Patents

Literature

36results about How to "Reduce incompleteness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

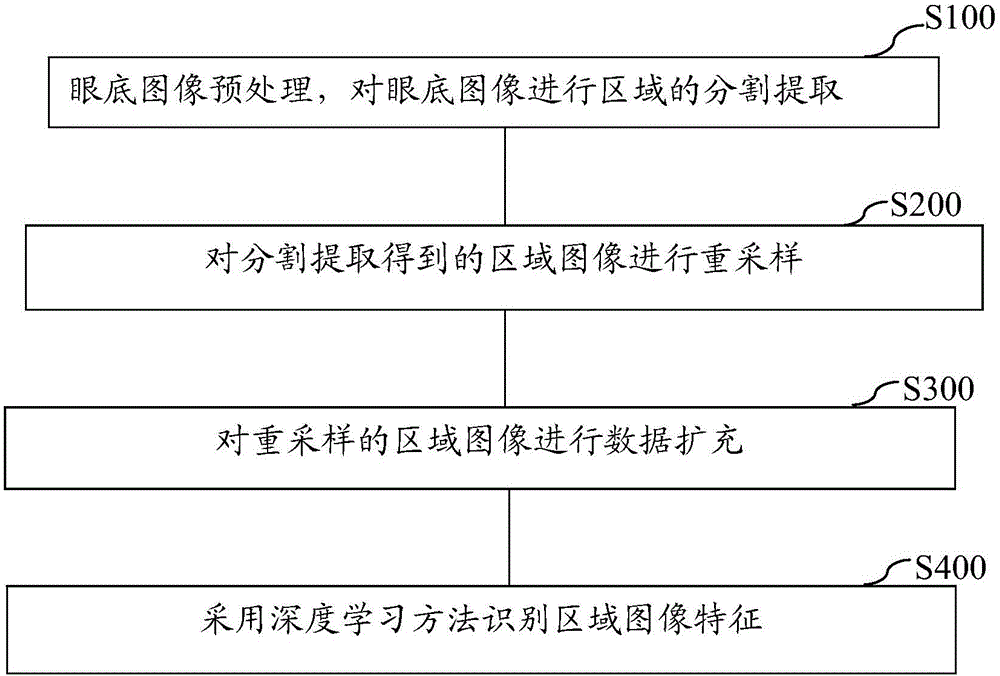

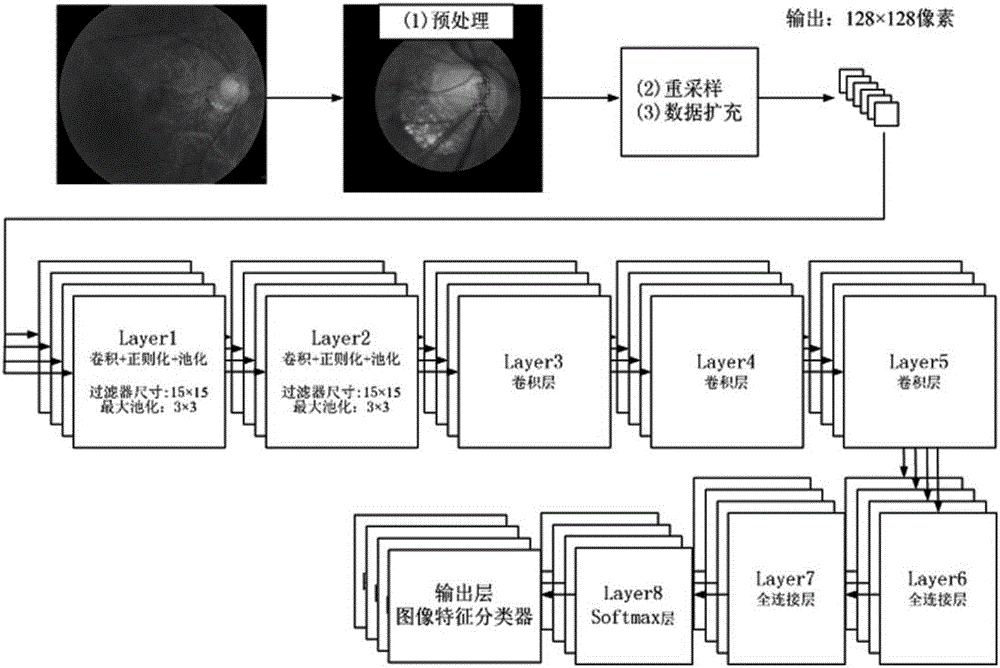

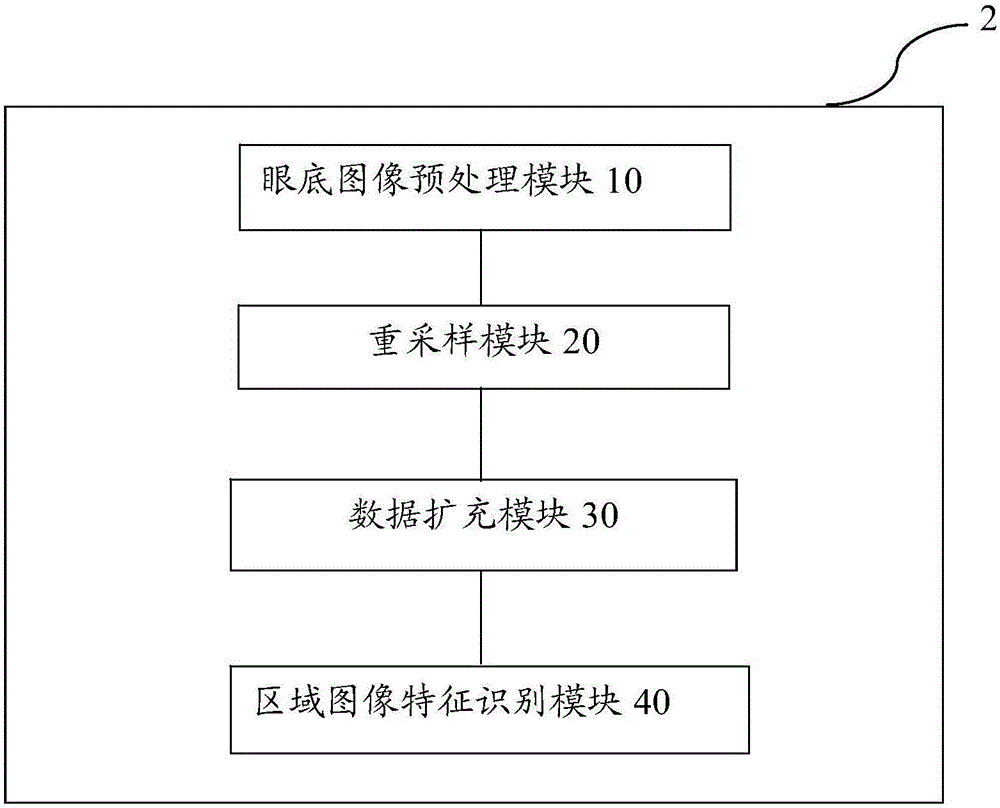

Depth-learning-based eye-fundus image processing method, device and system

ActiveCN106408564AAutomatic analysisAnalysis results are objectiveImage enhancementImage analysisPattern recognitionLearning based

The application discloses a depth-learning-based eye-fundus image processing method, device and system. The method comprises: eye-fundus image pretreatment is carried out and region segmentation extraction is carried out on the eye-fundus image; resampling is carried out on a regional image obtained by the segmentation extraction; data expansion is carried out on the regional image after resampling; and a regional image feature is identified by using a depth learning method. Therefore, an eye-fundus image can be analyzed automatically; the analysis result is objective and accurate; and the manpower cost is saved.

Owner:北京新皓然软件技术有限责任公司

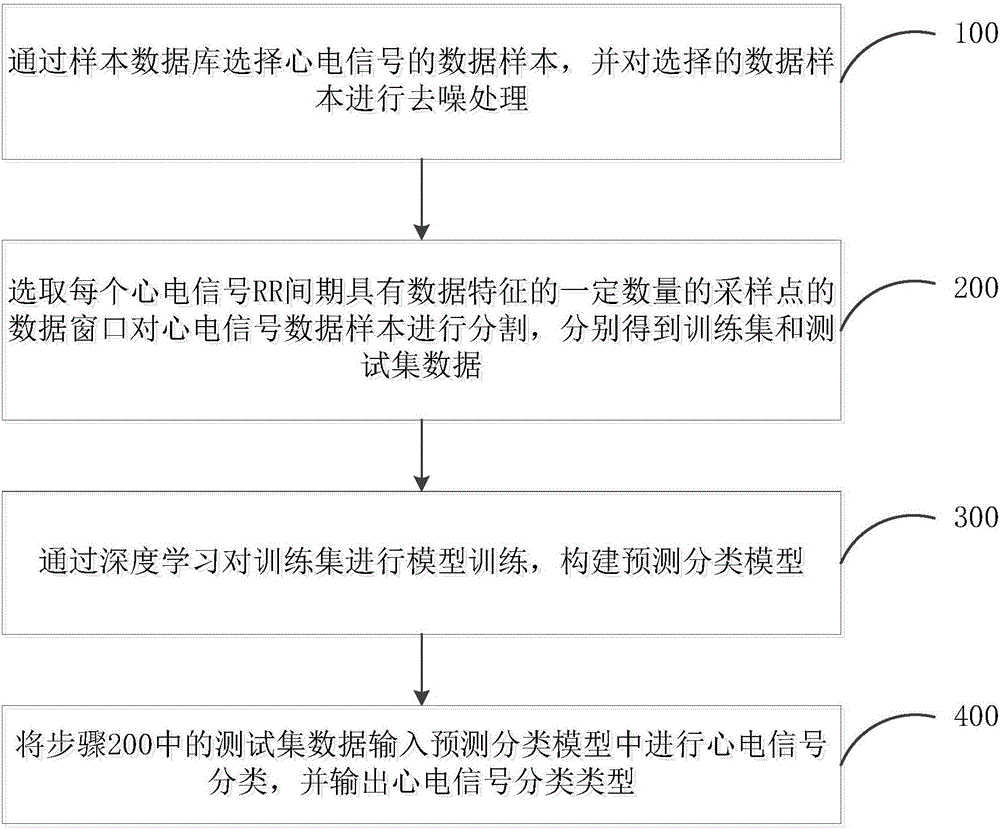

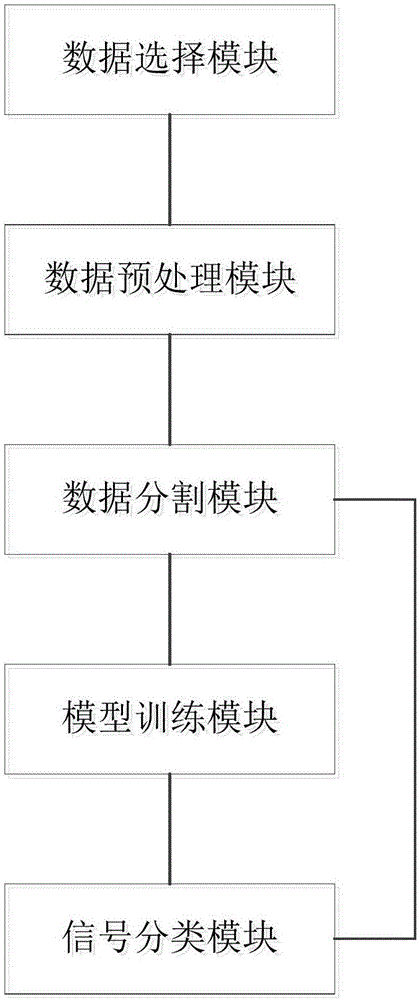

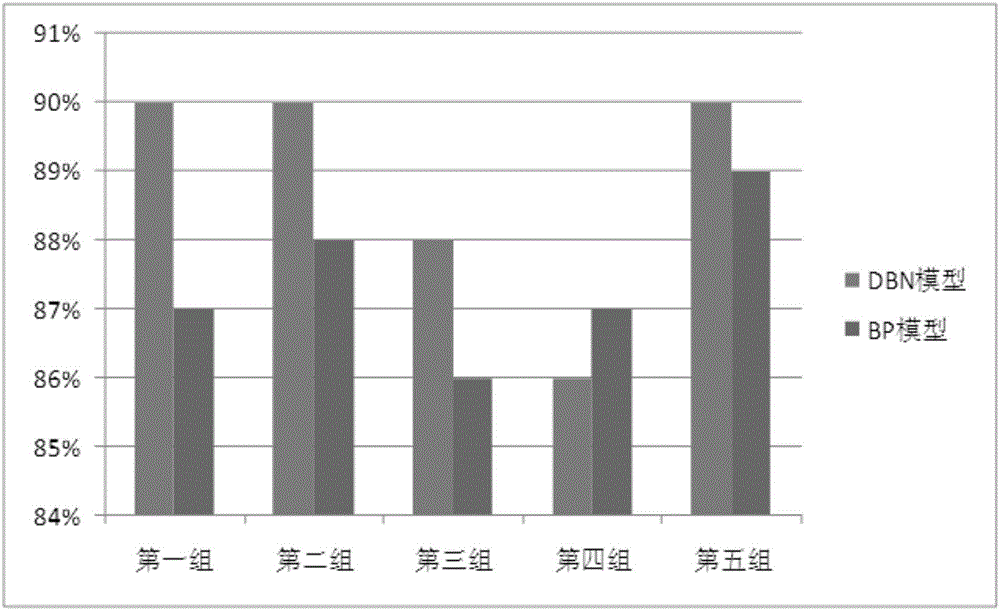

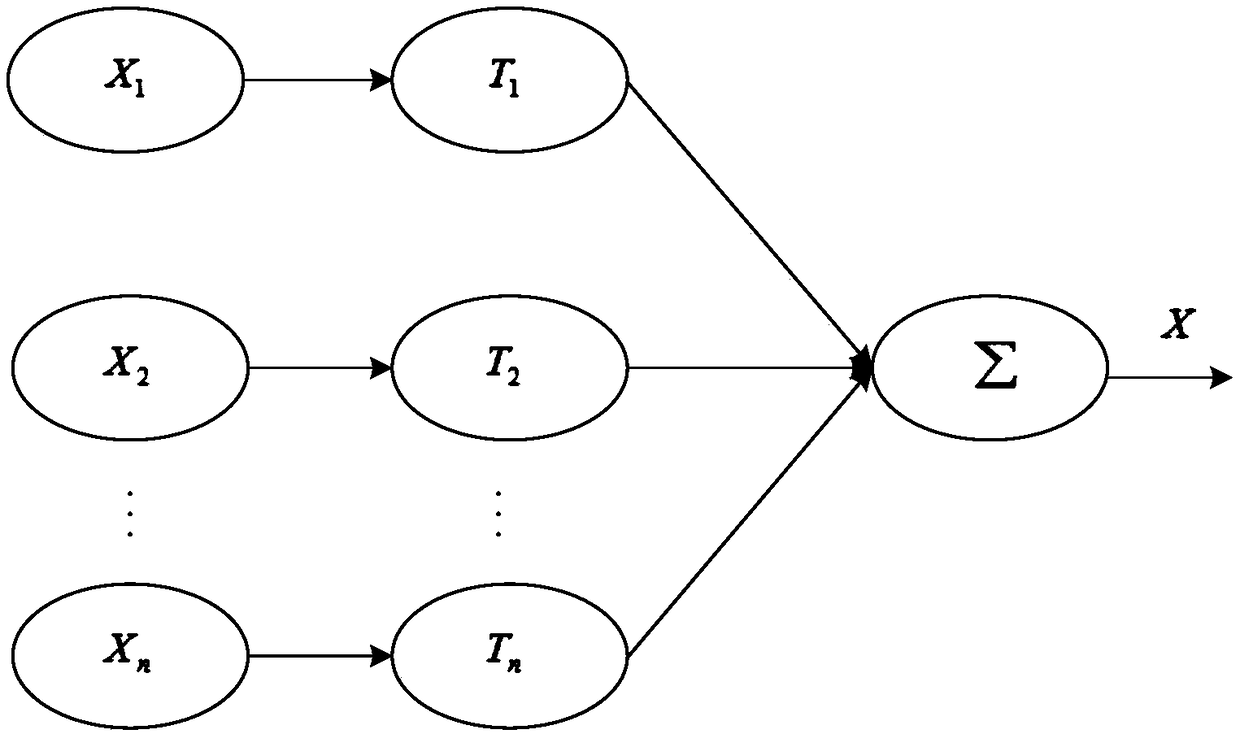

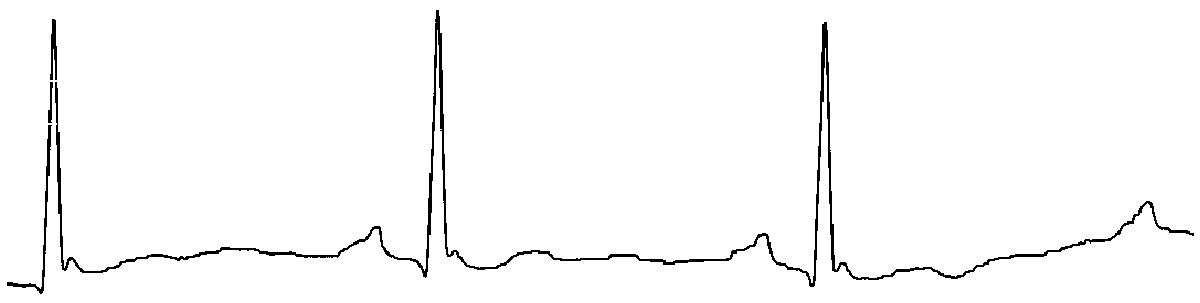

Electrocardiogram (ECG) signal classification method and device

InactiveCN106805965AReduce incompletenessImprove accuracyDiagnostic recording/measuringSensorsSignal classificationEcg signal

The invention relates to the technical field of ECG analysis and in particular relates to an ECG signal classification method and device. The ECG signal classification method comprises the following steps: a, segmenting the ECG signal, and respectively acquiring training set data and test set data; b, performing model training on the training set data through deep learning, and constructing a prediction classification model; and c, performing ECG signal classification on the test set data through the prediction classification model. According to the embodiment of the invention, the training set is subjected to model training through deep learning so as to obtain the prediction classification model, and the ECG signal classification is performed through the prediction classification model, so that incompleteness caused by artificial design characteristics is reduced, the ECG signal classification accuracy is improved, and more types of heart rate variability can be classified.

Owner:SHENZHEN INST OF ADVANCED TECH

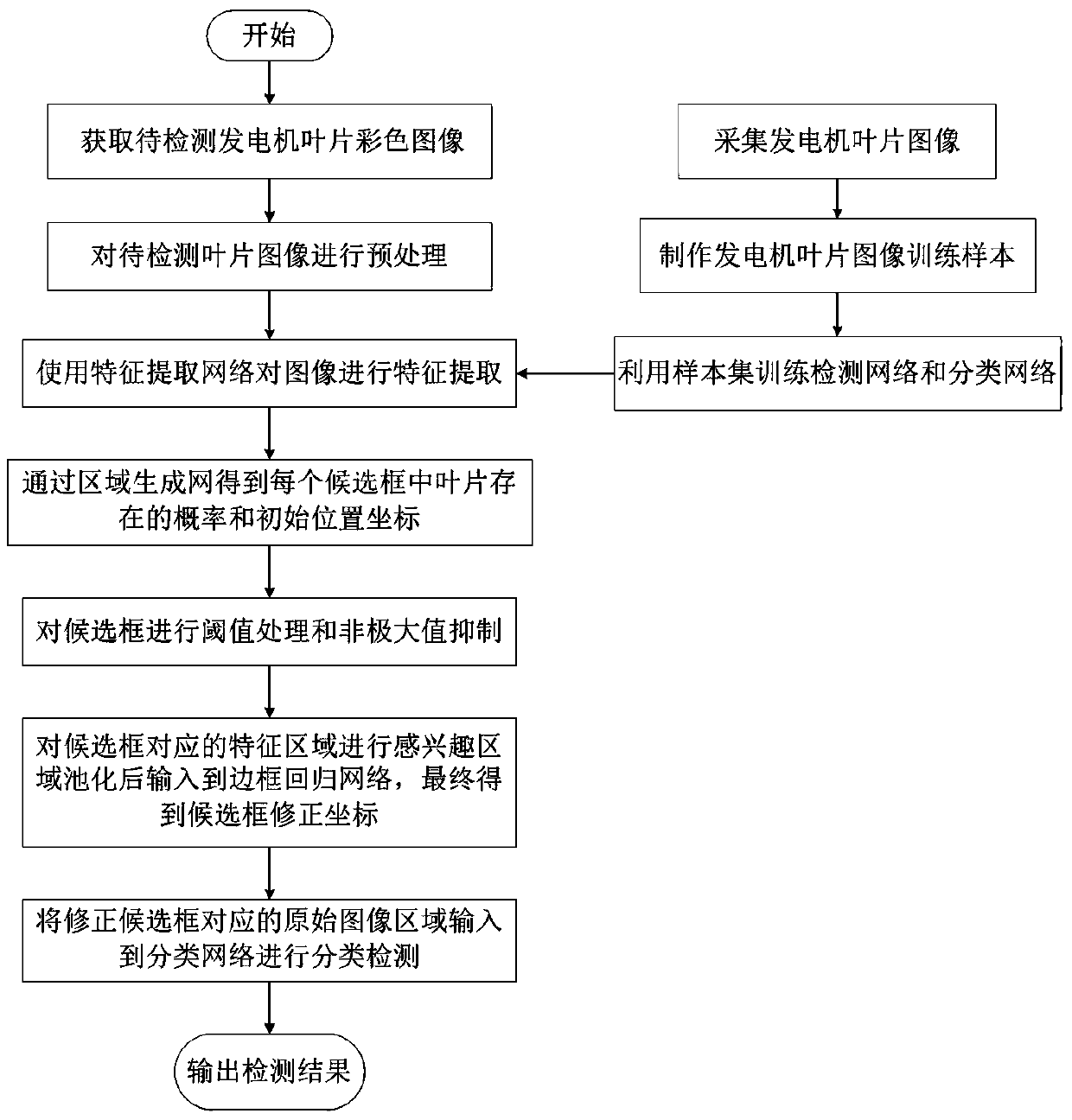

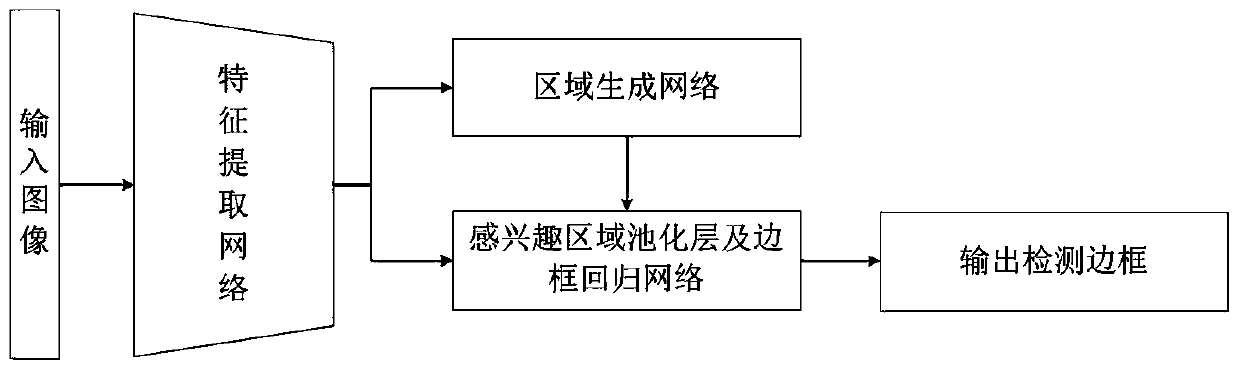

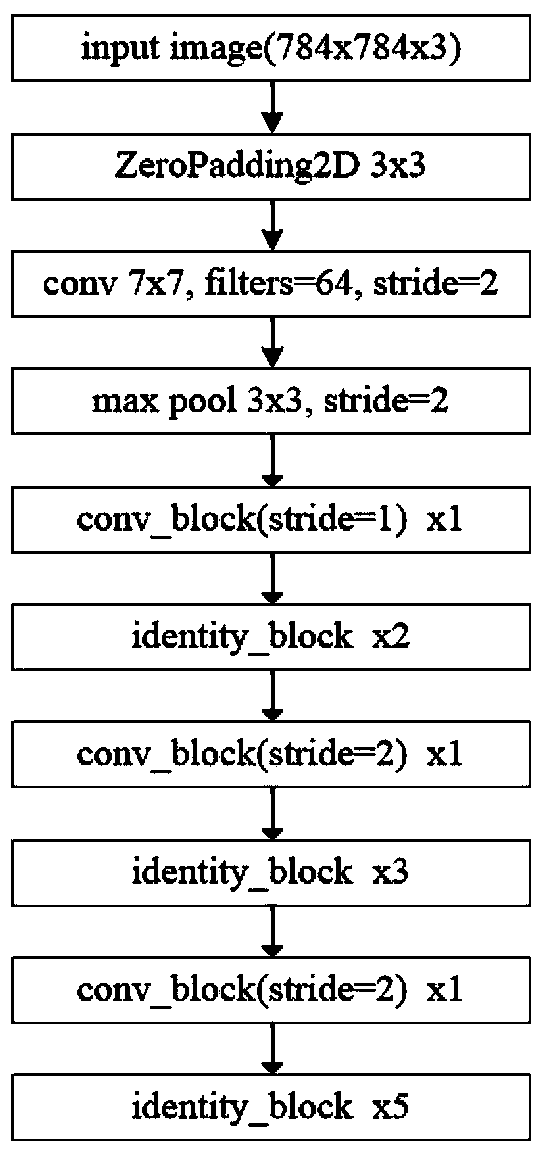

Convolutional neural network-based wind driven generator blade crack detection method

InactiveCN110111328AReduce incompletenessEasy to classifyImage analysisCharacter and pattern recognitionWind drivenVisual technology

The invention belongs to the technical field of computer vision, and discloses a convolutional neural network-based wind driven generator blade crack detection method, which comprises the following steps of (1) acquiring a generator blade image, and constructing a learning model training sample; (2) training a convolutional neural network model by using the model training sample; (3) preprocessingthe to-be-detected image; (4) carrying out feature extraction on the image by adopting a feature extraction network to obtain a feature map; (5) inputting the feature map into an area generation network to obtain a blade existence probability in each candidate box and the candidate box initial position coordinates; (6) performing the threshold filtering and non-maximum suppression on the candidate box; (7) inputting the feature map of each candidate box region into an interested region pooling layer and a frame regression network to obtain the candidate box correction coordinates; and (8) inputting the original image areas corresponding to the candidate frames into a classification network, and judging a blade crack classification result. According to the method, the interference of the image background content is eliminated, and the blade detection precision is improved.

Owner:上海中认尚科新能源技术有限公司

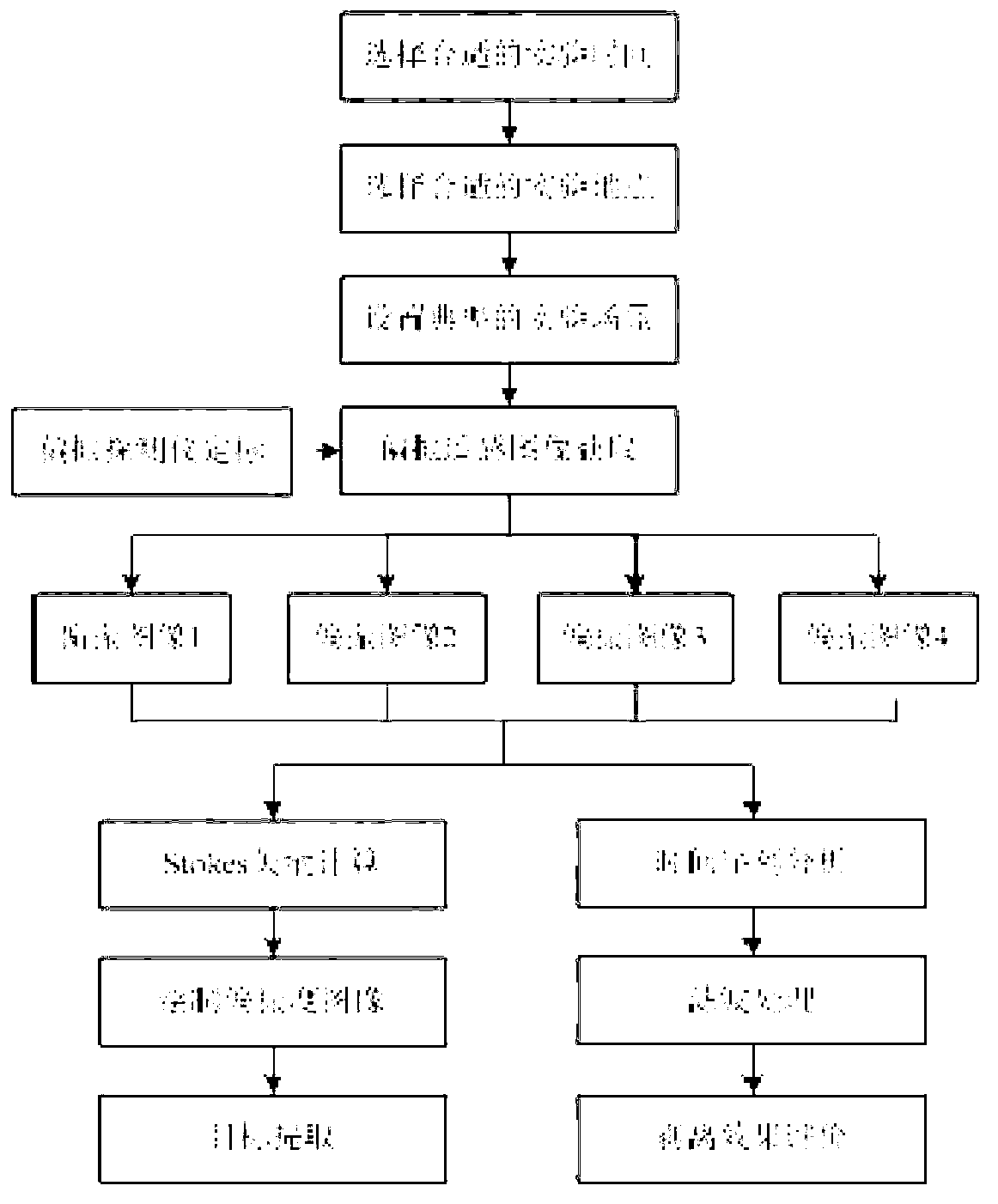

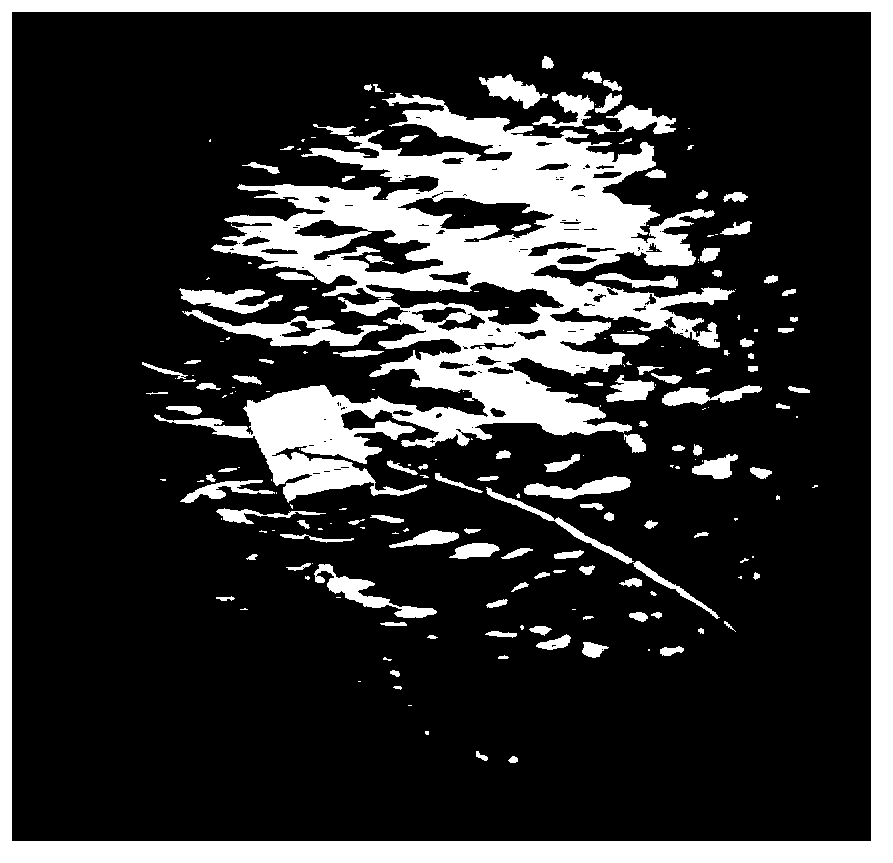

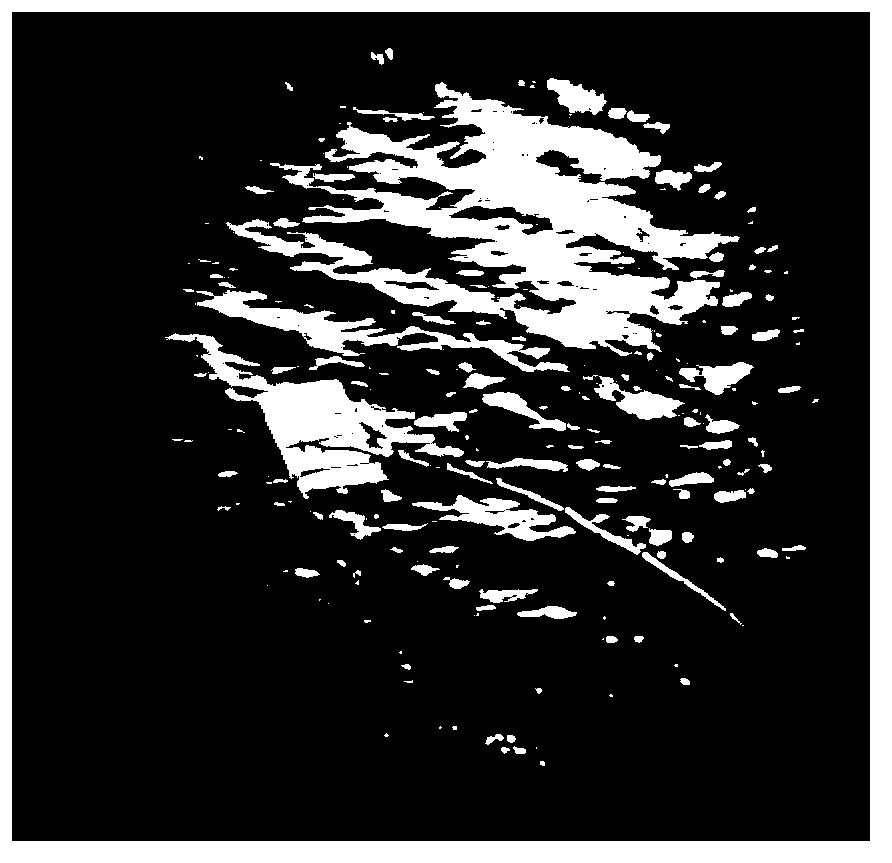

Wave water surface sun glitter stripping method based on polarization remote sensing detection

InactiveCN102998667ANarrow downReduce reflection strengthElectromagnetic wave reradiationWater colorPhysics

The invention relates to a wave water surface sun glitter stripping method based on polarization remote sensing detection, comprising the following four steps: step one, selecting proper time and point to carry out a water surface polarization remote sensing test; step two, selecting proper instruments to acquire a wave water surface sun glitter area time sequence polarization image; step three, processing a wave water surface sun glitter area polarization image; and step four, stripping wave water surface sun glitter. The method is a convenient and efficient wave water surface sun glitter correction method, and has the advantages of being high in precision and good in real-time without causing image data loss or relying on detection angle selection, and the like; and the method has extremely important application values in the fields of dynamic monitoring of sea surface ships, underwater target detection, water color remote sensing, and the like.

Owner:BEIHANG UNIV

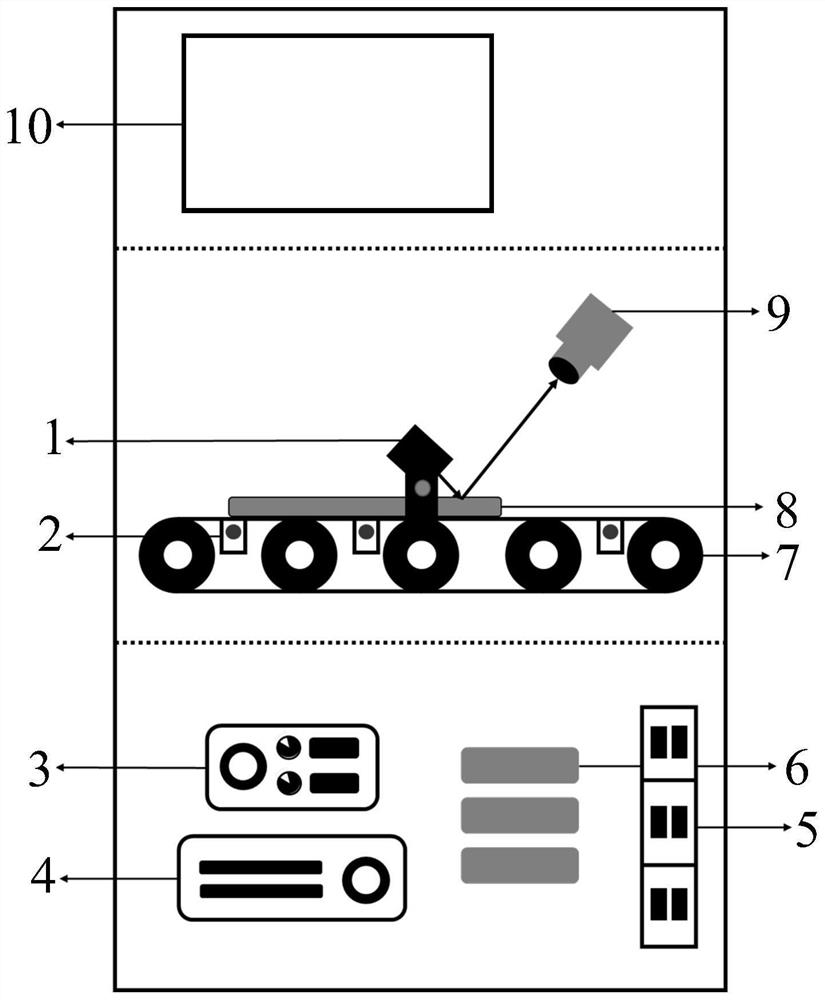

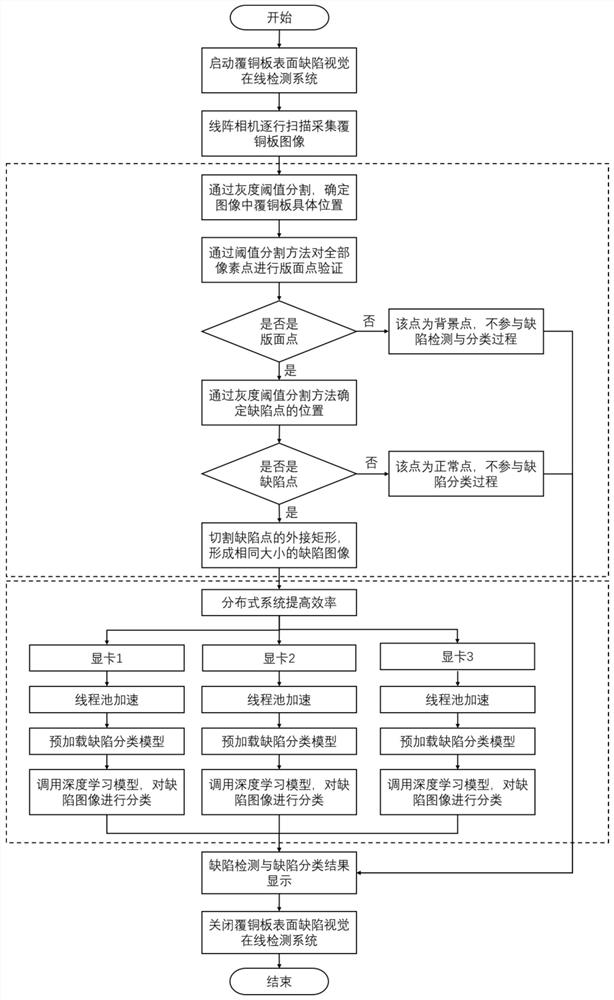

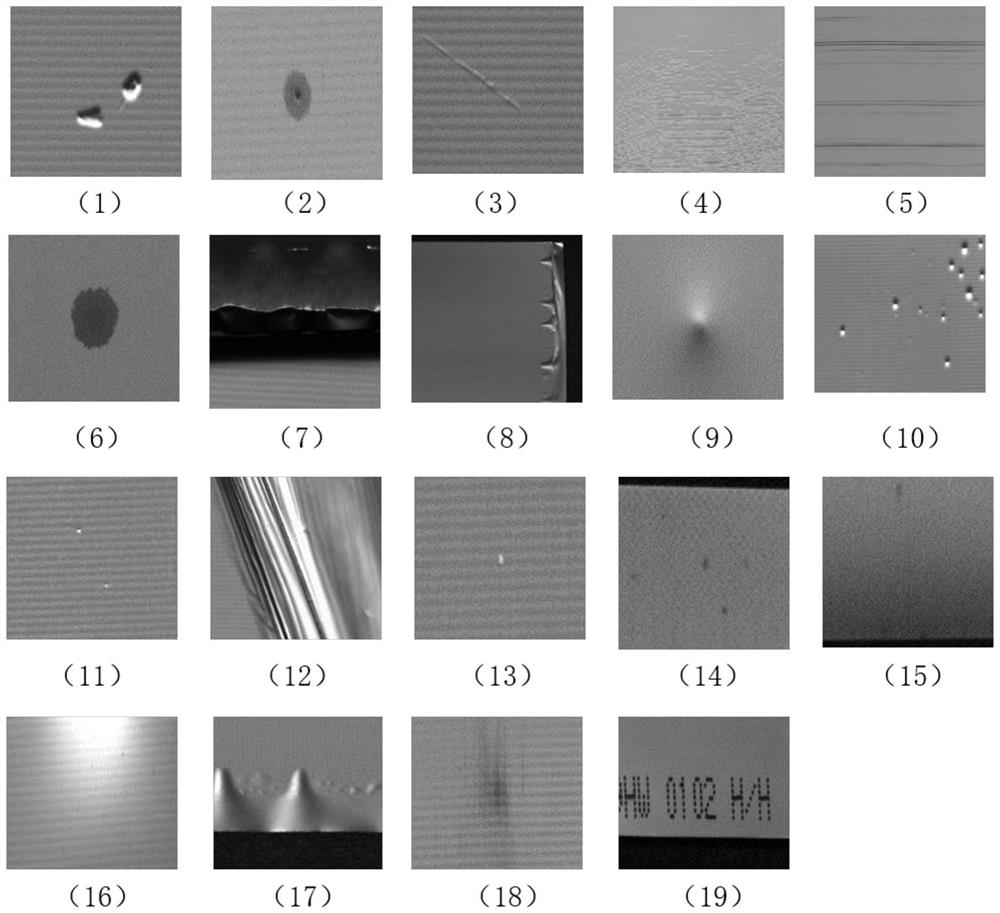

Copper-clad plate surface defect visual online detection method and device based on deep learning

PendingCN113155851AQuality assuranceEven detectionImage enhancementImage analysisContinuous scanningNeural network learning

The invention relates to a copper-clad plate surface defect visual online detection method based on deep learning, which comprises the following steps: continuously scanning a copper-clad plate passing through a conveyor belt at a constant speed line by line through a linear array scanning camera to complete image acquisition to obtain a complete and clear copper-clad plate image; carrying out defect detection on the acquired copper-clad plate image, if a defect is detected, marking the copper-clad plate as a defective copper-clad plate and giving an alarm, and simultaneously intercepting a defect image in the copper-clad plate; for defect images, adopting a deep neural network learning method, building a TensorFlow framework for defect classification, distinguishing different types of defects, and giving a targeted repair scheme; and displaying defect detection and defect classification results on the display screen, so that field staff can conveniently check the real-time state of the copper-clad plate in time and carry out subsequent processing. The invention further provides a corresponding device, and the problems that an existing copper-clad plate defect classification system is high in dependence on manpower and equipment, low in accuracy and long in consumed time can be solved.

Owner:XI AN JIAOTONG UNIV +1

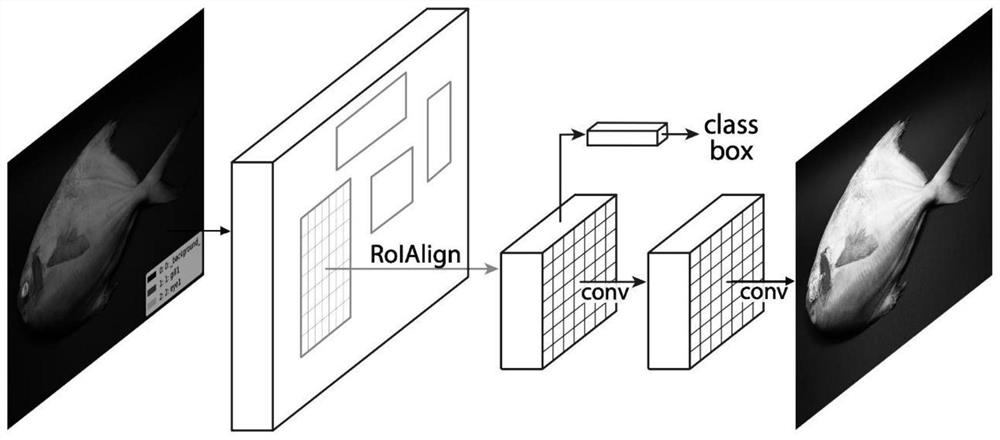

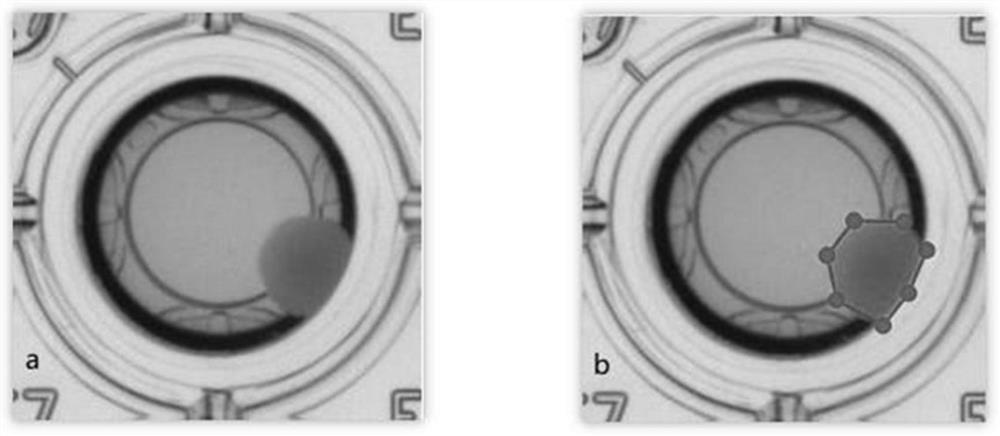

Frozen fresh pomfret freshness rapid grading method based on deep learning

PendingCN111768401AData augmentationBig amount of dataImage enhancementImage analysisCold chainData set

The invention discloses a frozen fresh pomfret freshness rapid grading method based on deep learning, which belongs to the technical field of refrigerated food quality evaluation. Specifically, freshness grading is carried out on a pomfret image based on a Mask R-CNN technology, a frozen fresh pomfret image is obtained, a digital image data set is established, feature learning is fused into the process of establishing the model, accurate detection and segmentation are carried out on fisheye and gill parts, feature learning can be carried out autonomously, and the freshness of the pomfret can be accurately segmented and classified. Therefore, quick detection and intelligent prediction of the quality deterioration of the frozen fresh pomfret are realized; and the expandability and mobility of the model are improved. A rapid, low-cost, accurate, nondestructive and real-time automatic detection technology is realized, and the health and benefits of consumers are guaranteed. Product qualityis controlled for different varieties of cold chain storage and transportation environments and supply chain sources, and technical support is provided for public health and epidemic prevention.

Owner:CHINA AGRI UNIV

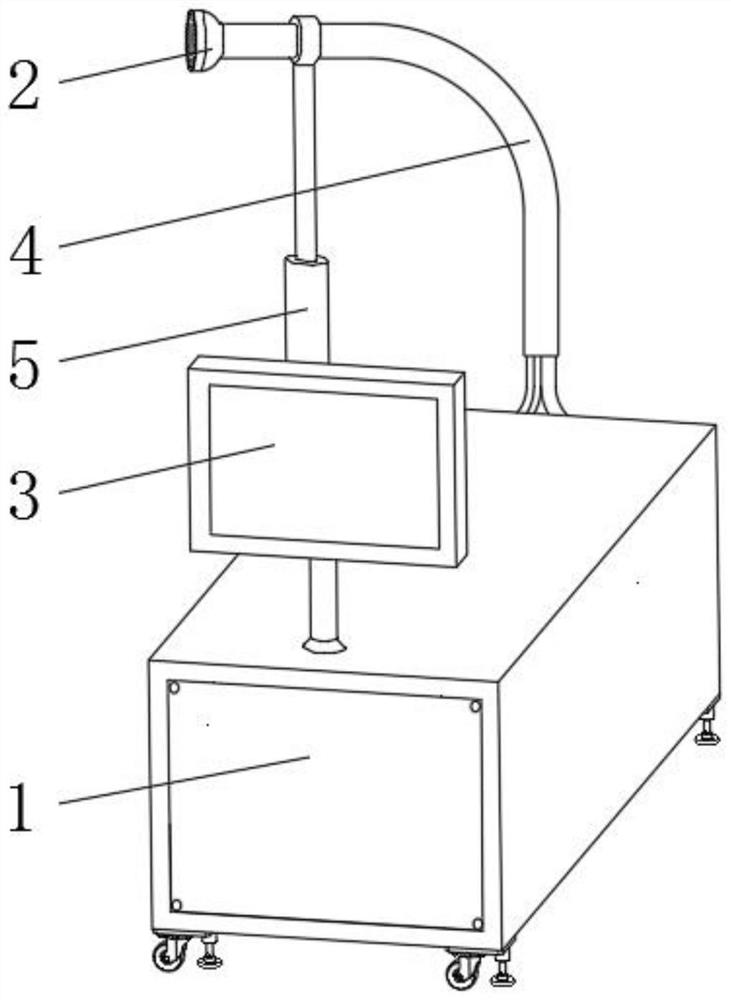

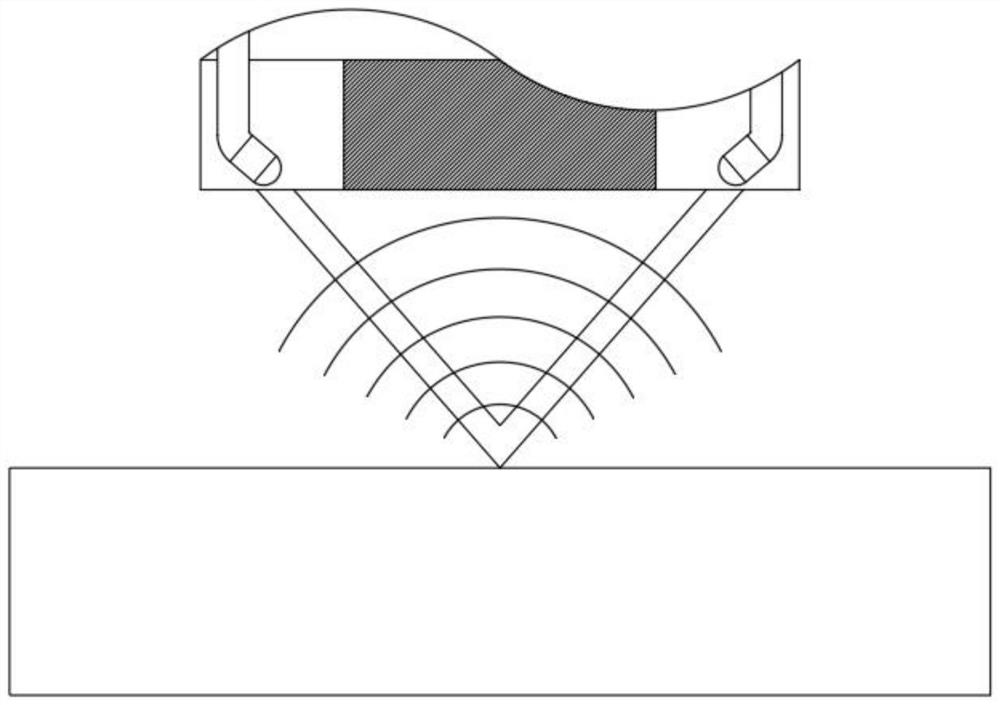

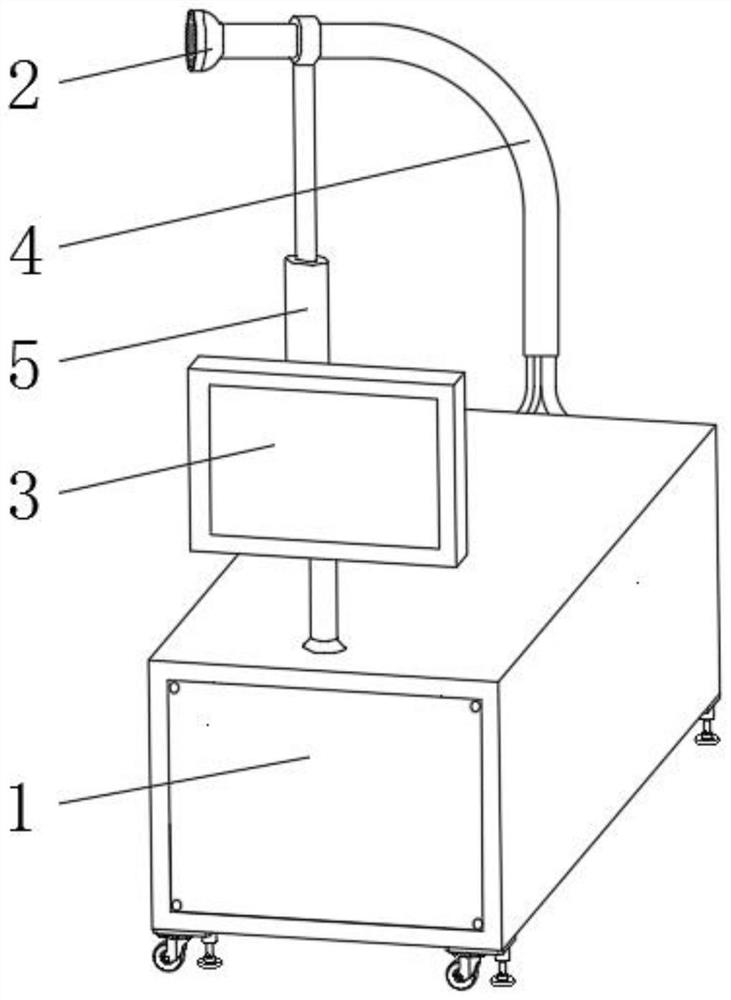

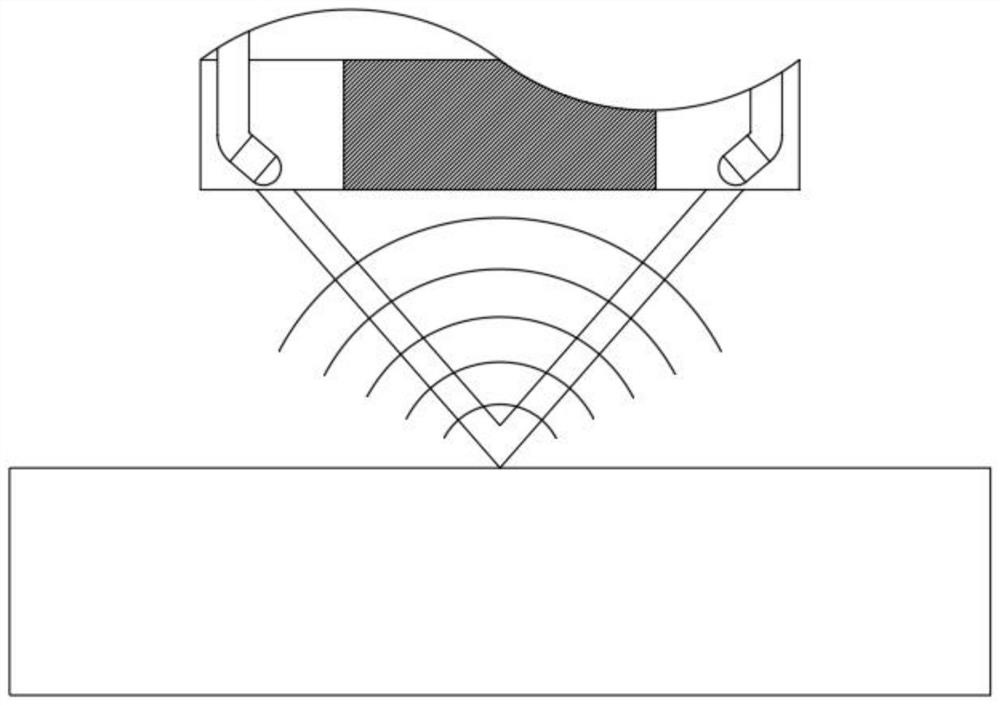

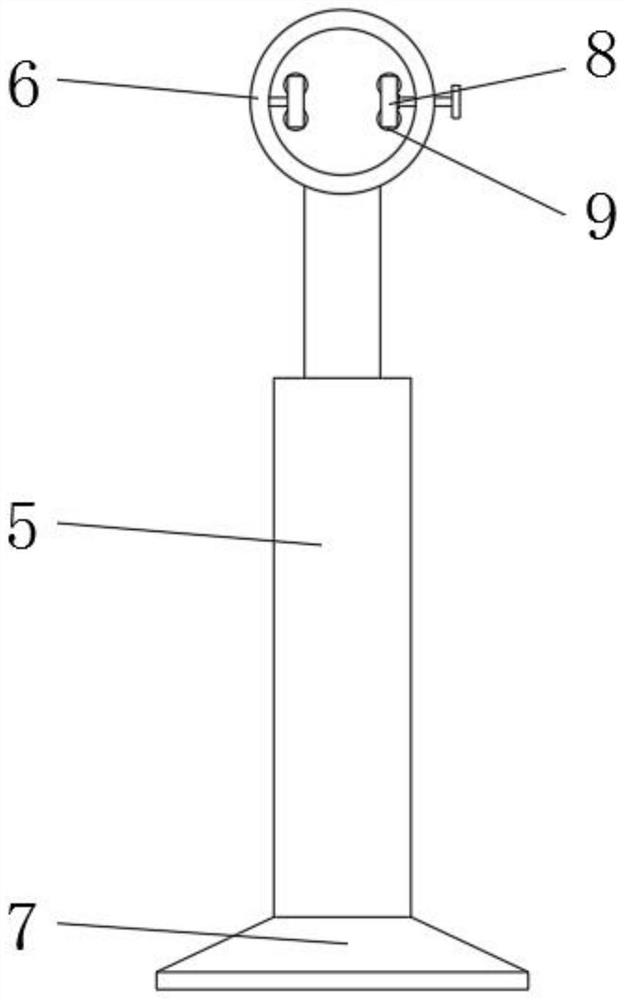

Photoacoustic imaging surgical navigation platform for guiding tumor excision

ActiveCN111839730AReduce incompletenessReduce recurrenceSurgical navigation systemsTumor reductionDisplay device

The invention discloses a photoacoustic imaging surgical navigation platform for guiding tumor excision, which comprises photoacoustic imaging equipment, and the photoacoustic imaging equipment comprises a main body, a probe and an image display. The invention discloses the photoacoustic imaging operation navigation platform for guiding tumor excision, and high-frame-rate photoacoustic images andultrasonic images can be provided; deep tissue tumors are visualized in real time; the position of the tumor can be positioned and a tumor boundary is accurately drawn; meanwhile, an aseptic scalpel can be visually improved through photoacoustic imaging; simultaneous development of the tumor and the scalpel under photoacoustic imaging is realized, and the focus can be thoroughly excised by directly viewing the tumor boundary without missing or mistaken cutting, the technology can be used for tumor positioning, boundary defining and accurate excision in the operation process, accurate intraoperative guidance is provided for tumor surgeons, the incompleteness of intraoperative tumor excision is reduced, the thorough excision rate is increased, normal tissue is reserved to the maximum extent,tumor recurrence is reduced, and the survival rate is increased.

Owner:厦门大学附属翔安医院

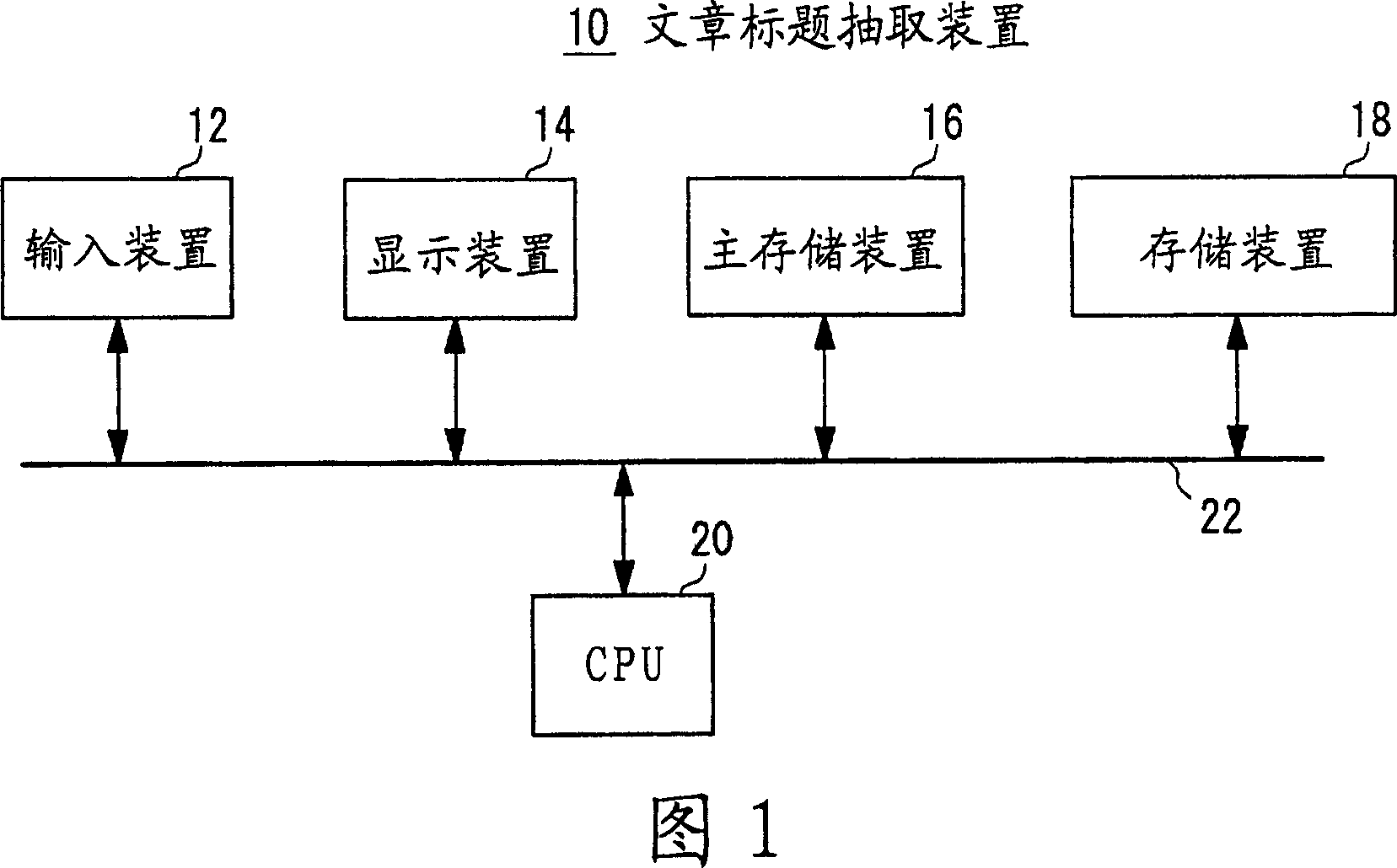

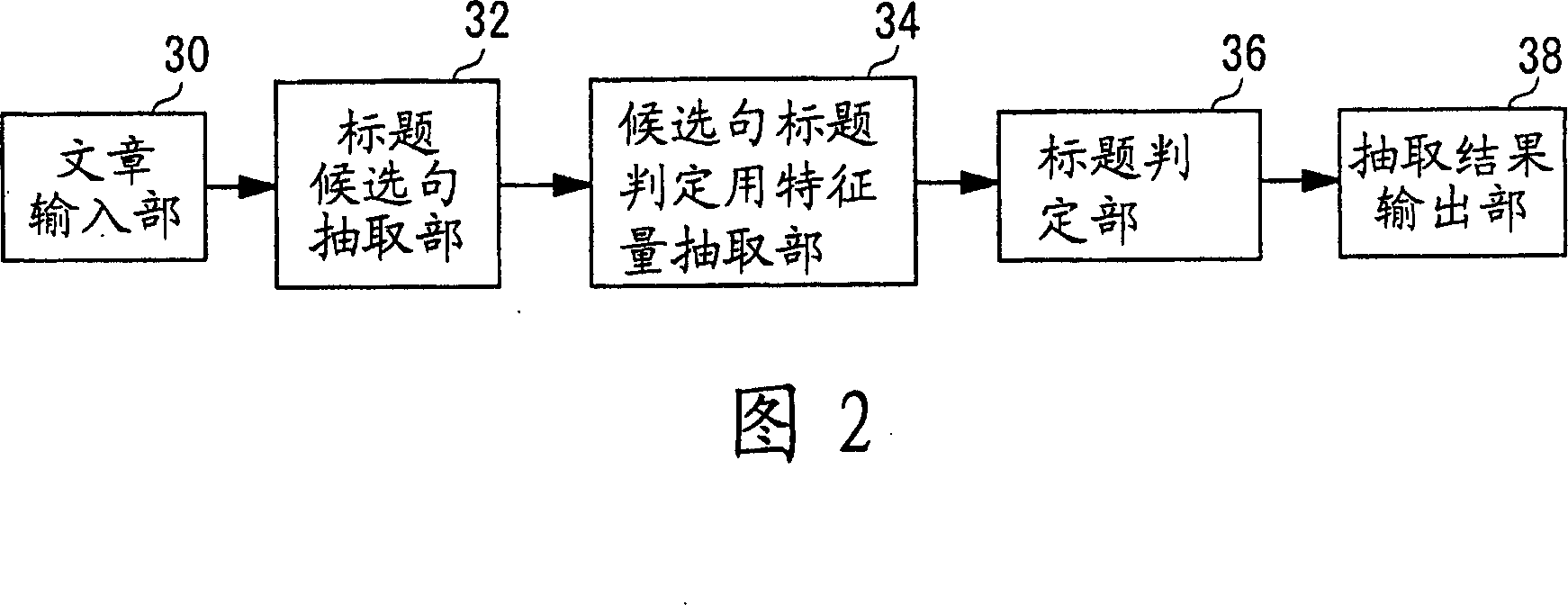

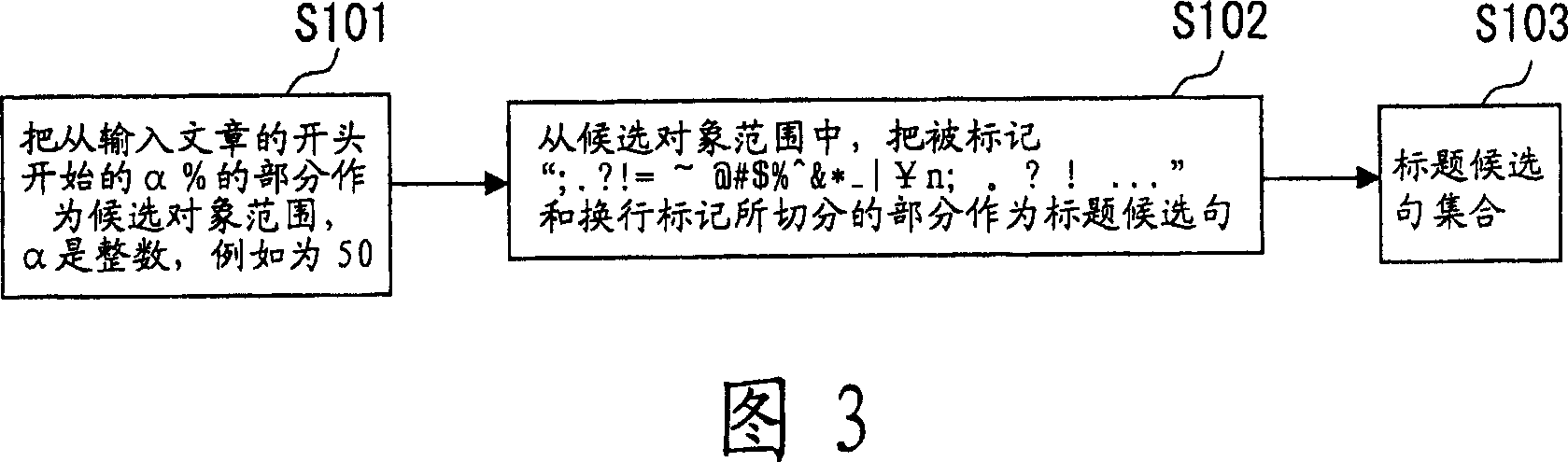

Automatic extraction device, method and program of essay title and correlation information

InactiveCN1955979AHigh precisionReduce the impact of misidentificationCharacter and pattern recognitionTest articleComputer science

An automatic-drawing device of article title and correlation information consists of title candidate sentence drawing unit for drawing out multiple title candidate sentence from test article inputted by article input unit, characteristic value drawing unit for drawing out characteristic value from each of multiple title candidate sentence and title deciding unit of deciding out title from multiple title candidate sentence according to drawn out characteristic value.

Owner:FUJIFILM BUSINESS INNOVATION CORP

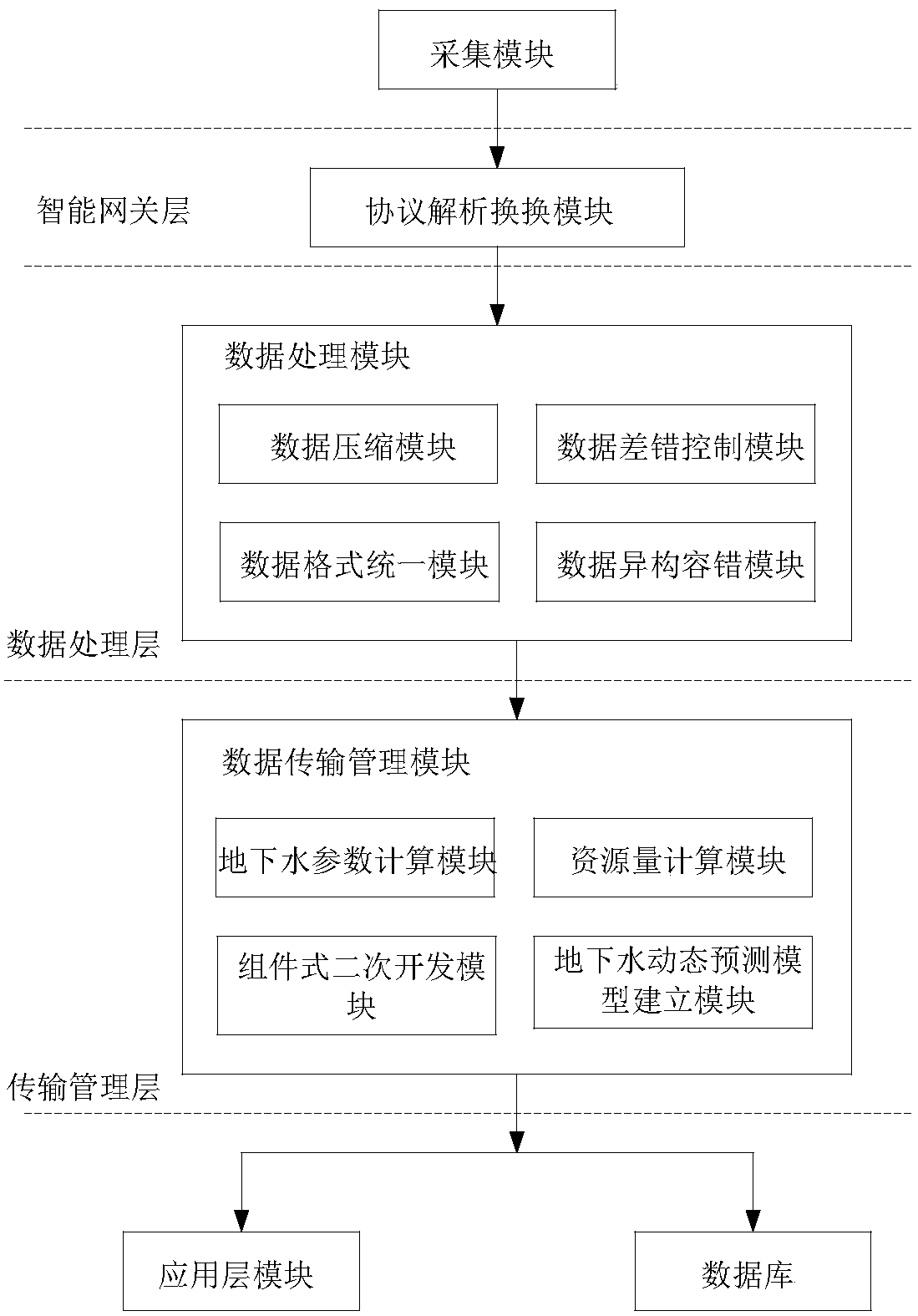

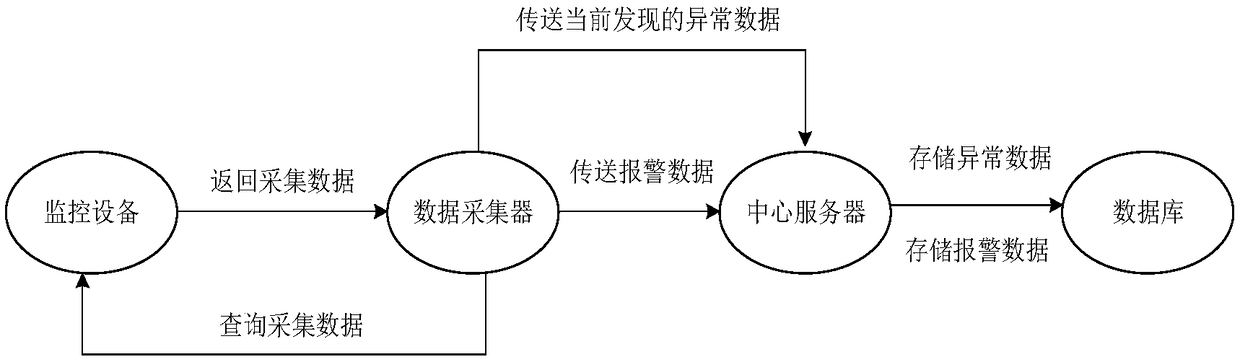

Water environment data transmission system and method based on Internet of Things

InactiveCN109413003AImprove accuracyAvoid errorsMeasurement devicesData switching networksReal-time dataMonitoring system

The invention provides a water environment data transmission system and method based on Internet of Things, belonging to the technical field of Internet of Things. The water environment data transmission system comprises a collection module, a protocol analysis and conversion module, a data processing module, a data transmission management module, a database and an application layer module. The method comprises a collecting step, a protocol analyzing and converting step, a data processing step, a data transmission management step, and a database and application layer step. The water environment data transmission system and method can be applied to various water environment monitoring systems, and have the advantages of real-time data monitoring, high accuracy and the like.

Owner:THE INST OF AUTOMATION HEILONGJIANG ACADEMY OF SCI +1

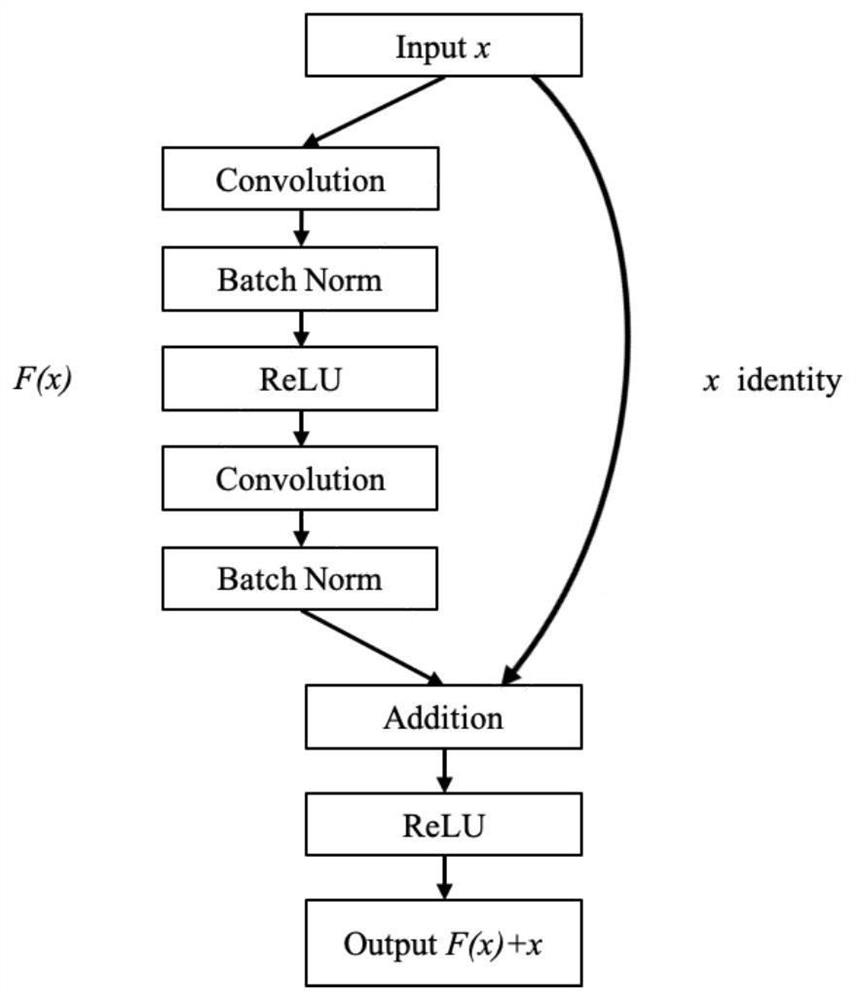

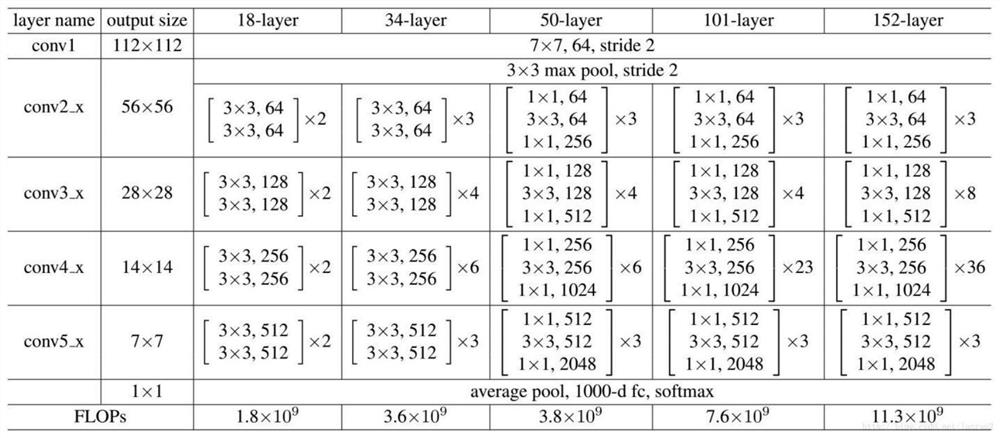

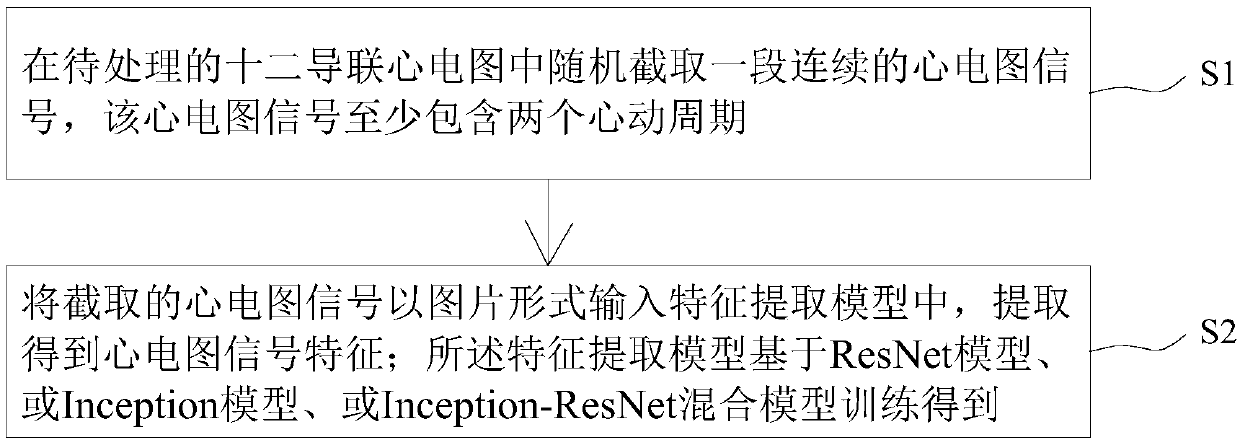

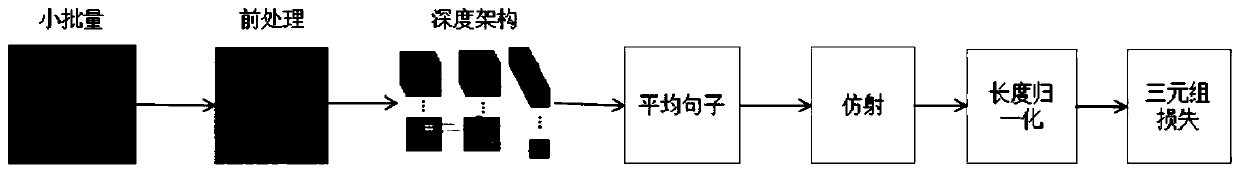

Electrocardiogram feature extraction method, device, system, equipment and classification method based on deep learning algorithm

PendingCN110897629AReduce incompletenessImprove accuracyDiagnostic recording/measuringSensorsFeature extractionCardiac cycle

The invention discloses an electrocardiogram feature extraction method, device, system, equipment and classification method based on a deep learning algorithm. The electrocardiogram feature extractionmethod based on the deep learning algorithm comprises the following steps: randomly intercepting a section of continuous electrocardiogram signal from a twelve-lead electrocardiogram to be processed,wherein the electrocardiogram signal at least comprises two cardiac cycles; and inputting the intercepted electrocardiogram signal into a feature extraction model in a picture form, and performing extraction to obtain electrocardiogram signal features, wherein the feature extraction model is obtained by training a ResNet model or an Inception model or an Inception-ResNet model. According to the electrocardiogram feature extraction method, device, system, equipment and classification method based on the deep learning algorithm provided by the invention, the incompleteness caused by artificialdesign features is reduced, and the accuracy and diversity of electrocardiogram feature extraction based on the deep learning algorithm are improved.

Owner:HANGZHOU ARTERYFLOW TECH CO LTD

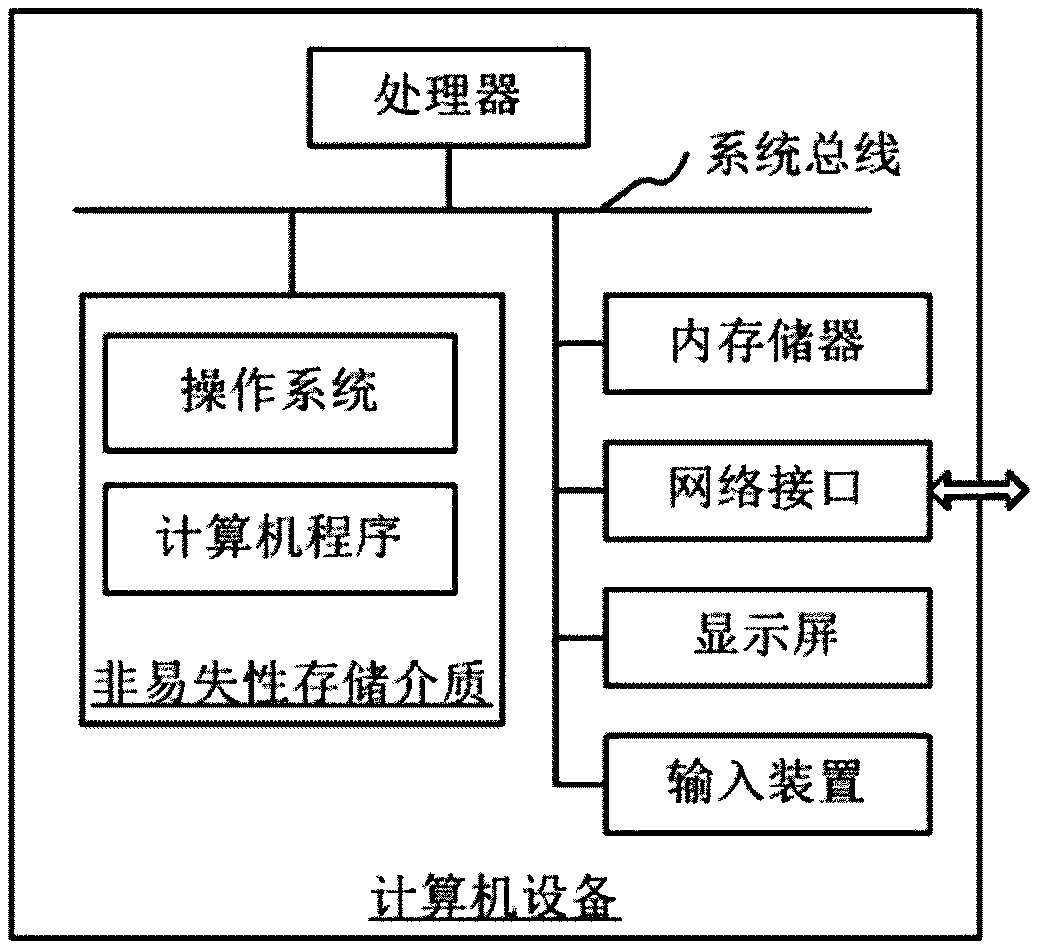

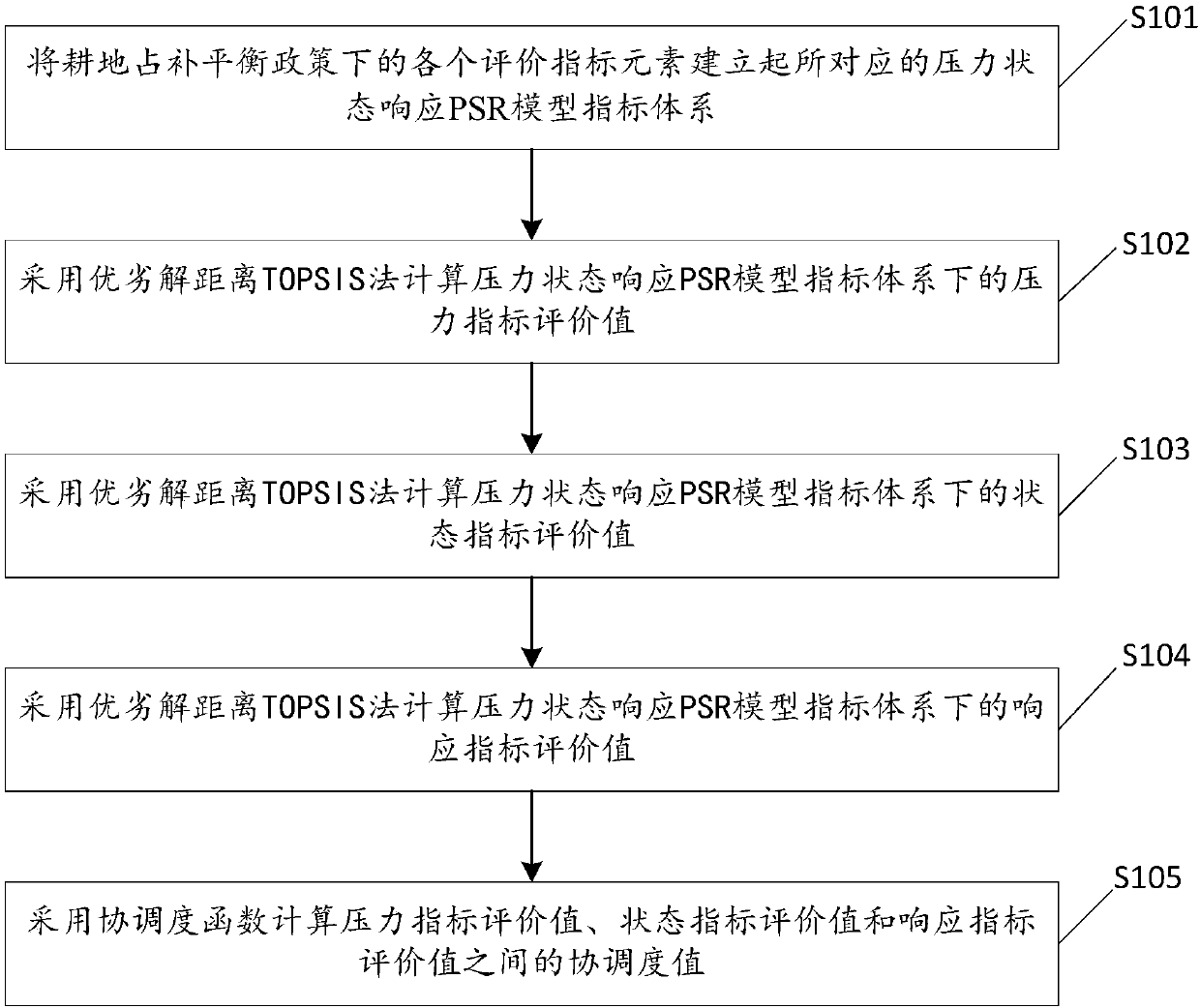

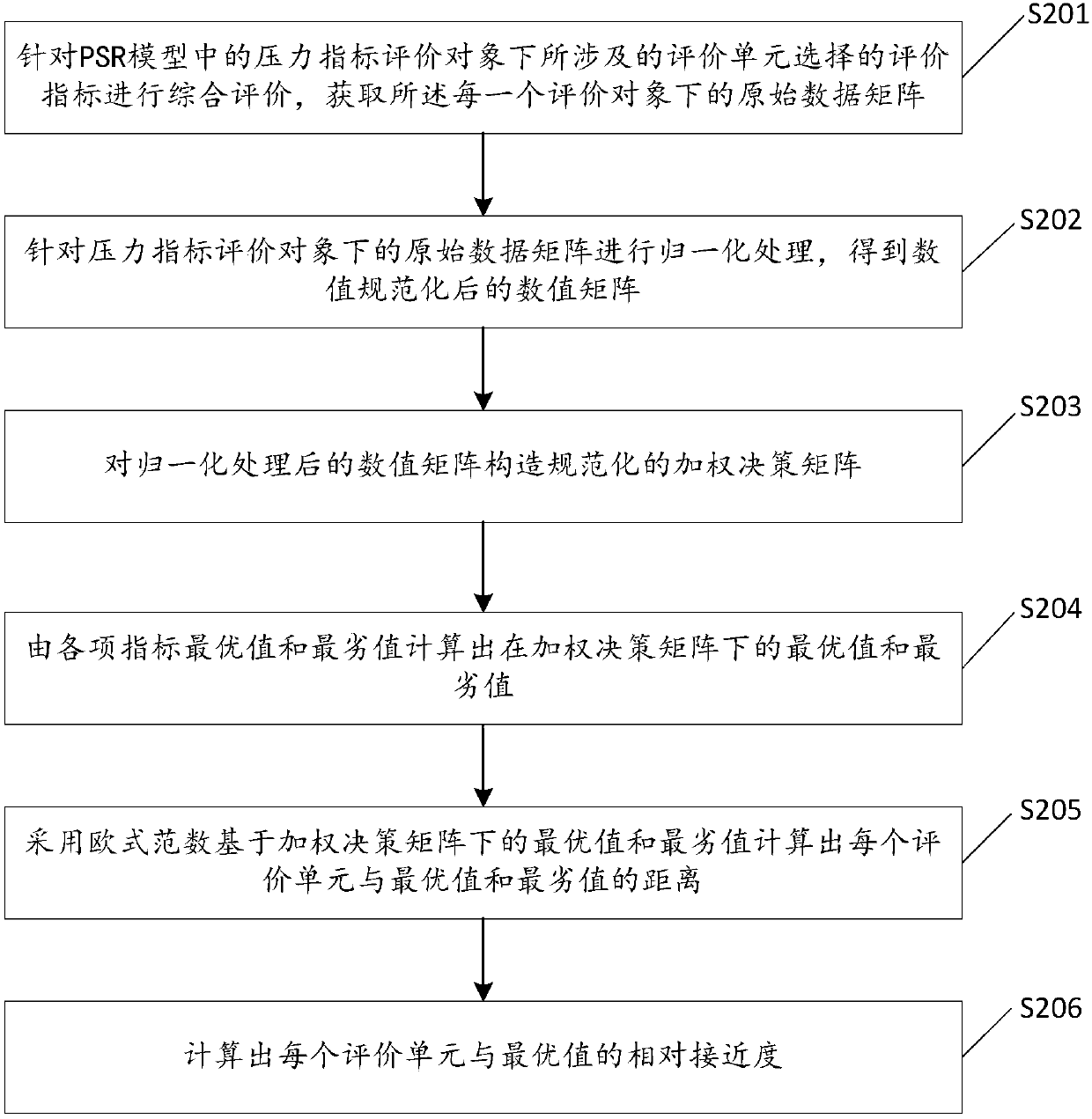

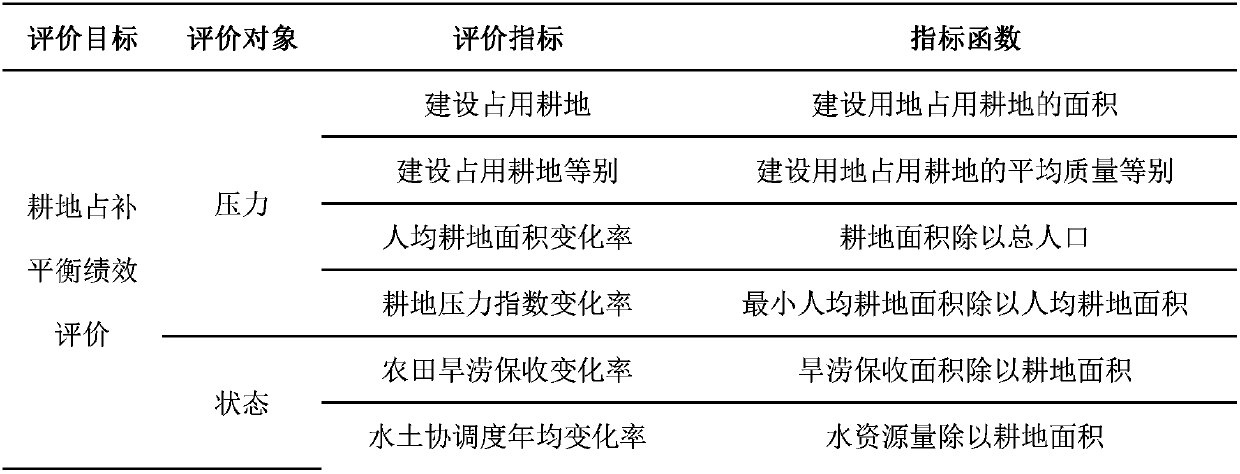

Method for evaluating performance of cultivated land requisition-compensation balance based on PSR model

The invention discloses a method for evaluating the performance of cultivated land requisition-compensation balance based on a PSR model. The method includes the steps of establishing a correspondingpressure state response (PSR) model index system for each evaluation index element under a cultivated land requisition-compensation balance policy; adopting a TOPSIS method to calculate a pressure index evaluation value, a state index evaluation value and a response index evaluation value under the PSR model index system; adopting a coordination index function to calculate a coordination degree value between the pressure index evaluation value, the state index evaluation value and the response index evaluation value. Through the method, the PSR model embodies the interaction between humans andthe environment, emphasizes the influence of population, society, and economy on policies, and can comprehensively evaluate the whole process of policies, effectively making up for the above defects..

Owner:SOUTH CHINA AGRI UNIV

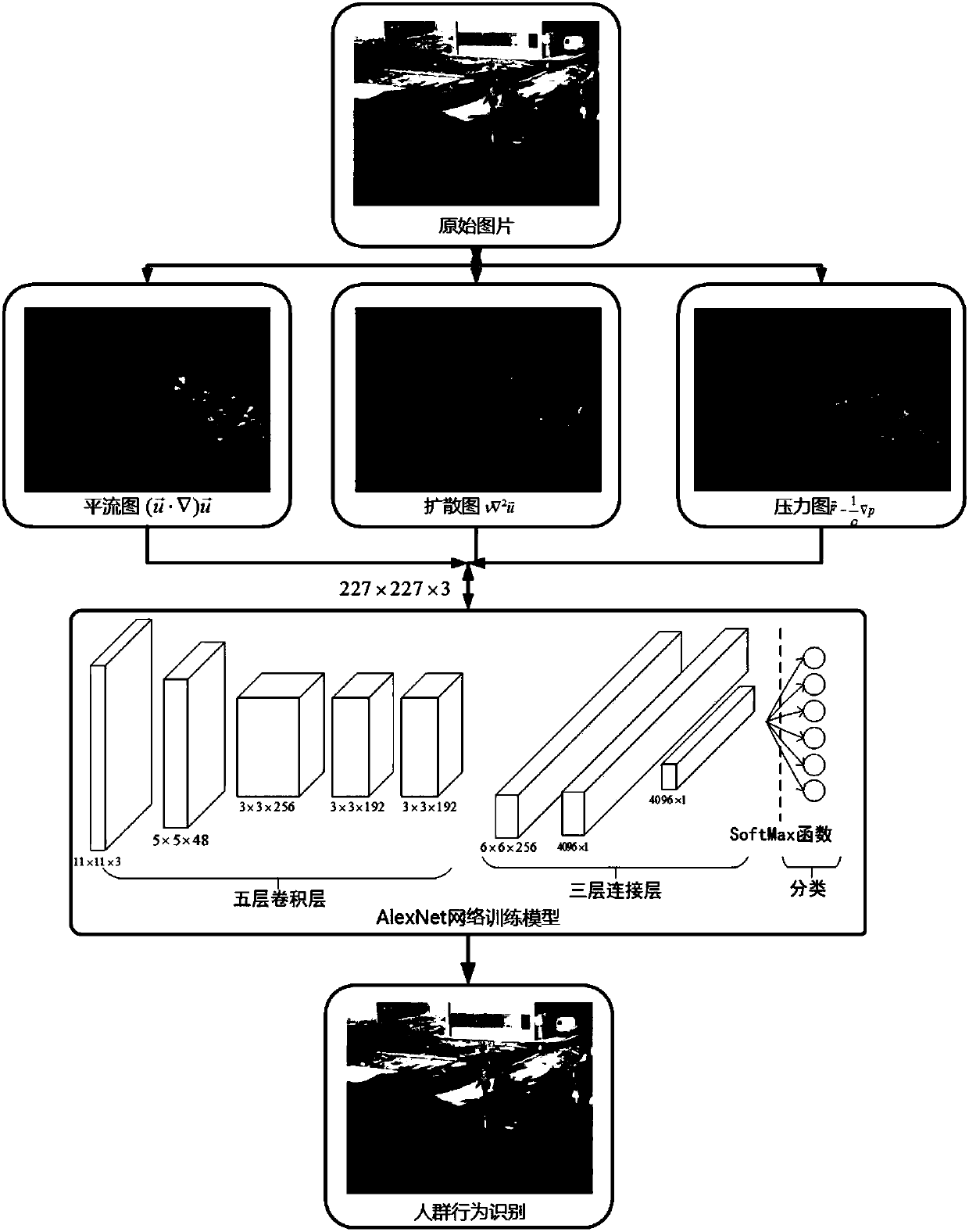

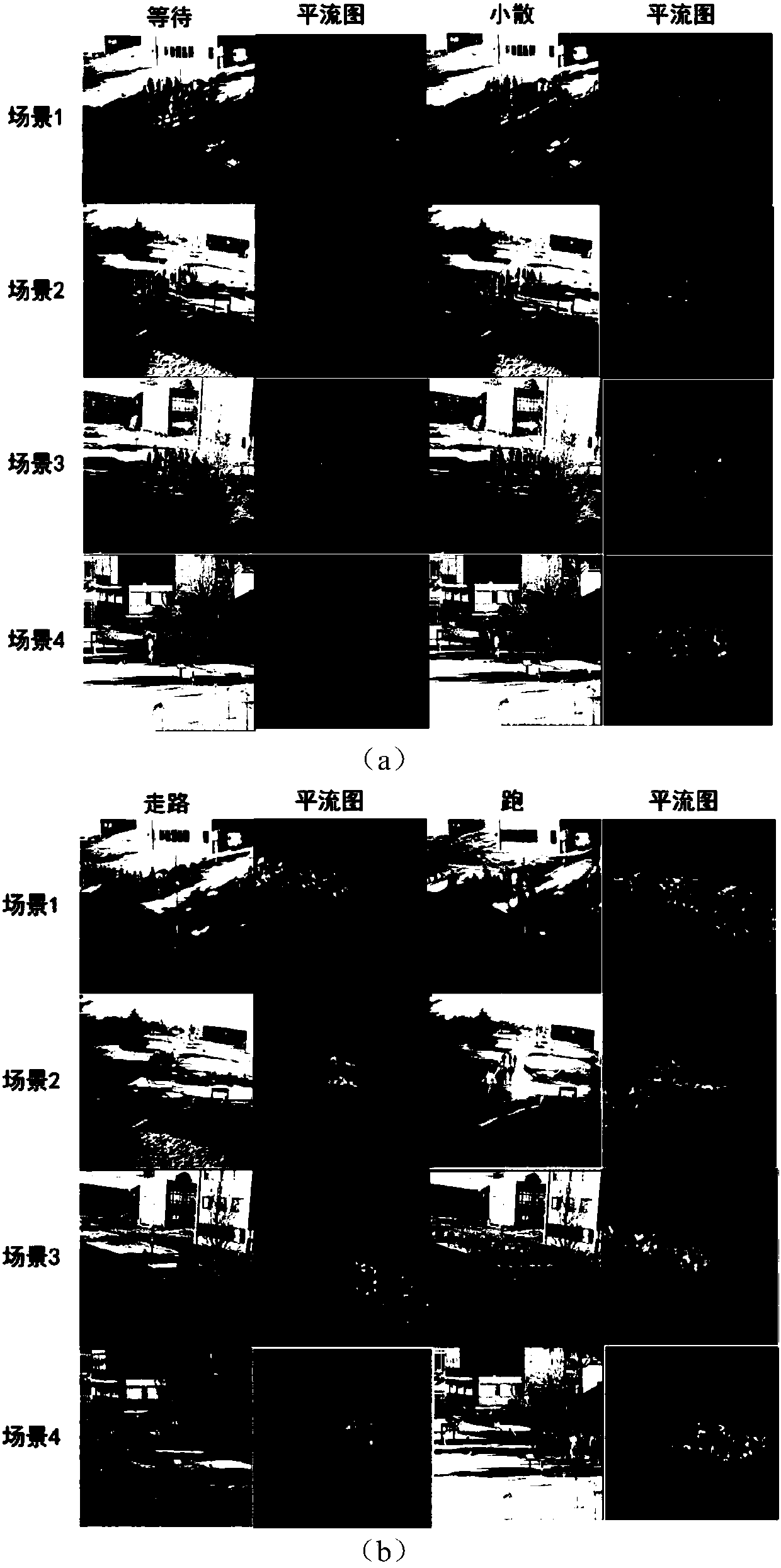

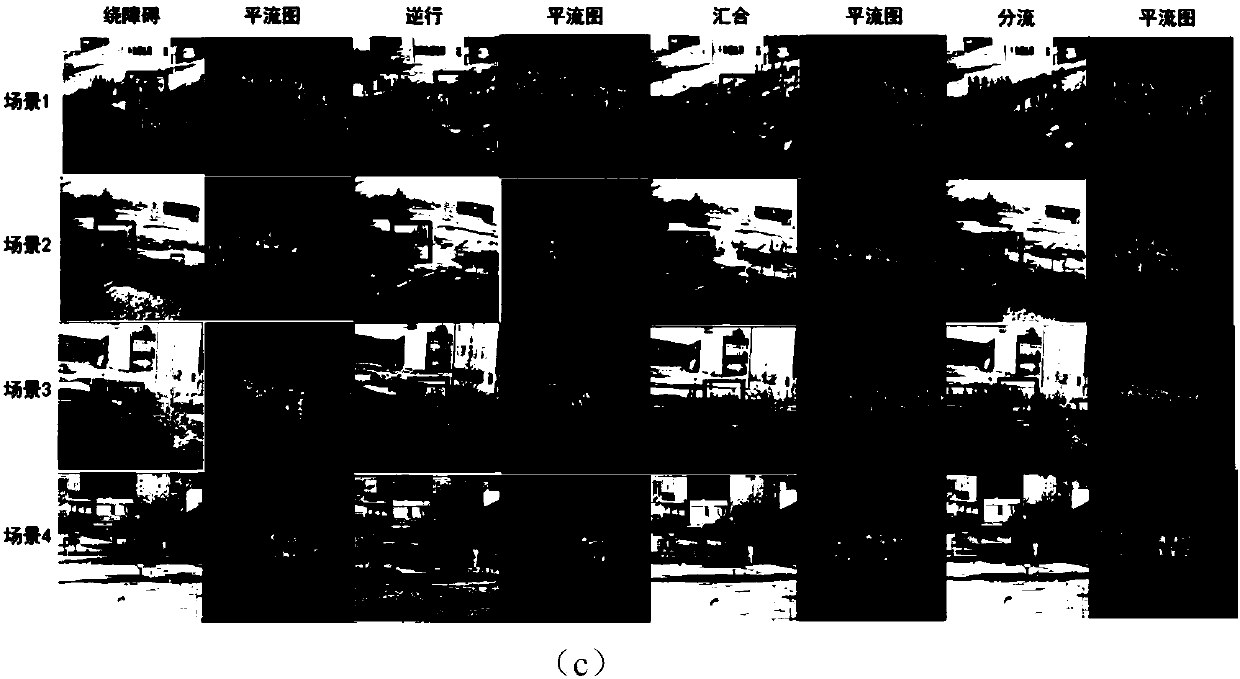

Behavior recognition method based on three descriptors of hydrodynamics

ActiveCN108537118AReduce incompletenessImprove accuracyCharacter and pattern recognitionArtificial lifeDiffusionCrowds

The invention provides a behavior recognition method based on three descriptors of hydrodynamics. The behavior recognition method based on three descriptors of hydrodynamics comprises the steps: calculating three descriptors of a picture, based on hydrodynamics, and respectively obtaining an advection descriptor, a diffusion descriptor and a pressure descriptor of the picture; integrating thermodynamic diagrams of different descriptors of the same frame into the input data type of the adopted neural network, inputting into the trained neural network, performing fine tuning on the neural network to obtain a model of different crowd behaviors; and by classifying the crowd behaviors through the obtained model, obtaining the detected crowd behavior type, and realizing behavior recognition. Thebehavior recognition method based on three descriptors of hydrodynamics has high accuracy for behavior recognition, can reduce a frame in which no event occurs as a frame in which an event occurs, and can also detect more frames in which events occur.

Owner:SHANGHAI JIAO TONG UNIV

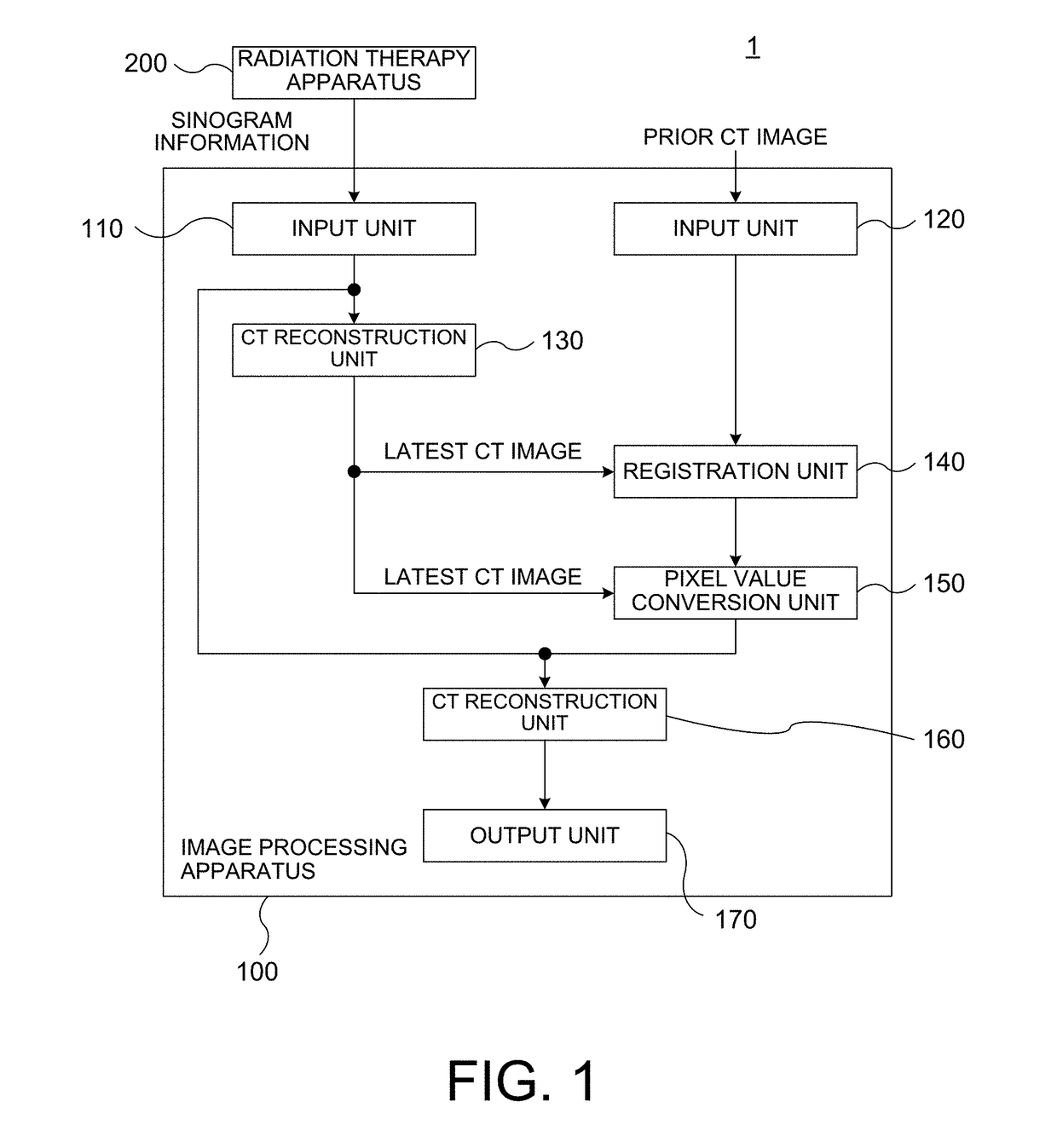

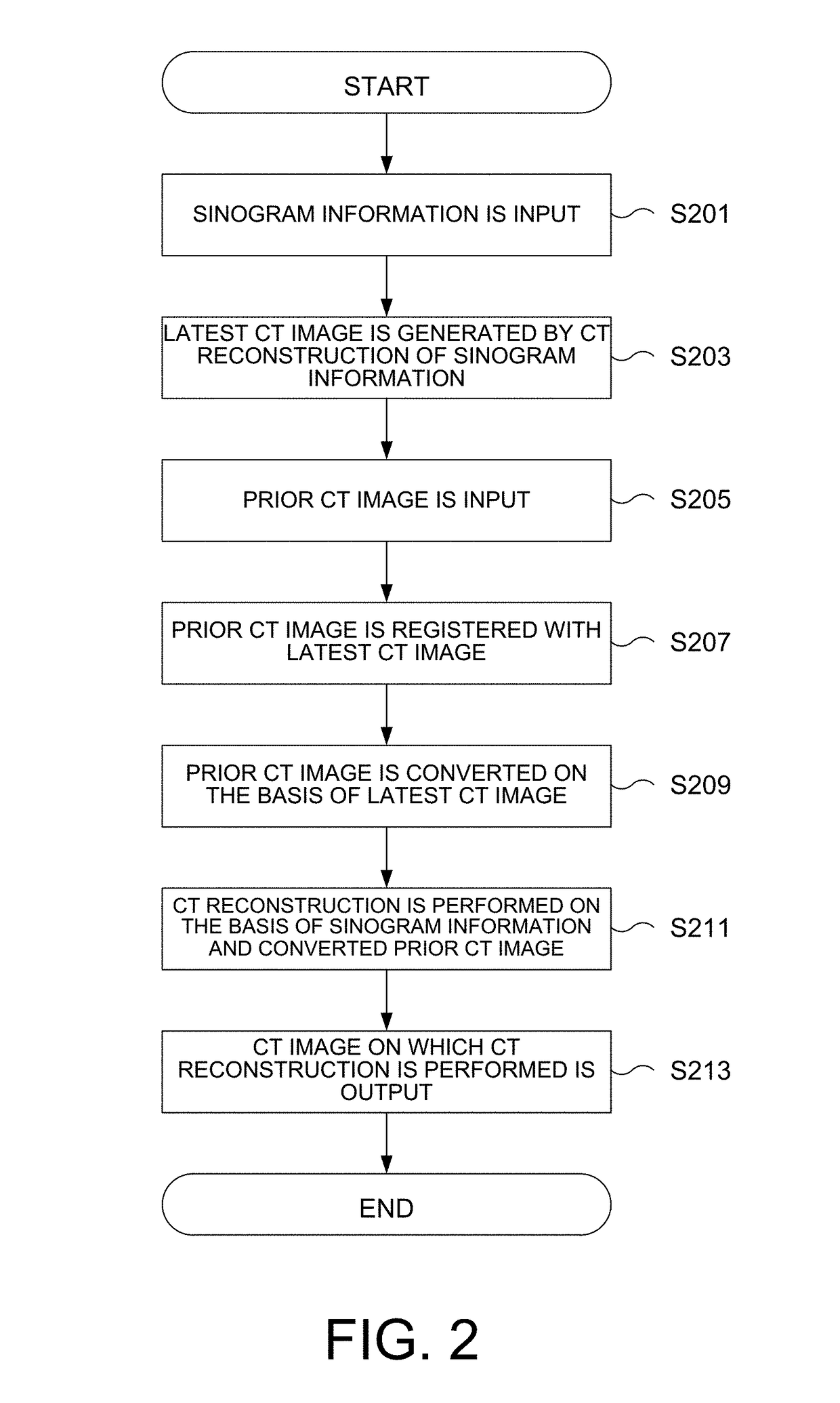

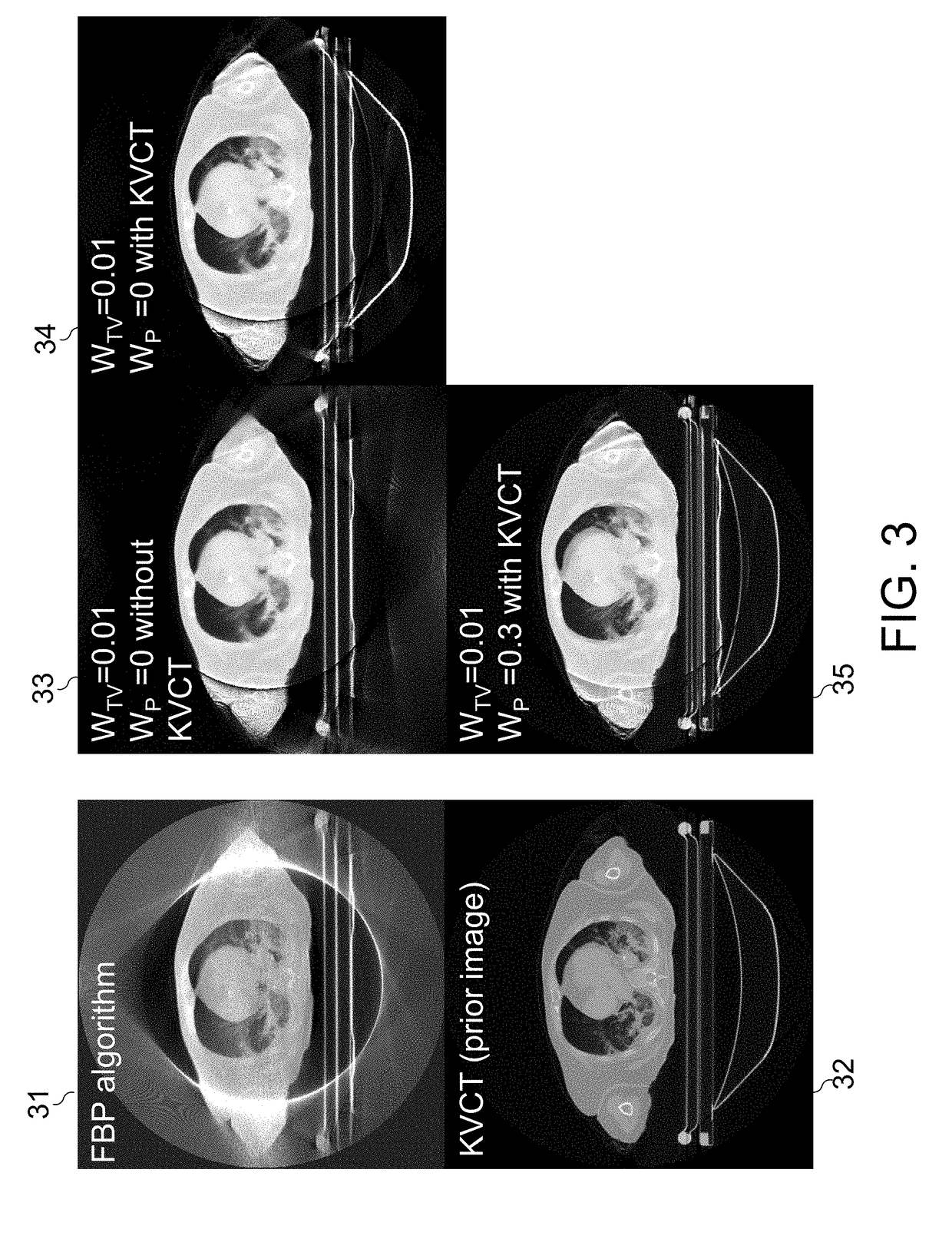

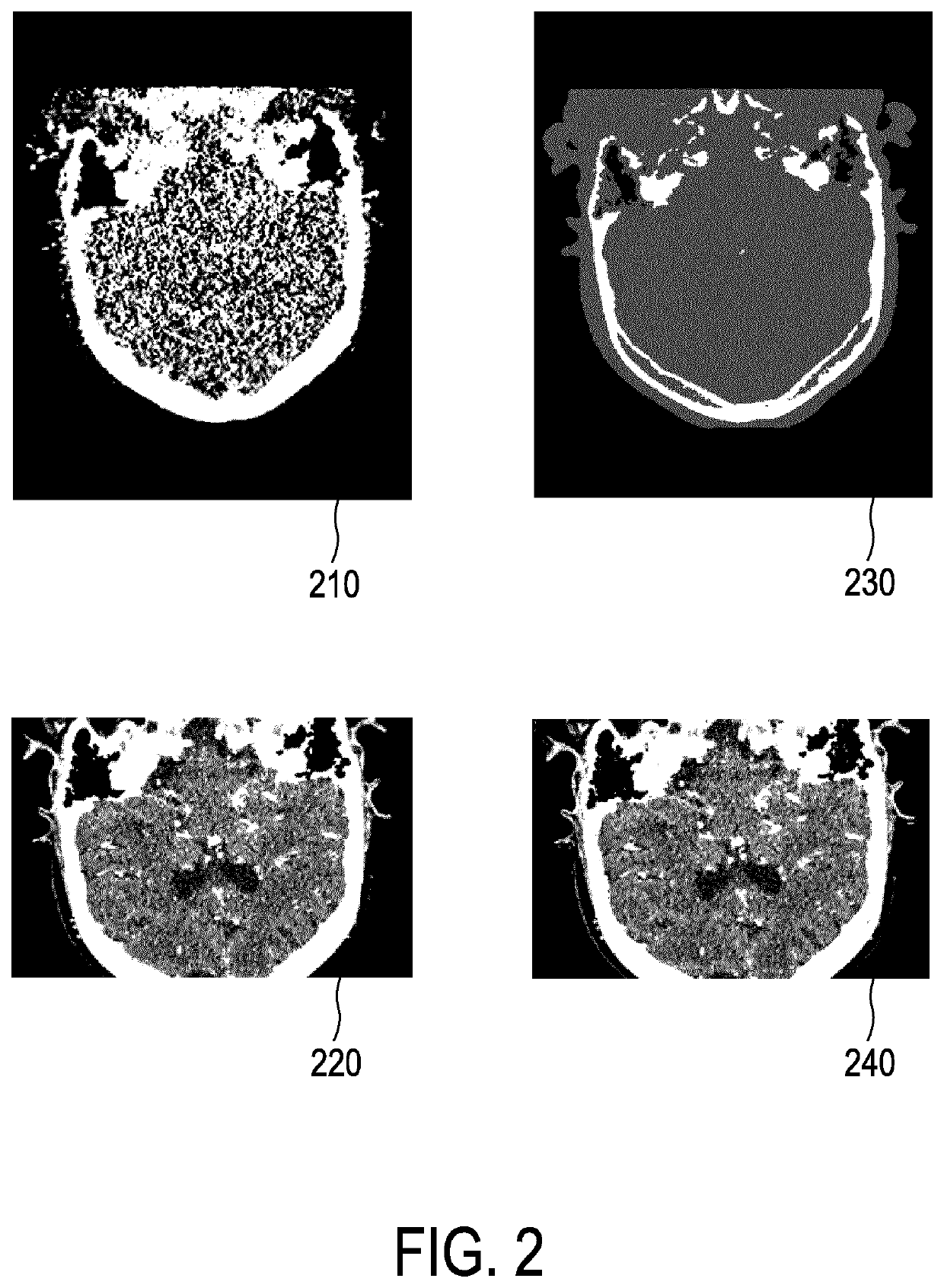

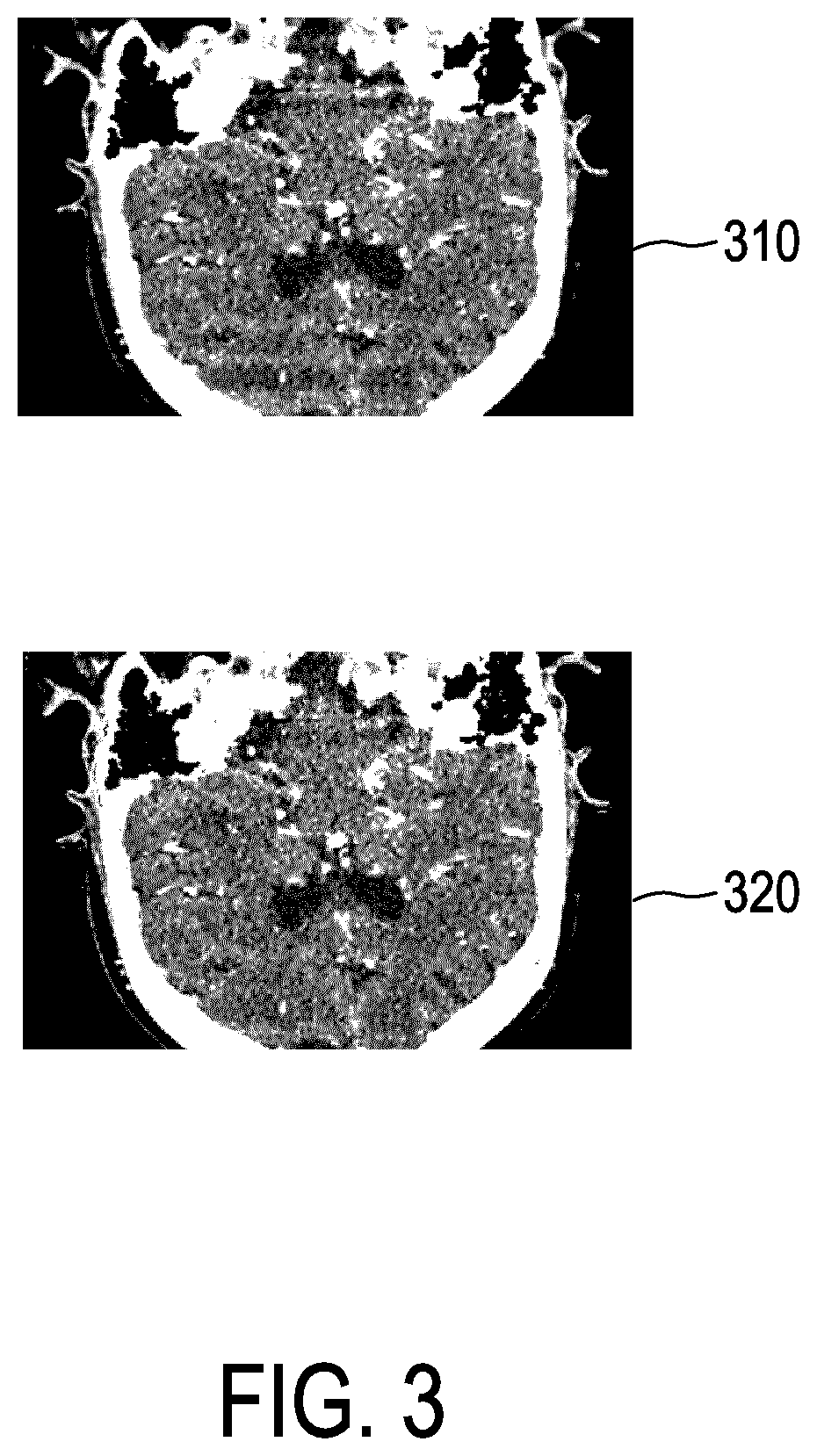

Image Processing Device and Image Processing Method

InactiveUS20180360406A1Expand field of viewReduce incompletenessReconstruction from projectionComputerised tomographsImaging processingTomographic image

Provided are an image processing apparatus and an image processing method that can suitably broaden a field of view. The image processing apparatus includes: first input means for receiving input of sinogram information acquired by projecting radiation onto an object; means for configuring a first tomographic image of the object from the sinogram information; second input means for receiving input of a prior tomographic image obtained by imaging the object before the sinogram information; conversion means for converting a pixel value of the prior tomographic image on the basis of a pixel value of the first tomographic image; and means for generating a second tomographic image from the sinogram information with use of the prior tomographic image, the pixel value of which has been converted.

Owner:THE UNIV OF TOKYO

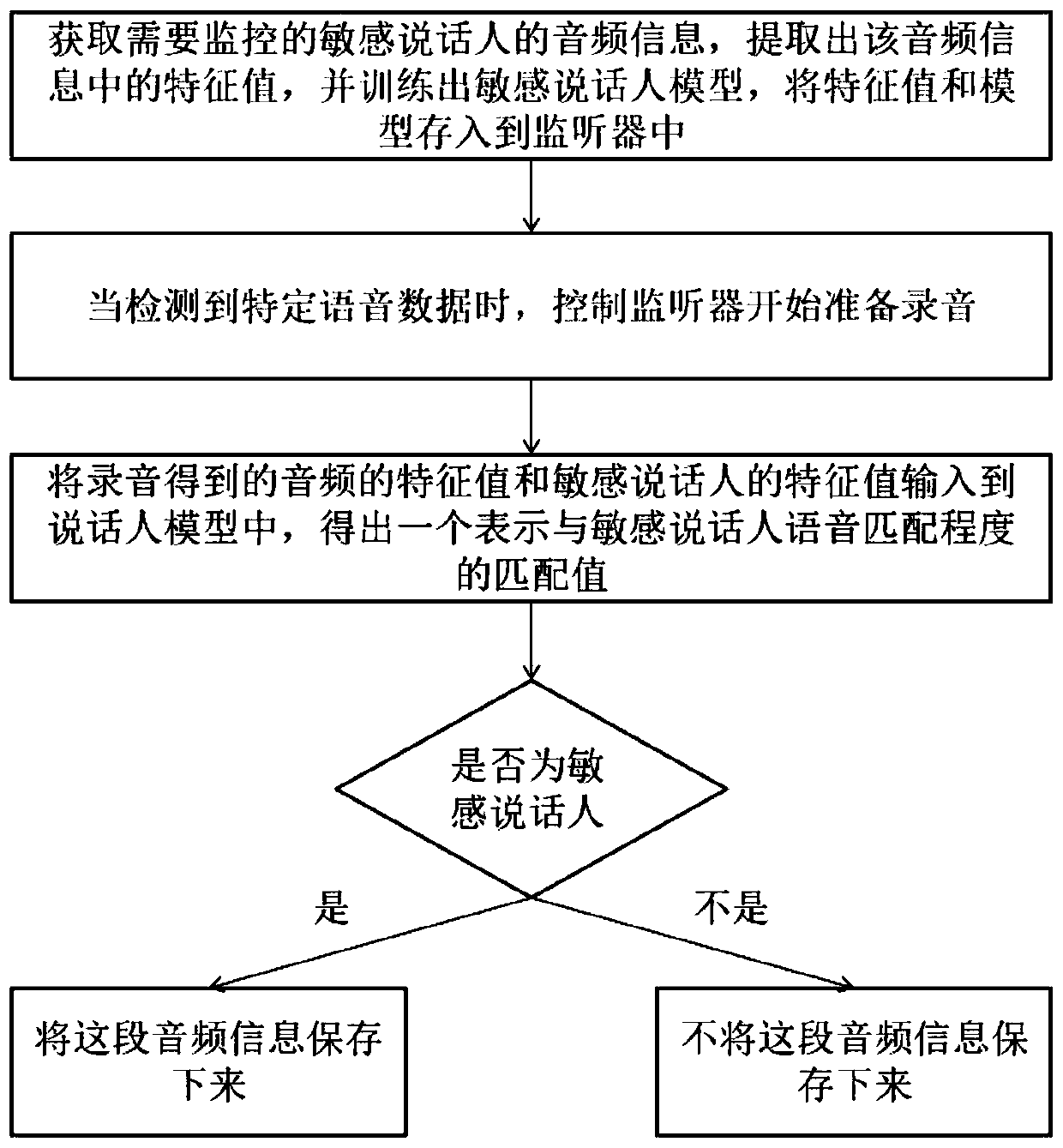

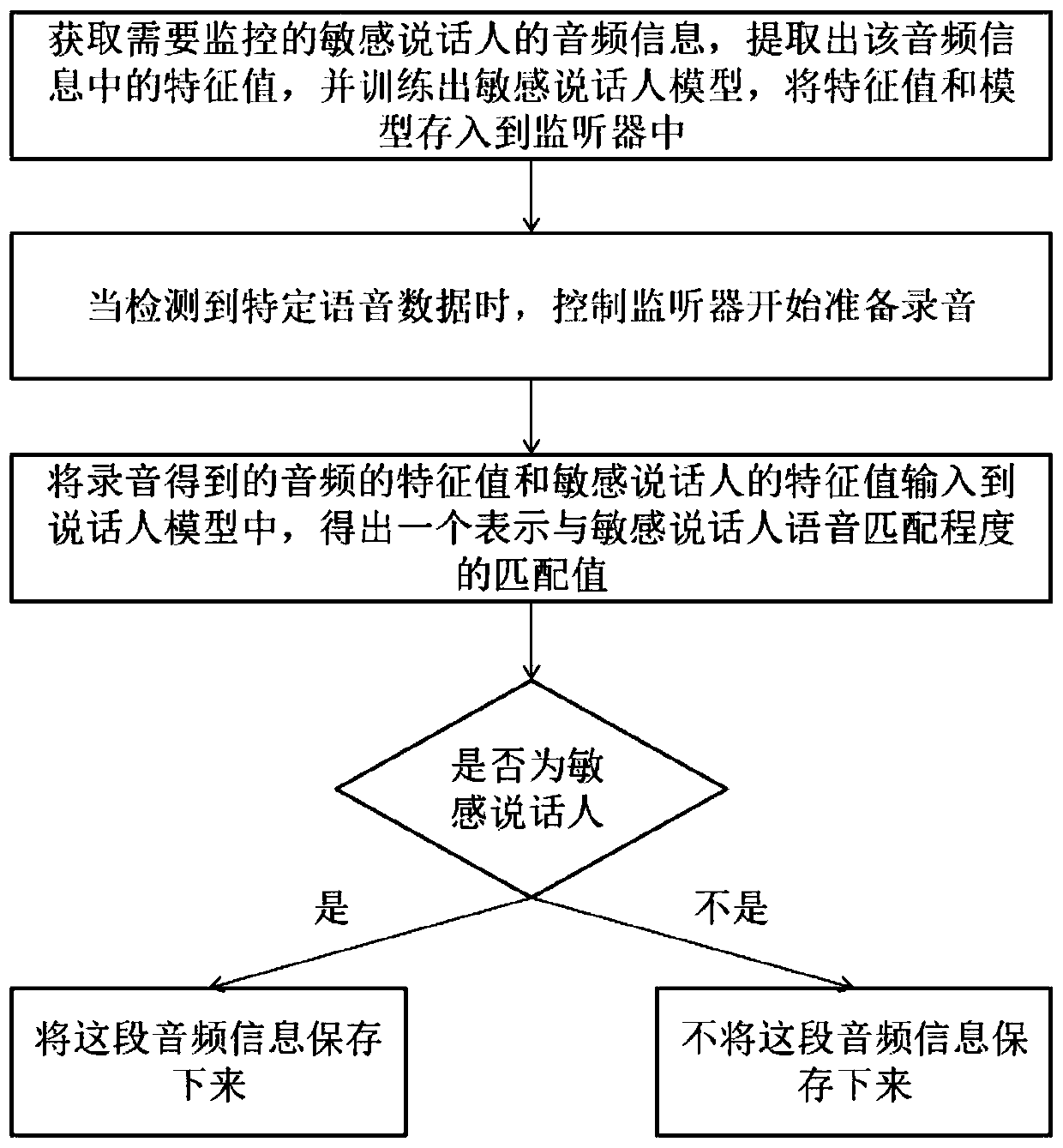

Sensitive speaker monitoring and recording control method and system based on deep learning

PendingCN111128199ASolve the problem that the recording does not distinguish between speakersResolve accuracySpeech analysisCosine similaritySpeech sound

The invention discloses a sensitive speaker monitoring and recording control method and system based on deep learning. The method comprises the following steps of: acquiring recorded audio information, extracting an audio characteristic value of the audio information by adopting a triple loss method based on a time pool and cosine similarity, inputting the audio characteristic value into a pre-trained speaker model of the sensitive speaker, and outputting a matching value of the voice matching degree with the sensitive speaker, comparing the matching value with a preset matching threshold value, if the matching value is smaller than the matching threshold value, determining that the speaker is not a sensitive speaker, and not recording the audio information, otherwise, storing the audio information, and meanwhile, updating the speaker model of the sensitive speaker. The method has the advantages that the accuracy of monitoring the sensitive speaker is improved; and the problem that existing recording does not distinguish speakers or cannot accurately judge a target speaker is solved.

Owner:ARMY ENG UNIV OF PLA

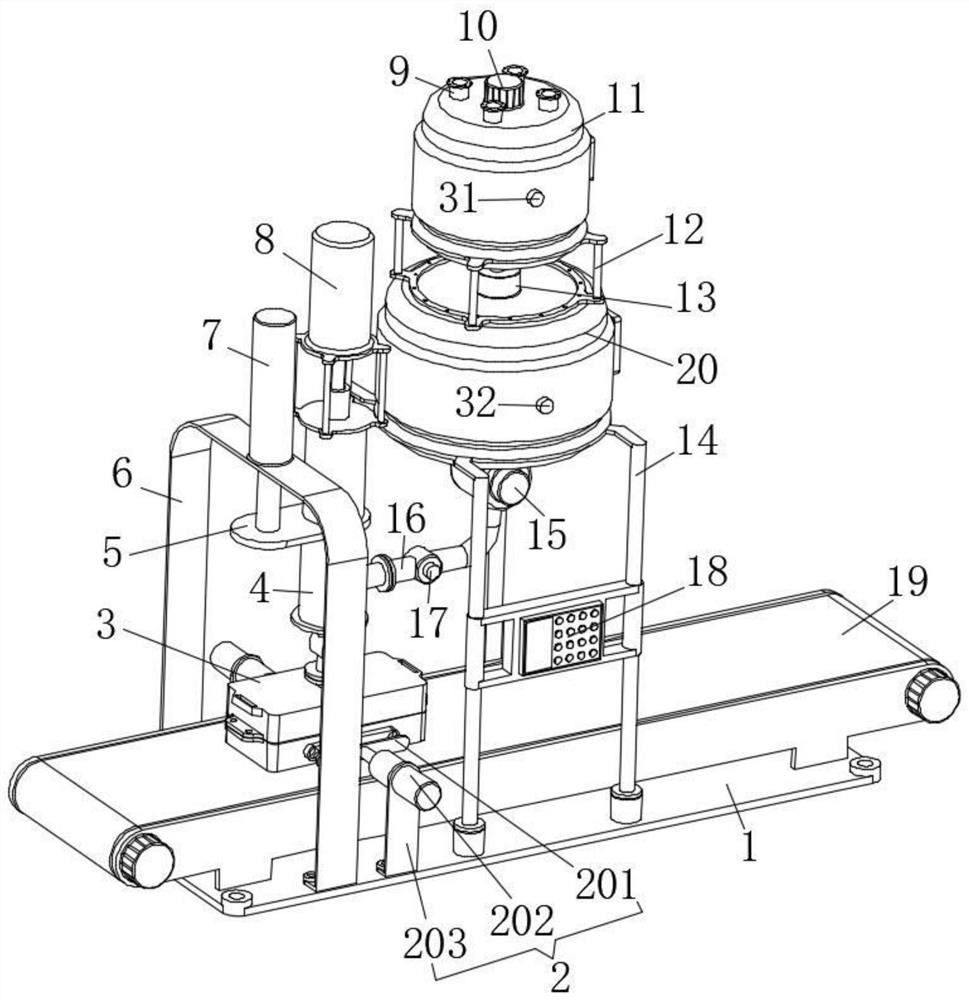

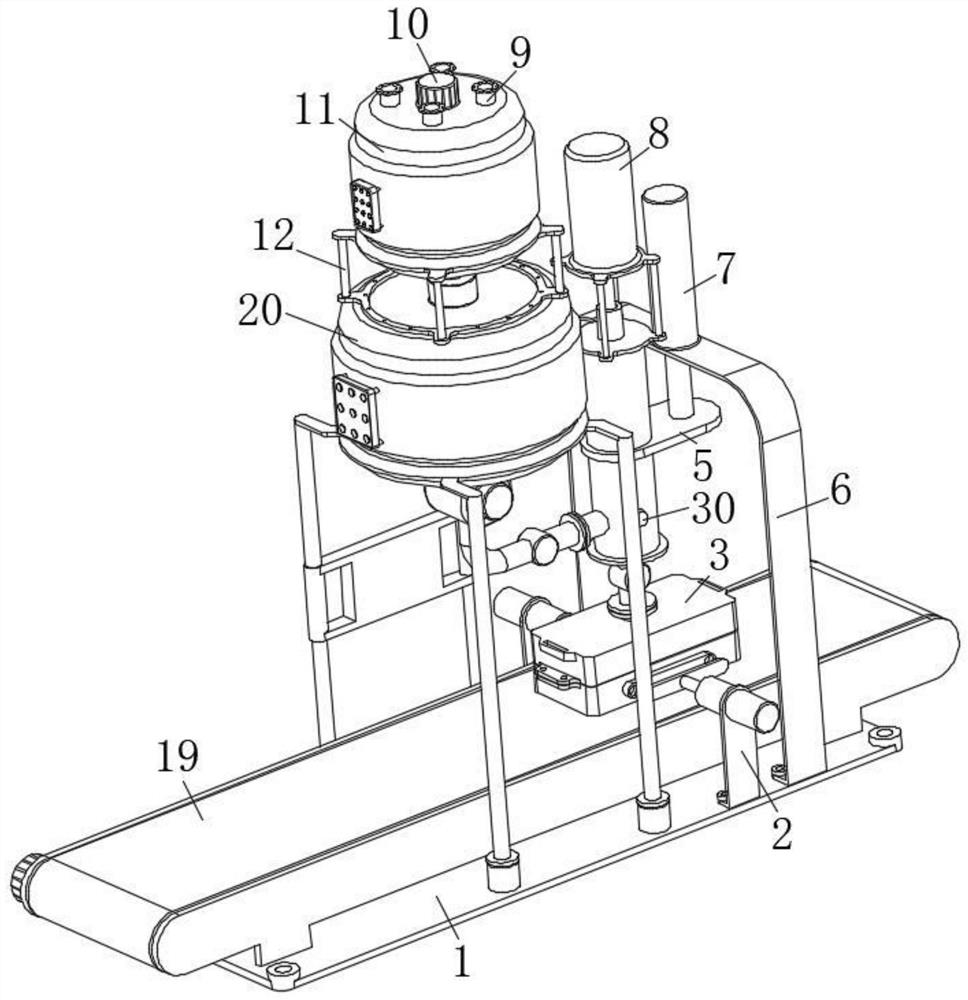

High-pressure casting device for cyclopentane household appliance new material

The invention relates to the technical field of material processing, in particular to a high-pressure casting device for a cyclopentane household appliance new material. The casting device comprises abase, a conveying belt for conveying a mold is fixedly installed on the base through a bolt, a clamping device used for clamping and positioning the mold is fixedly installed on the base through a bolt, and a supporting frame is fixedly installed on the base through a bolt. The casting device has the beneficial effects that when the high-pressure casting device is used, raw materials can be directly foamed and mixed through a mixing tank so as to prepare a mixture suitable for casting, and then high-pressure casting can be directly carried out; and a casting system, which is composed of a discharging pump, a first electromagnetic material valve, a material barrel, a second lifting push rod and a second electromagnetic material valve, of the casting device can effectively improve the casting pressure, and can also conduct accurate quantitative casting, so that incomplete finished products caused by insufficient casting pressure and insufficient casting amount are reduced, and the product quality is effectively improved.

Owner:合肥春池工业设计有限公司

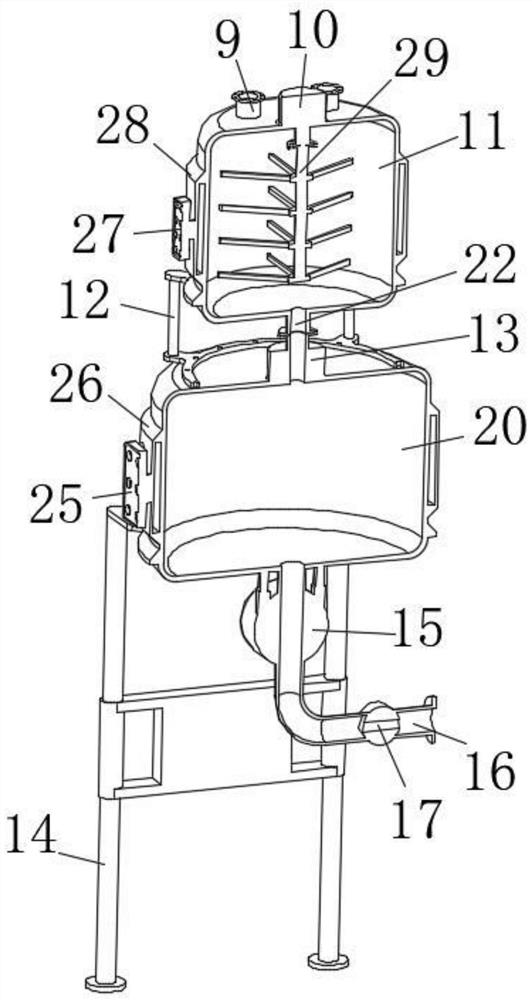

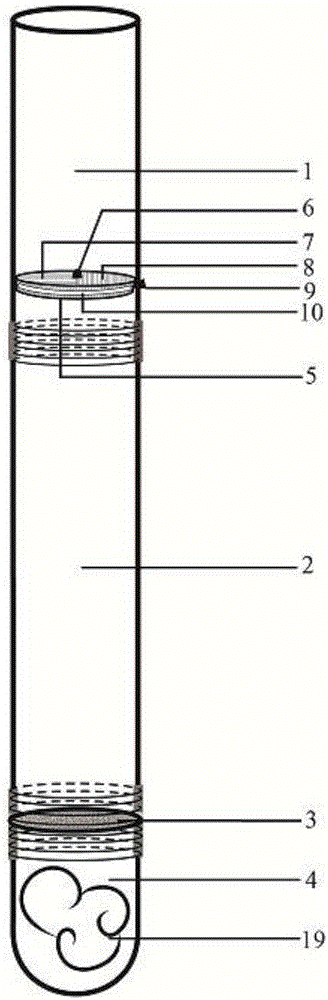

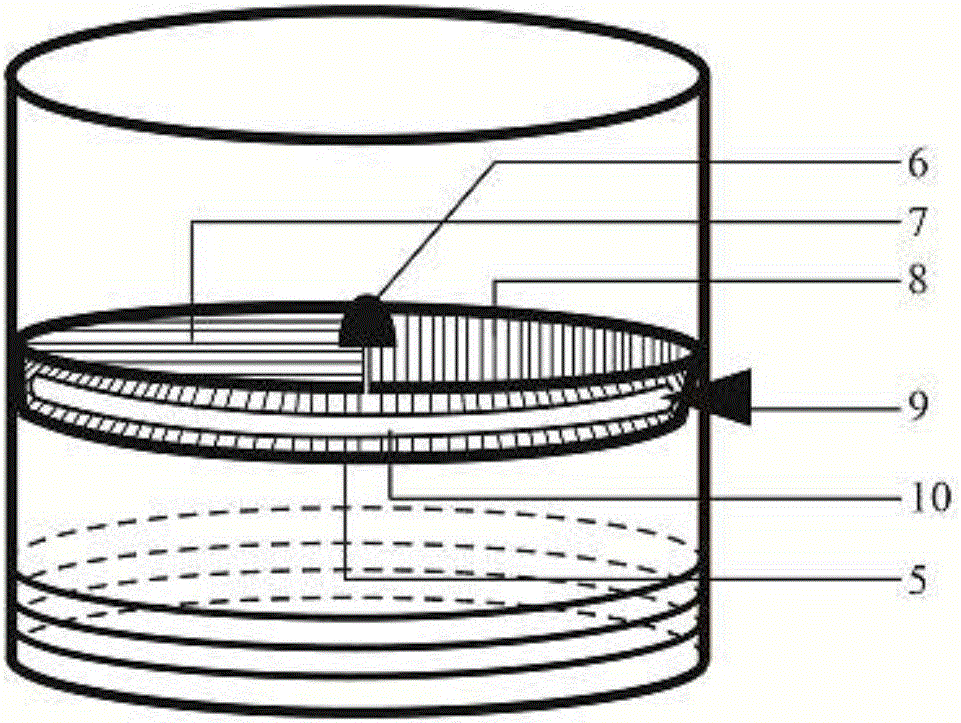

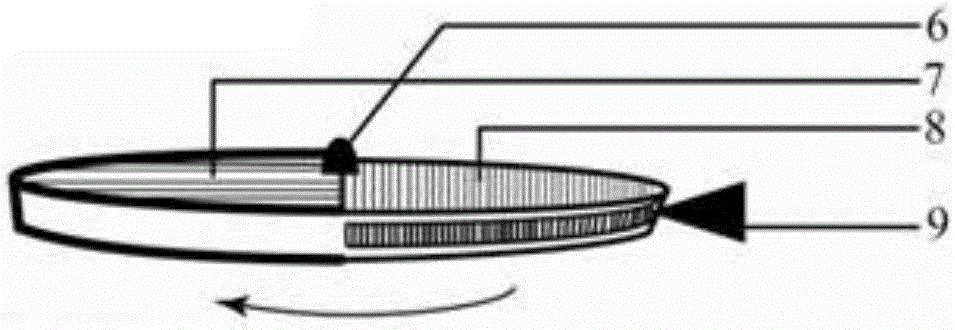

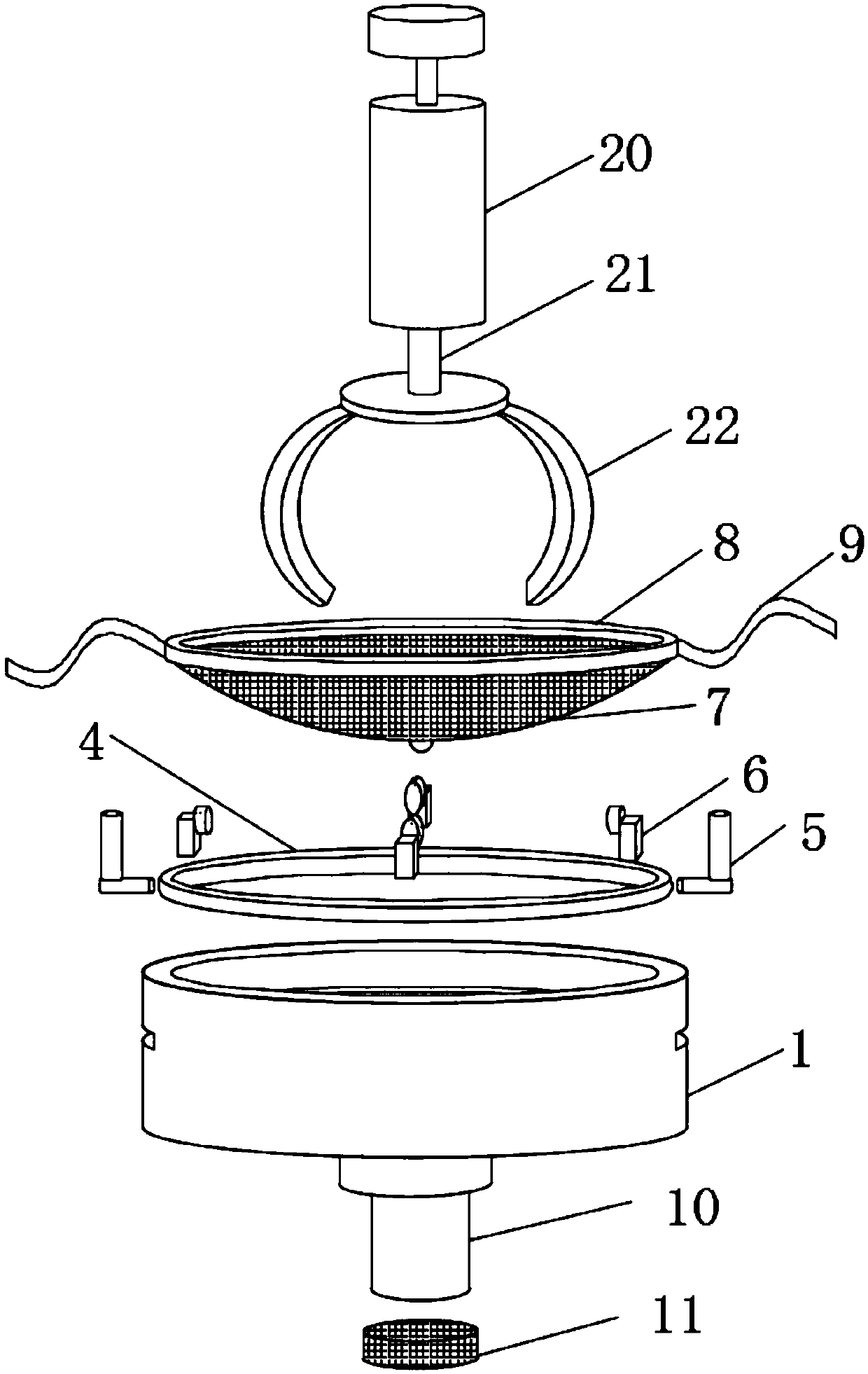

Field multifunctional insect detaining and collecting test tube device

PendingCN106804565AEasy to disassembleEasy to replaceInsect catchers and killersBiotechnologyPlastic materials

The invention discloses a field multifunctional insect detaining and collecting test tube device. One end of an insect detaining tube is open, the other end of the insect detaining tube and the top end of an insect storage tube are in threaded connection, and the bottom end of the insect storage tube, a ventilating screen and a generator are in threaded connection. An opening and closing baffle is arranged in the insect detaining tube, the ventilating screen is arranged at the joint of the insect storage tube and the generator, a ventilating screen hole plate is arranged on the ventilating screen, small screen holes are formed in the plate, and cotton is placed in the generator. The device has the advantages that all the parts are convenient to detach and replace; re-escape of insects is effectively avoided; drop resistance is achieved, and it is avoided that the appearance integrity of small insects is damaged due to the fact that plastic materials generate static; the insects in the tube can be paralyzed through alcohol gas to be in a coma, the active degree of the insects is reduced, limb damage and deficiency caused by space competition fight among the insects are reduced, DNA of insect specimens saved after alcohol fumigation is not prone to degradation, molecular relevant experiments can be carried out, and meanwhile later insect shape classification work is also promoted.

Owner:GUIZHOU UNIV

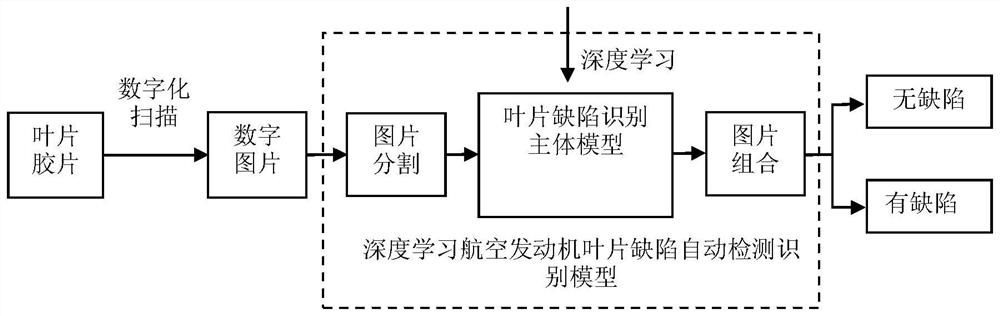

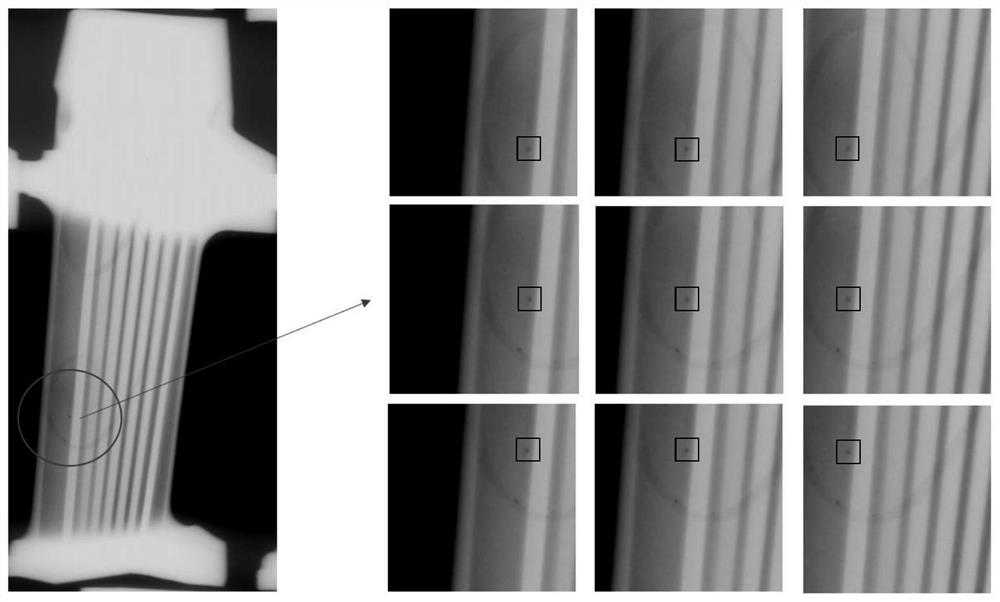

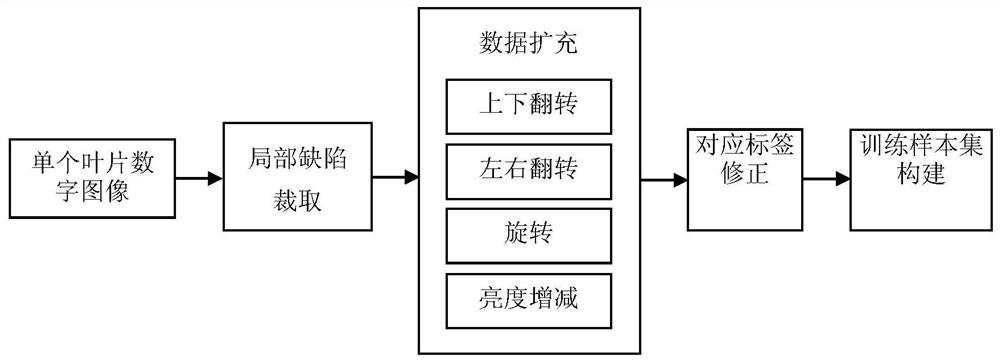

Deep learning defect automatic detection and identification method based on small sample aero-engine blade CT image

PendingCN113313695AGood defect detection and identification performanceReduce incompletenessImage enhancementImage analysisData expansionSmall sample

The invention discloses a deep learning defect automatic detection and identification method based on a small sample aero-engine blade CT image. The method comprises the following steps of carrying out digital processing on a blade CT film, manually calibrating the type and position of each defect to establish a defect sample label set, cutting a local defect area image of the blade, and performing data expansion and corresponding label correction expansion to establish a deep learning model training sample set, constructing a deep learning aero-engine blade defect detection and identification network, training a deep learning aero-engine blade defect detection and identification network, establishing an automatic detection and identification model according to the defect detection and identification network and the final training parameters, and inputting the CT image into the defect detection and identification model to automatically detect, identify and position the blade defect. According to the method, the problem that the number of defective blade samples is small is solved, the influence of human factors is overcome, and the radiographic detection efficiency of the aero-engine blade and the detection precision of tiny defects are greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

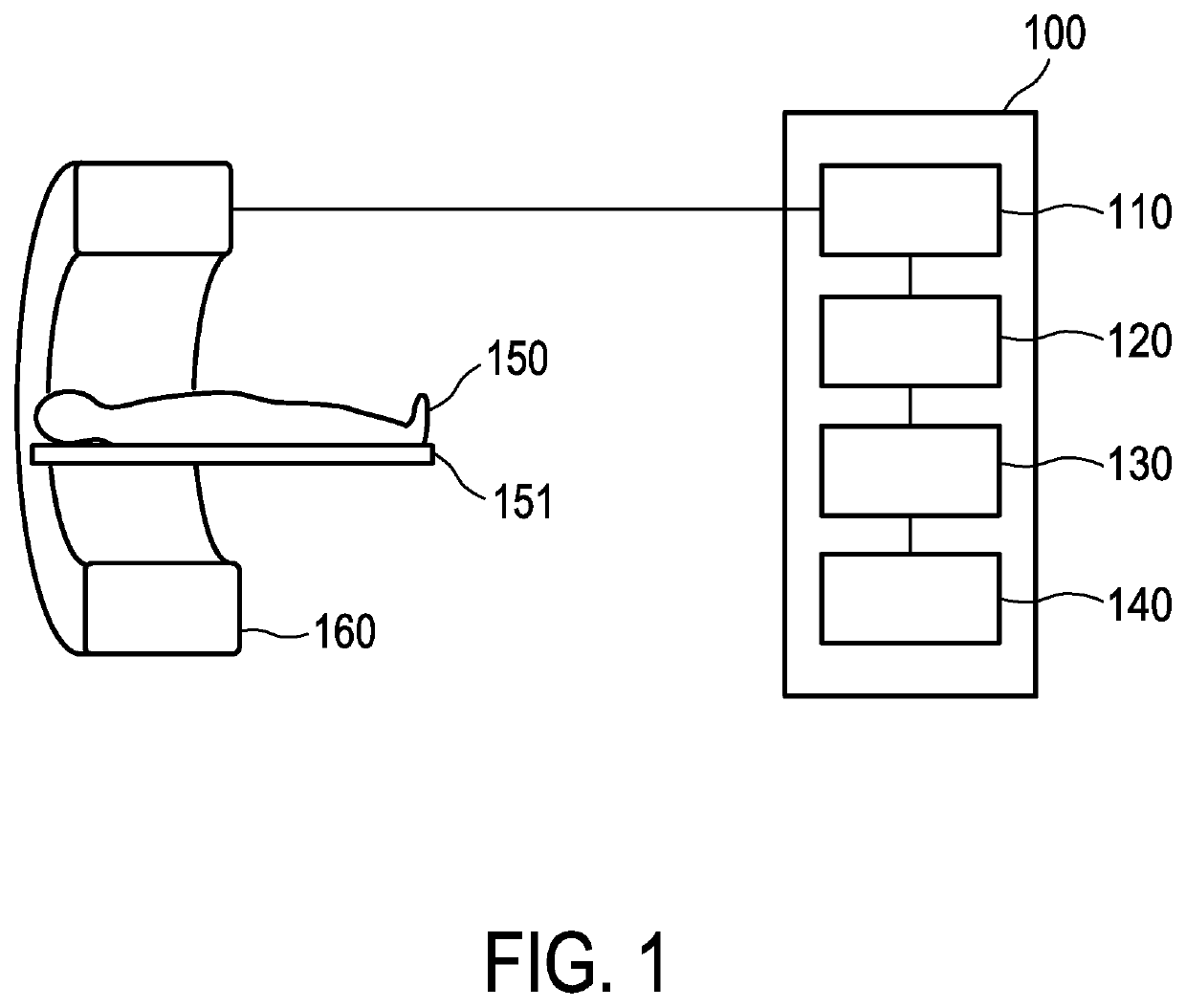

System for reconstructing an image of an object

PendingUS20220005239A1Reduce computing costGood first approximationReconstruction from projectionImage generationPattern recognitionVoxel

The invention refers to providing a system that allows to reduce the computational costs when using an iterative reconstructional algorithm. The system (100) comprises a providing unit (110) for providing CT projection data, a base image generation unit (120) for generating a base image based on the projection data, a modifying unit (130) for generating a modified image, wherein an image value of a voxel of the base image is modified based on the image value of the voxel, and an image reconstruction unit (140) for reconstructing an image using an iterative reconstruction algorithm that uses the modified image as a start image. Since the modifying unit is adapted to modify the base image, the base image can be modified such as to form an optimal start image for the chosen iterative reconstruction such that a faster convergence of the iterative reconstruction can be accomplished.

Owner:KONINKLJIJKE PHILIPS NV

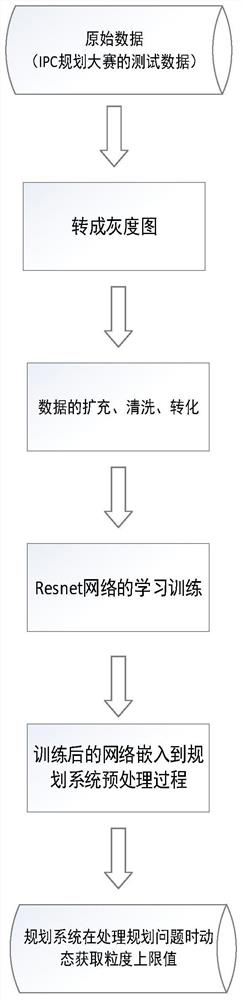

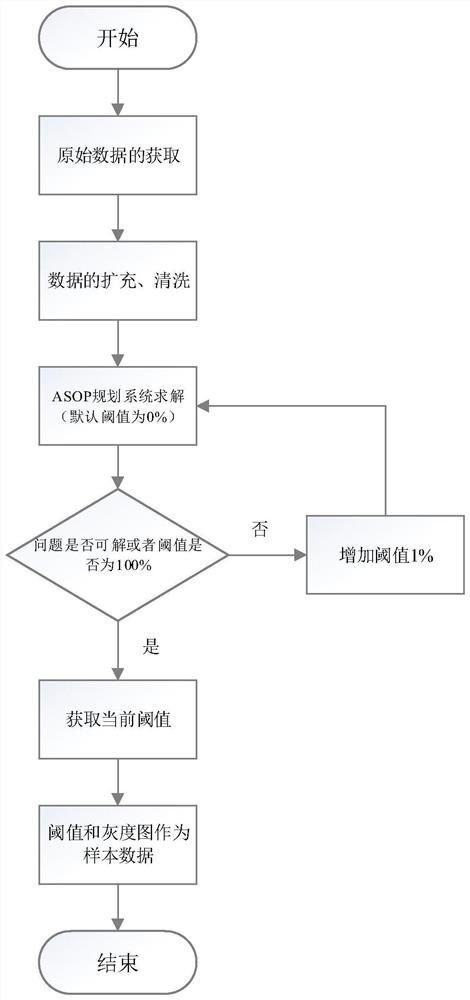

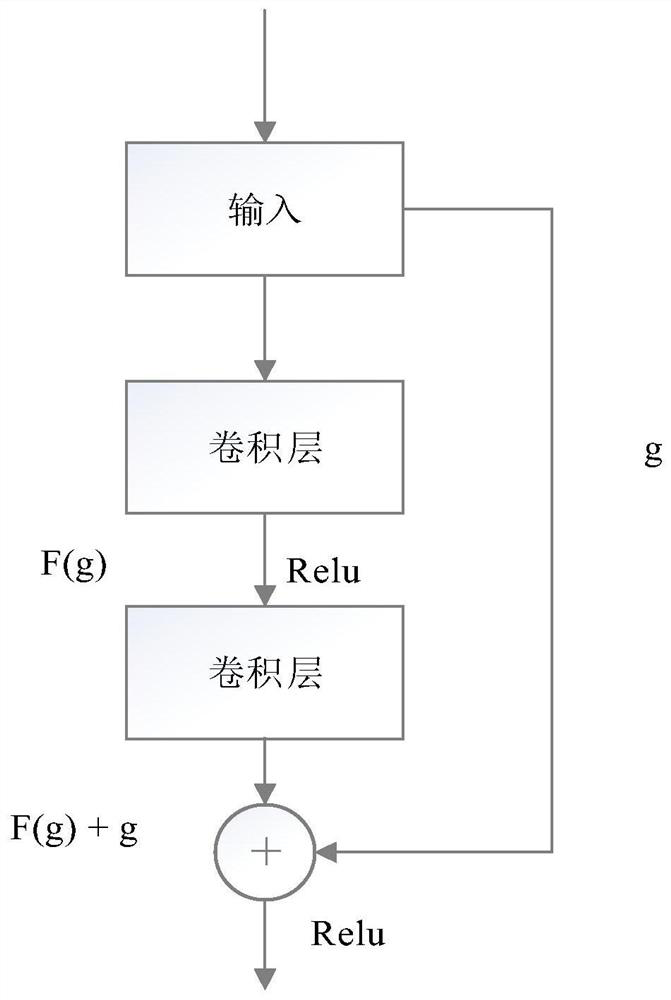

Planning sub-target merging method based on deep learning

PendingCN111967641AReduce incompletenessBalance solution quality and solution efficiencyDigital data information retrievalForecastingData cleansingData expansion

The invention discloses a planning sub-target merging method based on deep learning, which mainly solves the problem of granularity upper limit selection of sub-target merging in the preprocessing process of a planning system, and comprises the following steps: generating a data set, and performing data expansion and data cleaning on samples; training the obtained sample as a deep learning model,selecting a Resnet deep residual network as the model, and separately training planning problems in different fields to generate a feature model of each field; modifying a preprocessing code of the ASOP planning system, adding an updating function of a sub-target granularity threshold value. Through a trained model, the planning system can determine the upper limit of granularity according to a specific planning problem. According to the method, the upper limit threshold value of the granularity is determined from the macroscopic level through a deep learning method, so that the efficiency andthe quality of the planning system during problem solving are balanced, the planning capability of the planning system is effectively improved, and the labor cost is greatly reduced through dynamic autonomous adjustment of a computer.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

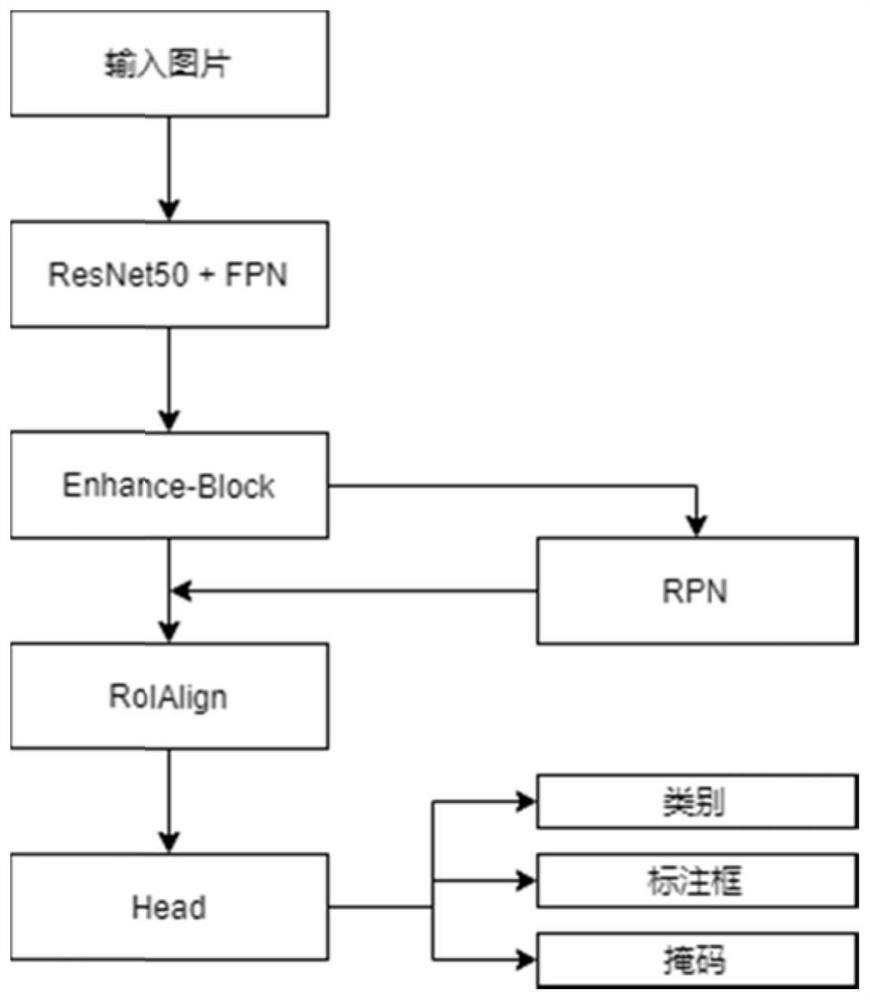

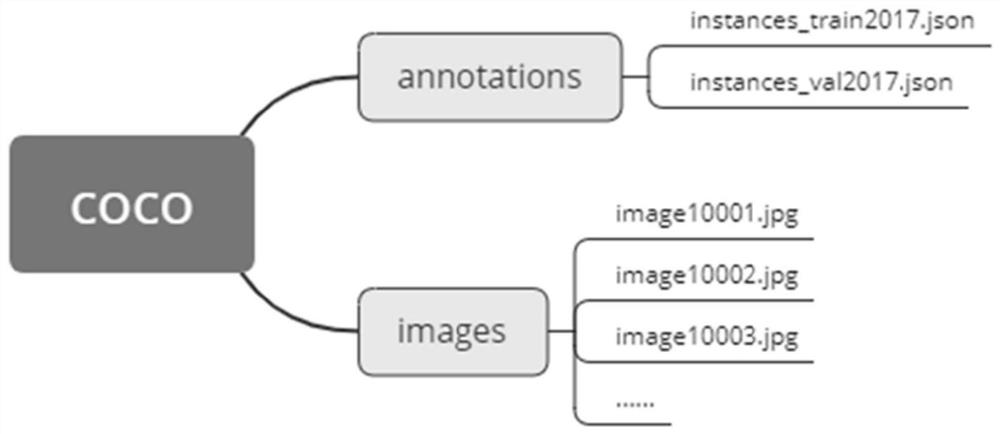

Cell image segmentation method based on deep learning

PendingCN113379672AAccurate detection and segmentationQuick checkImage enhancementImage analysisData setImaging processing

The invention discloses a cell image segmentation method based on deep learning, and belongs to the field of image processing. The method specifically comprises the following steps: segmenting cells in test tube holes by using an improved Mask R-CNN (Region-Convolutional Neural Network), obtaining cell images, establishing a digital image data set, fusing feature learning into a model establishing process, and accurately detecting and segmenting the cells in the test tube holes. A quick, low-cost and accurate automatic detection technology is realized, and the detection efficiency can be improved.

Owner:HANGZHOU DIANZI UNIV

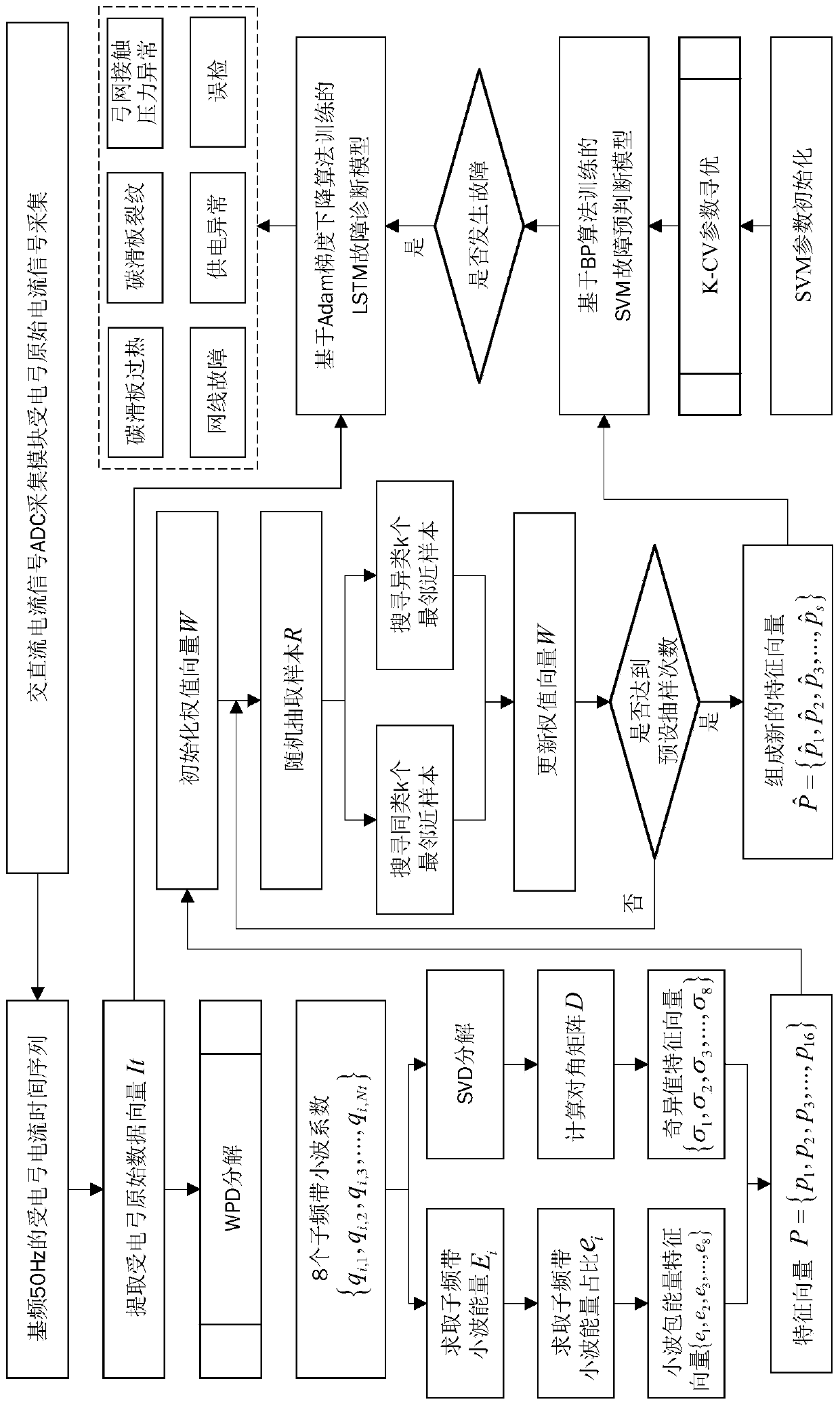

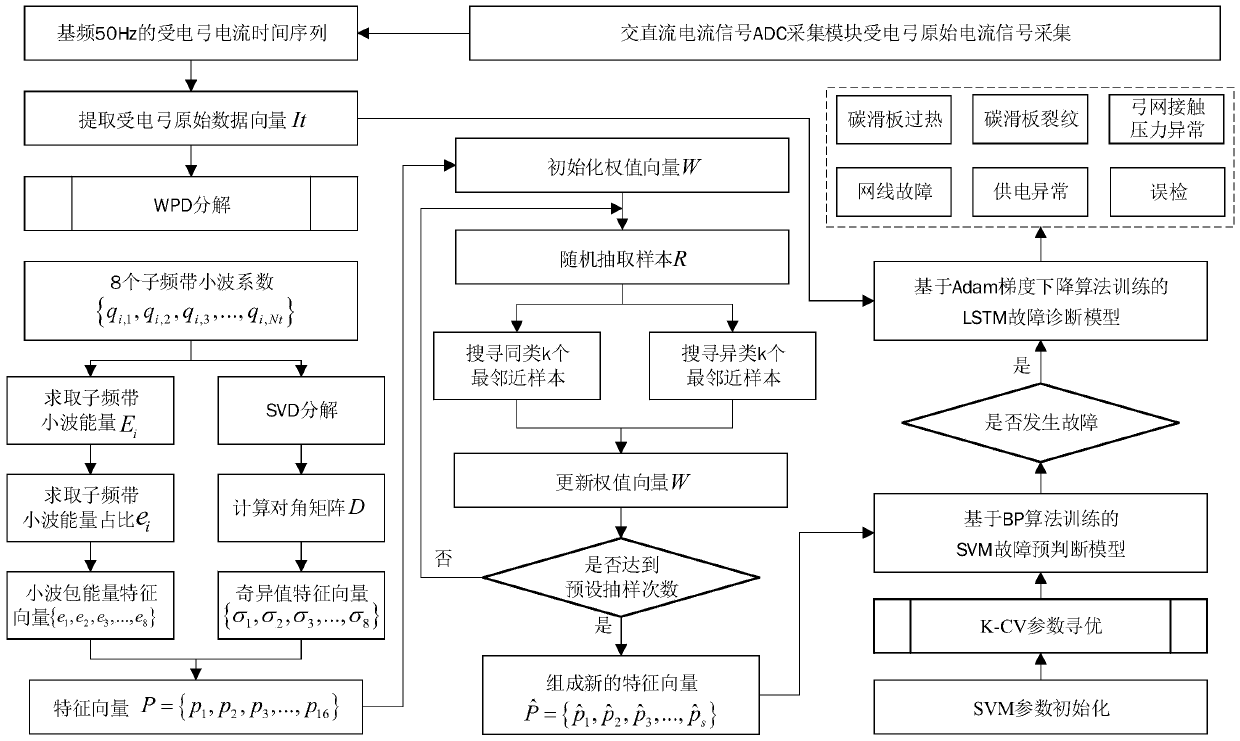

A non-intrusive real-time dynamic monitoring method for external power receiving devices of intelligent trains

ActiveCN110161343BImprove economyGuaranteed incompletenessTesting electric installations on transportNeural architecturesFeature vectorOriginal data

The invention discloses a non-intrusive real-time dynamic monitoring method for an external power receiving device of an intelligent train, which includes: obtaining the original current signal of the pantograph and performing preprocessing to obtain a plurality of original data vectors; performing wavelet packet decomposition on the original data vectors , extract feature quantities from each obtained sub-band and construct feature vectors; use feature vectors and pantograph fault classification marks as input and output data respectively, and train fault identification and prediction models; use original data vectors and fault types as input Output data and train the fault identification model; process the real-time current signal of the pantograph according to the aforementioned method to obtain the original data vector and eigenvector, and the fault identification and prediction model predicts the fault of the pantograph according to the eigenvector. If there is a fault, The fault recognition model recognizes the fault type of the pantograph according to the original data vector. The invention realizes the real-time on-line monitoring and fault type identification of the pantograph under the running state of the train.

Owner:CENT SOUTH UNIV

Welding equipment for rapid cooling and quenching of atomized water

InactiveCN110358900AReduce incompletenessQuenching speed is goodQuenching devicesWater storage tankWater resources

The invention discloses welding equipment for rapid cooling and quenching of atomized water. The welding equipment comprises a quenching tank, a mounting groove is formed in the quenching tank, a transition tube is fixedly connected with the interior of the mounting groove, and a through groove runs through the quenching tank. A water adding pipe is fixedly connected with the interior of the through groove, and an atomizing nozzle is fixedly connected to the transition tube. Compared with traditional gas quenching and water quenching, by means of atomized quenching, the quenching speed can bebetter controlled, so that defects of the surface of a quenched workpiece are fewer, the workpiece is more complete, and the product quality is improved. The quenching tank is arranged below an atomizing and quenching device, water resources can be repeatedly utilized, and a conservation effect is achieved. Compared with a traditional water storage tank, the occupied area is smaller, and the sizeis smaller. By means of multiple filtering devices, impurities of the repeatedly used water can greatly reduced. The filtering devices of the equipment are all convenient to dismount and mount, and the filtering devices can be conveniently replaced or cleaned.

Owner:岳福连

Web page processing request processing method and device and electronic device

ActiveCN109428919BReduce incompletenessEnhanced interactionWebsite content managementTransmissionEngineeringWeb page

The embodiment of the present invention provides a processing method and device for processing a webpage request and an electronic device, which can process the query request and the session identifier carried in the processing result message in the webpage during the interaction process between the client and the server about the processing progress. The processing step sequence number is added to the client side. On the client side, the processing step sequence number to be queried next time can be dynamically adjusted according to the processing step sequence number fed back by the processing result message. On the server side, the processing result can be recorded according to the processing step sequence number. , to provide the client with accurate processing results corresponding to the specific steps. Through such a mechanism, the interaction of processing results of web page processing requests between the client and the server can be facilitated, and the processing results of web page processing requests received by the client can be reduced. incompleteness, thereby showing the user the complete processing of the request for the web page.

Owner:ALIBABA GRP HLDG LTD

A high-speed machine laying weft winding method

ActiveCN111020860BGuaranteed surface qualityReduce incompletenessWarp knittingStructural engineeringWeft yarn

The invention discloses a high-speed machine laying weft winding method, belonging to the field of composite material production equipment, which can significantly increase the weaving speed, and the yarn is not easy to fall off from the weft needle. The steps are as follows: S1: the trolley moves right to the right side of the weft bed Stop and lay weft from right to left; S2: While the left yarn pressing plate is pressed down, the right rake needle moves forward for the first time, and during the first forward movement of the right rake needle, the right weft needle has already Hanging to the yarn; S3: While the left yarn pressing plate is lifted, the right rake needle moves forward for the second time, and the right rake needle seals the return thread opening; S4: The trolley moves along the length direction of the weft bed by one weft laying width ;S5: The trolley moves to the left along the weft laying direction, and it will cross the right weft needle, and the trolley continues to move to the left. When the right yarn pressing plate moves out of the right weft yarn needle, the right yarn pressing plate presses down to press the yarn into the right weft yarn At the same time, the raking needle on the right side moves back; S6: the trolley moves to the left and stops on the left side of the weft bed, and lays weft from left to right. The invention is suitable for the production of composite material fabrics.

Owner:NEWTRY COMPOSITE

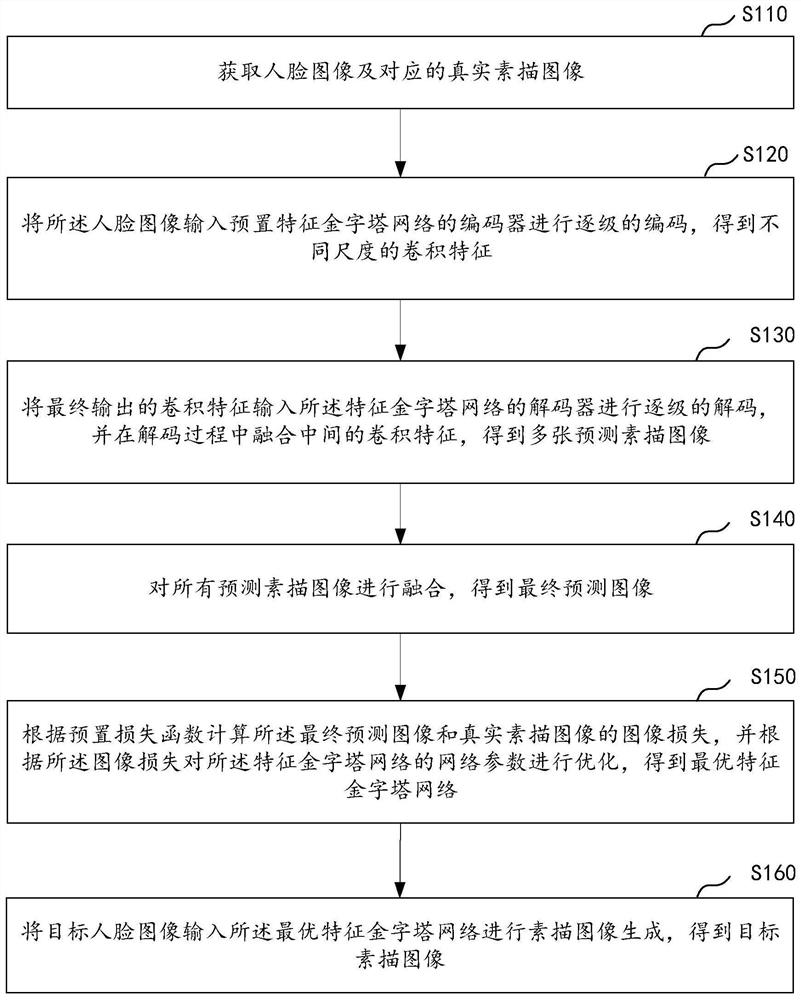

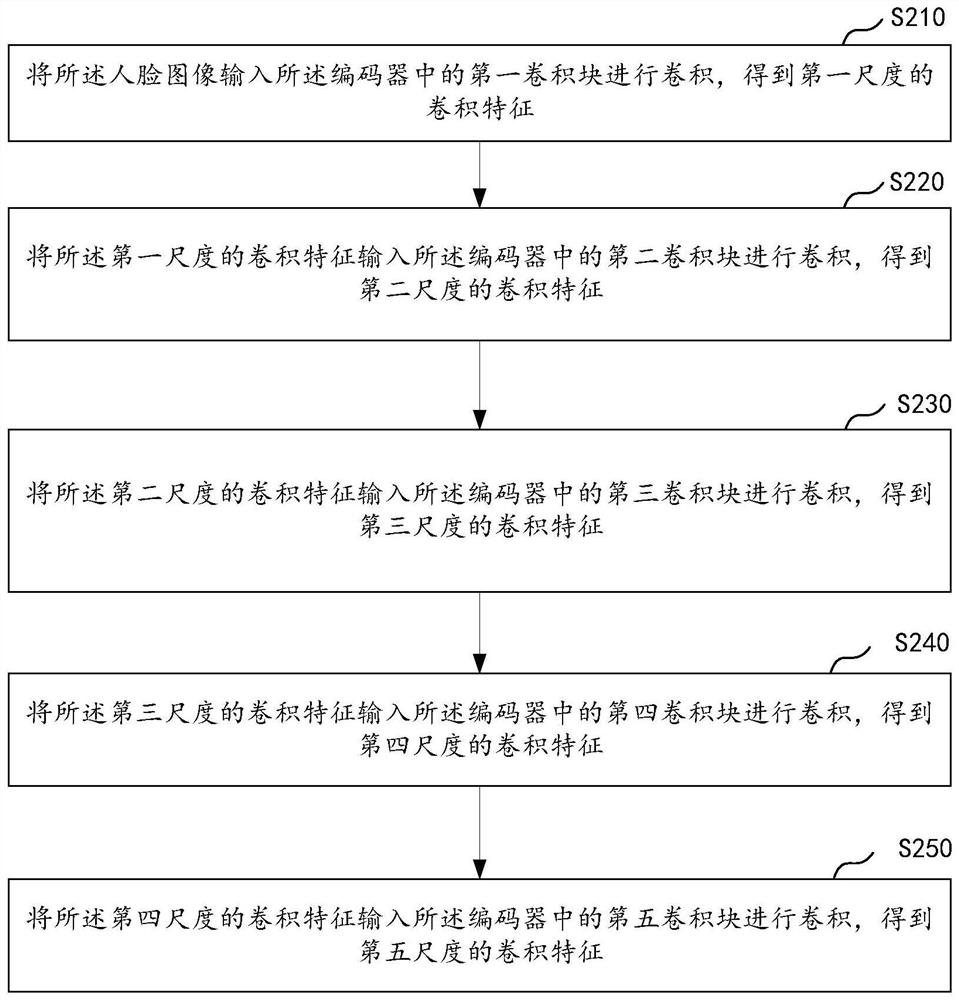

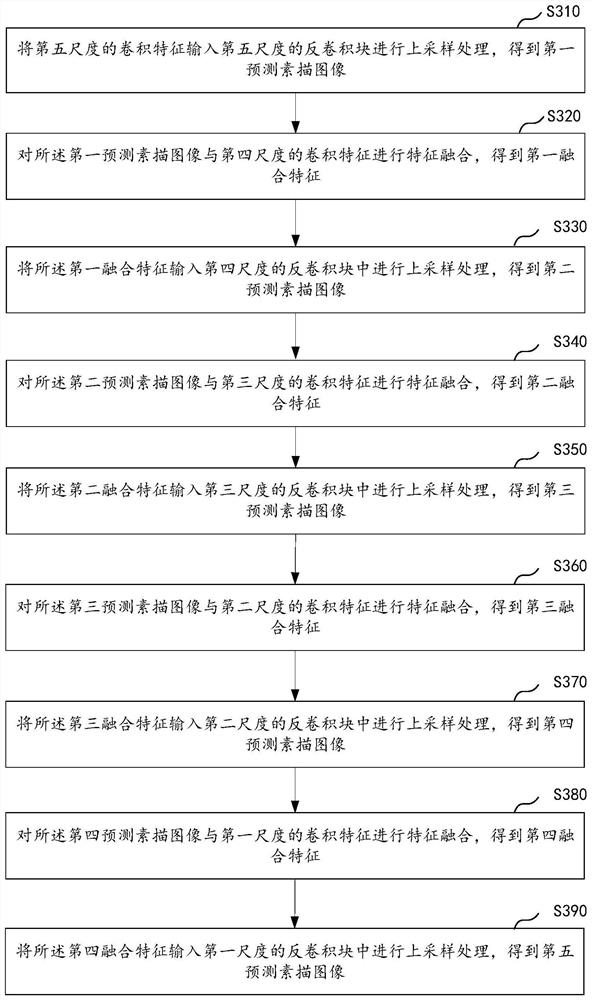

Sketch image drawing method and device, computer equipment and readable storage medium

PendingCN114693829AReduce information lossIntegrity guaranteed2D-image generationImage codingComputer equipmentEngineering

The invention discloses a sketch image drawing method and device, computer equipment and a storage medium. The method comprises the following steps: acquiring a face image and a corresponding real sketch image; inputting the face image into an encoder of a feature pyramid network for step-by-step encoding to obtain convolution features of different scales; inputting the finally output convolution features into a decoder of the feature pyramid network for step-by-step decoding, and fusing the middle convolution features in the decoding process to obtain a plurality of prediction sketch images; fusing all the predicted sketch images to obtain a final predicted image; calculating image loss of the final prediction image and the real sketch image according to a preset loss function, and optimizing network parameters of the feature pyramid network according to the image loss to obtain an optimal feature pyramid network; and inputting the target face image into the optimal feature pyramid network for sketch image generation to obtain a target sketch image. According to the method, the generated sketch image has richer details and is more natural and clearer.

Owner:SHENZHEN WONDERSHARE SOFTWARE CO LTD

A Photoacoustic Imaging Surgical Navigation Platform for Guided Tumor Resection

ActiveCN111839730BReduce incompletenessReduce recurrenceSurgical navigation systemsTumor reductionSound image

The invention discloses a photoacoustic imaging surgical navigation platform for guiding tumor resection, comprising: a photoacoustic imaging device, the photoacoustic imaging device including a main body, a probe and an image display. A photoacoustic imaging surgical navigation platform for guiding tumor resection according to the present invention can provide high frame rate photoacoustic images and ultrasonic images, visualize deep tissue tumors in real time, locate their locations and accurately outline tumor boundaries, and at the same time Photoacoustic imaging can visually improve the sterile scalpel, realize the simultaneous development of the tumor and the scalpel under photoacoustic imaging, and achieve complete resection of the lesion under direct vision of the tumor boundary without missing or mistaken cutting. The positioning, boundary definition and precise resection will provide surgical oncologists with precise intraoperative guidance, which will reduce the incompleteness of tumor resection during operation, improve the rate of complete resection, and preserve normal tissues to the maximum extent, thereby reducing tumor recurrence and improving tumor recurrence. survival rate.

Owner:厦门大学附属翔安医院

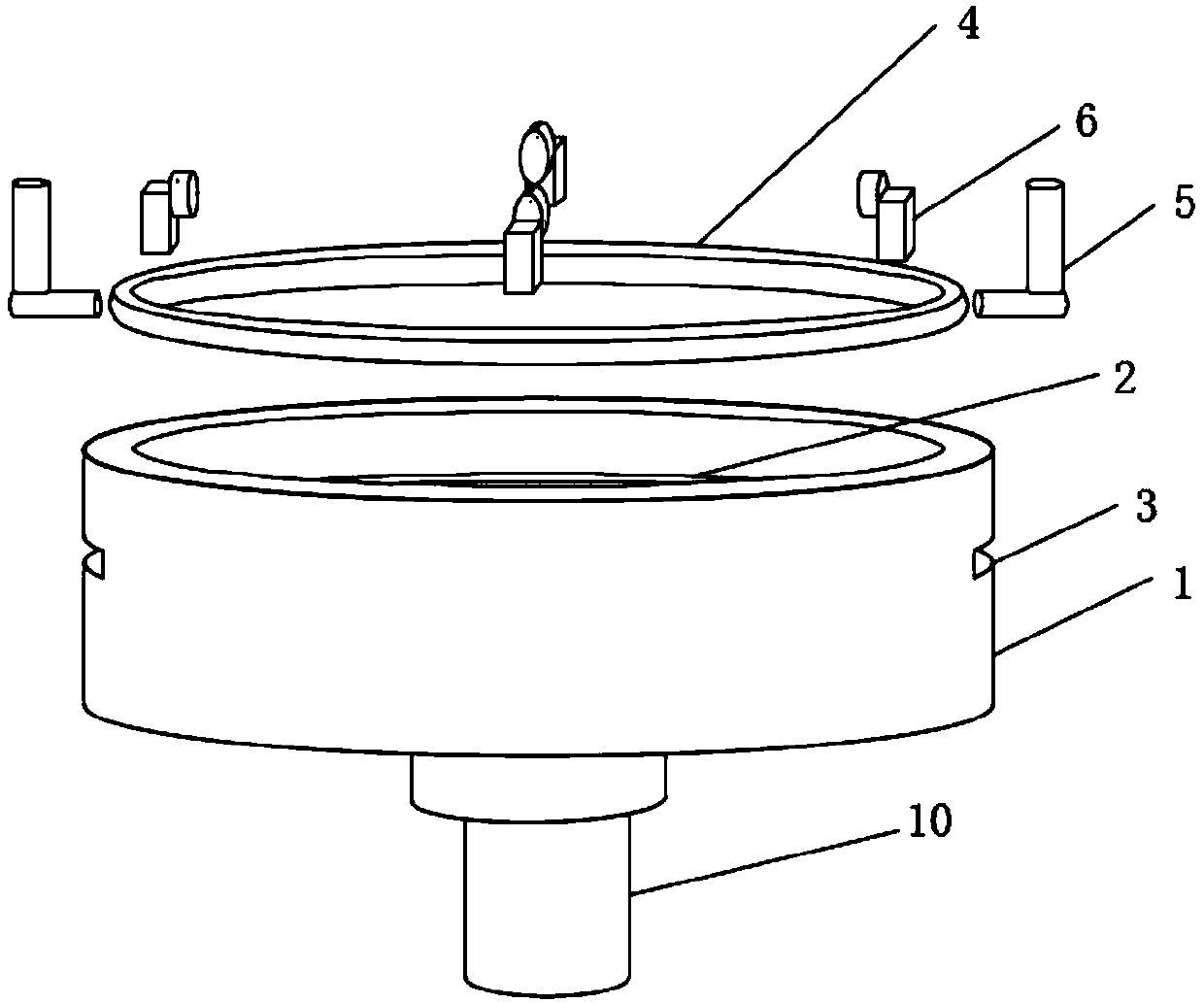

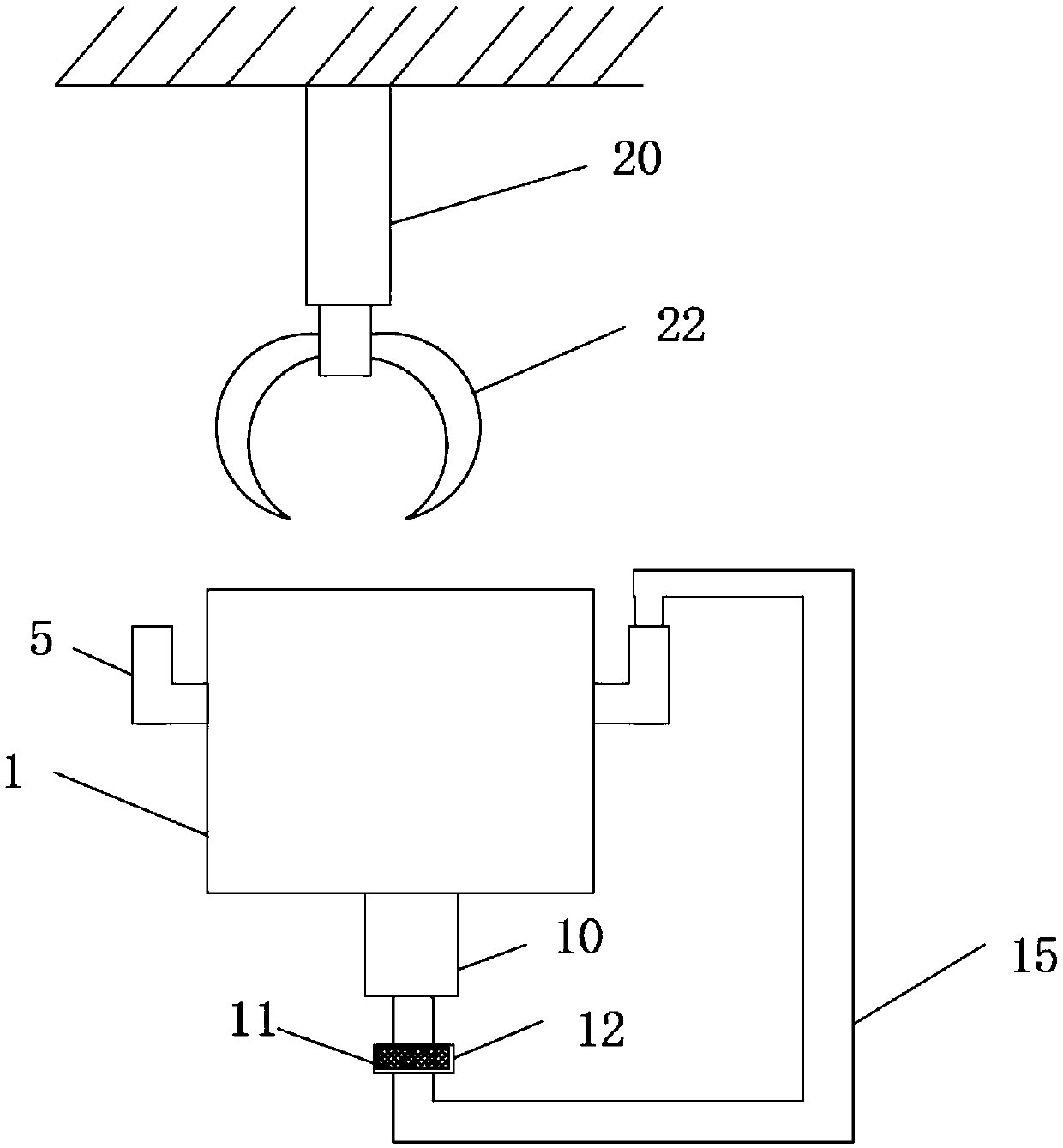

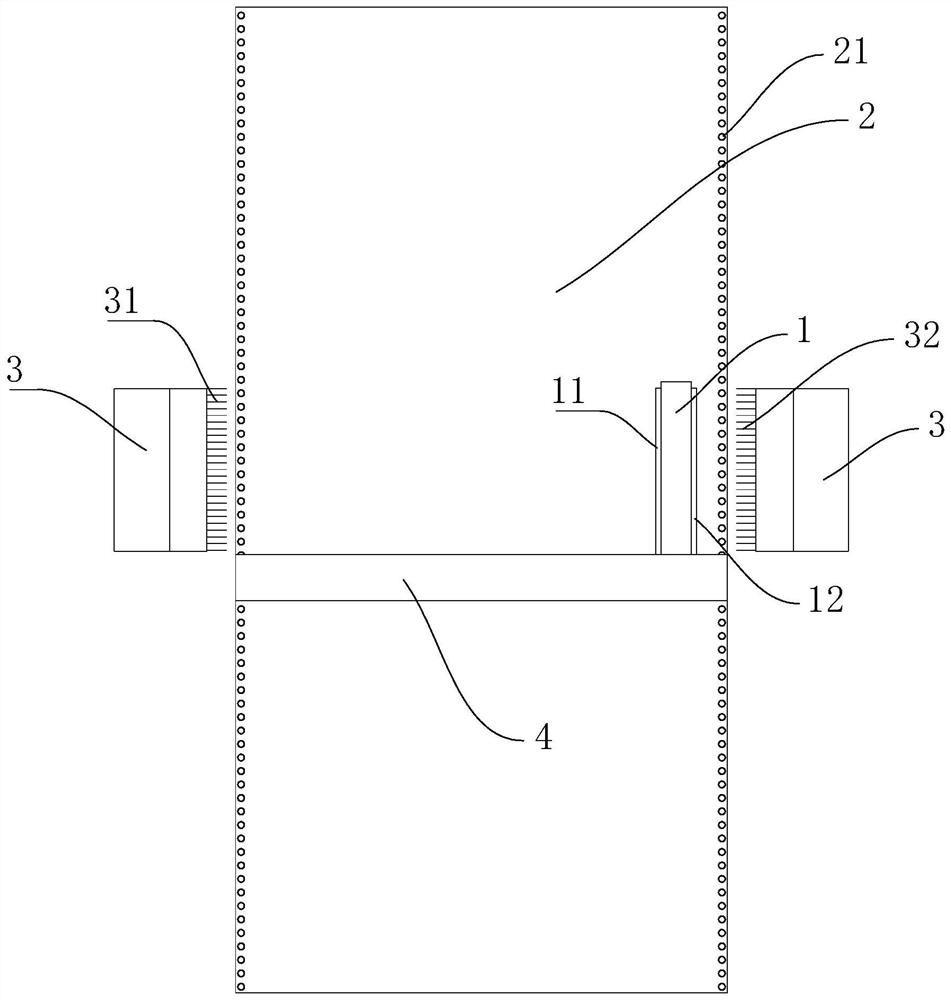

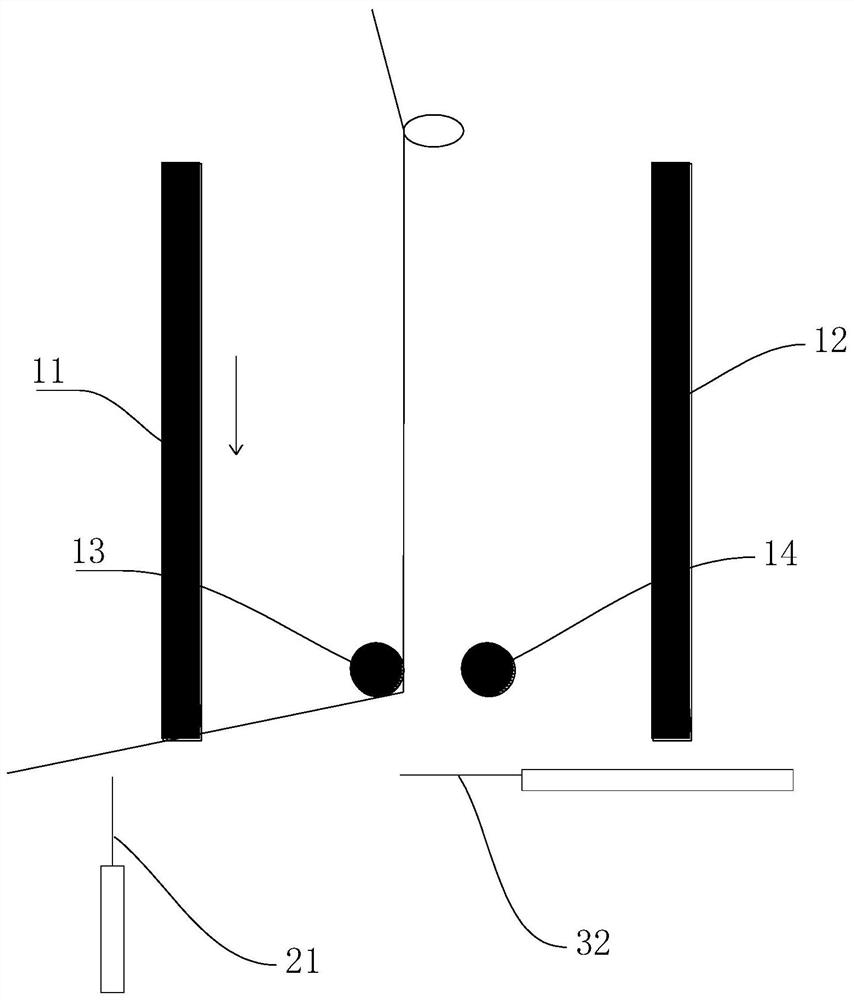

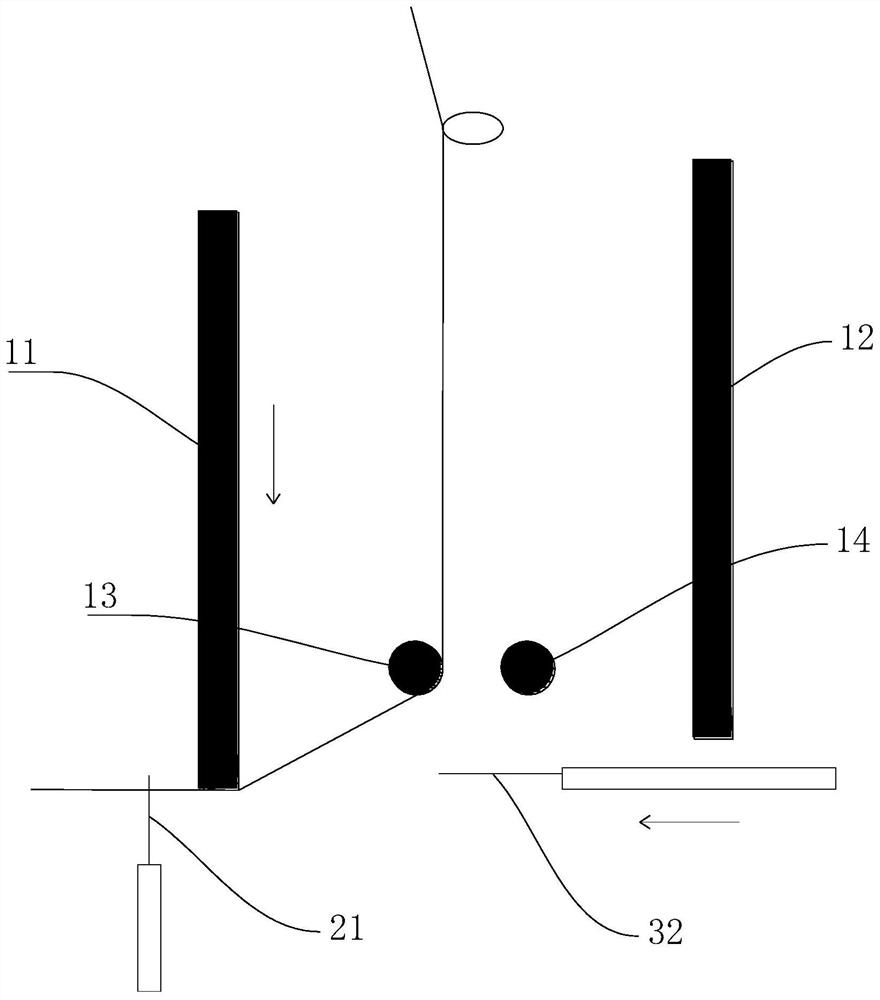

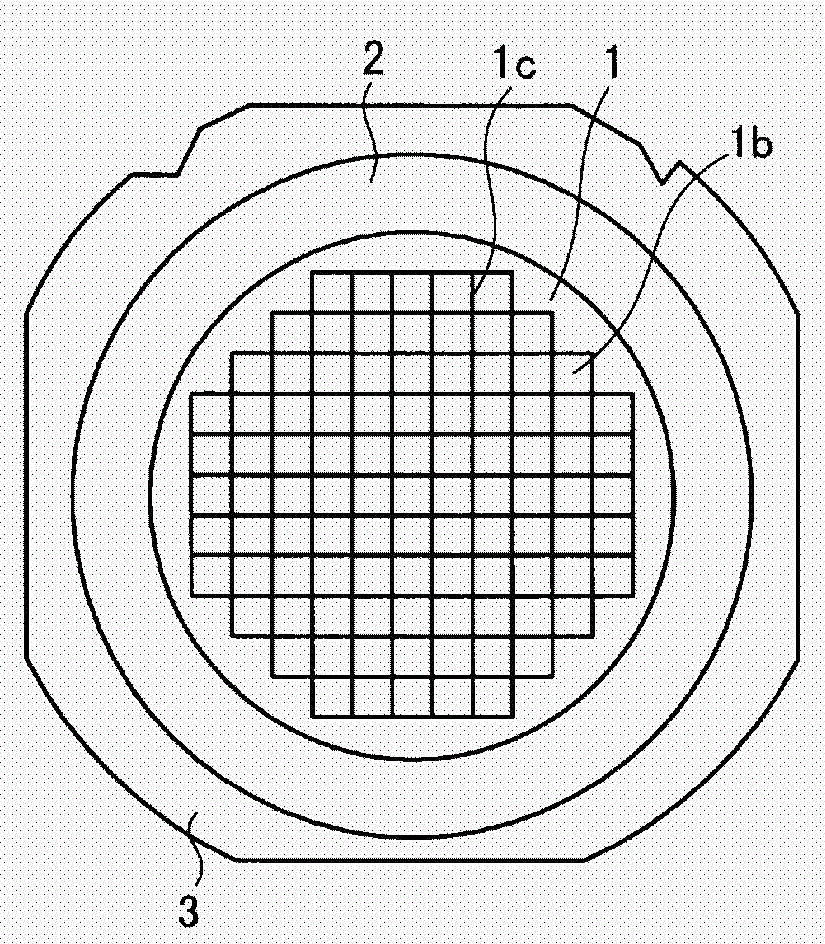

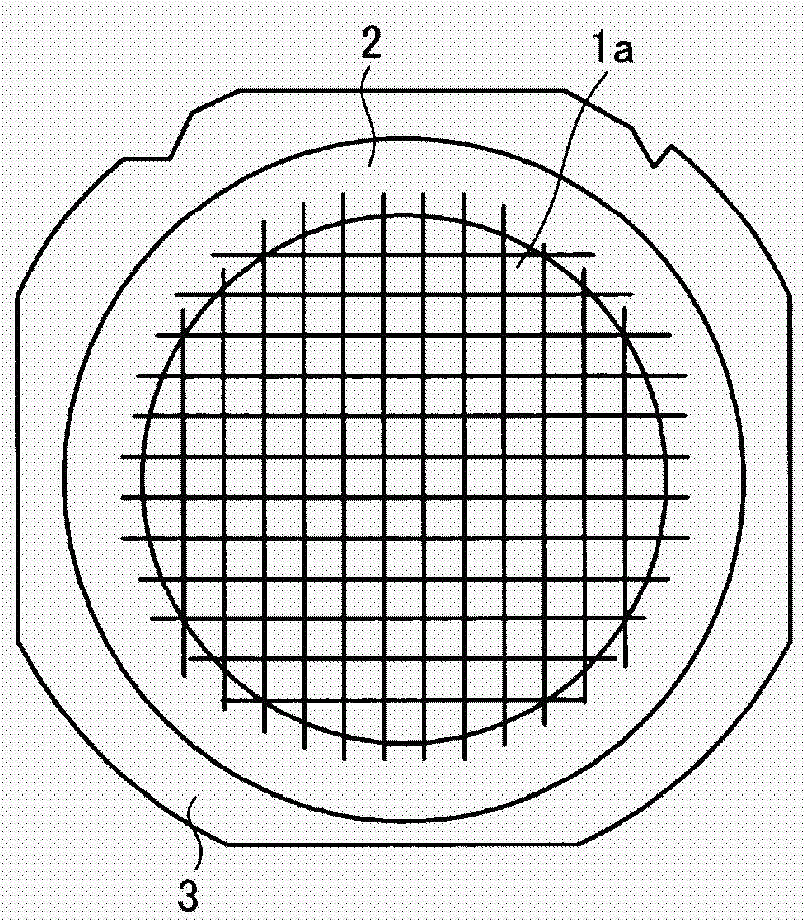

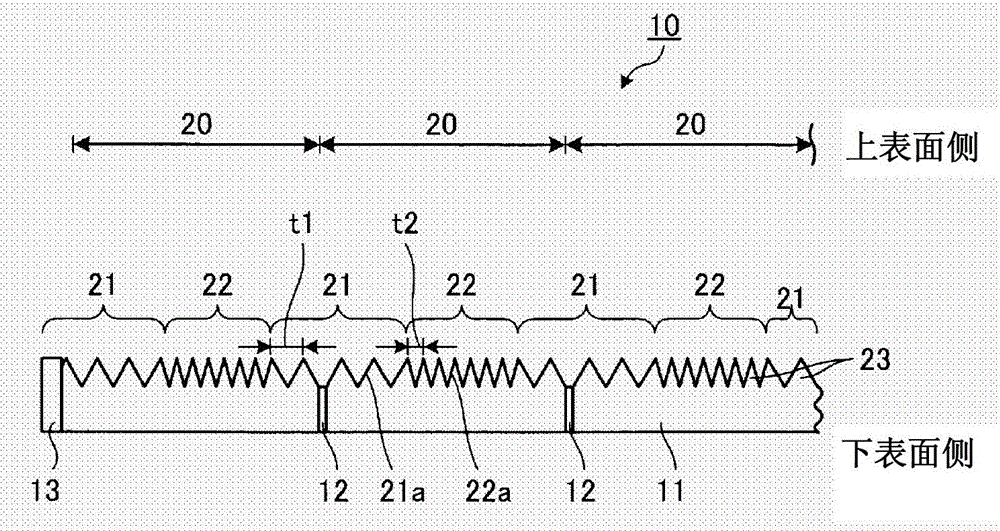

Semiconductor device manufacturing device and semiconductor device manufacturing method

InactiveCN102832158BReduce incompletenessAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor deviceSemiconductor chip

The present invention provides a semiconductor device manufacturing apparatus and a semiconductor device manufacturing method which are capable of reducing incompleteness and damages of semiconductor chips when being peeled off from a rubber belt. A pickup apparatus (10) is provided with a semiconductor chip maintenance table (11) for maintaining the semiconductor chip to be stuck on the rubber belt, and a first groove (21a) and a second groove (22a) disposed on the side, where the semiconductor chips are maintained, of the maintenance table (11), wherein the first groove (21a) and the second groove (22a) are connected with at least two air vents (12), and the width (t2) of an opening portion of the second groove is smaller than the width (t1) of the opening portion of the first groove. The semiconductor chip is maintained on peak parts of the first and the second grooves in a manner that the side stuck with the rubber belt faces downwards, a pressure-reducing mechanism is used to reduce pressure in an enclosed space enclosed by the rubber belt, the first groove and the second groove, and then the pickup apparatus (10) picks up the semiconductor chip from the maintenance table by using a chunk.

Owner:FUJI ELECTRIC CO LTD

Load-bearing detection cable armored steel wire pre-deformation production process

InactiveCN110911049AExtended service lifeImprove load carrying capacityApparatus for heat treatmentReduction of cables/conductors sizeElectrical conductorEngineering

The invention relates to the technical field of cable production, and further discloses a pre-deformation production process of the armored steel wire of the load-bearing detection cable. The method comprises the following steps: drawing: in the metal pressure processing, under the action of external force, the metal forcibly passes through the die (pressing wheel), the metal cross-section area iscompressed, the required cross sectional area shape and size are obtained; annealing: the monofilaments are taken out and the monofilaments are heat to a certain temperature; the toughness of the monofilaments is improved in a recrystallization mode so as to meet the requirements of wires and cables for conductive wire cores and stranding of conductors, in order to improve the flexibility of thewires and the cables and facilitate laying and installation, the conductive wire cores are formed by hinging a plurality of monofilaments, and the conductive wire cores can be divided into regular stranding and irregular stranding from the aspect of the stranding mode of the conductive wire cores. The pre-deformation production process for the armored steel wire of the load-bearing detection cablehas the advantages of high load-bearing capacity of the produced cable and the like, and solves the problems of poor load-bearing capacity and low cable strength of the cable.

Owner:JIANGSU HUANENG CABLE

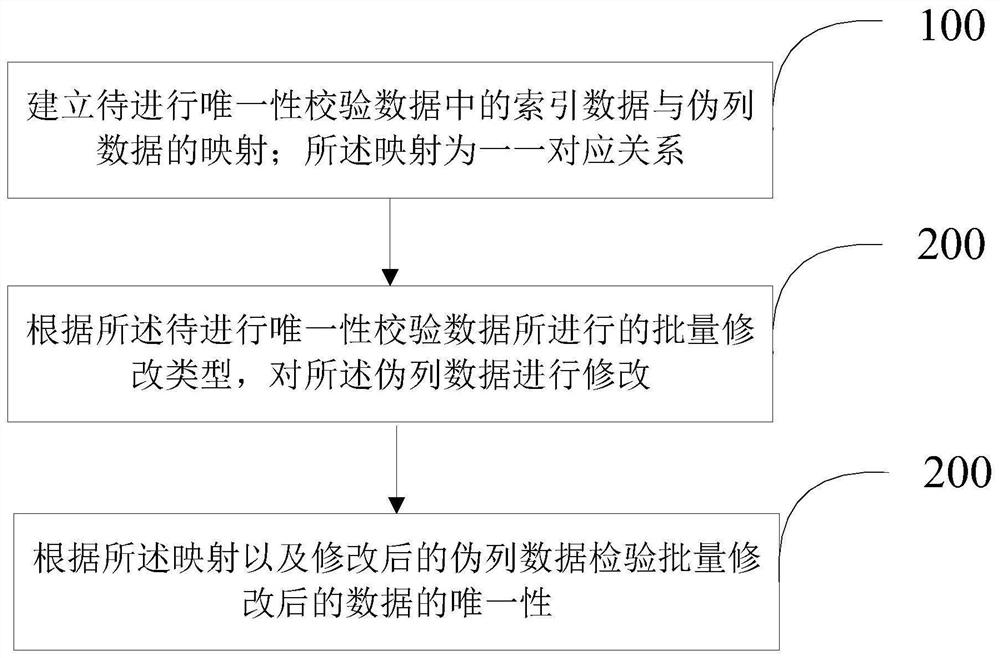

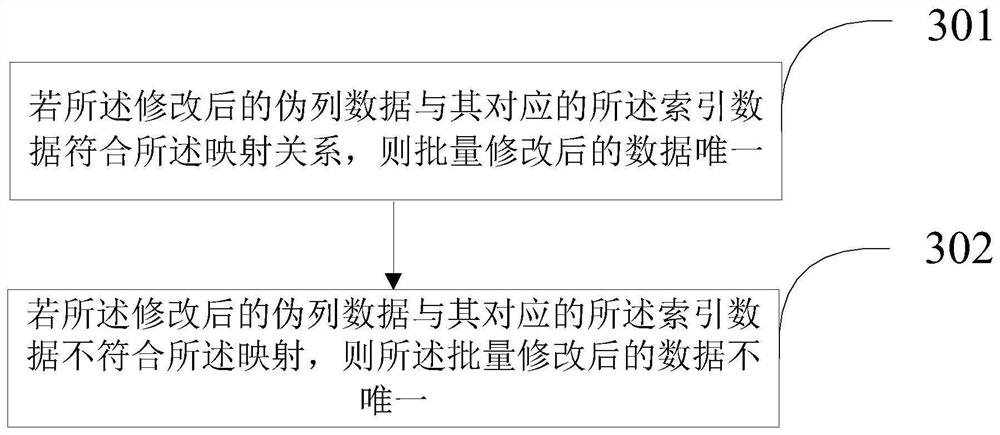

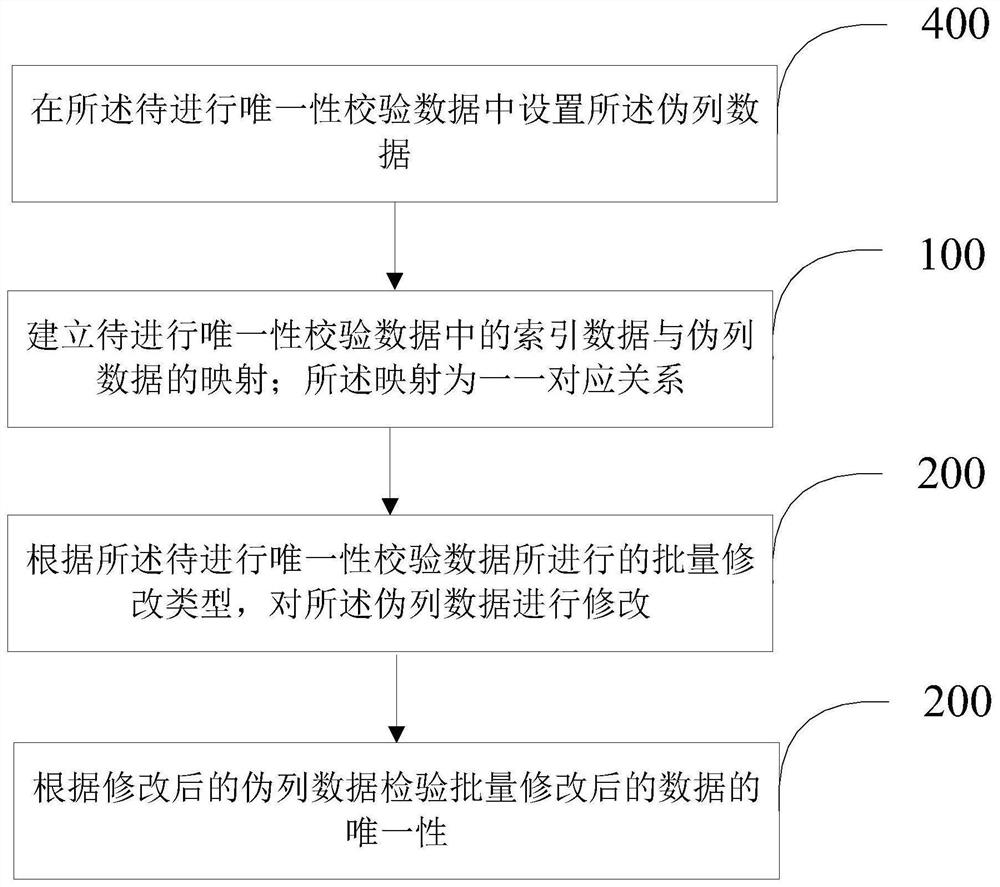

A data uniqueness verification method and device during batch modification

PendingCN112965967AScalableStrong scalabilitySpecial data processing applicationsDatabase indexingBusiness PersonnelBatch operation

The invention belongs to the technical field of big data, and provides a data uniqueness verification method and device during batch modification, and the method comprises the steps of building the mapping of index data and pseudo column data in data to be subjected to uniqueness verification, wherein the mapping is a one-to-one correspondence relationship; modifying the pseudo column data according to the batch modification type of the data to be subjected to the uniqueness verification; and checking the uniqueness of the batch modified data according to the mapping and the modified pseudo column data. According to the invention, the defects of the existing data uniqueness verification scheme are overcome, the existing business scene can be basically covered, and the data uniqueness verification requirement is met; and the operation steps of the business personnel during batch operation are reduced, so that the operation time of the business personnel during batch operation is saved.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

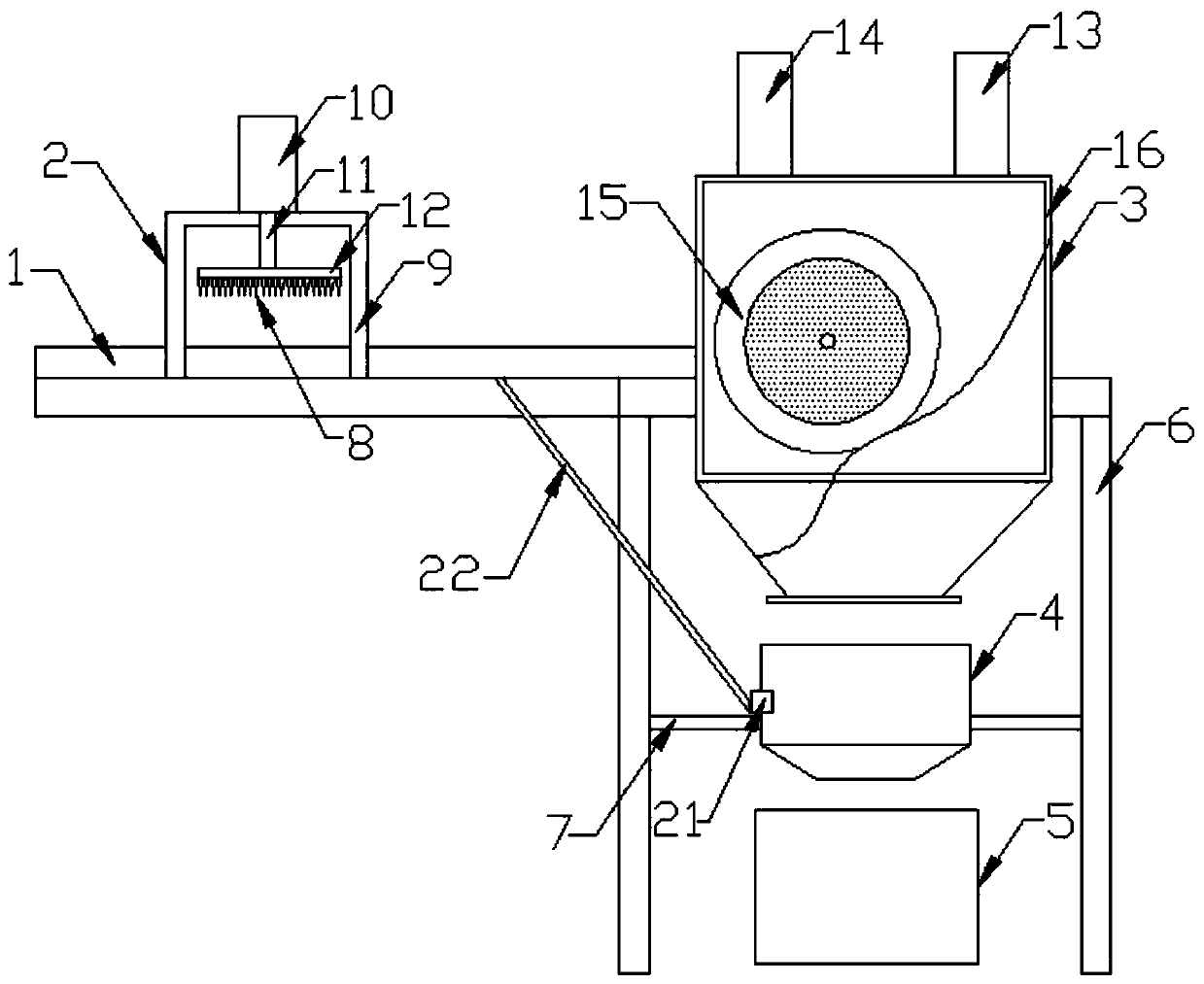

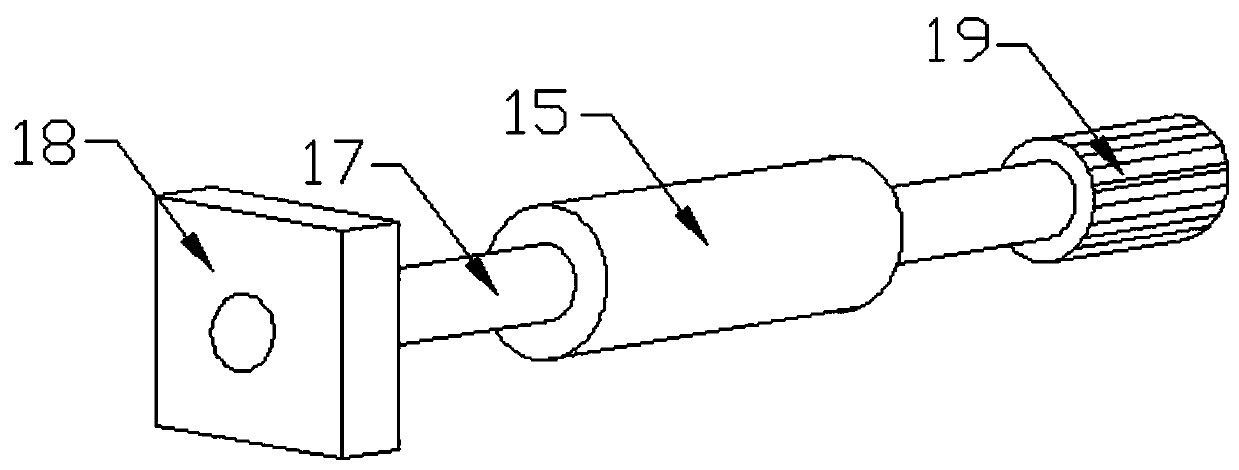

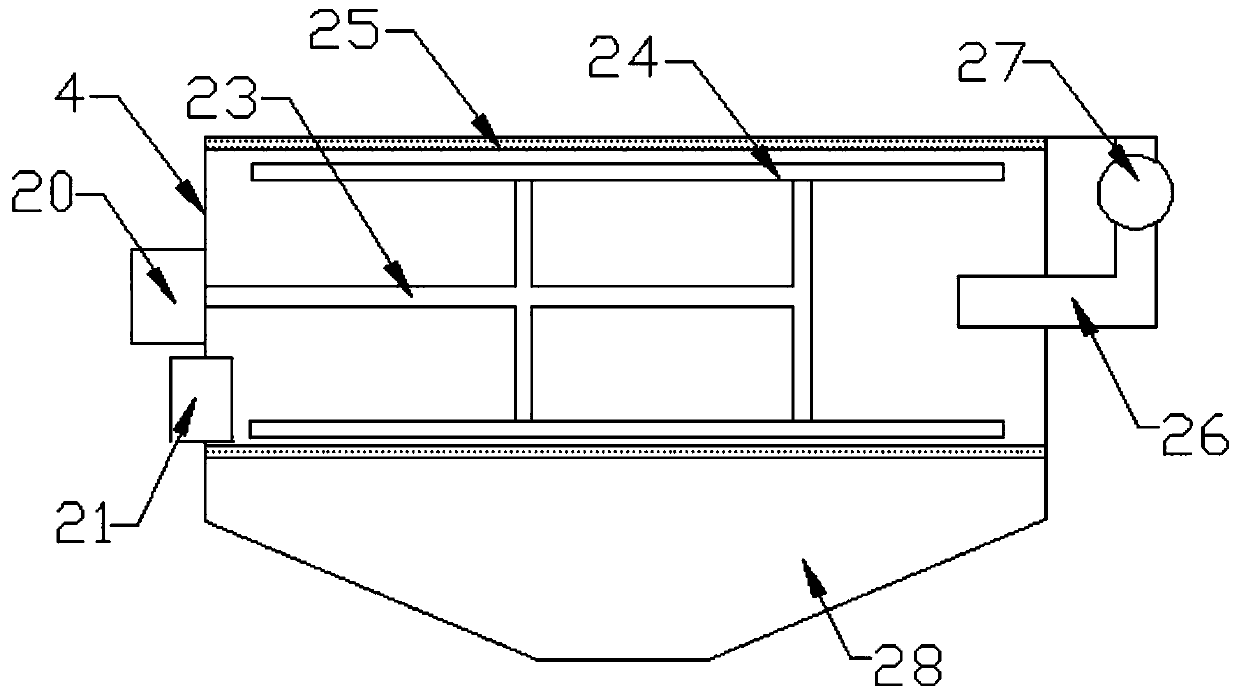

A kind of production technology and equipment of eva fine grinding powder

ActiveCN107214885BDoes not affect intrinsic propertiesGuaranteed finenessPlastic recyclingMaterials scienceGrinding

The invention discloses an EVA fine milled powder production technology which comprises the following steps: A, emptying; B, cutting; C, addition of an anti-sticking material; D, powder milling and cooling; E, secondary powder milling; and F, collection. EVA fine milled powder production equipment comprises a rack, a cutting device, a powder milling device, a screening device and a collection cylinder; the powder milling device is fixed on the rack; the screening device is arranged at the bottom of the powder milling device; auxiliary brackets for supporting the screening device are fixed on the two sides of the screening device respectively; the cutting device is arranged on one side of the powder milling device; and the collection cylinder is arranged at the bottom of the screening device. The EVA fine milled powder production technology and equipment can prevent EVA powder from being stuck with a powder milling structure without influencing the inherent attribute of the EVA powder, greatly reduces occurrence of dead mass and can ensure the fineness of the EVA powder and reduce occurrence of incompleteness condition during EVA powder milling by performing a secondary finishing and cutting structure.

Owner:浙江隆源高分子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com