Method for improving the yield of graphene prepared by supercritical fluid by pretreatment of natural graphite

A technology of supercritical fluid and natural graphite, which is applied in the direction of graphene, bulk chemical production, nano-carbon, etc., can solve the problems of unsatisfactory yield and achieve the effect of increasing yield and maintaining electrical and thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

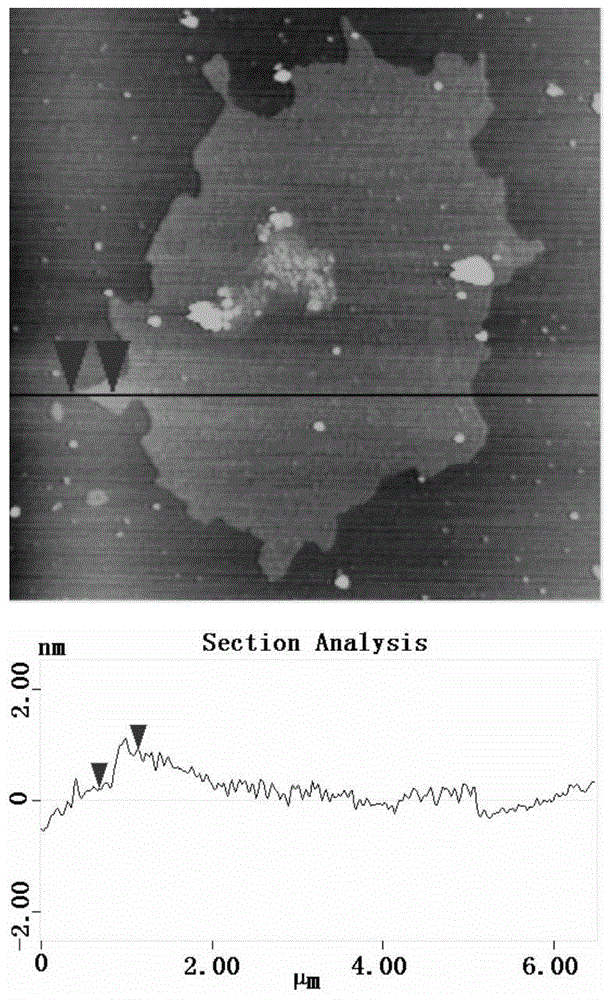

Image

Examples

Embodiment 1

[0036] Add the natural graphite powder and 95% concentrated sulfuric acid into the container according to the weight ratio of 10:1, and use ultrasonic stirring method, after stirring for 20 minutes, filter out the excess acid. Add ethanol by 3% of graphite powder weight, and stir evenly. Transfer the material to a cryogenic container and allow the material to cool to -10°C. Then the low-temperature material is quickly sprayed into a high-pressure reactor filled with supercritical ethanol, and the temperature of the high-pressure reactor is maintained at 245° C. and the pressure is 6.5 MPa. After the material stays in the autoclave for 60 minutes, it is quickly sprayed into the normal pressure production tank. The material was filtered, separated, washed, dried and the solid product collected. The solid product was added to a fresh dimethylformamide solution again, dispersed by ultrasonic waves for 120 minutes, left to stand for 12 hours, and then the precipitate was removed ...

Embodiment 2

[0038]Add natural graphite powder and 80% concentrated hydrochloric acid into the container according to the weight ratio of 1:2, adopt mechanical stirring method, and after stirring for 40 minutes, filter out excess acid. Add ethanol by 5% of graphite powder weight, and stir evenly. Transfer the material to a cryogenic container and allow the material to cool to -20°C. Then the low-temperature material is quickly sprayed into a high-pressure reactor filled with supercritical N-methylpyrrolidone. The temperature of the high-pressure reactor is maintained at 445° C. and the pressure is 4.8 MPa. After the material stays in the autoclave for 90 minutes, it is quickly sprayed into the normal pressure production tank. The material was filtered, separated, washed, dried and the solid product collected. The solid product was added to a fresh dimethylformamide solution again, dispersed by ultrasonic waves for 120 minutes, left to stand for 12 hours, and then the precipitate was remo...

Embodiment 3

[0040] Add the natural graphite powder and 90% concentrated nitric acid into the container according to the weight ratio of 1:1, adopt the mechanical stirring method, and after stirring for 50 minutes, centrifuge off the excess acid. Add ethylene glycol by 1% of graphite powder weight, and stir evenly. Transfer the material to a cryogenic container and allow the material to cool to -5°C. Then the low-temperature material is quickly sprayed into a high-pressure reactor filled with supercritical dimethylformamide. The temperature of the high-pressure reactor is maintained at 370° C. and the pressure is 6 MPa. After the material stays in the autoclave for 120 minutes, it is quickly sprayed into the normal pressure production tank. The material was filtered, separated, washed, dried and the solid product collected. The solid product was added to a fresh dimethylformamide solution again, dispersed by ultrasonic waves for 120 minutes, left to stand for 12 hours, and then the preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com