Method for producing ultraviolet radiation-temperature response type macromolecule hydrogel

A polymer hydrogel, temperature-responsive technology, applied in the field of intelligent polymer materials, can solve the problems of poor deformation stability and deformation controllability of photodeformable polymer hydrogel materials, limited application research, etc., and achieve industrialization. The effect of easy implementation, simple process method and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Synthesize an intermediate monomer AAAB containing an azophenyl group in the molecular chain by an existing mature method: dissolve 7.8g of p-aminoazobenzene in 80ml of benzene, add 5.6ml of triethylamine and a small amount of p-phenylenedi Phenol was dissolved by stirring, and 4ml of acryloyl chloride was added dropwise, heated under reflux at 60°C for 3h, cooled after the end, and the resulting crystals were filtered and dried. Dissolve the product with a small amount of ethanol and put it in the refrigerator for recrystallization. Orange-yellow crystals are precipitated, and the product is obtained after drying.

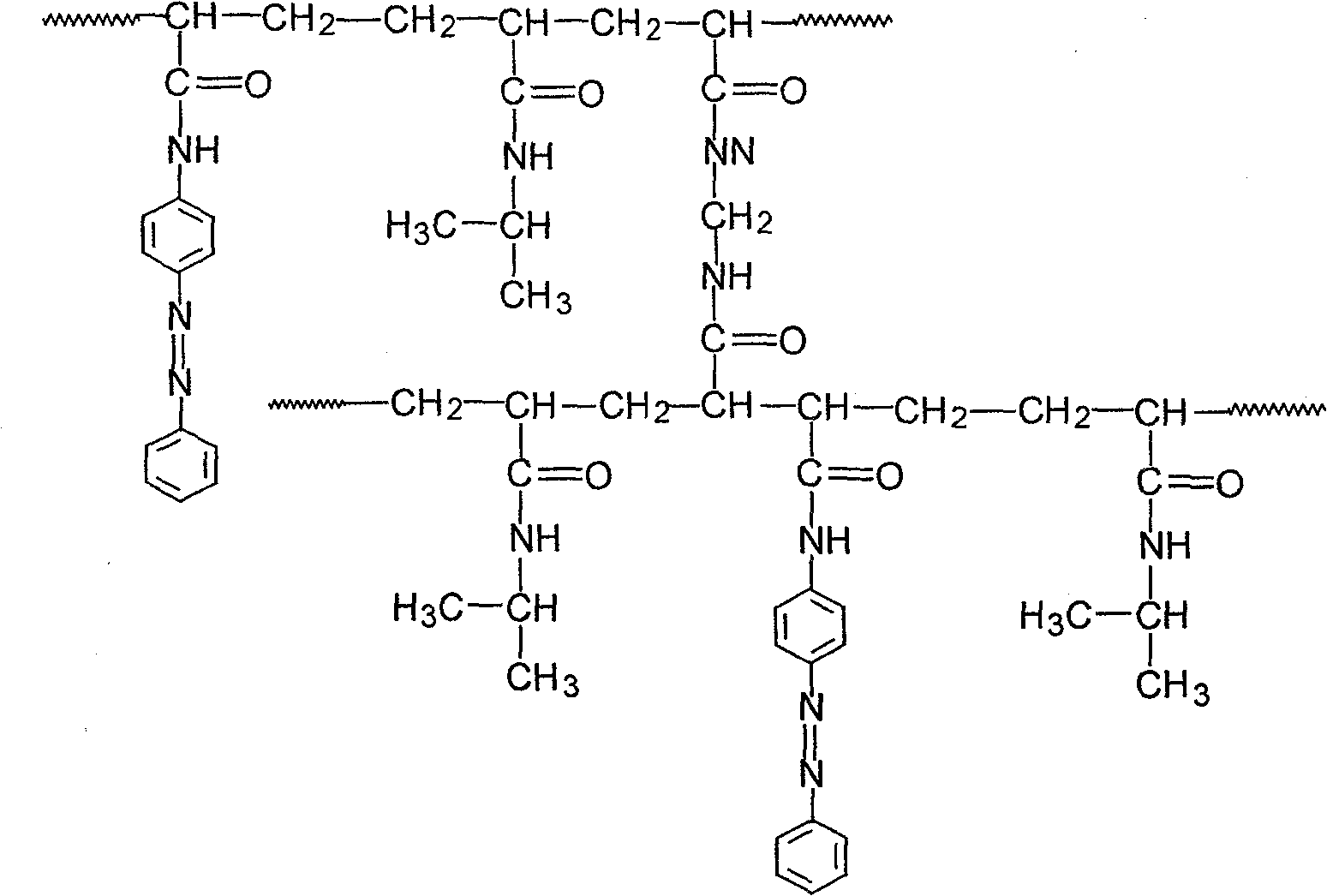

[0032] 2. Prepare P(NIPAAm-co-AAAB) copolymer hydrogel by using the intermediate monomer AAAB: Weigh the refined monomer NIPAAm and the intermediate monomer AAAB respectively according to the molar ratio NIPAAm:AAAB=99:1, and dissolve them with absolute ethanol Prepare a solution, adjust the amount of absolute ethanol in the mixing process so that the co...

Embodiment 2

[0036] 1. Same as embodiment 1.

[0037] 2. Prepare P(NIPAAm-co-AAAB) copolymer hydrogel by using the intermediate monomer AAAB: Weigh the refined monomer NIPAAm and the intermediate monomer AAAB respectively according to the molar ratio NIPAAm:AAAB=99:1, and dissolve them with absolute ethanol Prepare the solution, adjust the amount of absolute ethanol in the mixing process so that the concentration of NIPAAm in the mixed solution is controlled at 1mol / l. Add 0.04mol cross-linking agent MBAA to each liter of mixed solution, dissolve and stir evenly, and pass nitrogen for 20 minutes, then add 0.008mol initiator AIBN to each liter of mixed solution, stir and dissolve, continue to pass nitrogen for 30 minutes, and drop it with a dropper Add 1.0ml of TEMED, stir and mix evenly, pour the solution into the mold, put the mold in a constant temperature environment of 70°C, let it gel for 12 hours, and obtain the P(NIPAAm-co-AAAB) copolymer hydrogel;

[0038] The obtained copolymeriz...

Embodiment 3

[0041] 1. Same as embodiment 1.

[0042] 2. Prepare P(NIPAAm-co-AAAB) copolymer hydrogel by using the intermediate monomer AAAB: Weigh the refined monomer NIPAAm and the intermediate monomer AAAB respectively according to the molar ratio NIPAAm:AAAB=99:1, and dissolve them with absolute ethanol A mixed solution is made, and the amount of absolute ethanol is adjusted during the mixing process so that the NIPAAm concentration in the mixed solution is controlled at 1mol / l. Add 0.04mol cross-linking agent MBAA to each liter of mixed solution, dissolve and stir evenly, and pass nitrogen for 20 minutes, then add 0.01mol initiator AIBN to each liter of mixed solution, stir and dissolve, continue to pass nitrogen for 40 minutes, and drop it with a dropper Add 1.5ml of TEMED, stir and mix evenly, pour the solution into the mold, put the mold in a constant temperature environment at 75°C, and let it gel for 12 hours to obtain P(NIPAAm-co-AAAB) copolymer hydrogel;

[0043] The obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com