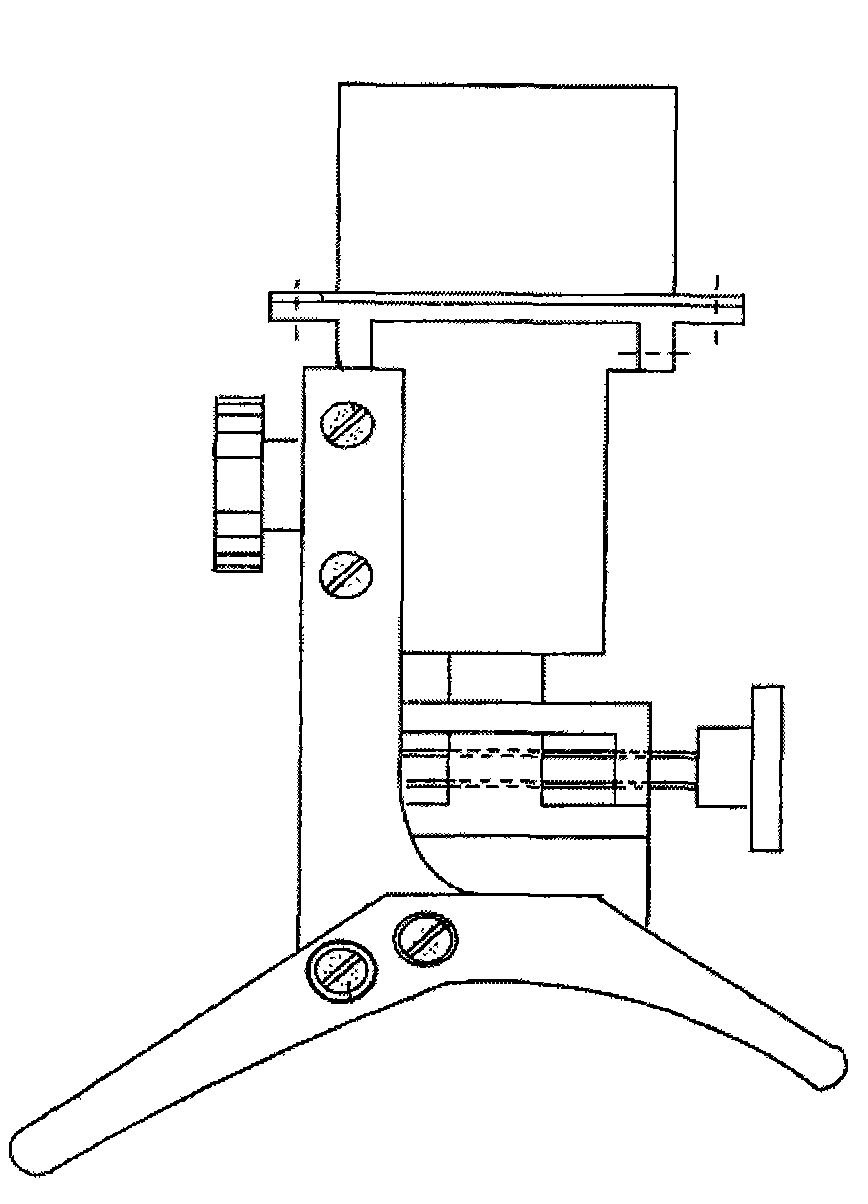

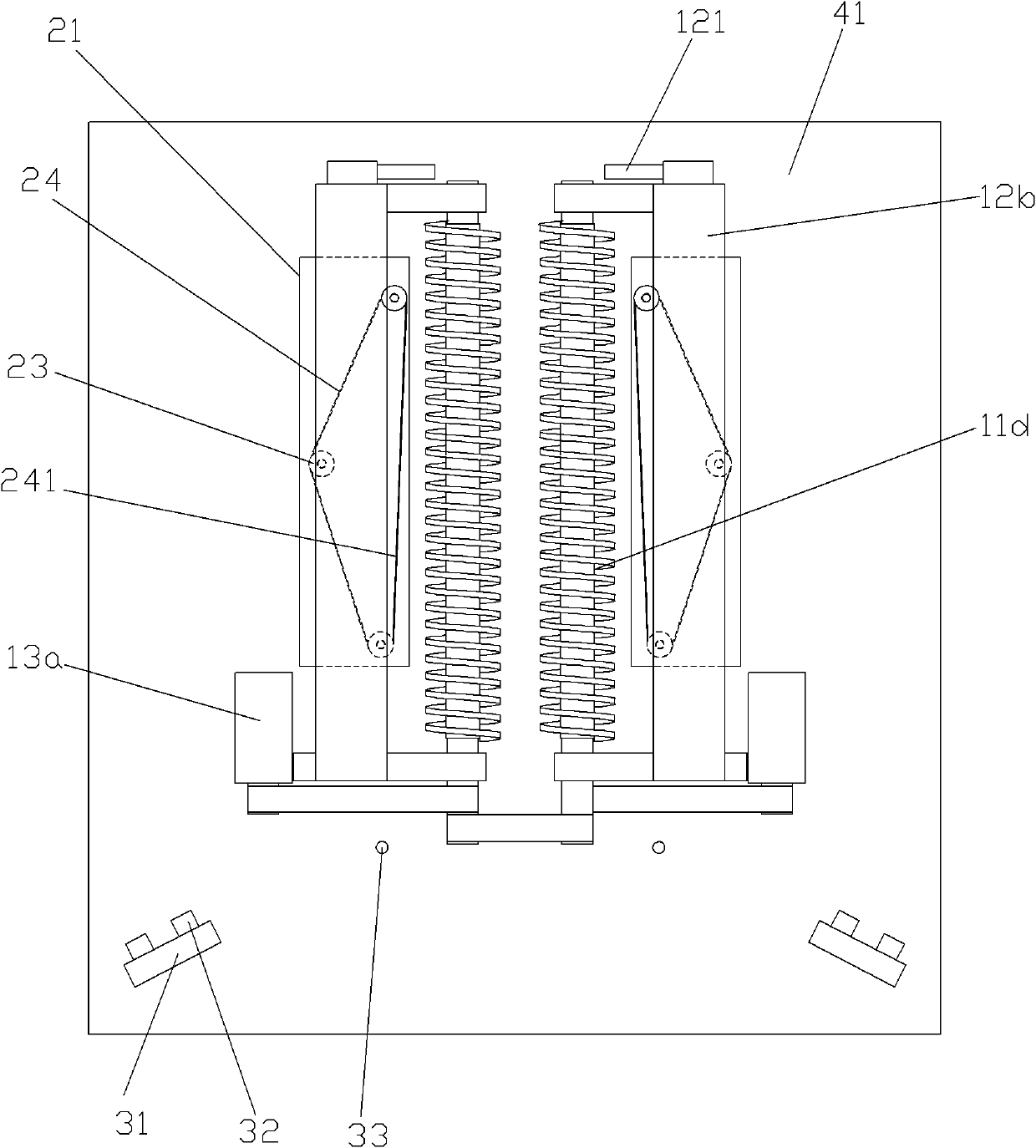

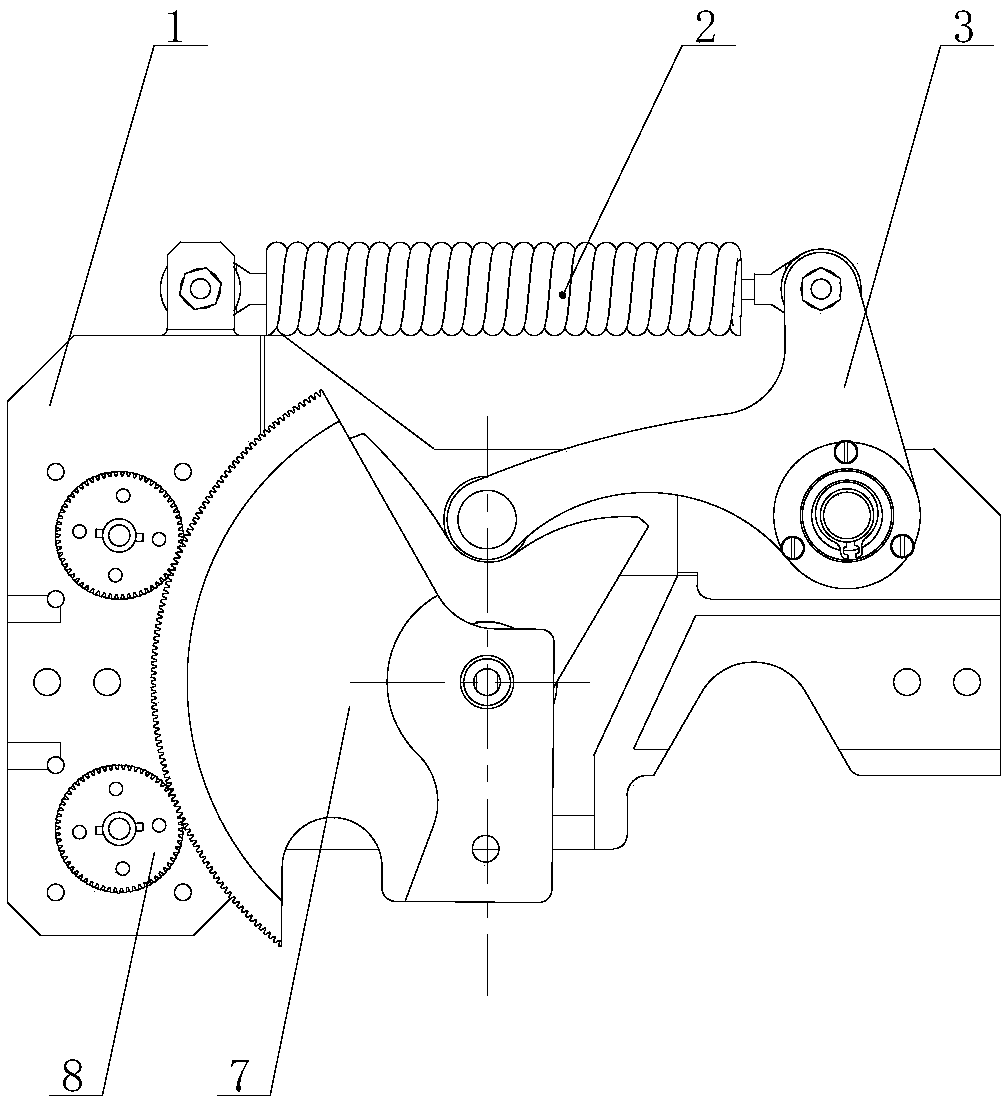

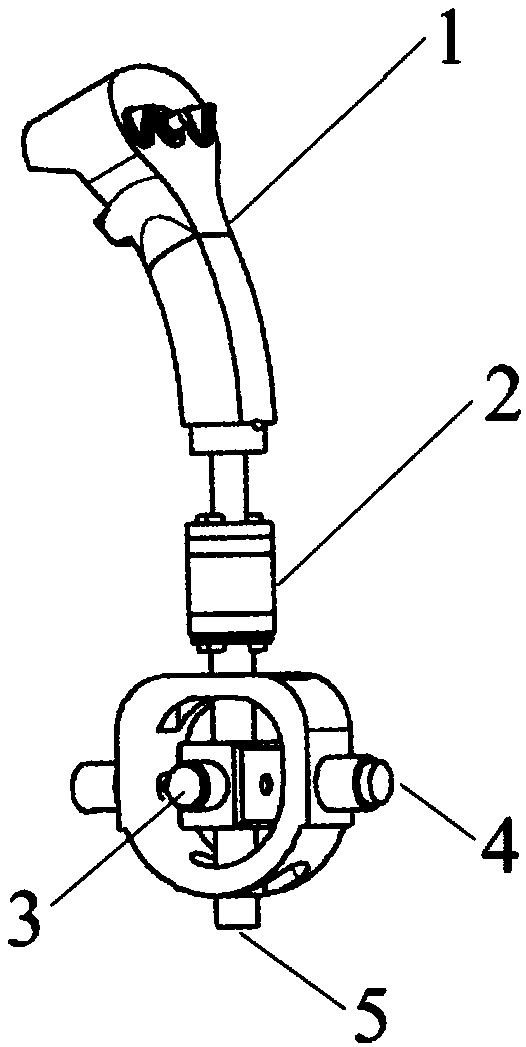

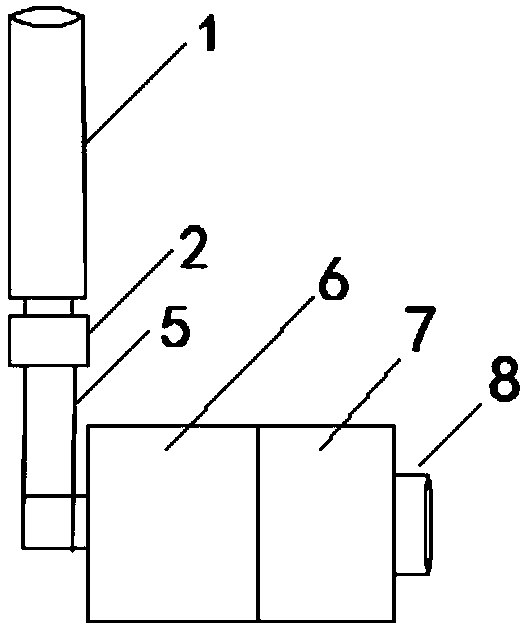

Fly-by-wire airplane side stick operating mechanism

ActiveCN107719643ABreak through the technical bottleneck of single force sense and small-range adjustmentImprove handling comfortWith power amplificationActuated personallyFly-by-wireTension compression

The invention belongs to the field of airplane control system design, and more specifically relates to a fly-by-wire airplane side stick operating mechanism. The fly-by-wire airplane side stick operating mechanism comprises a force feedback device. According to conventional fly-by-wire airplane side stick operating mechanisms, side stick operating is realized via design of a spring loading mechanism between moving parts and a housing, and through cooperation of a spacing mechanism. The disadvantages are that: the profile is long, the size is large, the weight is difficult to reduce, the tension compression symmetry is limited, and generation and broad width adjusting of bidirectional different force sense are impossible to realize. The invention provides a fly-by-wire airplane side stick operating force feedback device which is used for generation and adjusting of fly-by-wire airplane side stick operating artificial sense force. Forward rotating or backward rotating of a rocker arm rotating shaft driven by a pilot control handle are both capable of driving springs to stretch, the larger the rotating angle stroke, the higher the spring stretching degree, and the larger the force sense, so that generation of bidirectional artificial sense force is realize.

Owner:LANZHOU FLIGHT CONTROL

Electronic door lock

InactiveCN104929444AImprove securityNon-mechanical controlsElectric permutation locksPasswordElectric machinery

The invention relates to an electronic door lock. The electronic door lock comprises a door leaf or window sash, a door or window frame and an electronic lock head, the electronic lock head is installed on the door leaf or the window sash and inside a side stick of the door leaf or the side stick of the window sash in a clamped mode and corresponds to an groove in the door leaf or the window sash; the electronic lock head comprises a lock head body, a motor, a controller, a vibration sensor and a battery, the lock head body is connected with the motor, and the motor and the vibration sensor are connected with the battery through the controller; the vibration sensor is installed inside the door leaf or the window sash, and according to comparison results between vibration sensor detected signals and password signals stored in the controller, the controller starts the forward and backward rotation of the motor. According to the electronic door lock, the controller detects the vibration sensor detected signals and starts the forward and backward rotation of the motor, thereby the door lock is unlocked, no key or card exists, so that no loss occurs, the door lock is installed inside the side stick of the door leaf or the side stick of the window sash, no key hole exists, the door lock is entirely located in a hidden place, the safety is higher, and one more protection means is added to a family.

Owner:GUANGXI UNIV

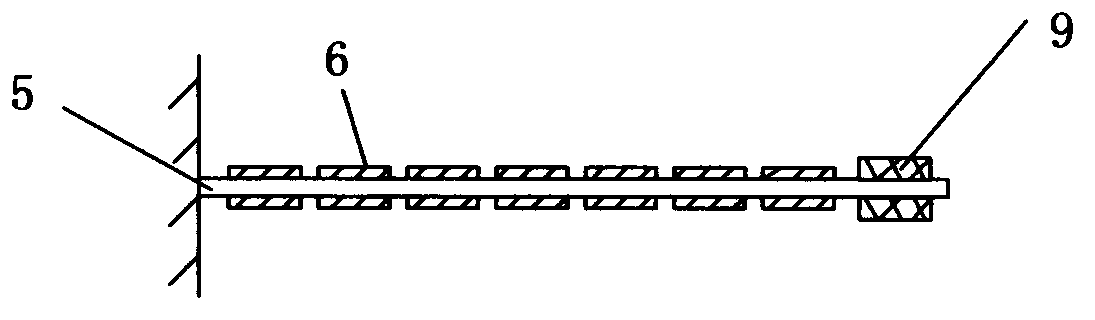

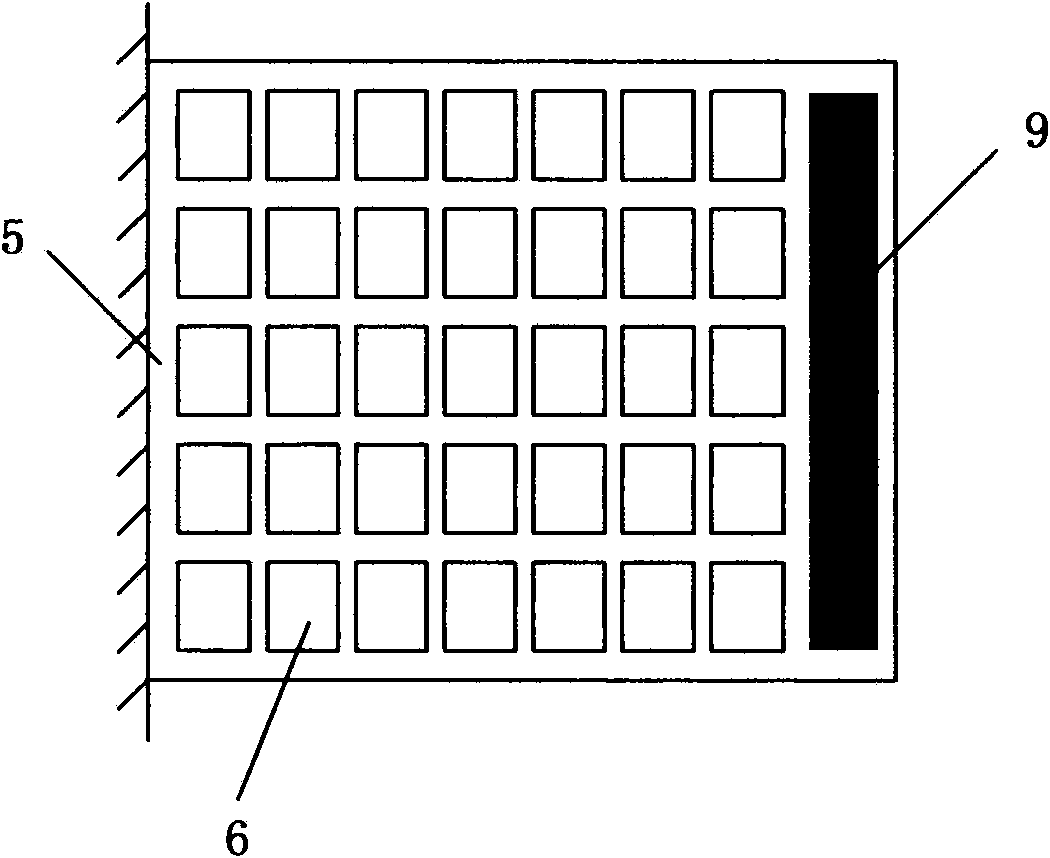

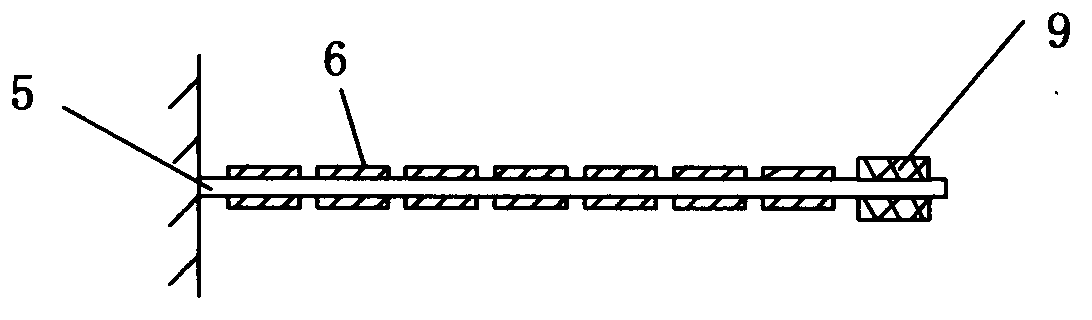

Broadband piezoelectric generating device

The invention discloses a broadband piezoelectric generating device. A plurality of cantilever plates with two sides stuck with a plurality of piezoelectric elements are combined together; one end of each cantilever plate is fixed and the other end of each cantilever plate is free; and the different cantilever plates are kept in parallel. As the structural sizes of the cantilever plates are different, the bending resonance frequencies of the cantilever plates are also different. The combined type piezoelectric generating device can convert the mechanical vibration energy of a certain frequency range of an environment into electric energy so as to realize broadband power generating; and as the energy of the plurality of piezoelectric elements is collected, the power generating capacity is larger and the power generating efficiency is higher.

Owner:扬州博达电气设备有限公司

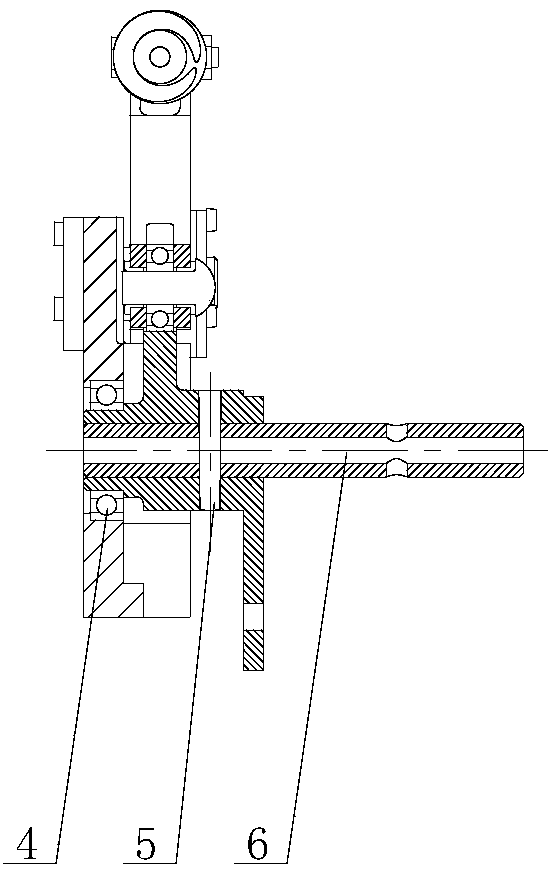

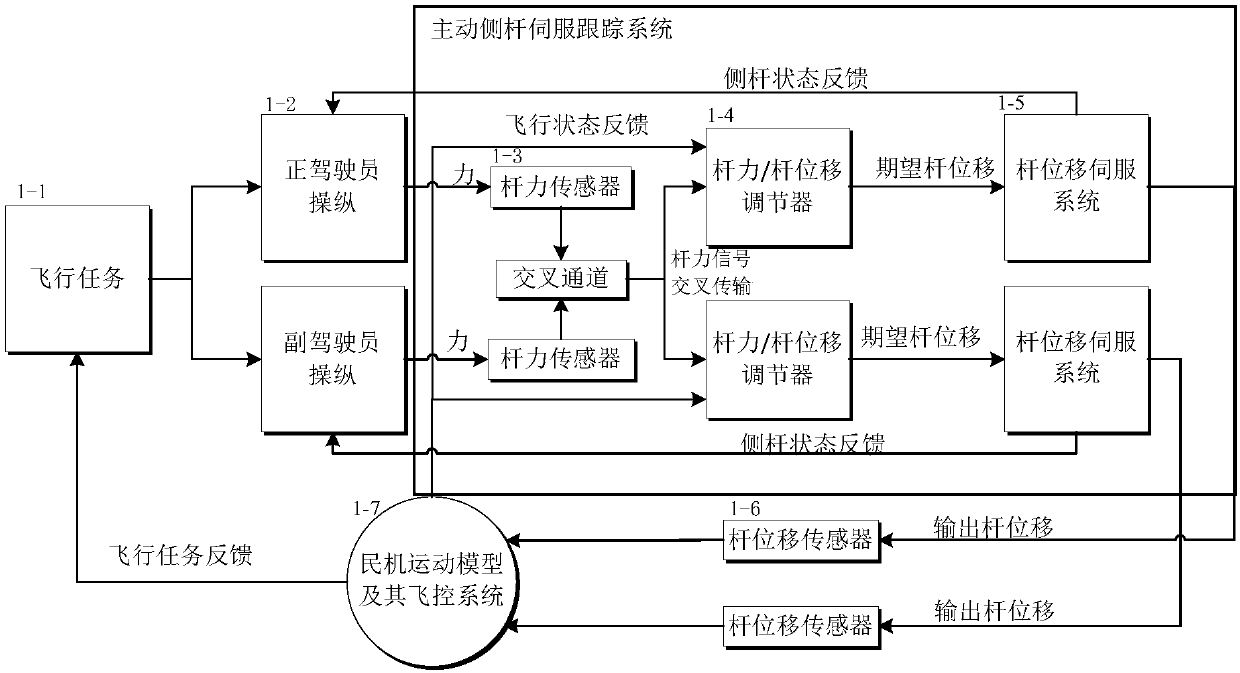

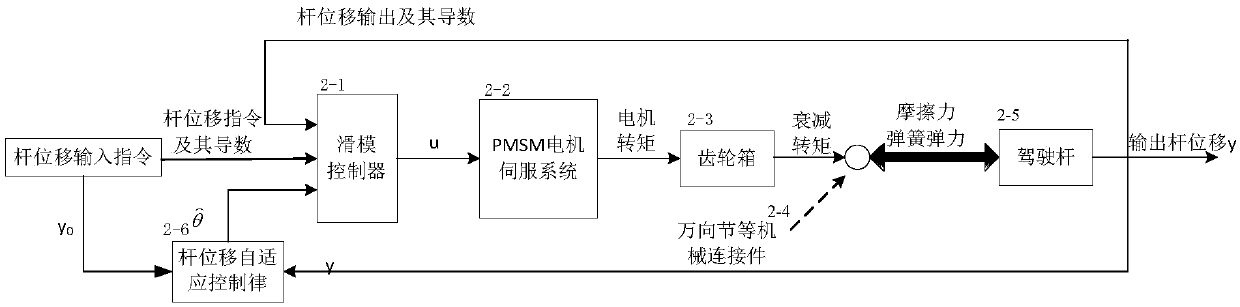

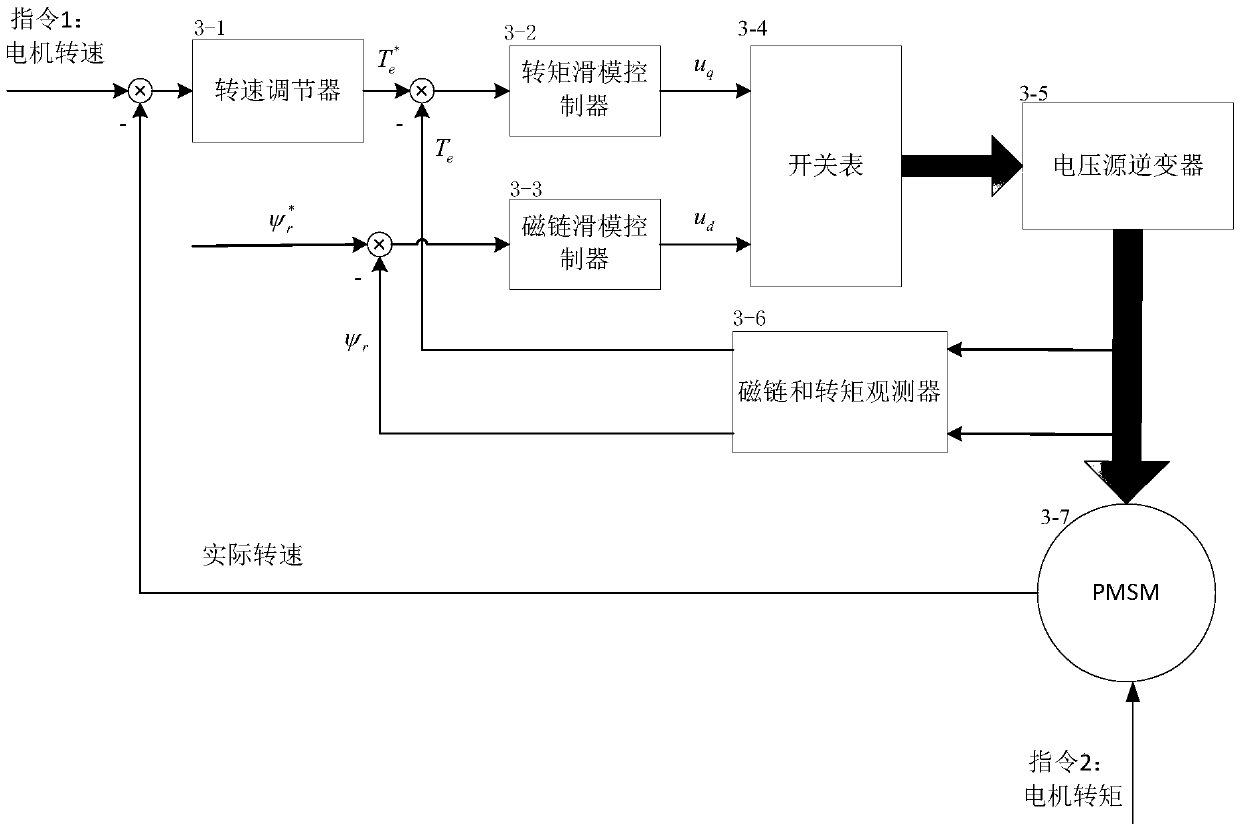

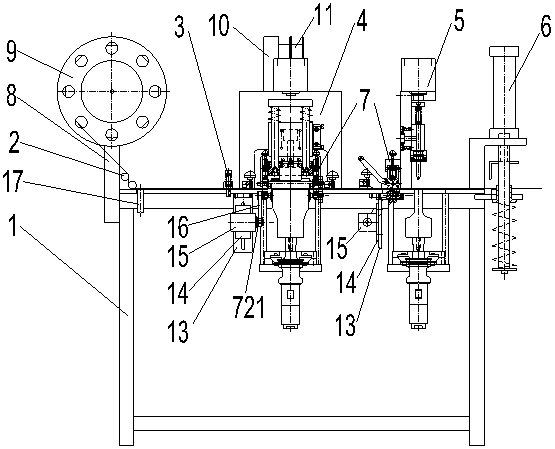

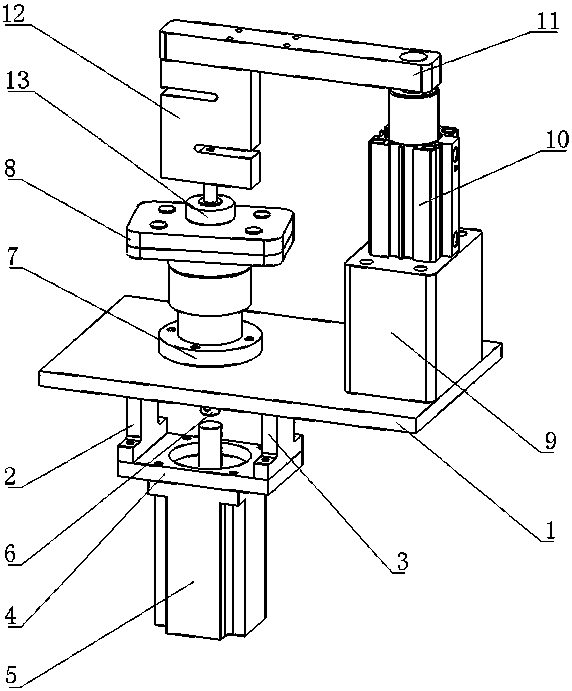

Civil aircraft man-in-loop system, and active side stick servo tracking control system and method

ActiveCN108873919AImplement lever force feedbackRealize Rod Displacement TrackingAttitude controlPosition/course control in three dimensionsVariable stiffnessControl system

The present invention provides an active side stick servo tracking control system. The active side stick servo tracking control system comprises a stick force sensor and cross channel transmission part, a stick force and stick displacement regulator, an active side stick displacement servo system, and a stick displacement sensor. The active side stick displacement servo system comprises a motor rotation speed feedback loop, a motor flux linkage and torque feedback loop, a holding rod angular speed feedback loop and a position feedback loop. The present invention provides a civil aircraft man-in-loop system with an active side stick and a servo control method of the active side stick servo tracking control system. Through integration of sliding-mode control and self-adaptation control, thecivil aircraft man-in-loop system, and the active side stick servo tracking control system and method can effectively achieve high-dynamic tracking performance of the side stick displacement and adaptive performance of spring variable stiffness so as to have active reference meaning for the large civil aircraft active side stick control.

Owner:SHANGHAI JIAO TONG UNIV

Blanket binding and sticking band ultrasonic welding machine

The invention discloses a blanket binding and sticking band ultrasonic welding machine. The machine comprises a working cabinet; band passing wheels, a pressing mechanism, a sticking band side sticking and cutting mechanism, a main band forward fixed-length feeding and cutting mechanism and a collecting mechanism are arranged on the surface of the working cabinet in transverse axial position in sequence; the sticking band side sticking and cutting mechanism and the main band forward fixed-length feeding and cutting mechanism are provided with band pressing and feeding mechanisms on feed sides;the band pressing and feeding mechanisms are connected with the surface of the working cabinet through left and right fixed frames; the band passing wheels are arranged on the feed side of the sticking band side sticking and cutting mechanism; support frames are arranged on feed sides of the band passing wheels; and band spools are connected through the support frames. Compared with the prior art, the blanket binding and sticking band ultrasonic welding machine replaces manual operations by automatic feeding, pressing and collection through the band passing wheels, the pressing mechanism, thesticking band side sticking and cutting mechanism, the main band forward fixed-length feeding and cutting mechanism and the collecting mechanism, improves the working efficiency, and improves the product quality.

Owner:南通国派纺织品有限责任公司

Array type piezoelectric generating device

The invention discloses an array type piezoelectric generating device. A plurality of cantilever plates with two sides stuck with a plurality of piezoelectric elements are combined together; one end of each cantilever plate is fixed and the other end of each cantilever plate is free; and the different cantilever plates are kept in parallel. As the structural sizes of the cantilever plates are different, the bending resonance frequencies of the cantilever plates are also different. The combined type piezoelectric generating device can convert the mechanical vibration energy of a certain frequency range of an environment into electric energy so as to realize broadband power generating; and as the energy of the plurality of piezoelectric elements is collected, the power generating capacity is larger and the power generating efficiency is higher.

Owner:扬州博达电气设备有限公司

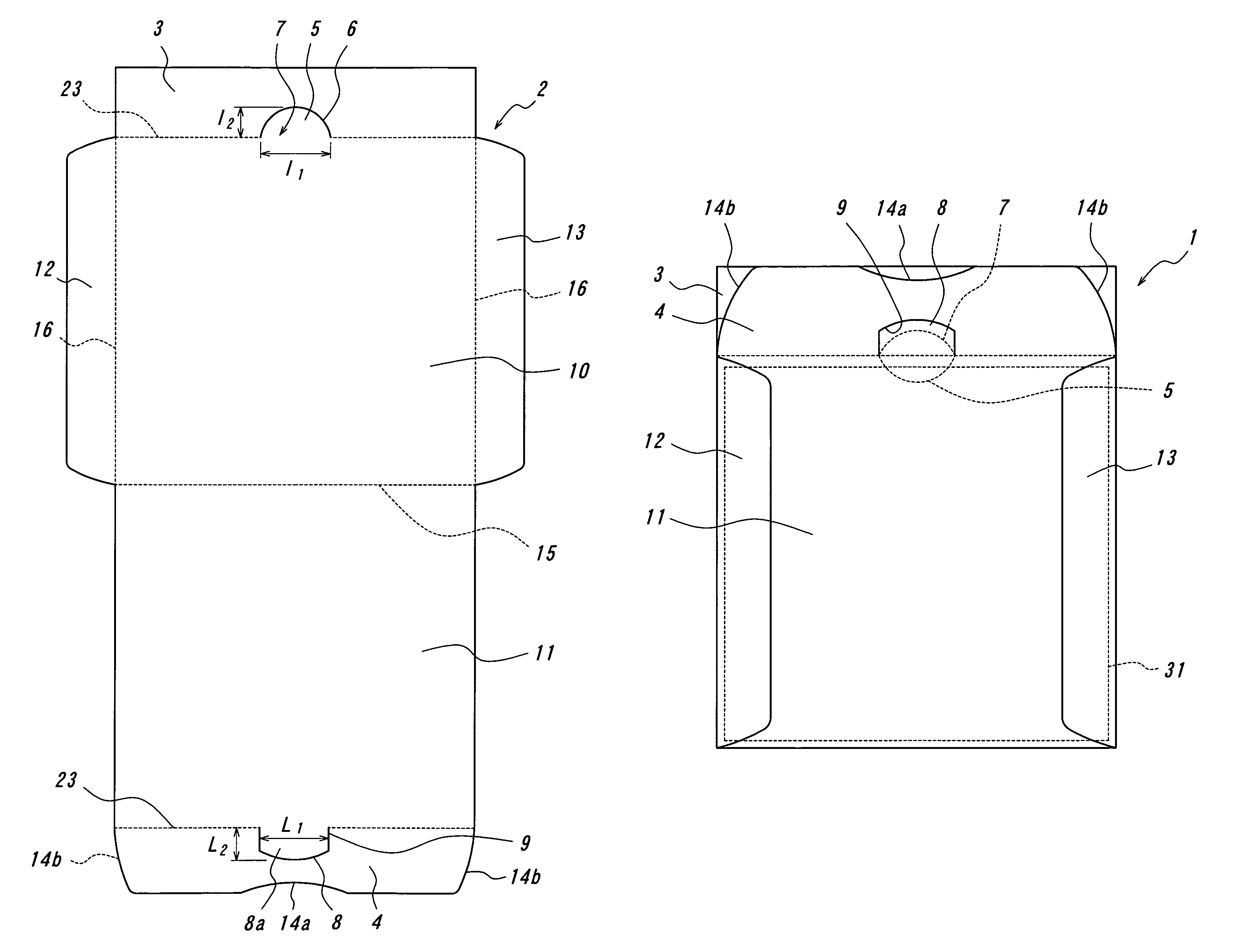

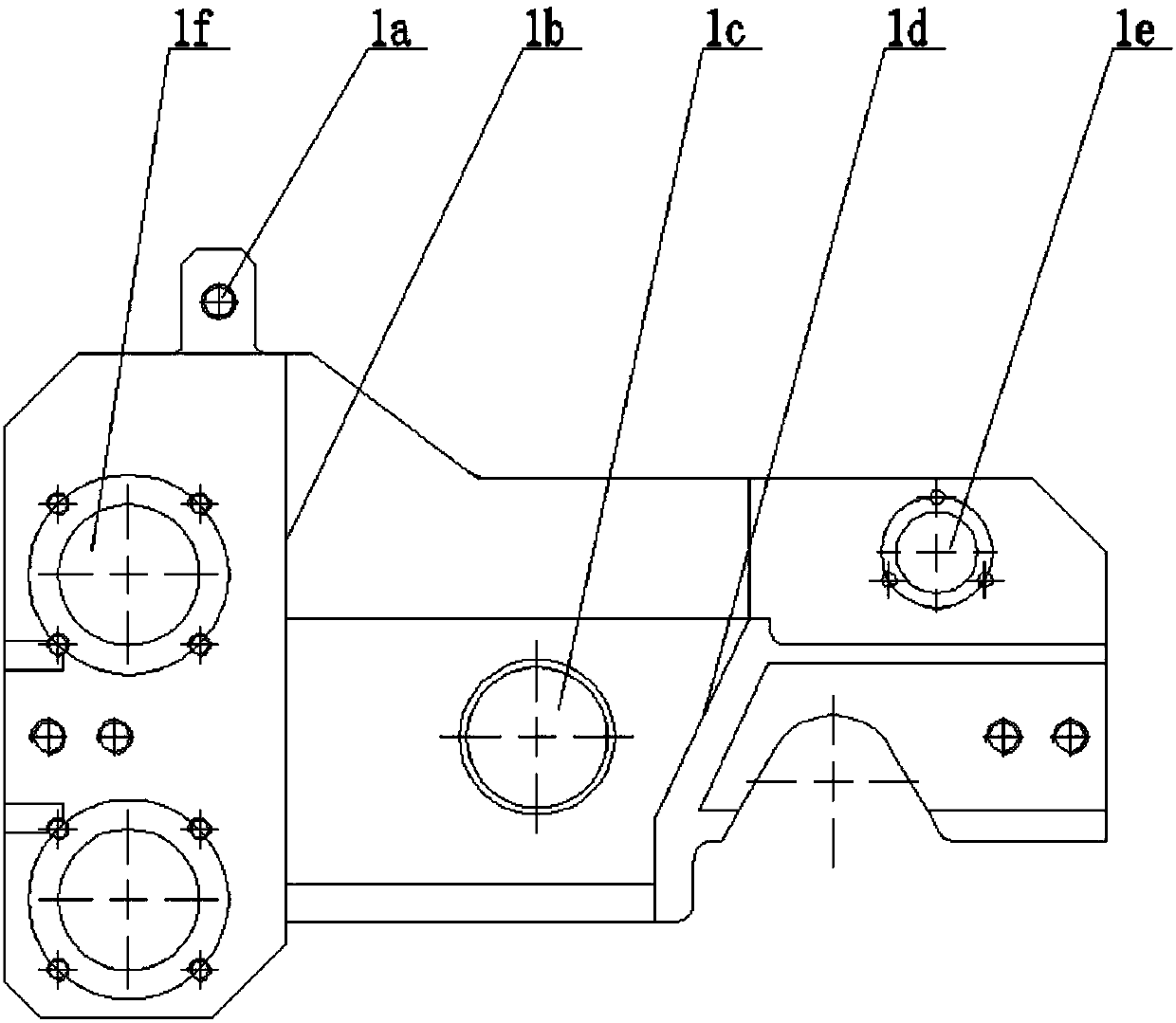

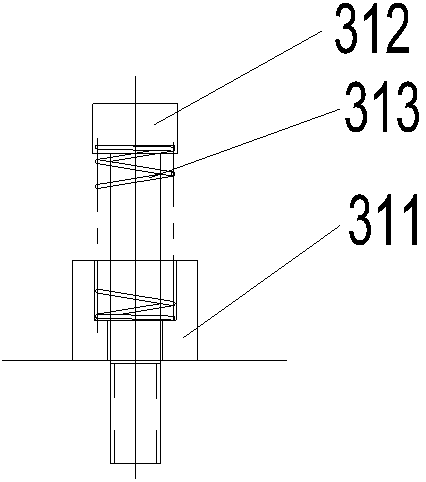

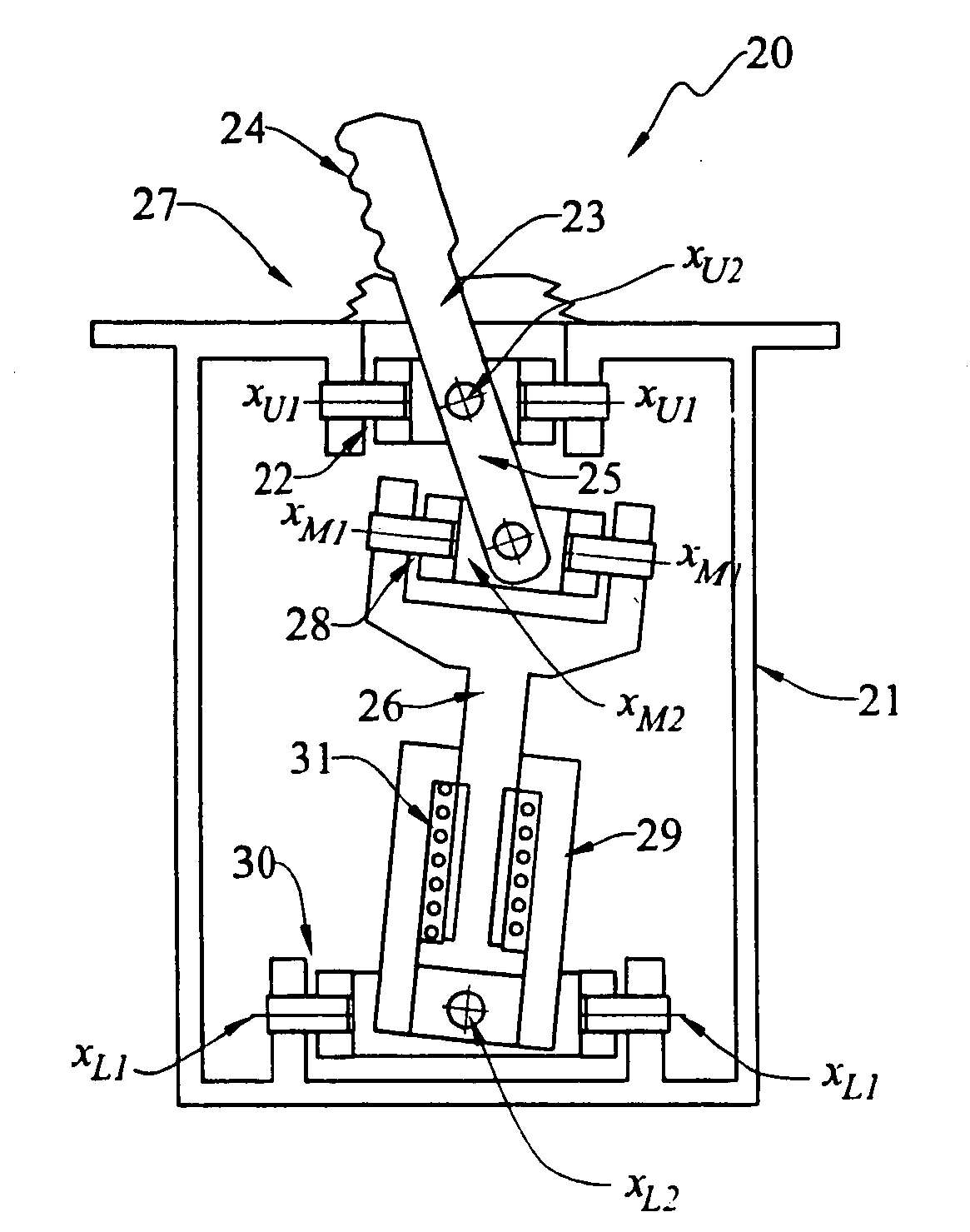

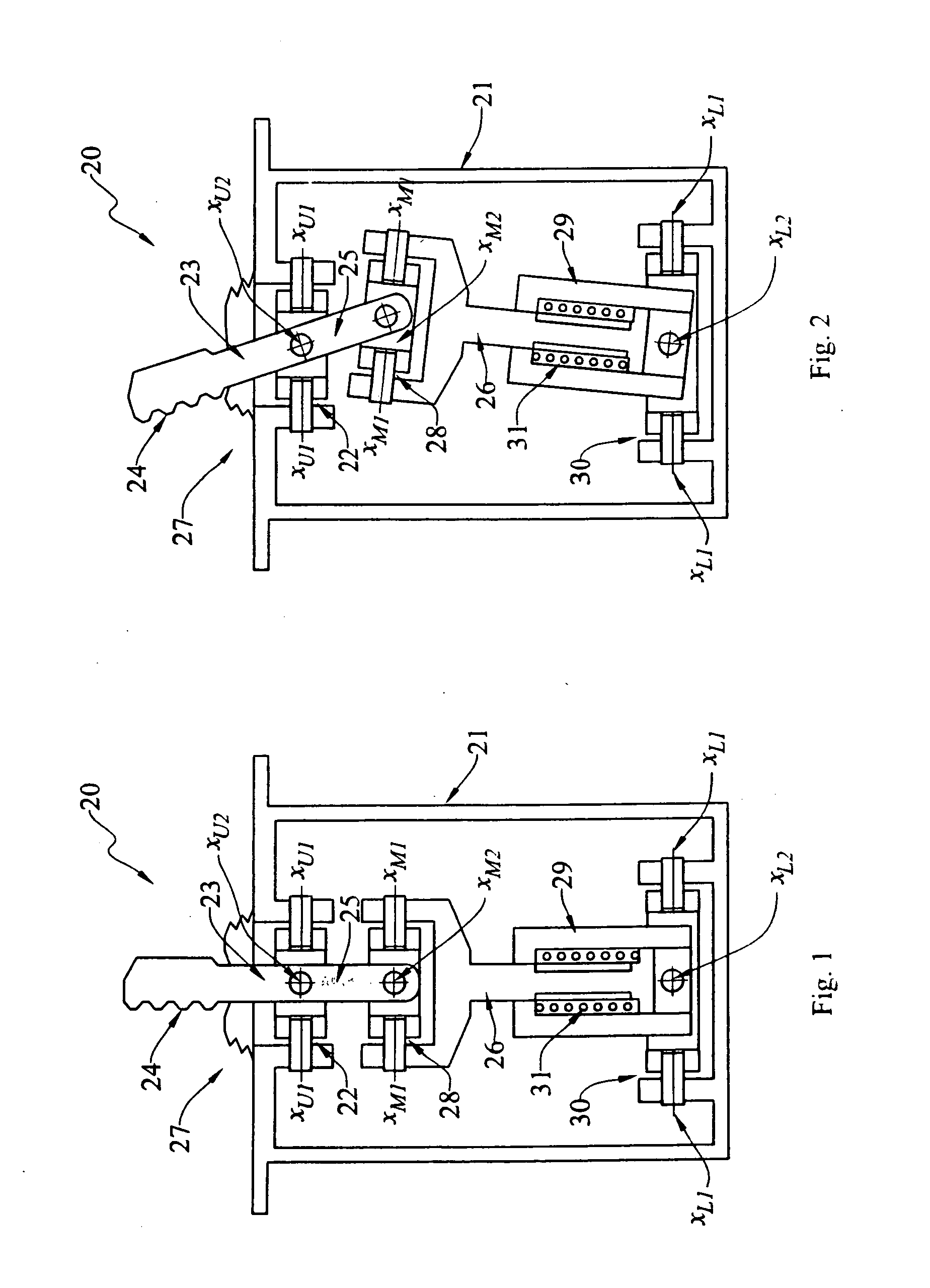

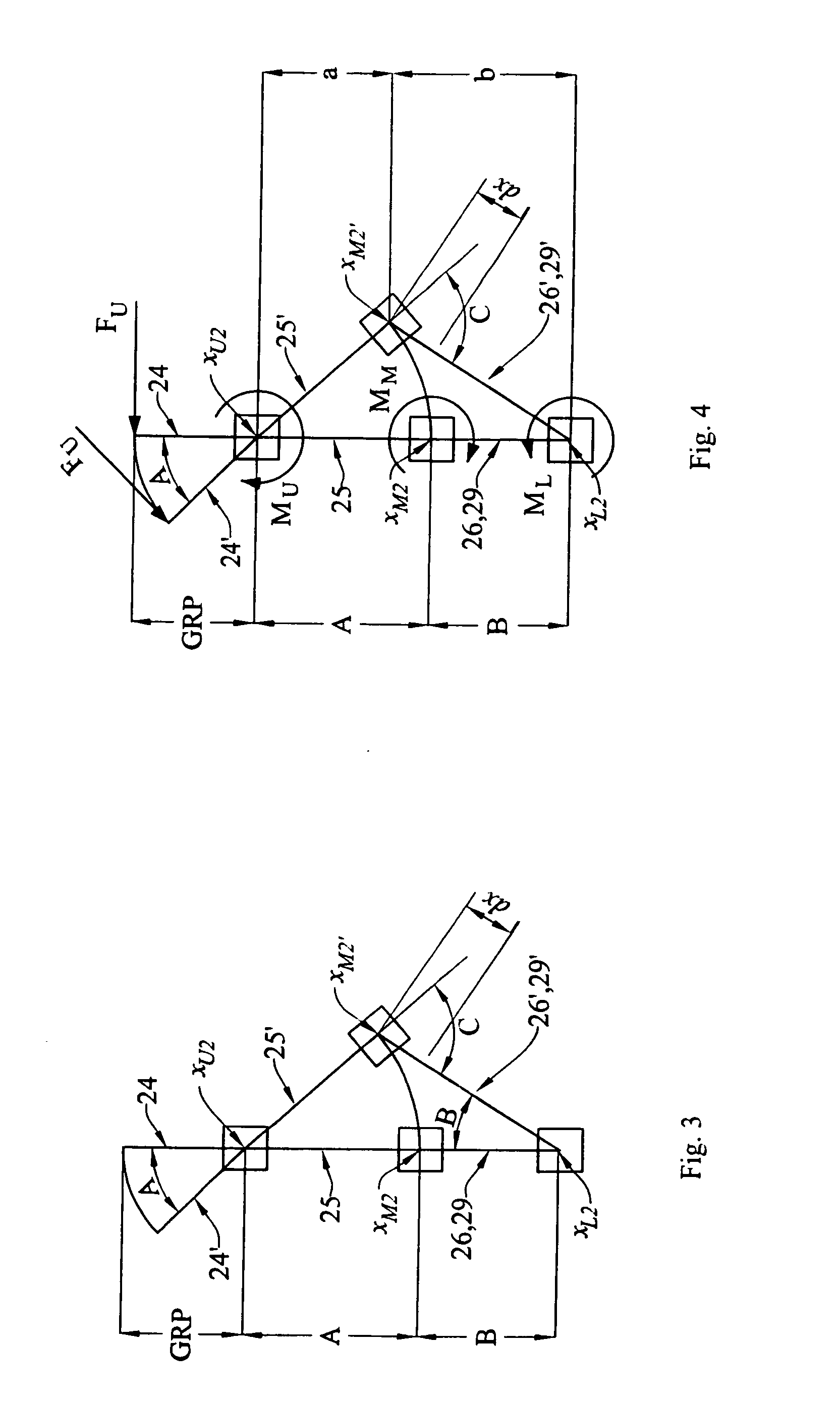

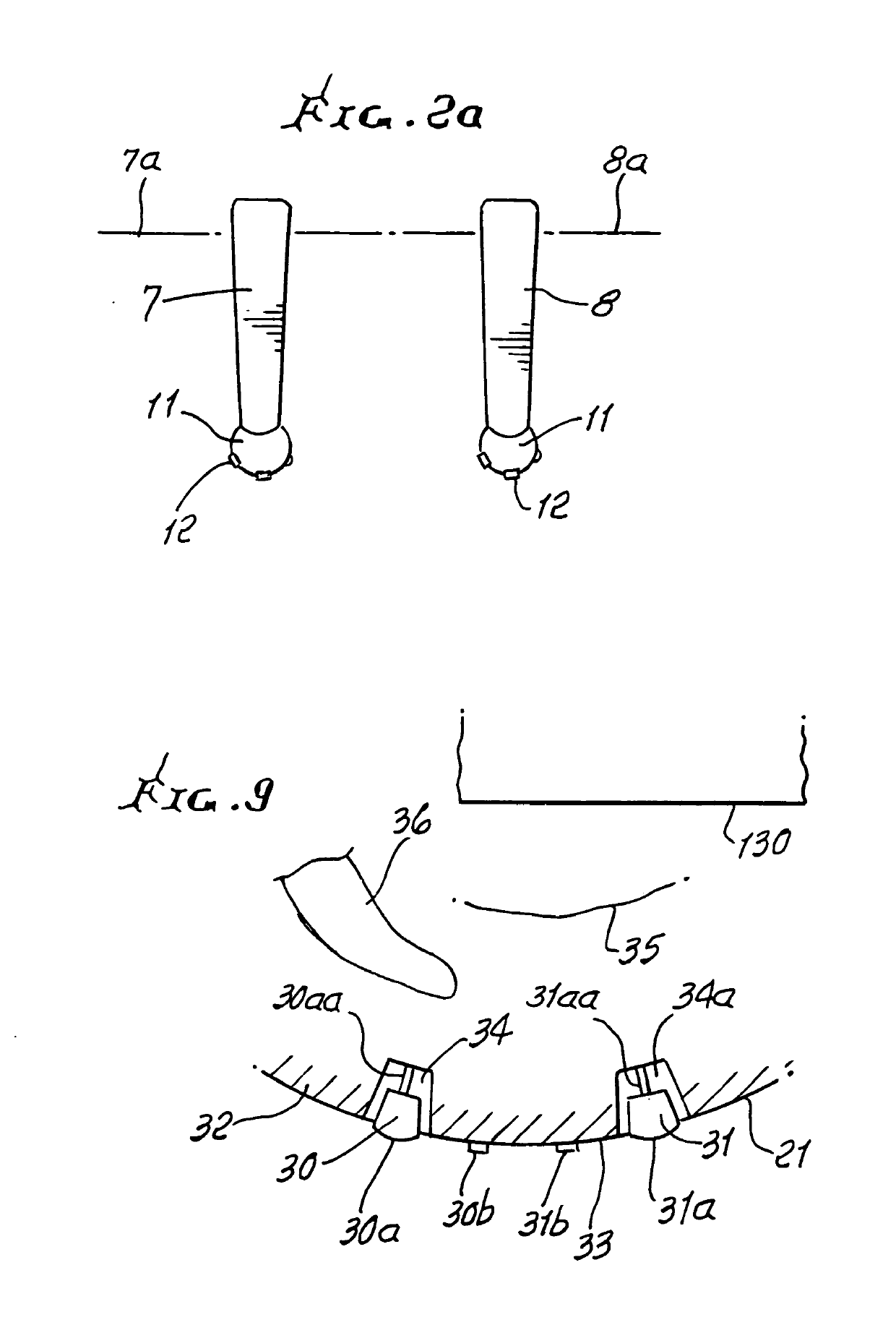

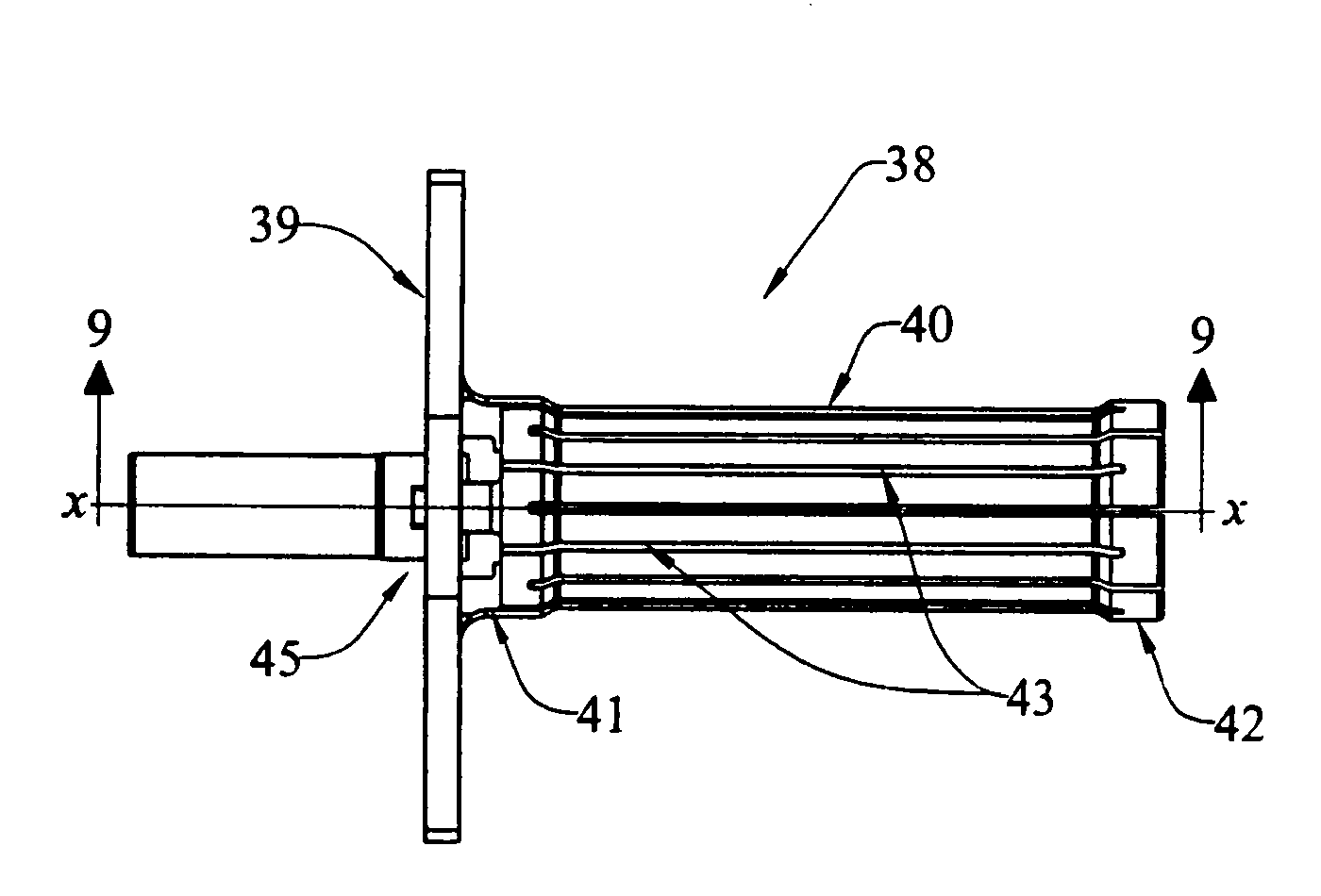

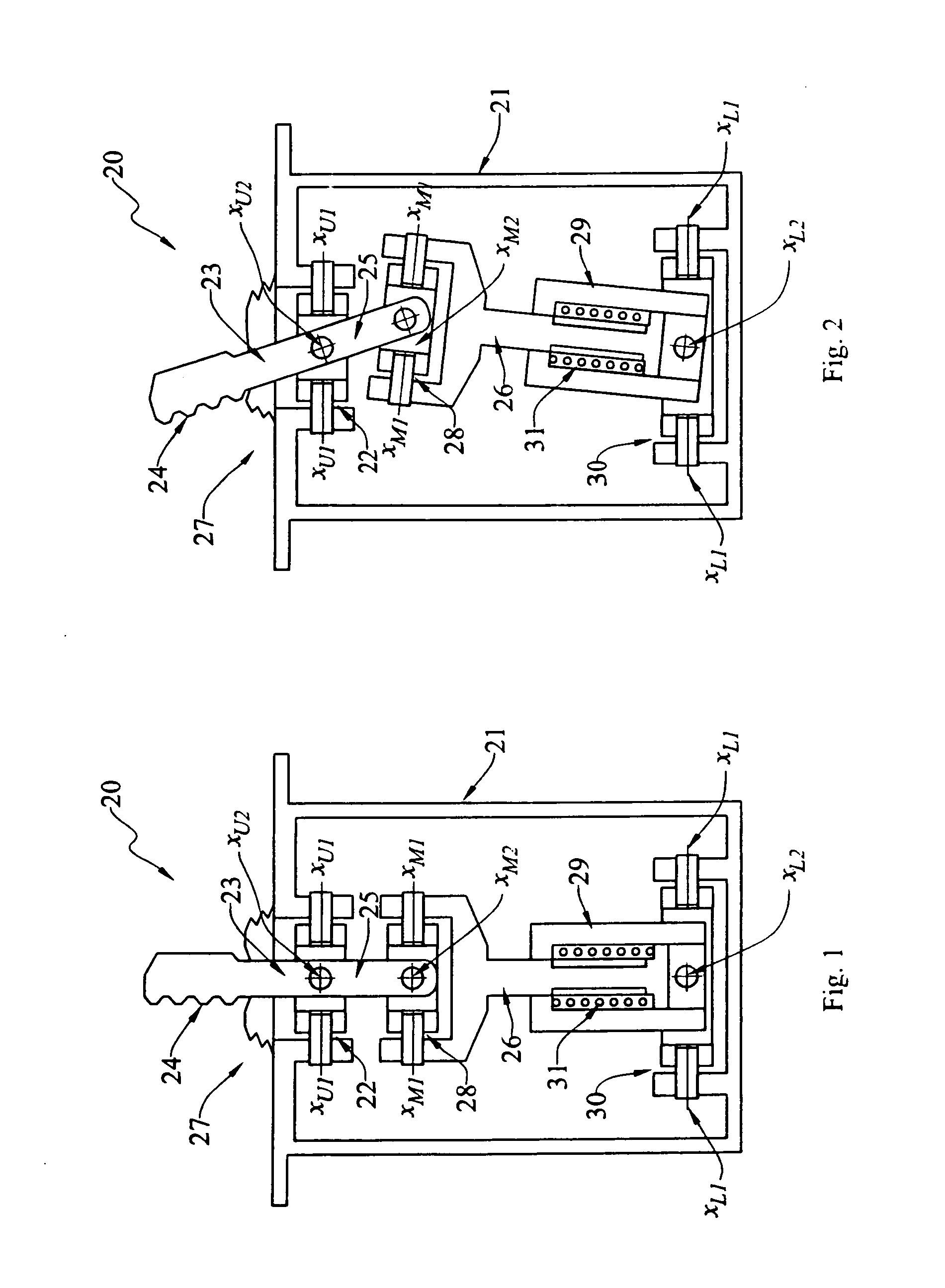

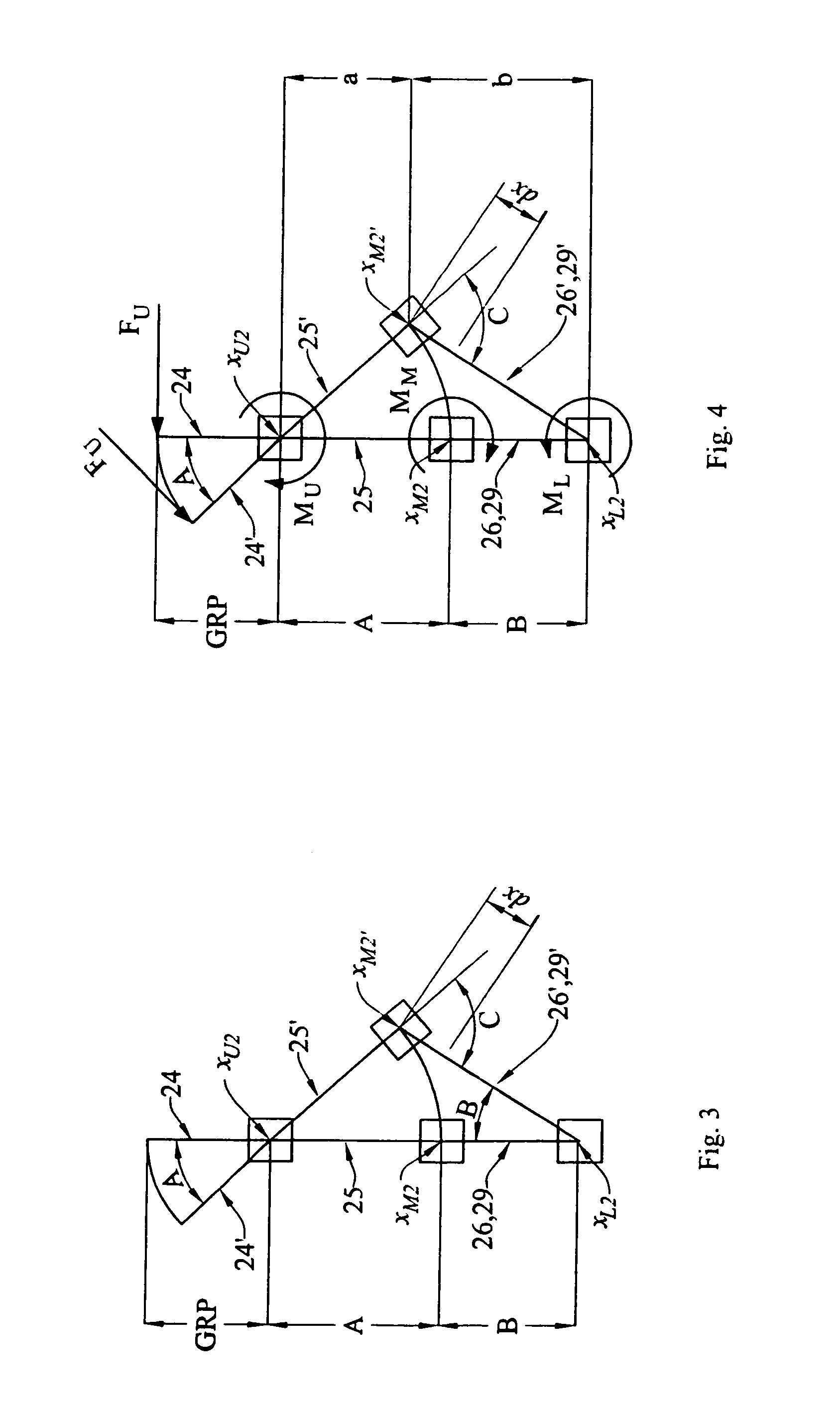

Control stick adapted for use in a fly-by-wire flight control system, and linkage for use therein

ActiveUS20110296941A1Eliminate backlashManual control with multiple controlled membersTorsion springsFly-by-wireJoystick

This invention provides an improvement in a control stick (e.g., joystick, side-stick, etc.) (20) adapted to control the movement of an object (e.g., an airfoil surface). The improvement includes: a support (21); an intermediately-pivoted upper member (23) mounted on the support, the upper member having an upper portion (24), and lower portion (25); an intermediate member (26) having an upper portion pivotally connected to the upper member lower portion, and having a lower portion; and a lower member (29) having a lower portion pivotally mounted on the support, and having an upper portion; and wherein the intermediate member lower portion is movably mounted on the lower member upper portion such that pivotal movement of the upper member upper portion relative to the support will produce pivotal movement of the intermediate and lower members relative to the support; and a resilient member (31) arranged to bias the direction of relative movement between the intermediate and lower members. The various pivotal connections may be provided by gimbals such that the various members are mounted for compound pivotal movement about two mutually-perpendicular axes.

Owner:MOOG INC

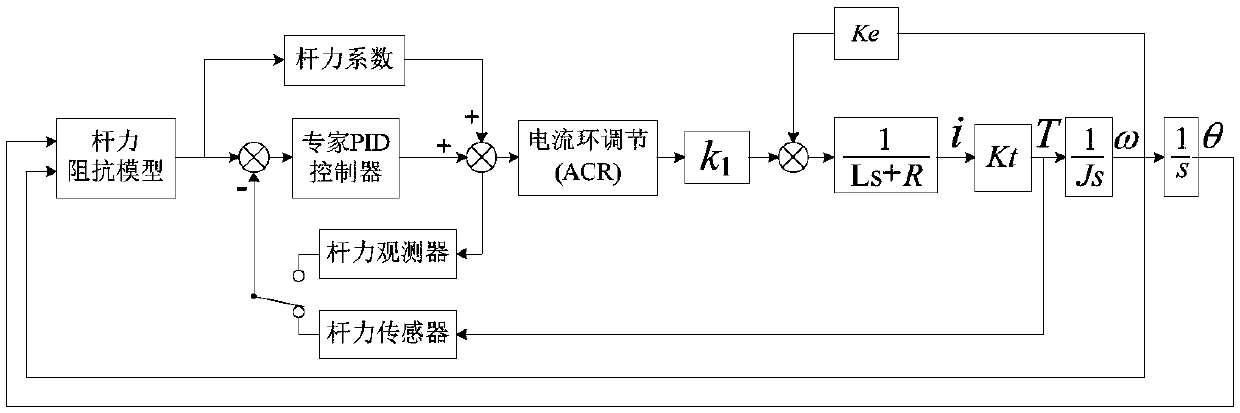

High-accuracy stick force control method of aircraft active side stick system

ActiveCN108639313AImprove rod force control accuracyRod damping adjustableActuated automaticallyStable stateClosed loop feedback

The invention discloses a high-accuracy stick force control method of an aircraft active side stick system. For an active working mode of an aircraft active side stick, an impedance control strategy based on torque is adopted, and a stick force control method based on expert PID with feedforward is designed; and therefore, the stick force control accuracy is guaranteed. The active side stick correspondingly adopt a high-accuracy stick force sensor and a stick force observer based on a current and friction model in a stable state and a dynamic state to perform stick force closed loop feedback so that the the accuracy of a force feedback signal is guaranteed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Fixing device for side sticking film of mobile phone rear housing

The invention discloses a fixing device for a side sticking film of a mobile phone rear housing, which comprises a base board. The left half portion of the lower surface of the base board is providedwith a first vertical plate. The right side of the first vertical plate is provided with a second vertical plate with the same structure. The lower surfaces of the first vertical plate and the secondvertical plate are provided with a motor mounting plate. The lower end of the motor mounting plate is provided with a rotary motor. A rotating shaft is arranged above the rotary motor. The upper surface of the base board is provided with a bearing mounting bracket. A vacuum chuck is arranged above the bearing mounting bracket. The left side of the bearing mounting bracket is provided with a cylinder fixed block. The upper end of the cylinder fixed block is provided with a rotary pressing cylinder. A piston rod of the rotary pressing cylinder is sleeved with an oscillating deck. The left half portion of the lower surface of the oscillating deck is provided with a pressure sensor. The lower end of the pressure sensor is provided with a pressing wheel. In general, the fixing device for the side sticking film of the mobile phone rear housing has the advantages of fixing firmly and not causing damage to the rear housing.

Owner:李艳军

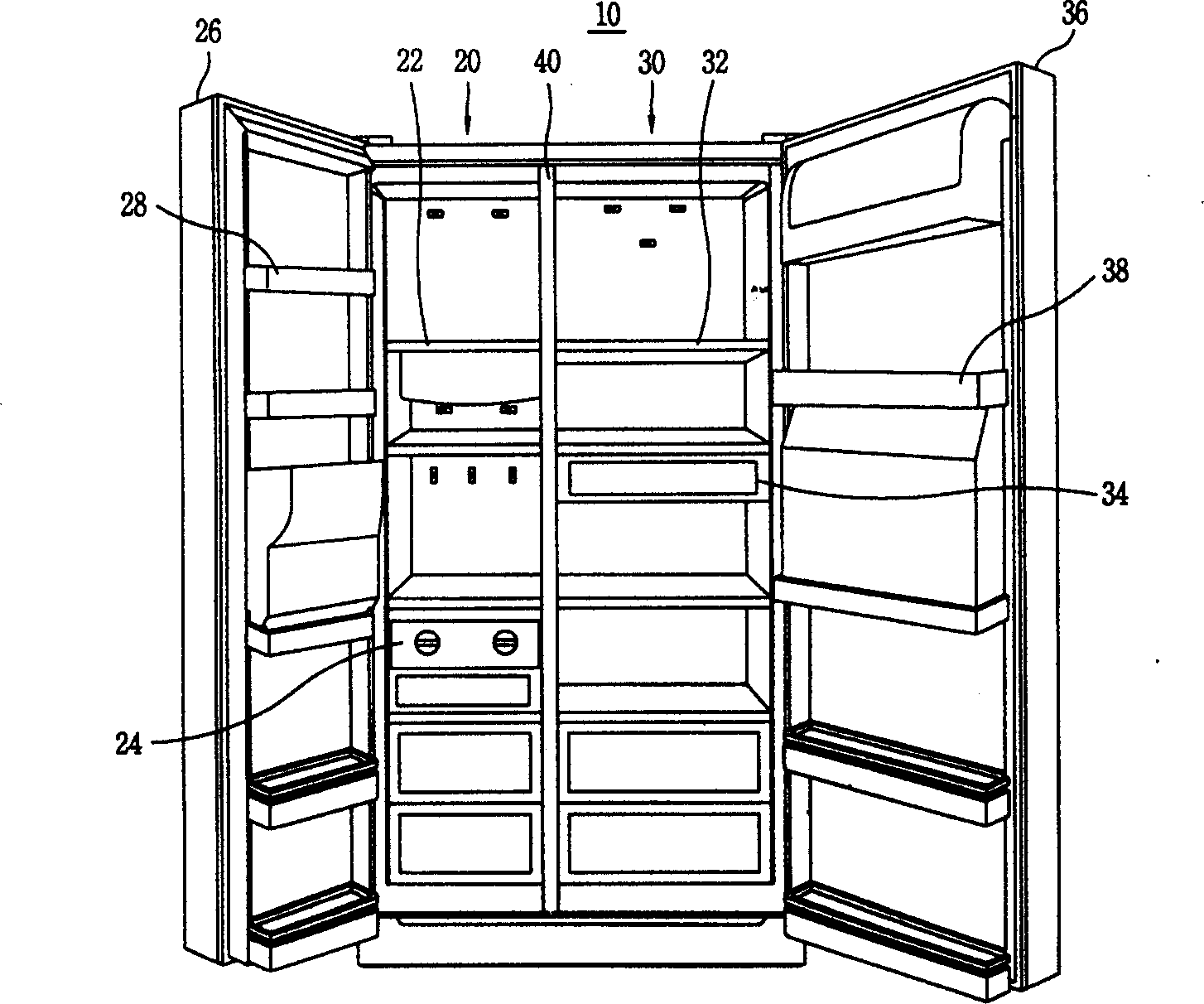

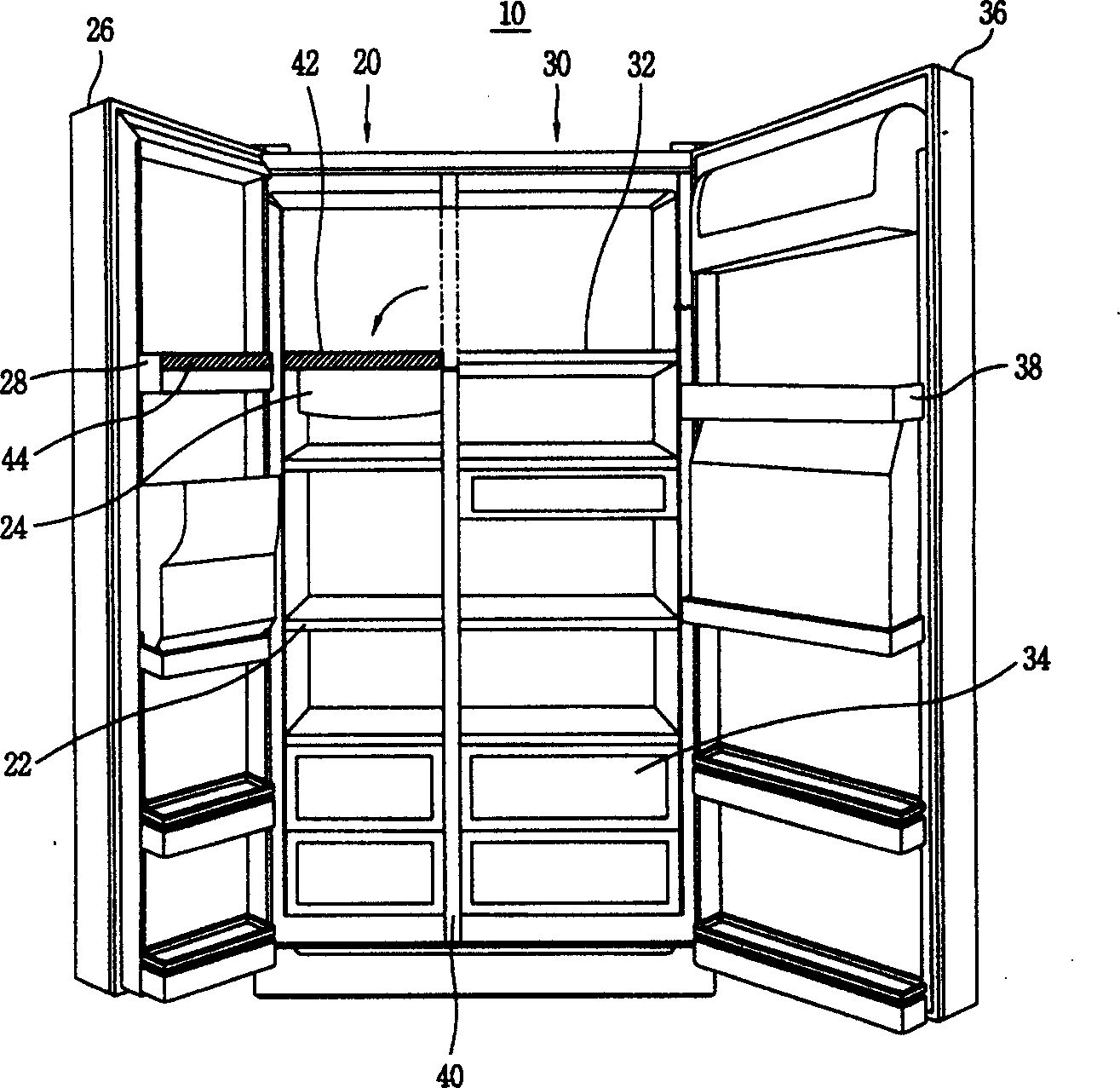

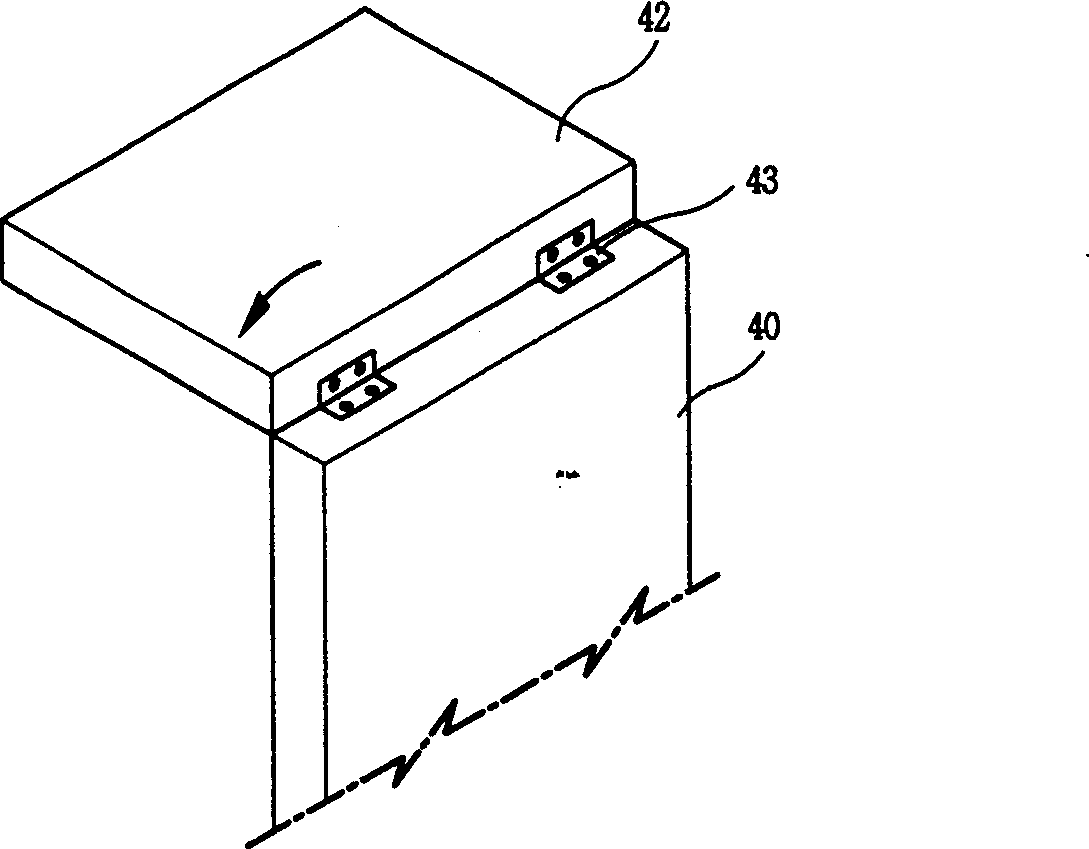

Refrigerator with adjustable cold storing and freezing space

InactiveCN1721789ALeakage and other losses do not occurLighting and heating apparatusDomestic refrigeratorsCooling chamberEngineering

This invention discloses one separate refrigerator with isolation wall as center to form frozen and cooling chambers, which comprises the following parts: isolation wall with proper length according to the width of the frozen chamber located on top part; inner side formed in the frozen chamber door; frozen door side stick to the transverse isolation wall; one sealed device of the isolation wall.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

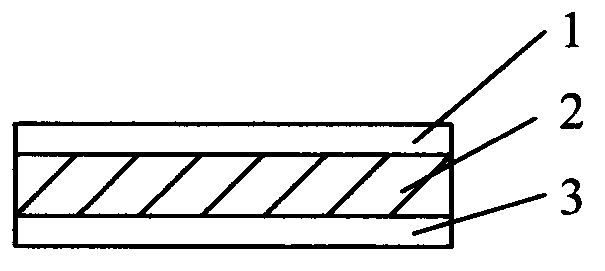

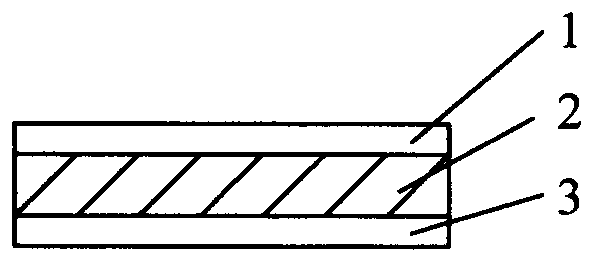

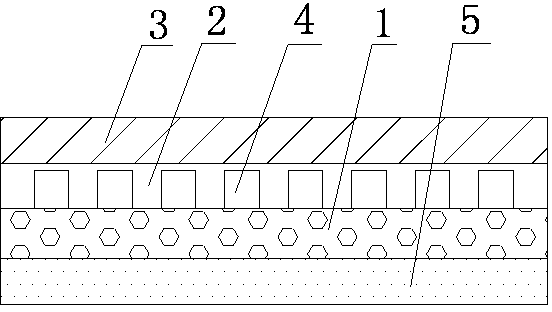

Improved composite wallpaper

The invention relates to an improved composite wallpaper, which is characterized in that: it includes a base layer, an intermediate bonding layer and a decorative layer. The base layer and the decorative layer are tightly connected together through the intermediate bonding layer, which is provided with fine through holes. The back side of the base layer is uniformly coated with a water soluble adhesive. The improved composite wallpaper provided in the invention has the advantages that: the structure is simple, the trouble of manual brushing and coating of a binder can be avoided, uniformity of a wallpaper wall side sticked to the wall can be ensured, the wallpaper is convenient to spread out, the breathable effect of the wallpaper is good, the wallpaper can be prevented from go mouldy, and the service life is long, so that the wallpaper meets the demands of customers.

Owner:NANTONG SHENLONG NEW MATERIALS

Automatic side-sticking equipment used during filter element production

ActiveCN102553351BLow costTo achieve the purpose of automatic weltingFiltration separationPaper tapeMiddle line

The invention relates to automatic side-sticking equipment used during filter element production. The equipment at least comprises a filtering material spiral separating device and a paper tape pressing and sticking device, wherein the filtering material spiral separating device comprises four screw rods of which the radial cross sections are arranged in matrix; in the vertical direction, the two screw rods at the left are arranged on a first bracket, and the two screw rods at the right are arranged on a second bracket; in the horizontal direction, the two screw rods positioned above are synchronously driven by a first motor and a first synchronous driving mechanism, and the two screw rods positioned below are synchronously driven by a second motor and a second synchronous driving mechanism; filtering material passages in the axial direction of the screw rods are formed between the screw rods positioned above and the screw rods positioned below; and belt sections, close to the two sides of the filtering material passages, in the paper tape pressing and sticking device, deflect towards the middle lines of the filtering material passages along the conveying direction. Automatic side sticking between filtering materials and paper tapes is realized through the equipment; and the production efficiency and the accuracy of side sticking are greatly improved.

Owner:东莞市海莎过滤器有限公司 +1

Precise vertical tile sticking device for decoration

The invention discloses a precise vertical tile sticking device for decoration comprising a side sticking device, a controller, moving wheels, a side plate, a body, a top base, and a hand push rack. The side sticking device is installed in the body; the side plate is arranged at the left side of the body; and the top of the body is fixedly connected with the bottom of the top base. The bottom sideof the hand push rack is welded to the top side of the right end of the top base. The back of the controller is vertically connected with the front side of the body. With the precise vertical tile sticking device, the vertical tile at the wall side can be pressed tightly and different-distance pressing of the tiles is carried out based on the thicknesses of the tiles. The pushing distance of a lower displacing block is adjusted by changing the height of an upper lifting block and thus the pressing distance of the tile is controlled, so that the overall compaction flatness of the tile is ensured. Meanwhile, with a fixation sleeve, the friction force is increased by the adjusting bolt and thus the left-pushing speed of the fixation sleeve is changed, so that a phenomenon that the tile is crushed because the pressing block moves to the left quickly is avoided.

Owner:湖南尤美设计装饰工程有限公司

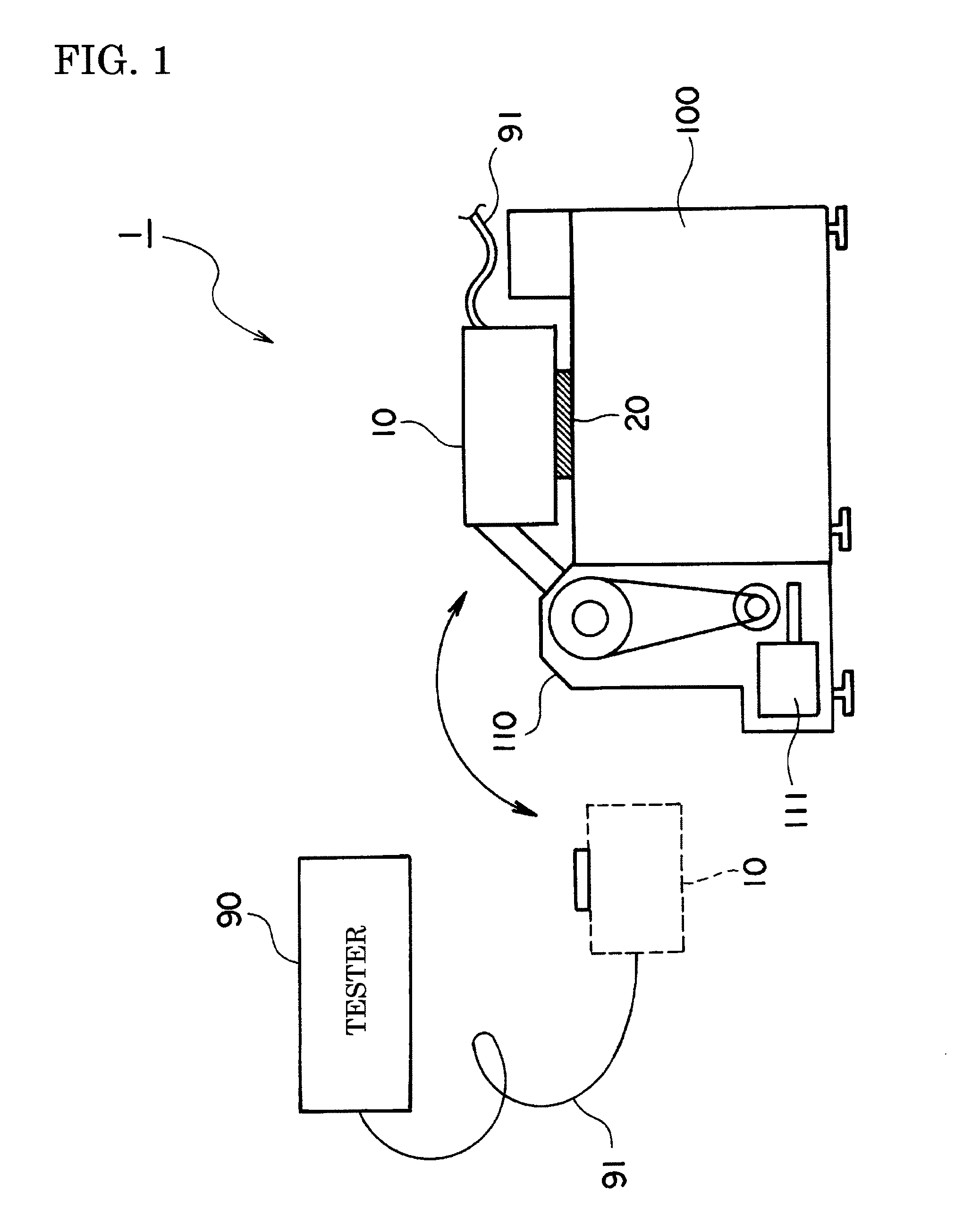

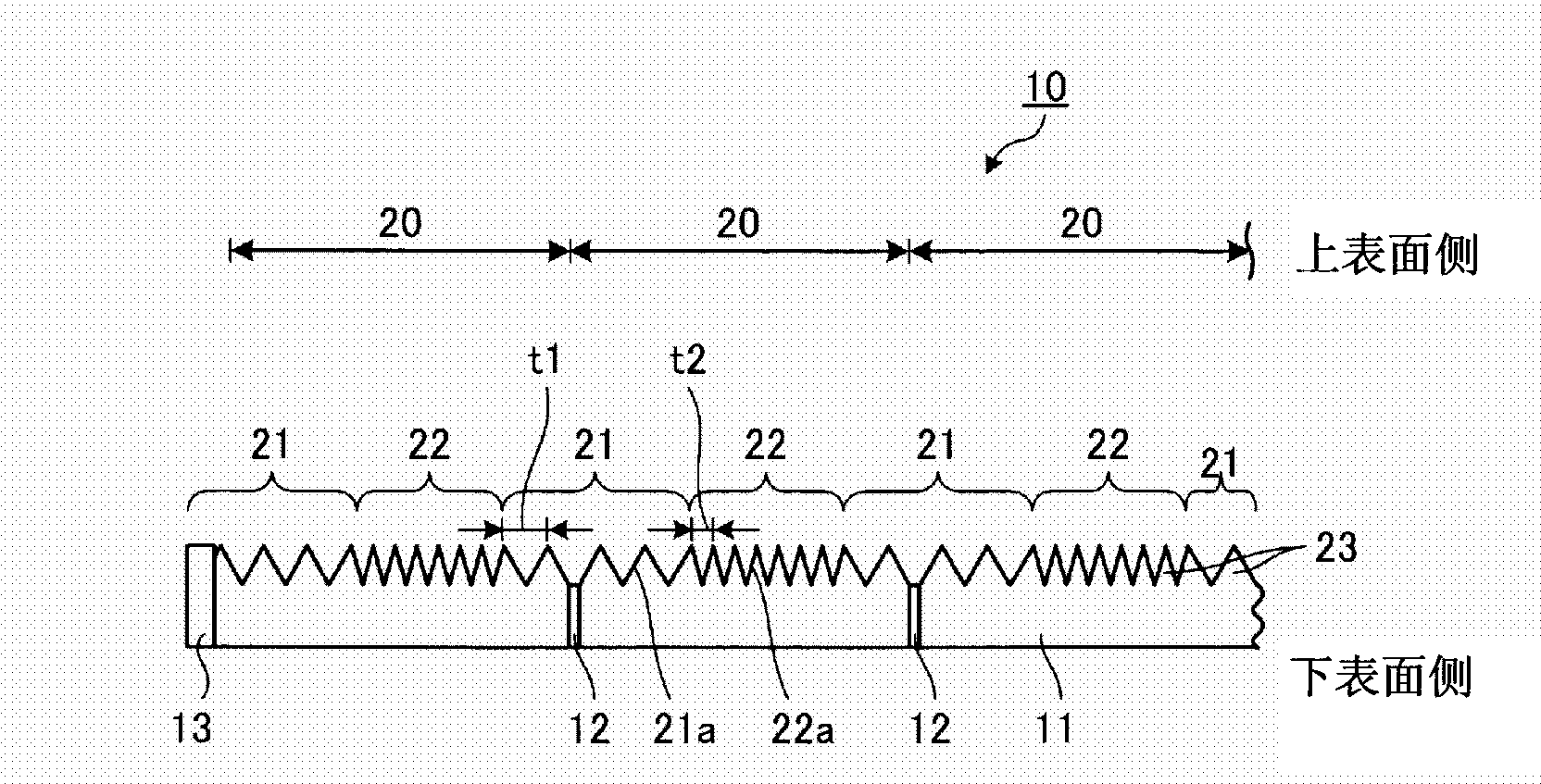

Semiconductor device manufacturing apparatus and semiconductor device manufacturing method

InactiveCN102832158AReduce incompletenessAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipSide-stick

The present invention provides a semiconductor device manufacturing apparatus and a semiconductor device manufacturing method which are capable of reducing incompleteness and damages of semiconductor chips when being peeled off from a rubber belt. A pickup apparatus (10) is provided with a semiconductor chip maintenance table (11) for maintaining the semiconductor chip to be stuck on the rubber belt, and a first groove (21a) and a second groove (22a) disposed on the side, where the semiconductor chips are maintained, of the maintenance table (11), wherein the first groove (21a) and the second groove (22a) are connected with at least two air vents (12), and the width (t2) of an opening portion of the second groove is smaller than the width (t1) of the opening portion of the first groove. The semiconductor chip is maintained on peak parts of the first and the second grooves in a manner that the side stuck with the rubber belt faces downwards, a pressure-reducing mechanism is used to reduce pressure in an enclosed space enclosed by the rubber belt, the first groove and the second groove, and then the pickup apparatus (10) picks up the semiconductor chip from the maintenance table by using a chunk.

Owner:FUJI ELECTRIC CO LTD

Cockpit seat armrest avionics cursor control device

The invention concerns an improved CCD integration within pilot seat armrests, with benefits including ease and accuracy of CCD use, premium space savings on cockpit consoles, the ability to be retracted when not in use, always remaining within comfortable and easy reach of tall and short pilots alike and not interfering with other devices such as “side-stick” flight controls. The compactness and accuracy of use of the invention, its ability to be stowed, and its space-saving features set this CCD apart from existing CCDs and improve cockpit structure and pilot operation of aircraft that employ this invention.

Owner:AERION INTPROP MANAGEMENT CORP

Socket type LED apparatus

InactiveCN101275717AImprove cooling effectSolve heating problemsCoupling device connectionsPoint-like light sourceElectricityComputer module

The invention discloses a jack type LED device, including a first seat, a second seat, an electric installation, a heat sink and an LED module, wherein the first seat can be inserted on the second seat, the heat sink can be arranged between the first seat and the second seat. The electric installation includes two condition pins and two condition slots respectively arranged on the first and the second butting surface. The LED module is arranged on the first seat, having a condition basis material with one side sticked with the heat sink and a condition part electrically connected with the condition pins. The alternated radiators can make the heat energy reduced descendingly to reach the better heat emission effect.

Owner:EVERLIGHT ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com