Semiconductor device manufacturing device and semiconductor device manufacturing method

A technology for manufacturing devices and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as semiconductor chip damage and semiconductor chip surface damage, and achieve the effect of reducing incompleteness and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

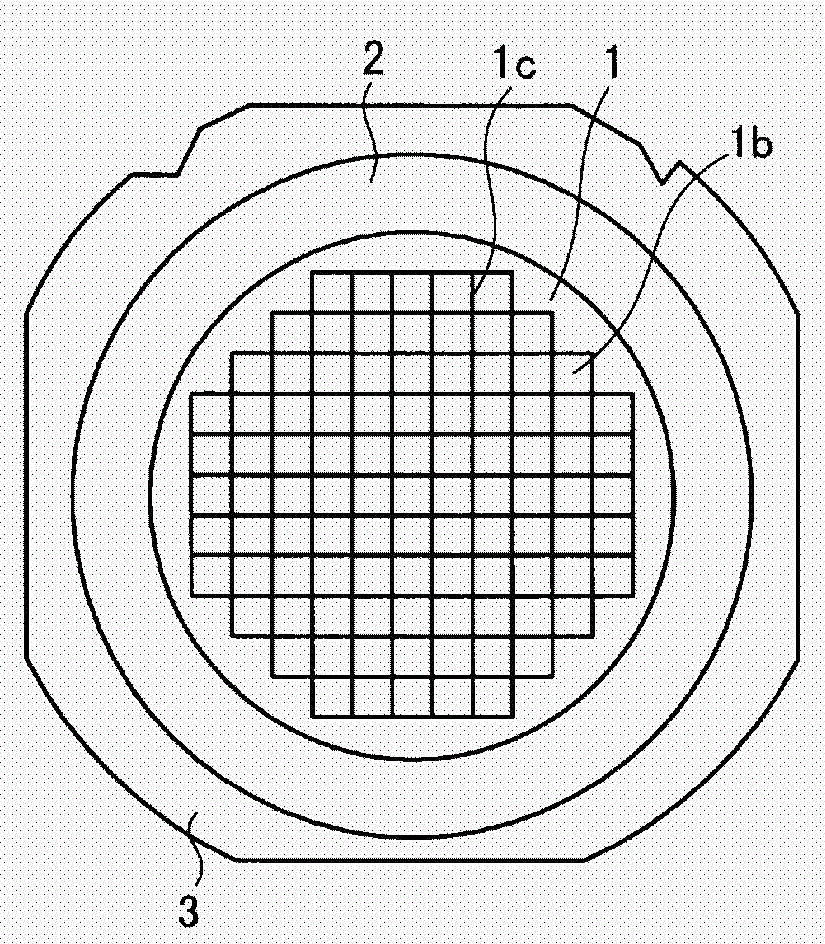

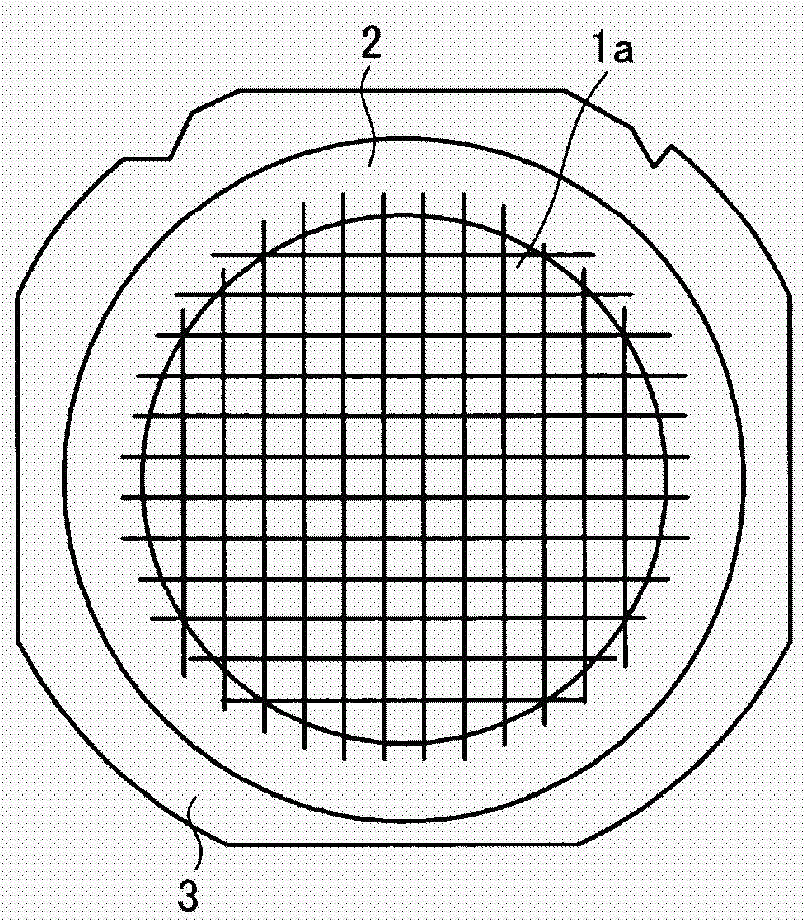

[0071] figure 1 It is a plan view showing a semiconductor wafer processed in the semiconductor device manufacturing apparatus of the first embodiment. figure 2 yes means figure 1 A plan view of the diced state of the semiconductor wafer is shown. The semiconductor wafer 1 before being processed in the semiconductor device manufacturing apparatus of the first embodiment will be described. Such as figure 1 , 2 As shown, a semiconductor wafer 1 is diced with a tape (dicing tape) 2 attached thereto, and is cut into individual semiconductor chips 1 a on which a device surface structure (electronic circuit) is formed.

[0072] Specifically, the semiconductor wafer 1 is cut into individual semiconductor chips 1a by dicing, for example, as follows. First, if figure 1 As shown, in each formation region 1 b of the semiconductor chip, the surface structure of the device is formed on the surface side of the semiconductor wafer 1 . The formation regions 1b of the semiconductor ...

no. 2 approach )

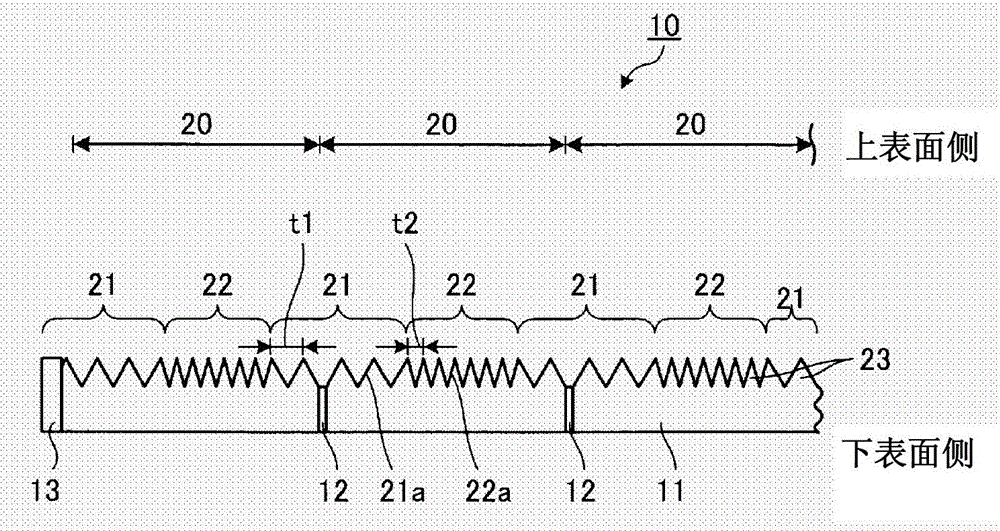

[0113] Figure 11 It is a cross-sectional view showing main parts of the semiconductor device manufacturing apparatus of the second embodiment. in addition, Figure 12 It is a cross-sectional view showing a semiconductor chip held in the semiconductor device manufacturing apparatus of the second embodiment. The semiconductor device manufacturing apparatus (pickup apparatus) 40 of the second embodiment differs from the semiconductor device manufacturing apparatus of the first embodiment in that the cross-sectional shapes of the first groove 51 a and the second groove 52 a are rectangular.

[0114] Such as Figure 11 As shown, the holding table 11 of the pick-up device 40 has: a first groove 51a and a second groove 52a arranged on the upper surface of the holding table 11; at least one air hole connected with the first groove 51a and the second groove 52a 12 ; and the outer wall portion 13 that contacts the side surface of the holding table 11 and surrounds the holding table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com