Automatic side-sticking equipment used during filter element production

An automatic and welting technology, applied in the direction of filtration separation, chemical instruments and methods, separation methods, etc., can solve the problems of high labor cost, low production efficiency, and waste formation, so as to improve production efficiency, save material costs, and improve the adhesion The effect of edge accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

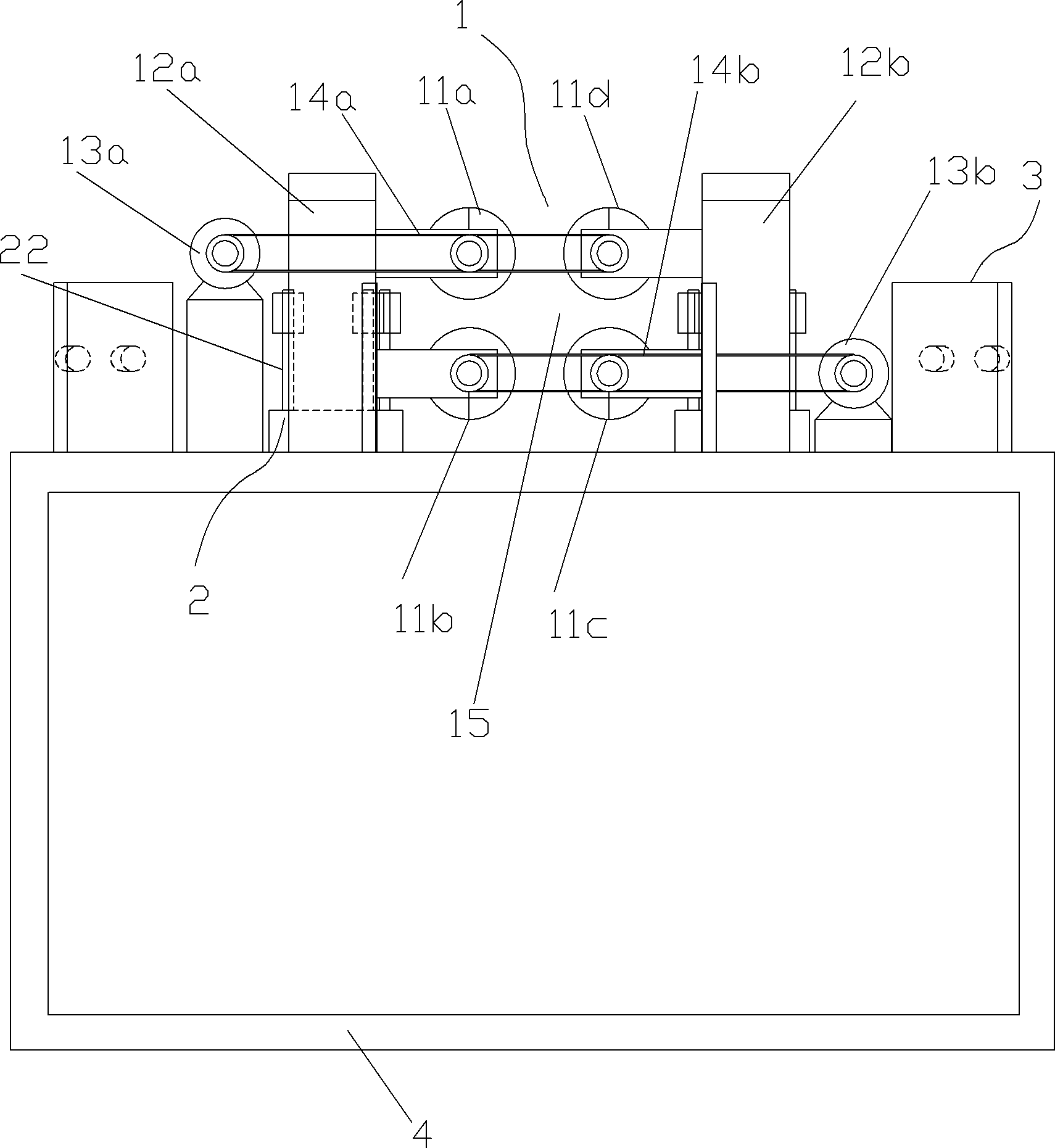

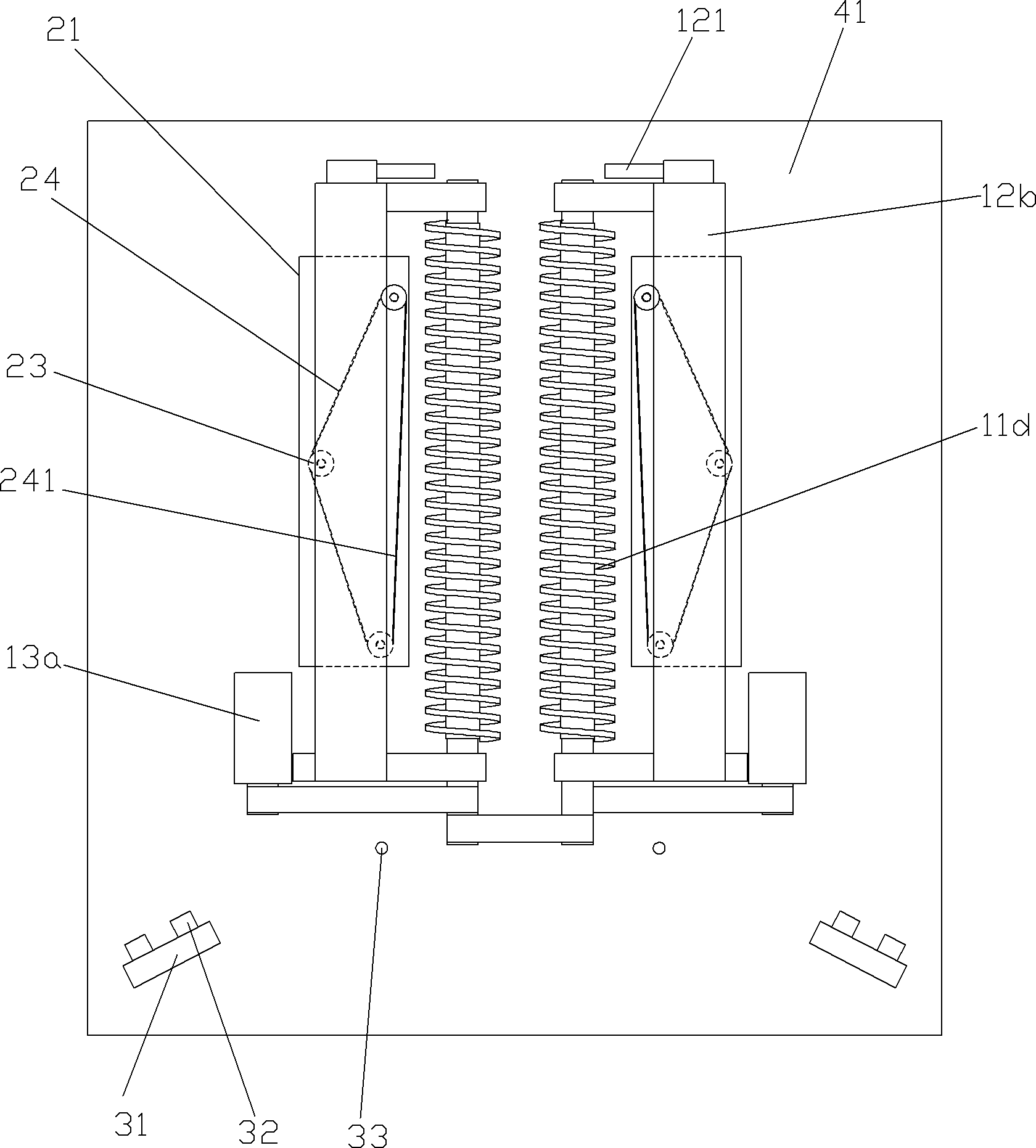

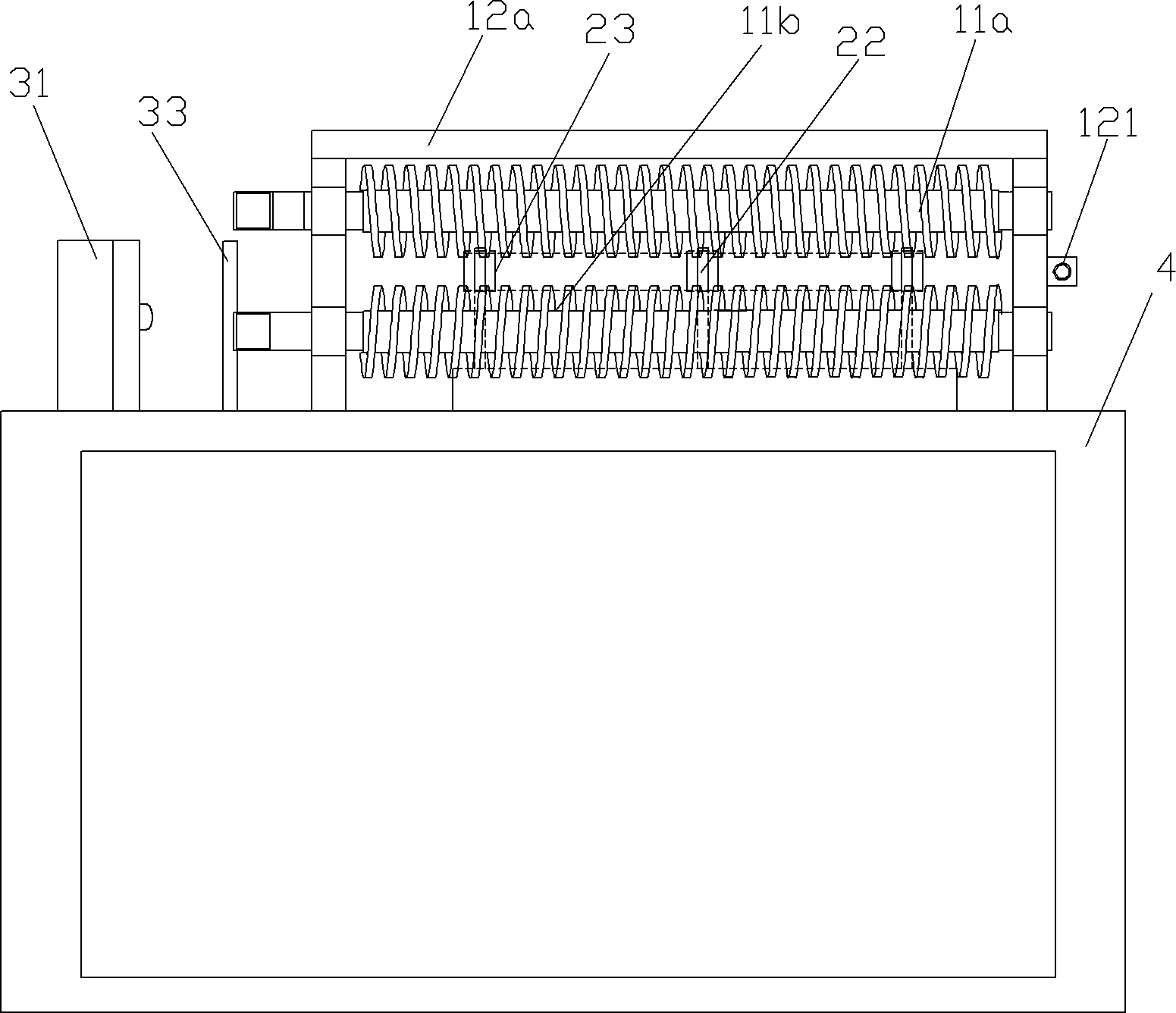

[0016] combine Figure 1 ~ Figure 3 As shown, the automatic welting equipment of the present invention at least includes a filter material spiral separator 1 and a paper tape pressing device 2, wherein,

[0017] The filter material spiral separator 1 includes four screw rods 11a, 11b, 11c, 11d arranged in a matrix in the radial section, wherein, in the vertical direction, the two screw rods 11a, 11b on the left side are installed on the first bracket 12a, the two screw rods 11c and 11d on the right side are installed on the second bracket 12b; in the horizontal direction, the two screw rods 11a and 11d on the upper side are synchronously driven by the first motor 13a and the first synchronous transmission mechanism 14a. The two screws 11b and 11c below are synchronously driven by the second motor 13b and the second synchronous transmission mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com