Polyphenyl ether resin composition and preparation method thereof, and wire duct and preparation method thereof

A technology of polyphenylene ether resin and polystyrene resin, which is applied in the field of polyphenylene ether resin composition and its preparation, can solve the problem of high melt viscosity of polyphenylene ether resin, difficulty in meeting the requirements of wire groove extrusion molding process, impact sensitivity Sexuality, poor oil resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

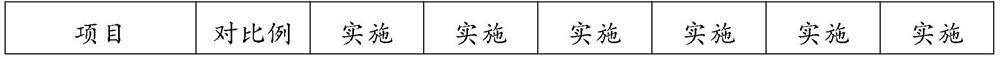

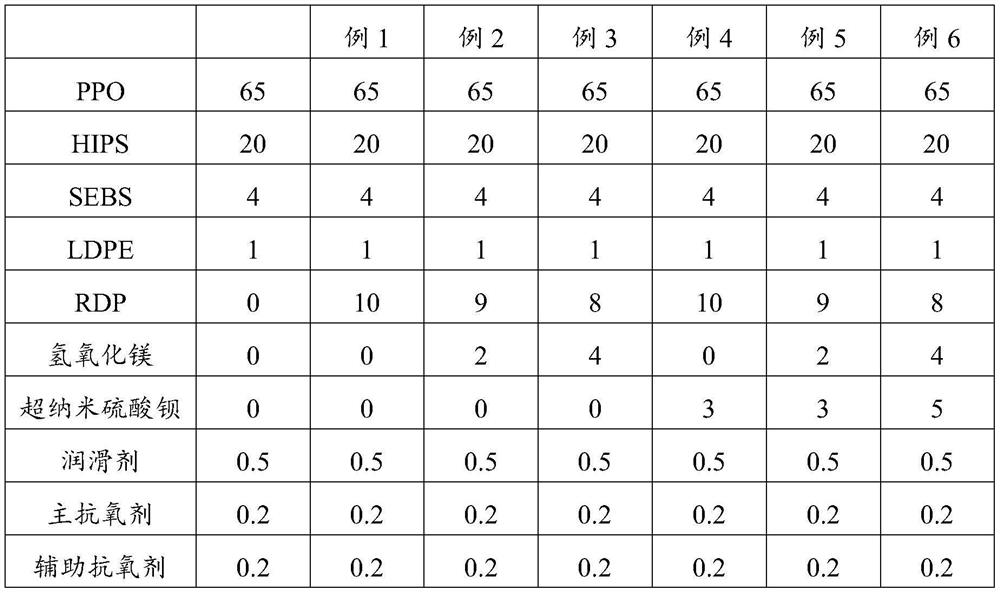

Examples

preparation example Construction

[0050] The present invention also provides a preparation method of the polyphenylene ether resin composition described in the above technical solution, comprising the following steps:

[0051] The prepared raw materials are put into a twin-screw extruder for melt extrusion and granulation to obtain a polyphenylene ether resin composition.

[0052] In the present invention, the method of adding the preparation raw materials into the twin-screw extruder preferably includes: adding polyphenylene ether resin from the first weight feeder port; mixing the remaining preparation raw materials, and feeding the obtained mixture from the second weight feeder The mouth of the device is added. In the present invention, the mixing of the remaining preparation raw materials is preferably carried out under stirring conditions, and the stirring speed is preferably 100-150 rpm; the stirring time is preferably 2-3 minutes.

[0053] In the present invention, when the flame retardant is liquid, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com