Building coating with self-cleaning function and preparation method thereof

An architectural coating and self-cleaning technology, used in antifouling/underwater coatings, coatings, and biocide-containing paints. , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

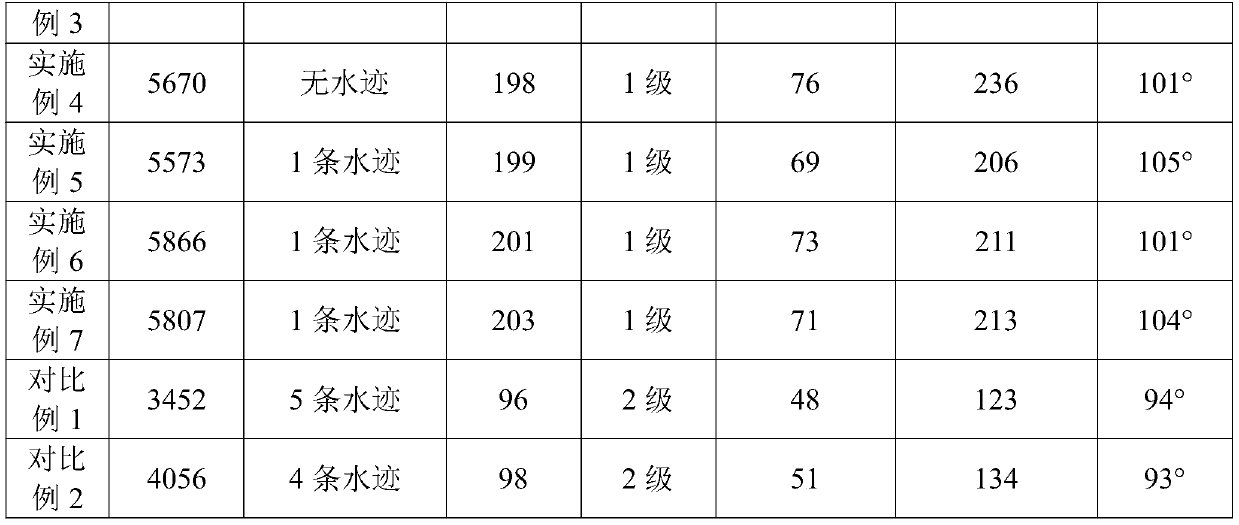

Examples

preparation example Construction

[0021] The preparation method of the building coating with self-cleaning function provided by the invention comprises:

[0022] S1. Mix the film-forming substance, filler, coupling agent and solvent to obtain the first mixture, wherein the filler includes hydrophobic white carbon black particles and micron-sized silica particles, and the film-forming substance is a hydrophobic resin, And the molecular chain of the resin contains hydroxyl groups.

[0023] Specifically, based on 1 part of the film-forming substance, the amount of the filler is 0.2-1.2 parts, the amount of the coupling agent is 0.01-0.02 parts, and the amount of the solvent is 20-30 parts.

[0024] Among them, the mass ratio of silica particles to silica particles is 10:1-1:1, preferably 6:1-1:1, and at the same time, considering that the particle size of fumed silica particles can reach 10nm- 20nm, the silica particles can be preferably fumed silica particles, so that the silica particles can be better and more...

Embodiment 1

[0042] Mix 0.1g of hydrophobic white carbon black, 0.6g of micron-sized silicon dioxide, 0.02g of KH550, 1g of 58% fluorine resin F100 and 20g of solvent, wherein the mass ratio of the solvent is 7:2:1 A mixture of xylene, butyl acetate and MIBK. First use the INVT stepless frequency conversion high-speed agitator to stir. When stirring, place the reaction tank under the impeller of the agitator, and adjust the height of the impeller up and down. It is advisable for the impeller to be in the middle of the mixture. Fix the reaction tank with left and right fixing clips to prevent displacement. position, and then stirred by a stirrer at a speed of 800r / min for 45min to obtain the first mixture.

[0043] The first mixture was added to the SHR high-speed mixer for the first grinding treatment, and the rotation speed was kept at 1000 r / min for 45 minutes to obtain the second mixture.

[0044] The second mixture is ground by QZM.1 conical grinder. When grinding, the motor speed is tr...

Embodiment 2

[0046] Mix 0.6g of hydrophobic white carbon black, 0.1g of micron-sized silica, 0.01g of KH550, 1g of 58% fluorine resin F100 and 20g of solvent, wherein the mass ratio of the solvent is 7:2:1 A mixture of xylene, butyl acetate and MIBK. First use the INVT stepless frequency conversion high-speed agitator to stir. When stirring, place the reaction tank under the impeller of the agitator, and adjust the height of the impeller up and down. It is advisable for the impeller to be in the middle of the mixture. Fix the reaction tank with left and right fixing clips to prevent displacement. position, and then stirred by a stirrer at a speed of 800r / min for 50min to obtain the first mixture.

[0047] The first mixture was added to the SHR high-speed mixer for the first grinding treatment, and the rotation speed was kept at 1000 r / min for 45 minutes to obtain the second mixture.

[0048] The second mixture is ground by QZM.1 conical grinder. When grinding, the motor speed is transmitt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com