Zirconia ceramic bone implantation prosthesis and preparation method thereof

A zirconia ceramic and bone implant technology, applied in prosthesis, medical science, tissue regeneration, etc., can solve the problems of unknown biocompatibility, affect the final performance, and the air is not easy to be discharged, so as to shorten the sintering time and improve the resistance. Hydrothermal aging properties, the effect of improving the absorption rate

Active Publication Date: 2018-12-28

北京安颂科技有限公司

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method has the following disadvantages: (1) the composition is complex, and the final bone implant prosthesis is ZrO 2 - ZrC composite ceramics, the biocompatibility of the composite ceramics with the human body is unknown; (2) Secondary molding, wherein the first molding is one-way pressure compression molding, the pressure is 20-100MPa, the molding process is likely to cause uneven green body and Form secondary particles with higher hardness, and the air of the secondary particles is not easy to be discharged during the secondary molding (molding pressure is 200-280MPa), which affects the final performance; (3) The powder making process is complex

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

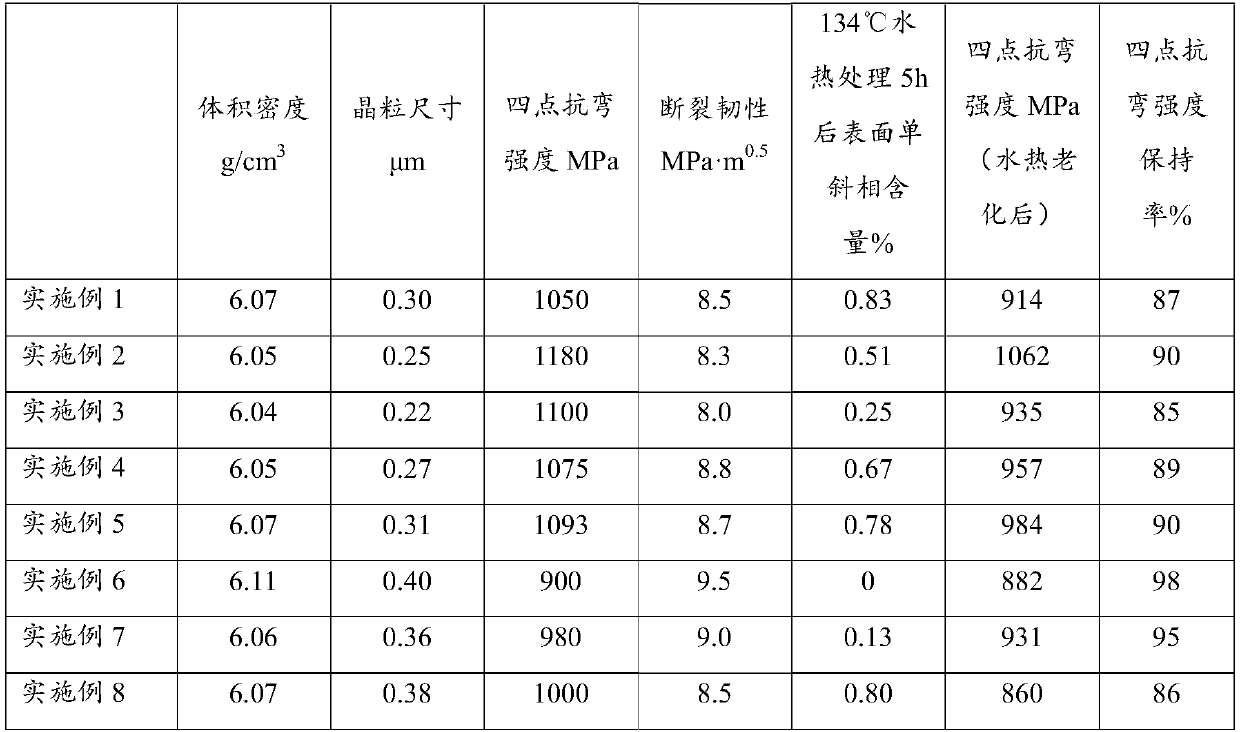

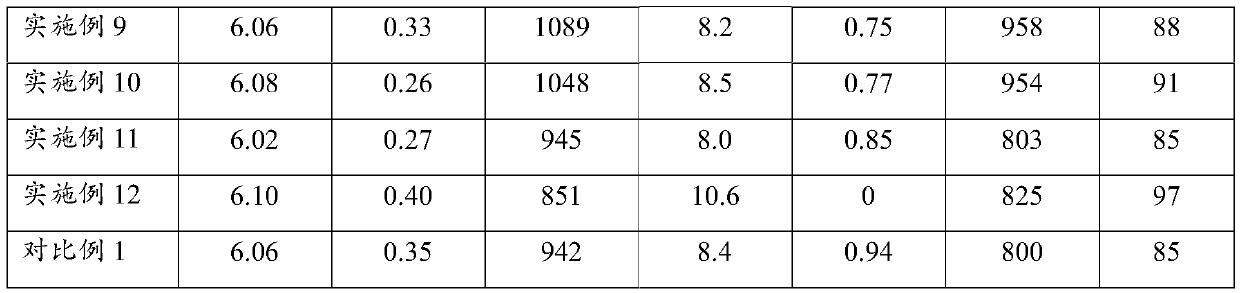

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a zirconia ceramic bone implantation prosthesis and a preparation method thereof. The preparation method comprises the following steps: mixing and grinding zirconia powder, a stabilizer A and silica sol to obtain slurry, wherein the stabilizer A is one or a mixture of two of yttrium oxide and ytterbium oxide by the weight of the zirconia powder as a standard; adding a solvent into the slurry, uniformly mixing, and carrying out spraying drying to obtain micro particles; putting the micro particles into a mold, and carrying out cold isostatic molding at 150-500MPa to obtain a raw blank; pre-sintering the raw blank at 700-1200 DEG C to obtain a biscuit; sintering the biscuit in a microwave sintering furnace at 900-1500 DEG C, and keeping warm for 0.2-2 hours to obtain azirconia ceramic; processing the zirconia ceramic to obtain the zirconia ceramic bone implantation prosthesis. According to the invention, by means of combination of Y / Yb and silica sol doping, pre-sintering and microwave sintering, the sizes of crystal granules, the density, the bending strength, the fracture toughness and the hydrothermal aging resistance of the zirconia ceramic bone implantation prosthesis are improved.

Description

technical field The invention relates to the field of ceramic materials, in particular to a zirconia ceramic bone implant prosthesis and a preparation method thereof. Background technique Zirconia (ZrO 2 ) is chemically inactive, has the characteristics of high melting point, high refractive index, low thermal expansion coefficient and excellent biocompatibility, and is widely used in the fields of refractory materials, structural ceramics, bioceramics and electronic functional ceramics. Zirconia has three crystal forms: monoclinic phase with a density of 5.65g / cm 3 , the stable temperature is lower than 1100℃; tetragonal phase, the density is 6.10g / cm 3 , the stable temperature range is 1100-2300 ° C; cubic phase, the density is 6.27g / cm 3 , and the stable temperature is higher than 2300°C. Therefore, at room temperature, zirconia exists in the form of monoclinic phase. During the sintering process of zirconia, monoclinic tetragonal phase transformation will occur, re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B35/48C04B35/622C04B35/626A61L27/10A61L27/50

CPCA61L27/10A61L27/50A61L2430/02C04B35/48C04B35/622C04B35/62605C04B2235/3225C04B2235/3418C04B2235/602C04B2235/6567C04B2235/77C04B2235/785C04B2235/96

Inventor 吴梦飞曹玉超李敏杰张云龙张纪锋梁涛

Owner 北京安颂科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com