Socket type LED apparatus

An LED device, a socket-type technology, applied to coupling devices, lighting devices, components of lighting devices, etc., can solve problems such as damage to LED chips, damage to peripheral components, etc., to achieve the effect of convenient replacement and enhanced heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

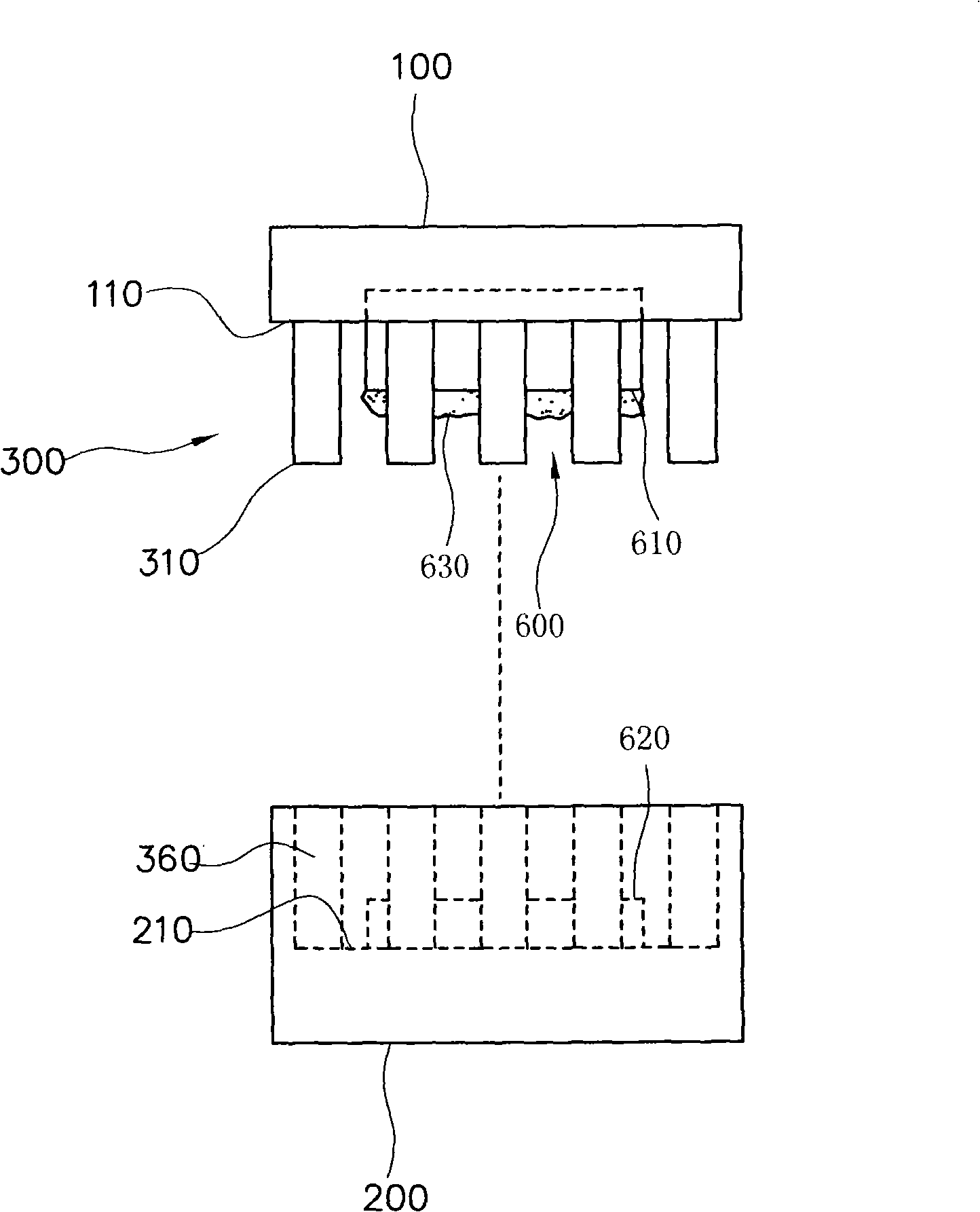

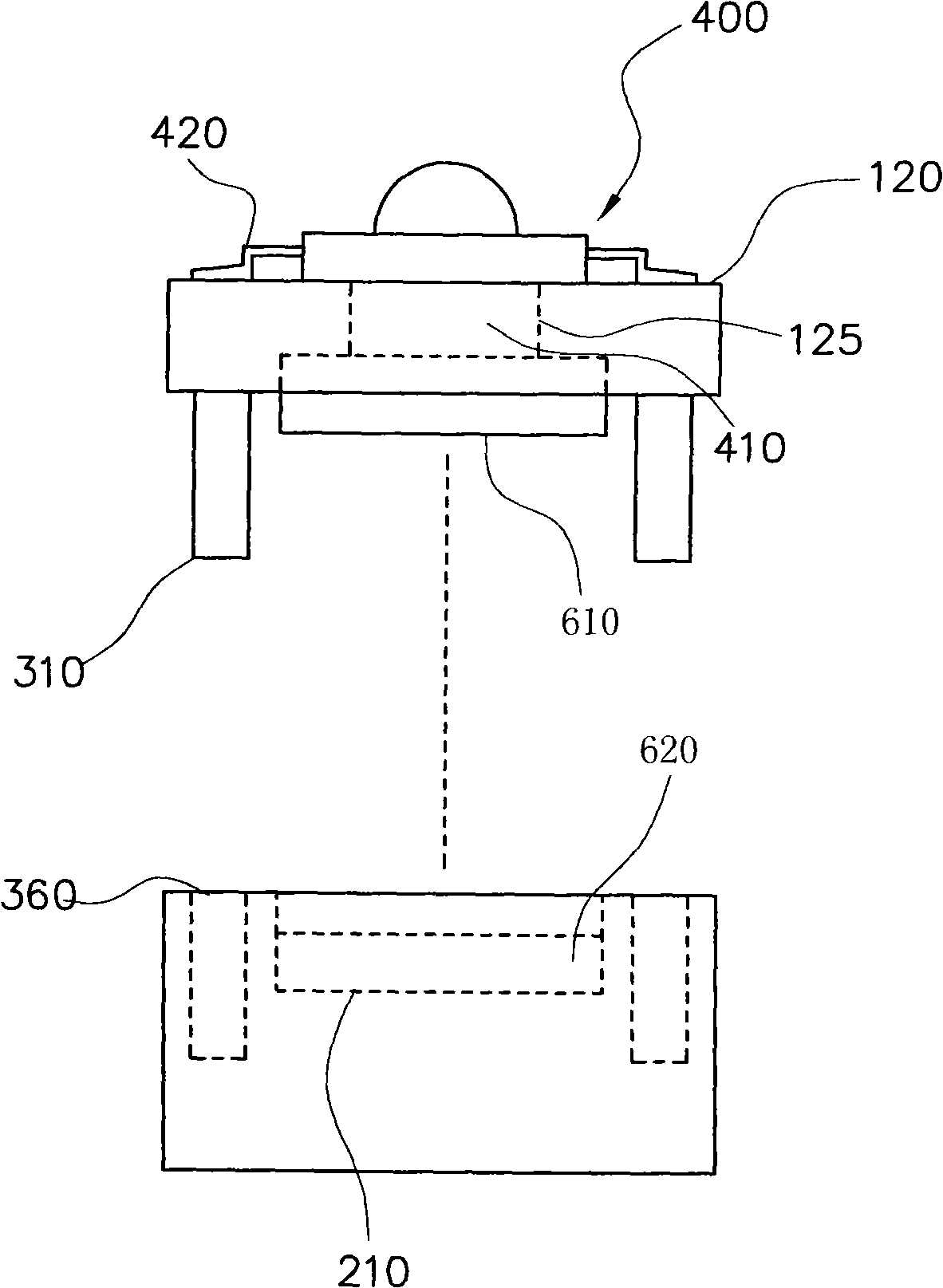

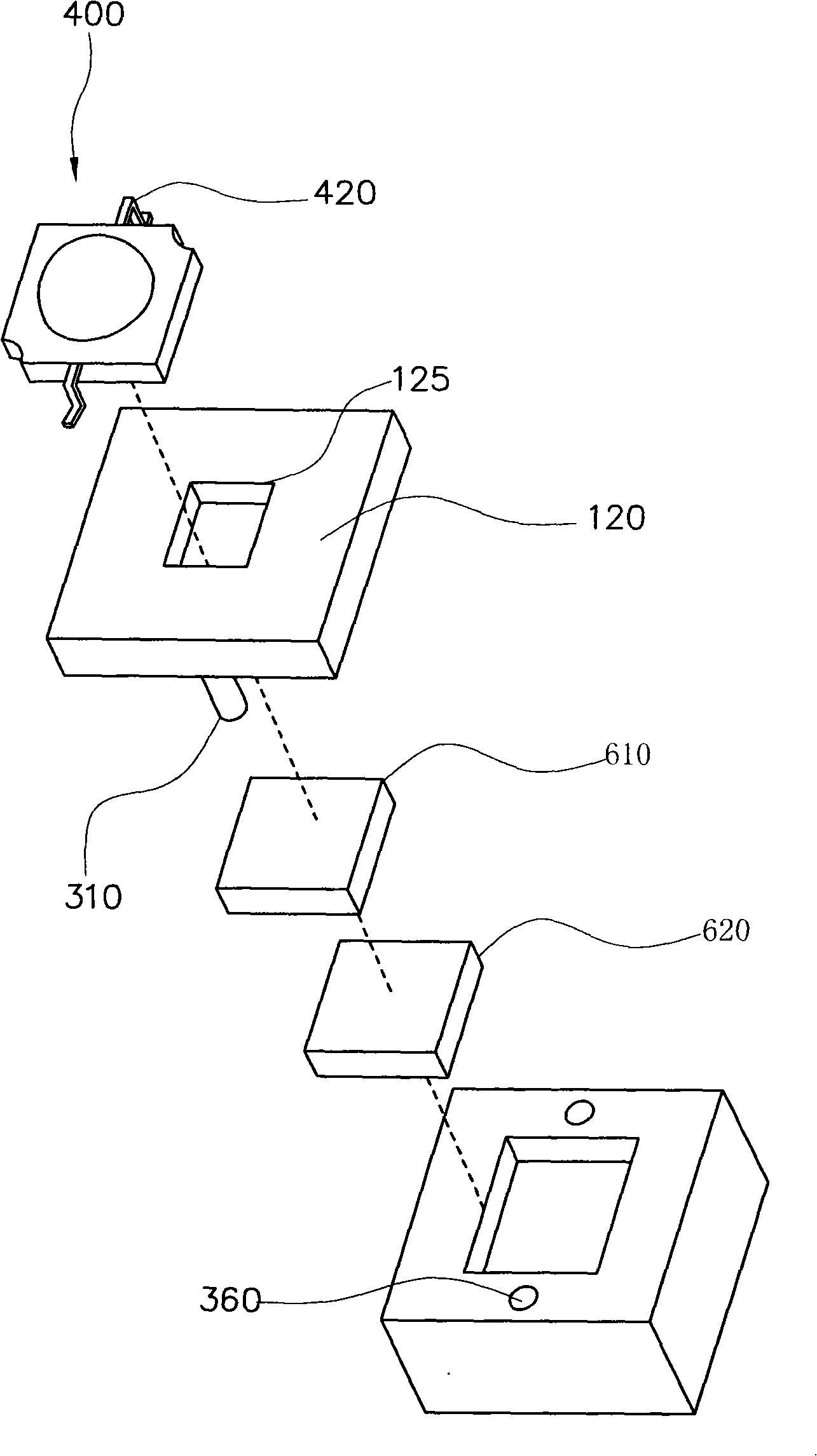

[0028] Please refer to figure 1 , is a schematic diagram of the side structure of a heat dissipation socket according to an embodiment of the present invention. The heat dissipation socket of this embodiment includes a first seat body 100, a second seat body 200, a conductive device 300, and a heat dissipation device 600. This heat dissipation socket can be a PLCC (Plastic Leaded Chip Carrier, PLCC, plastic led foot chip carrier) socket.

[0029] The first base body 100 is made of insulating material such as plastic or ceramics, and includes a first abutting surface 110 . The second seat body 200 is also made of insulating material such as plastic or ceramics and is detachably disposed on the first seat body 100 , and includes a second mating surface 210 corresponding to the first mating surface 110 . The heat dissipation device 600 is disposed between the first base body 100 and the second base body 200, wherein the heat dissipation device 600 can be an integrally formed he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com