Copper-clad plate surface defect visual online detection method and device based on deep learning

A technology of deep learning and detection methods, applied in the direction of measuring devices, optical testing flaws/defects, scientific instruments, etc., can solve problems such as strong dependence on labor and equipment, long time consumption, and low accuracy, so as to reduce incompleteness, The effect of improving efficiency and enhancing portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

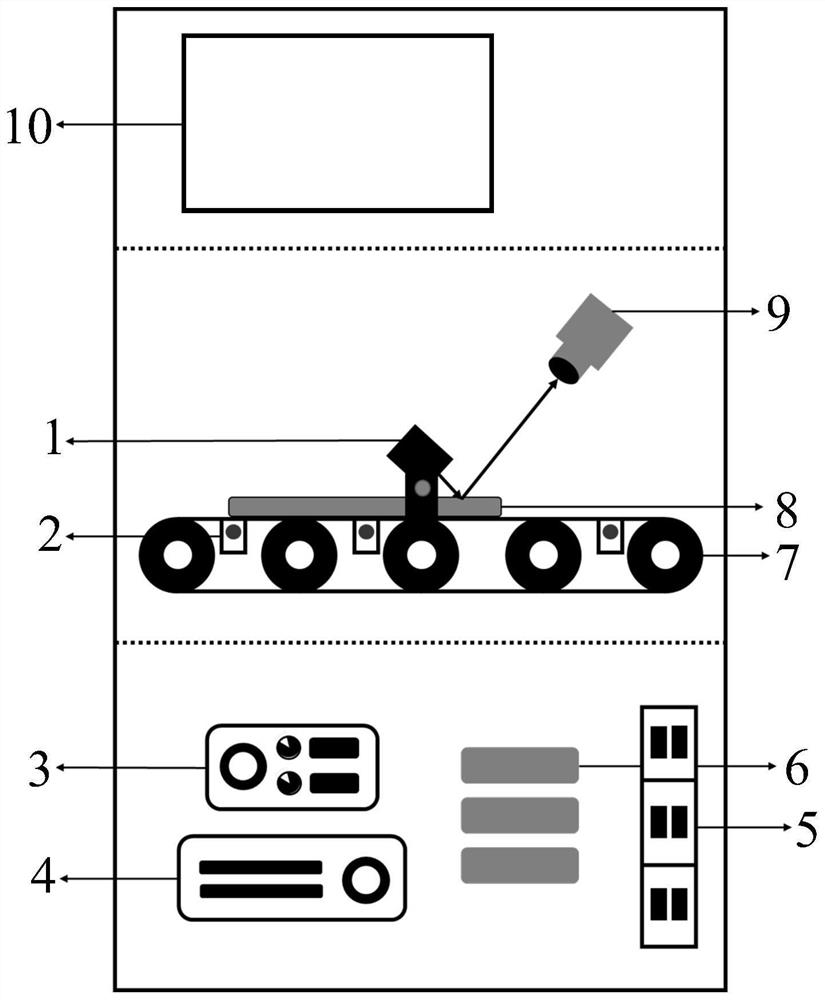

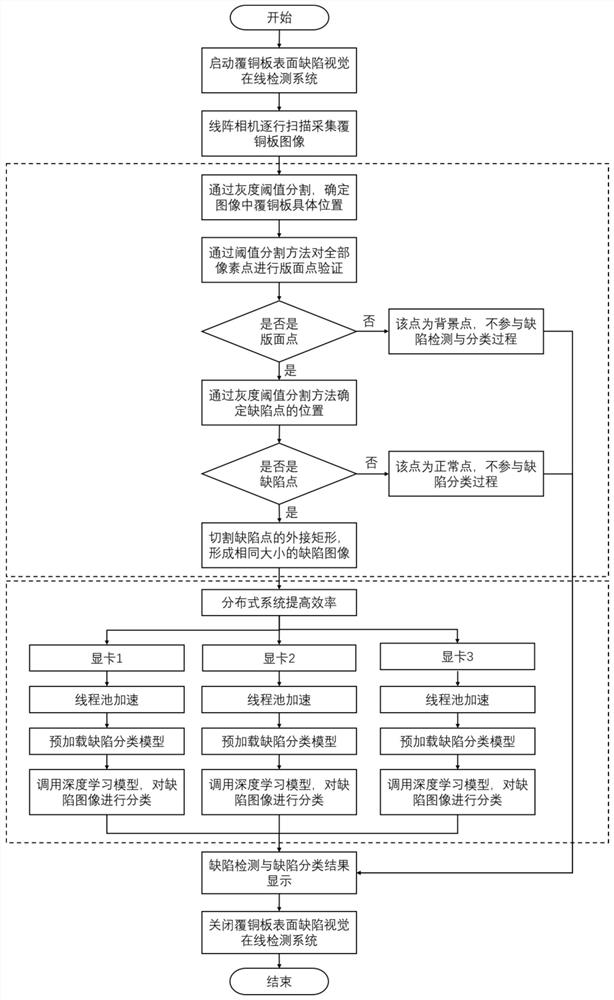

[0050] figure 1 The structure of the visual on-line detection device for surface defects of copper clad laminates of the present invention is shown, which is mainly composed of a photoelectric sensor 2, a line light source 1, a line scan camera 9, an industrial computer 4, a display 10, and the like. The copper clad laminate conveying equipment 7 is composed of several uniformly moving rollers, which are responsible for conveying the copper clad laminate 8 at a uniform speed; the line light source 1 and the line scan camera 9 are installed directly above the middle of the copper clad laminate conveying equipment 7. , the photoelectric sensor 2 detects that the copper-clad laminate 8 passes through, and obtains the image data of the copper-clad laminate 8 through the line scan camera 9, and the line light source 1 can provide sufficient light to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com