A kind of production technology and equipment of eva fine grinding powder

A production process and production equipment technology, applied in the production process and equipment field of EVA fine grinding, can solve the problems of no secondary fine grinding, lower recovery rate, environmental hazards, etc., to ensure the degree of fineness and reduce incomplete sex, to avoid the effect of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

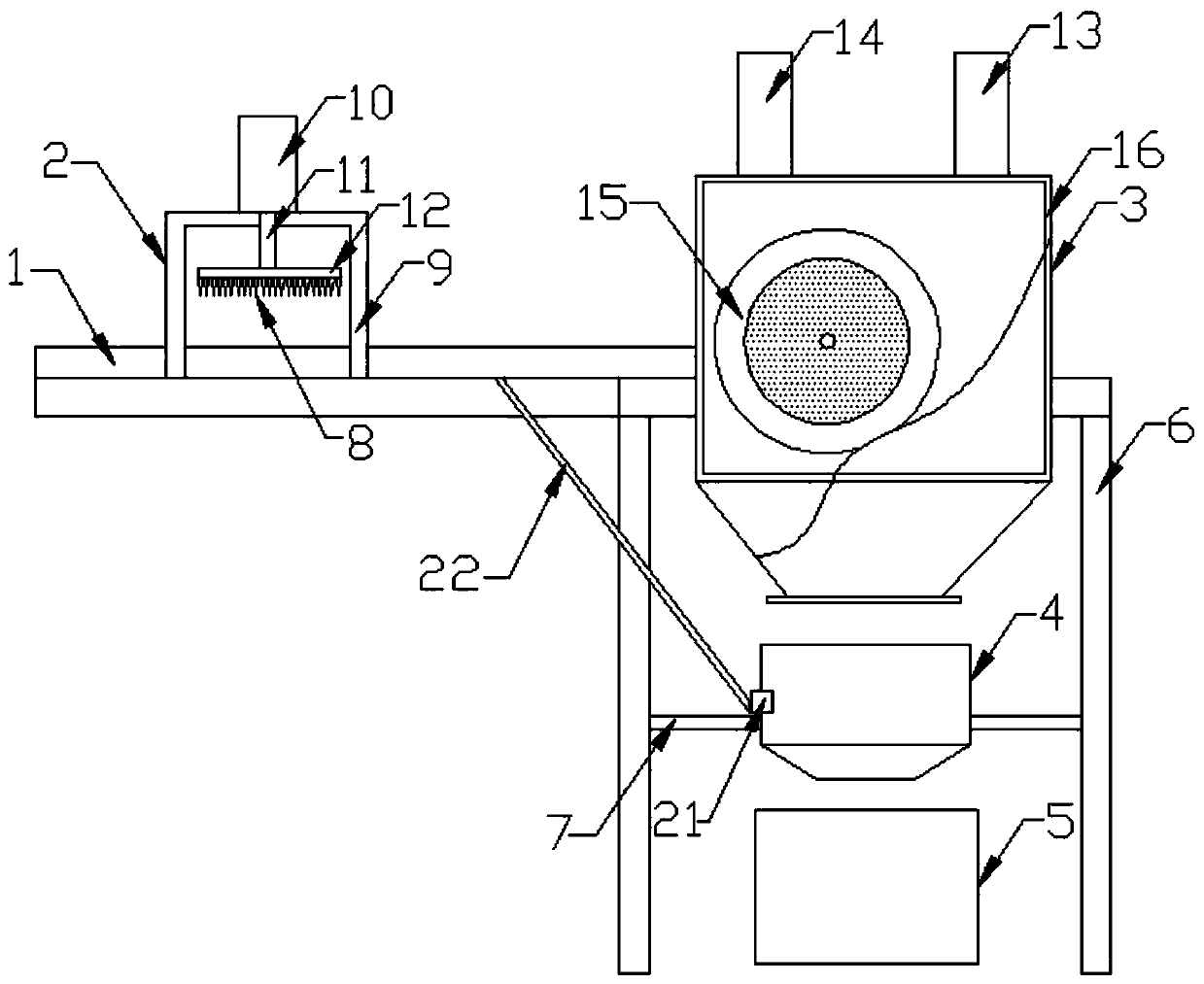

[0027] Such as Figure 1-3 Shown, the present invention provides a kind of production technology of EVA fine milling and equipment thereof, comprises the following steps:

[0028] A: Unloading: Place the EVA scraps on the conveyor belt 1 one by one.

[0029] : Cutting: EVA scraps are sent to the cutting device 2, and the cutting device 2 cuts them into small EVA scraps of 5mm-10mm, which is convenient for the milling device 3 to grind the EVA scraps.

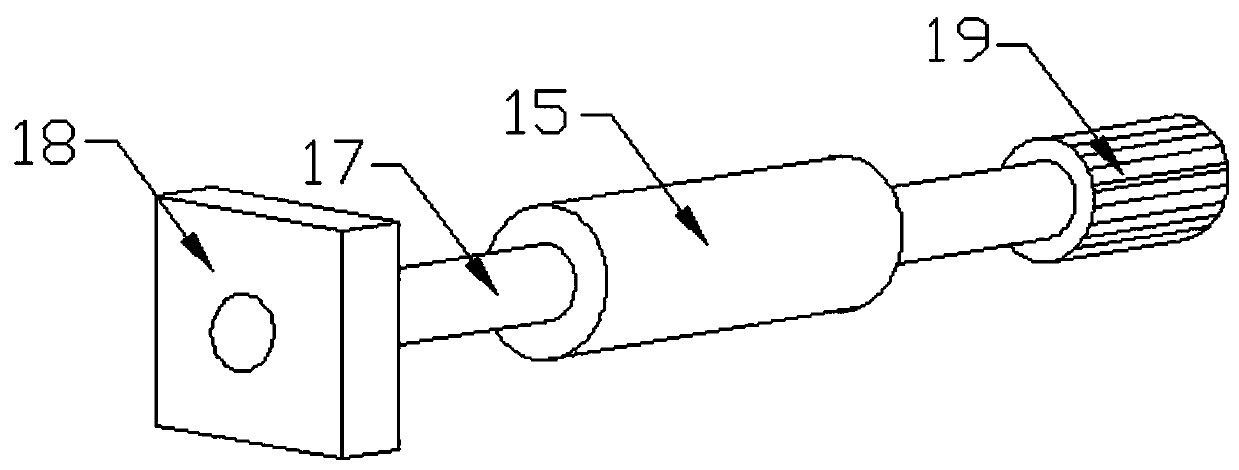

[0030] : Add anti-adhesive material: On the way of the small EVA scraps being conveyed to the grinding device 3, polyphenylene sulfide powder is mixed into the small EVA scraps, wherein the polyphenylene sulfide powder accounts for 3% of the weight of the EVA scraps, avoiding emery wheel 15 Sticky with EVA scraps.

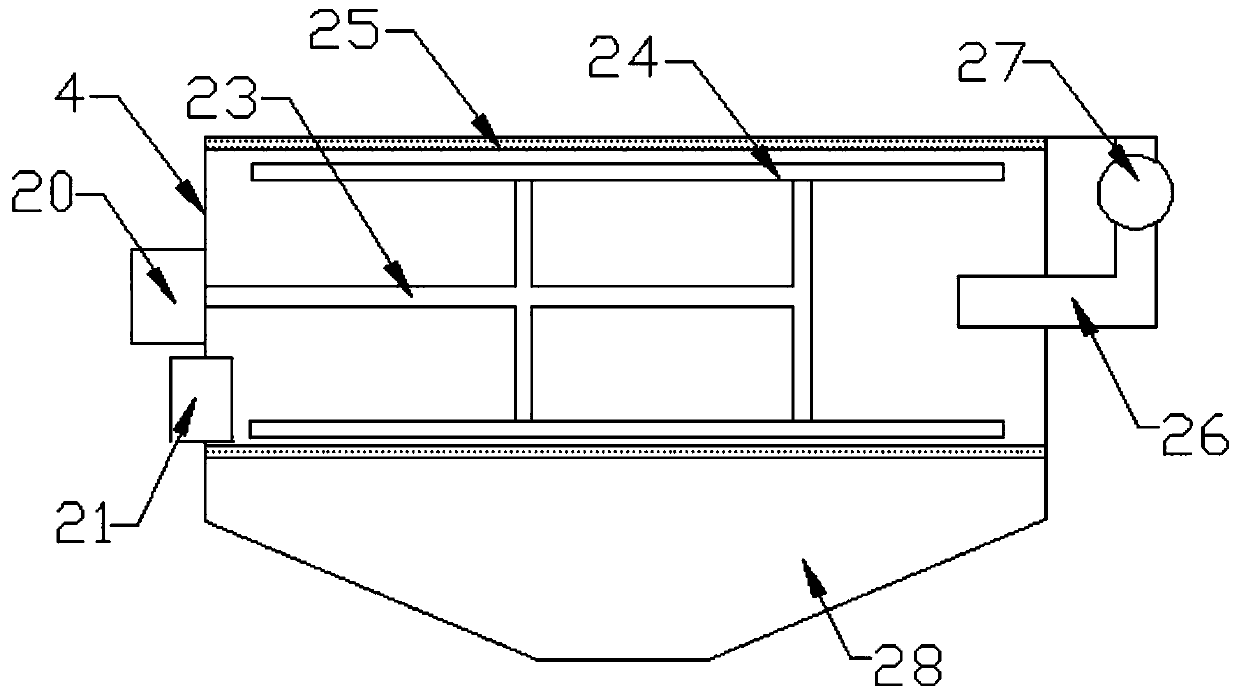

[0031] : Grinding and cooling: Put the small EVA leftovers into the grinding device 3, finely grind them into powder by the hollow emery wheel 15, and simultaneously feed cooling air into the milling device 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com