Toughened polylactic acid composite material and preparation method thereof

A composite material and polylactic acid technology, applied in the field of toughened polylactic acid composite material and its preparation, can solve problems such as non-uniformity and stability, and achieve the effects of improving compatibility, excellent comprehensive performance, and increasing thermal deformation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

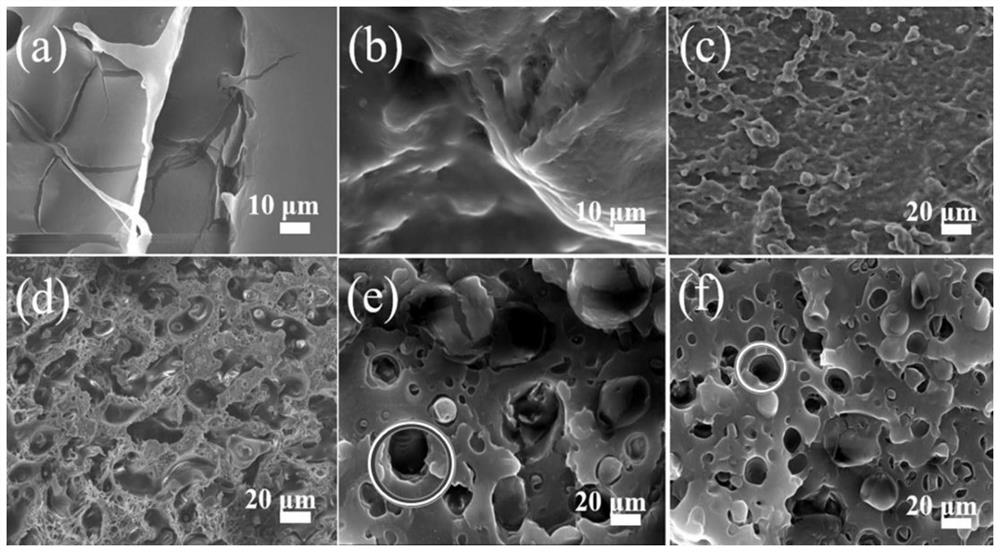

Image

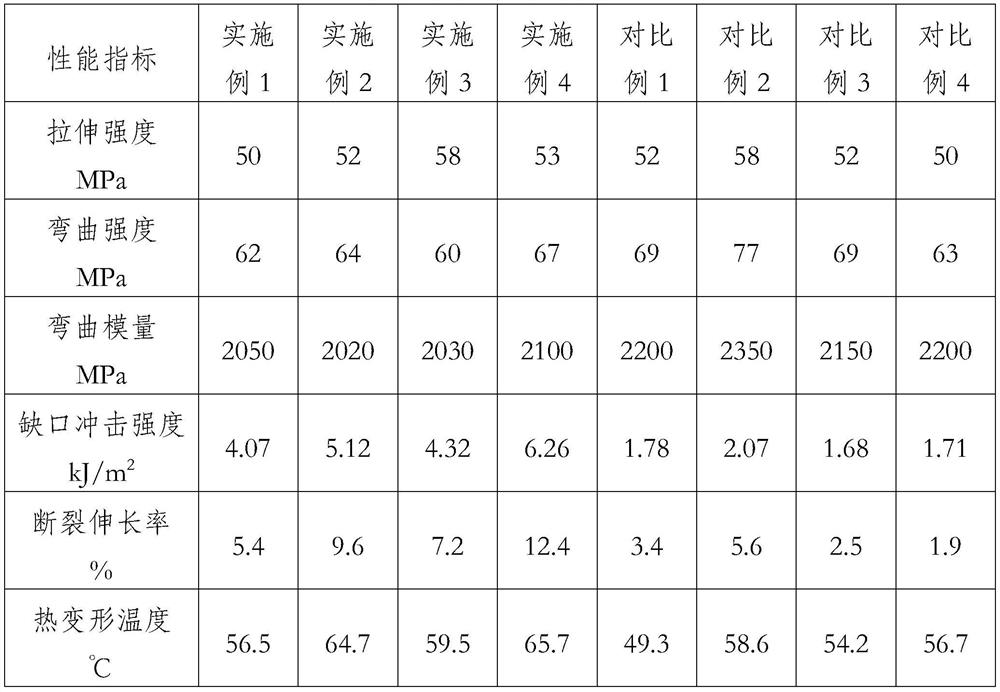

Examples

Embodiment 1

[0028] Prepare materials according to the following parts by weight: 37 parts of polylactic acid PLA, 58 parts of polyethylene terephthalate-1,4-cyclohexanedimethanol (PCTG), 3 parts of compatibilizer, 0.2 part of antioxidant .

[0029] The above-mentioned raw materials are put into a high mixer and mixed evenly to obtain a premixed material. Then the premixed material is added into a twin-screw extruder, melted and extruded to granulate, the screw temperature of each section of the twin-screw extruder is controlled between 180-210°C, and the screw speed is 500 rpm. The obtained particles were dried at 60°C for 6 hours to obtain the finished material.

Embodiment 2

[0031] Prepare materials according to the following parts by weight: 37 parts of polylactic acid PLA, 58 parts of polyethylene terephthalate-1,4-cyclohexanedimethanol (PCTG), 5 parts of compatibilizer, 0.2 part of antioxidant .

[0032] The above-mentioned raw materials are put into a high mixer and mixed evenly to obtain a premixed material. Then the premixed material is added into a twin-screw extruder, melted and extruded to granulate, the screw temperature of each section of the twin-screw extruder is controlled between 180-210°C, and the screw speed is 500 rpm. The obtained particles were dried at 60°C for 6 hours to obtain the finished material.

Embodiment 3

[0034] Prepare materials according to the following parts by weight: 36 parts of polylactic acid PLA, 57 parts of polyethylene terephthalate-1,4-cyclohexanedimethanol (PCTG), 7 parts of compatibilizer, and 0 part of toughening agent , 0.2 parts of antioxidant.

[0035] The above-mentioned raw materials are put into a high mixer and mixed evenly to obtain a premixed material. Then the premixed material is added into a twin-screw extruder, melted and extruded to granulate, the screw temperature of each section of the twin-screw extruder is controlled between 180-210°C, and the screw speed is 500 rpm. The obtained particles were dried at 60°C for 6 hours to obtain the finished material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com