Near infrared up-conversion long afterglow luminescent material and preparation method thereof

A long afterglow luminescence and near-infrared technology, applied in the field of micro-nano materials, can solve the problems of complex preparation process, harsh preparation conditions and high preparation cost, and achieve the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1) A certain stoichiometric ratio of ZnO, Ga 2 o 3 , SnO 2 , Cr 2 o 3 , Yb 2 o 3 and Er 2 o 3 The powder is thoroughly ground and mixed in an agate mortar.

[0049] 2) The ground powder is pre-fired at 900° C. for 2 hours in an air atmosphere and atmospheric pressure in a muffle furnace. The block was sintered at 1300°C for 15 hours in an air atmosphere and one atmospheric pressure.

[0050] 3) The sintered product is cooled to room temperature, and ground again in a mortar to obtain the near-infrared up-conversion long-lasting luminescent material Zn 3 Ga 2 SnO 8 : 1%Cr 3+ , 5%Yb 3+ , 0.5% Er 3+ .

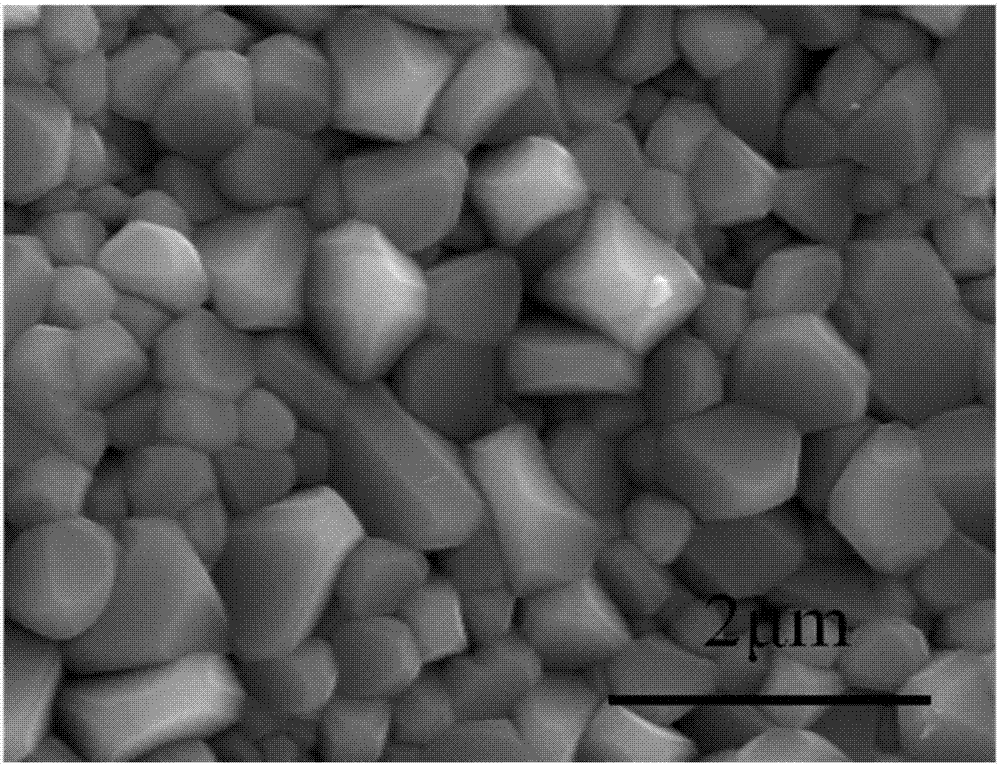

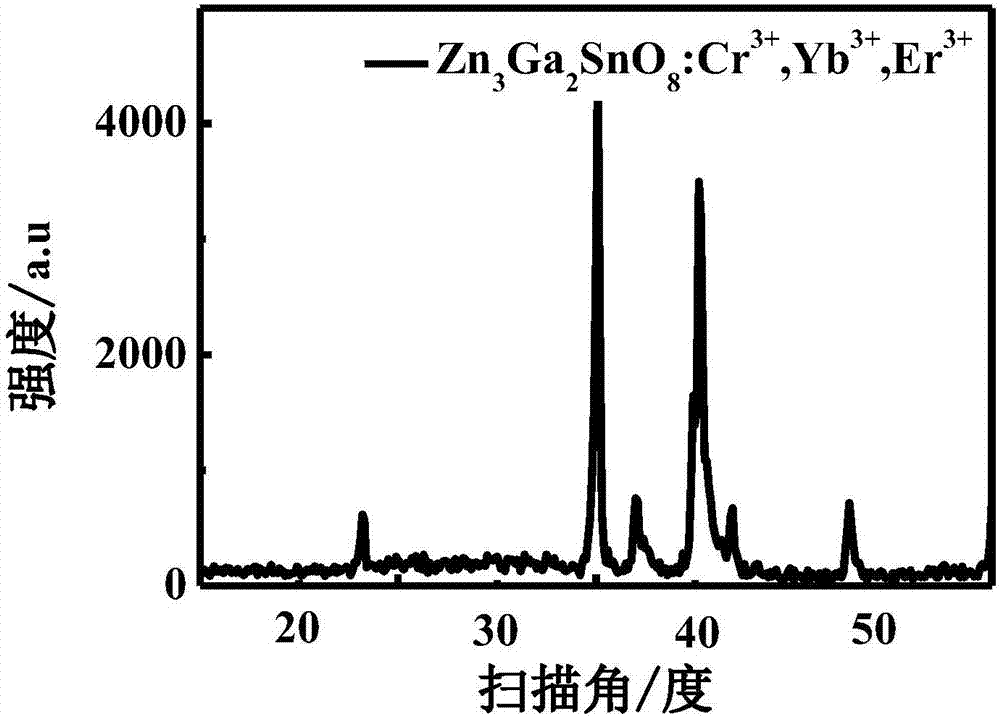

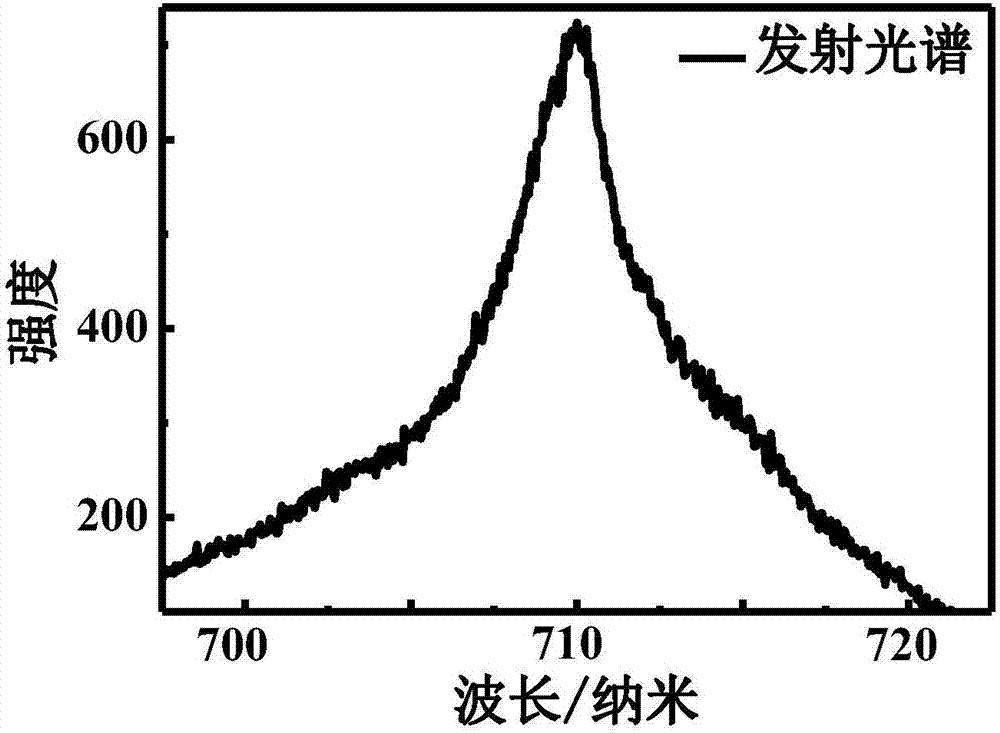

[0051] Use a scanning electron microscope (SEM, TDCLS-4800, Toshiba, Japan) to observe that the luminescent particles are micro-nano structures, such as figure 1 As shown, the luminescent particles with micro-nano structure are more convenient to be applied in more fields. XRD spectrum (D / MAX-2500, 10-60°, Rigaku Corporation) analyzes the characteristic pea...

Embodiment 2

[0054] Using the same method as in Example 1, the raw material powder was pre-fired in a muffle furnace at 900° C. for 2 hours. The pre-fired samples were ground again in a mortar and then sintered at 1600 °C for 3 h.

[0055] Observation with a scanning electron microscope to observe that the luminescent particles are micro-nano structures, such as Figure 5 As shown, the particle diameter is larger than that of the material prepared in Example 1, because the increase of the sintering temperature and the extension of the holding time make the grain growth more complete and the structure more compact. Test afterglow performance under the same conditions, the excitation afterglow intensity of this particle is stronger than embodiment 1, especially in the initial stage, as Image 6 .

Embodiment 3

[0057] Using the same method as in Example 1, the raw material powder was pre-fired in a muffle furnace at 900° C. for 2 hours. After the pre-fired samples were ground again in a mortar, a certain amount of samples were pressed into discs with a diameter of about 15 mm and a thickness of about 1 mm by using a powder tablet press.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com