Silicon nitride heating body and its pressureless lower temperature sintering producing method

A silicon nitride heating element, silicon nitride technology, applied in the direction of heating element materials, etc., can solve the problems of limited scale effect, high energy consumption, low production efficiency, etc., achieve product variety, expand application fields, chemical good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The silicon nitride heating element of the present invention is made through the following process steps:

[0020] Dry-press buried wire non-pressure low-temperature sintering process:

[0021] Raw material preparation: weighing according to the formula of silicon nitride 90%, magnesium oxide 2%, yttrium oxide 2%, aluminum oxide 5%, silicon oxide 1%, put into a ball mill jar and add ethanol for ball milling for 12 hours, then pour Put it into a container, dry it in an oven, and sieve it for later use.

[0022] Blank preparation: Process the metal mold according to the shape requirements of the heating element of 150mm×30mm×5mm, and press the mixed material powder processed by the above process into the blank, and place the heating wire on the blank according to the set requirements while pressing the blank inside, as attached figure 1 , attached figure 2 Shown in, press molding under the pressure of 20MPa.

[0023] Debinding process: Put the above-mentioned ceramic...

Embodiment 2

[0026] Rolled film screen printing pressureless low temperature sintering process:

[0027] Raw material preparation: silicon nitride 70%, magnesium oxide 10%, yttrium oxide 10%, aluminum oxide 5%, silicon oxide 5%. The formula was weighed, put into a ball mill jar and added ethanol for ball milling for 12 hours, then poured into a container, dried in an oven, and sieved for later use.

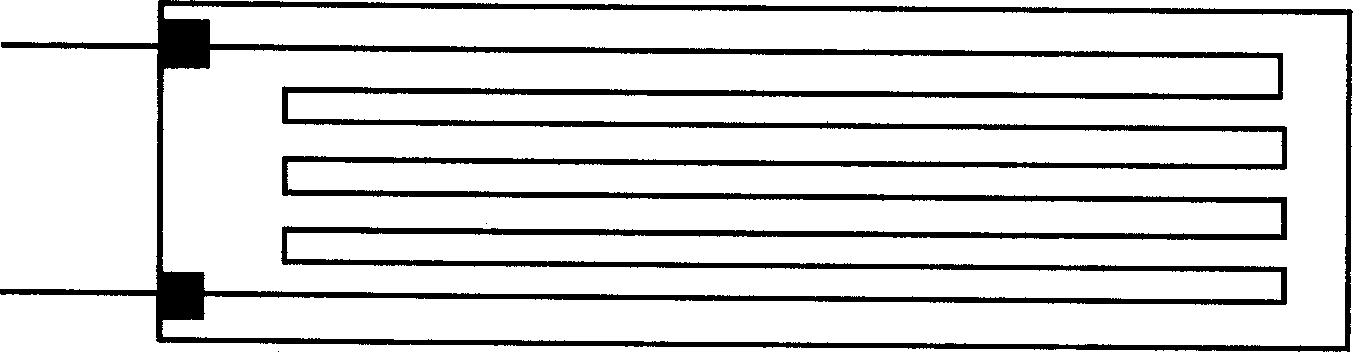

[0028] Plain embryo preparation: add binder to the mixed material powder treated by the above process, the binder is mainly composed of polyvinyl butyl ester, phthalate dibutyl ester, n-butanol, trichloroethylene, tetrachloroethylene , ethanol, nitroglycerin and other binders for roll forming, and then cut into the required size and shape of the molded sheet substrate, including the upper ceramic substrate and the lower ceramic substrate, such as image 3 and Figure 4 shown. The lower ceramic substrate is screen-printed with electrothermal film slurry, and the upper and lower ceramic subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com