High-temperature-resistant near-infrared absorption high-entropy ceramic and preparation method thereof

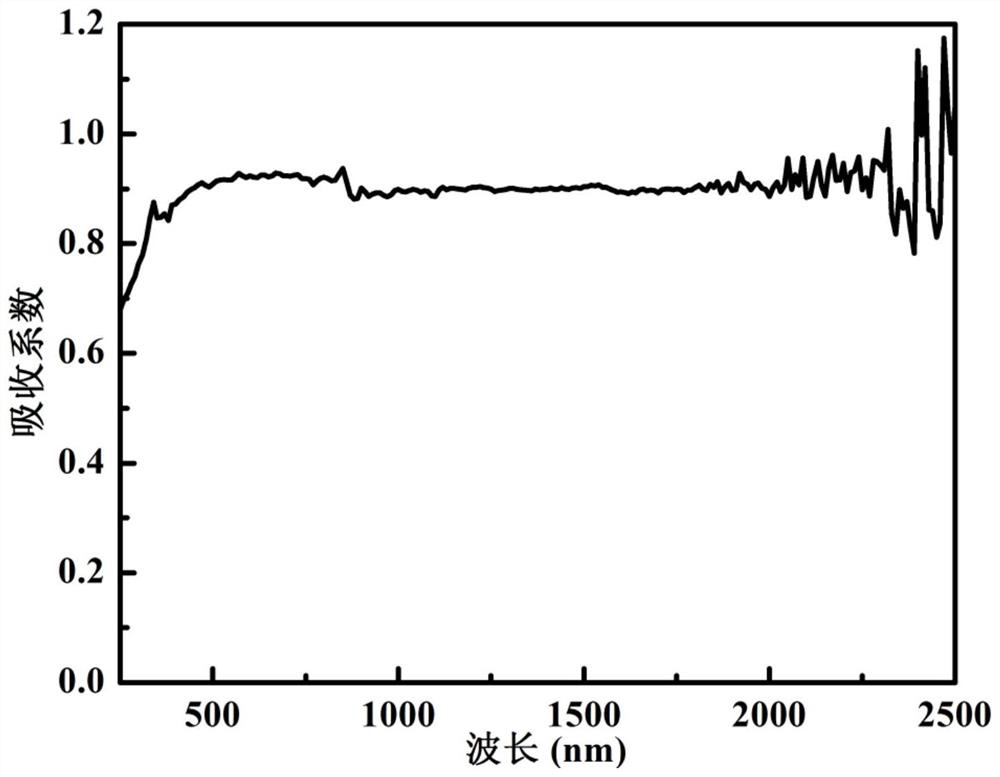

A near-infrared, high-temperature-resistant technology, applied in the fields of high near-infrared absorption, high-entropy ceramics and their preparation, high-purity, high relative density, can solve problems such as infrared emissivity gap, achieve good relative density, high near-infrared absorption, Good effect of particle size adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042]The present invention provides a method for preparing high-temperature resistant near-infrared absorption high-entropy ceramics, which is used to prepare the above-mentioned high-temperature resistant near-infrared absorption high-entropy ceramics, including the following steps:

[0043](1) Mix the raw material powder of high-entropy ceramics with absolute ethanol in a ball mill tank to obtain a uniformly mixed slurry;

[0044](2) The obtained slurry is dried to obtain a mixed powder, and the dried powder is placed in a high-temperature furnace for calcination to obtain a ceramic powder;

[0045](3) The obtained ceramic powder is put into a spark plasma sintering furnace for high temperature sintering, the atmosphere is vacuum, the sintering temperature is not lower than the sintering temperature in step (2), the sintering time is not longer than 30 min, and the sintering pressure is controlled at 20-40 MPa to obtain High-entropy ceramic block.

[0046]In a preferred embodiment, in step (...

Embodiment 1

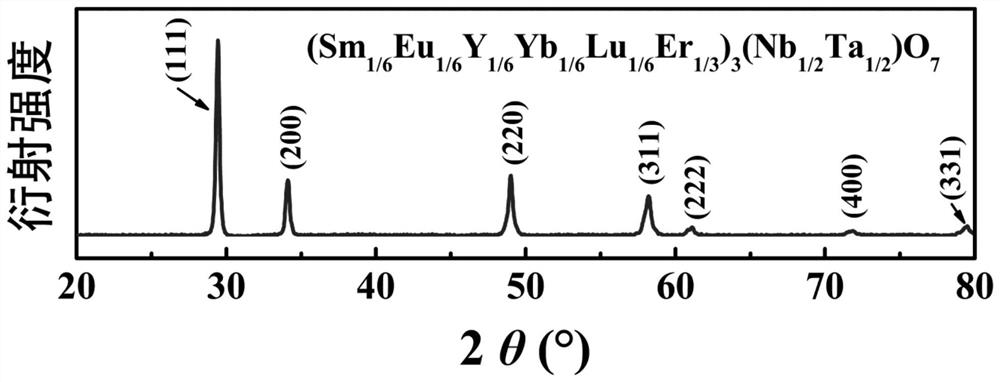

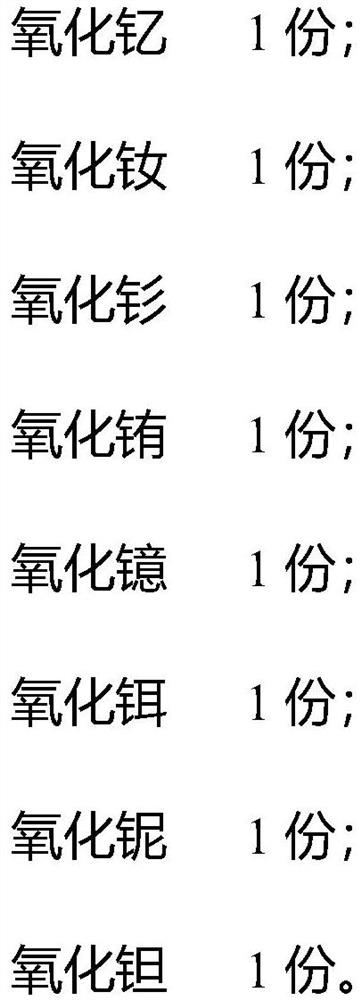

[0054]Will Y2O3, Nd2O3, Sm2O3, Eu2O3, Yb2O3, Er2O3, Nb2O5And Ta2O5Press Y2O3: Nd2O3: Sm2O3: Eu2O3: Yb2O3: Er2O3: Nb2O5: Ta2O5=1:1:1:1:1:1:1:1:1:1, and mix in a ball mill tank. The mixing time is 6 hours. The mixing medium is anhydrous ethyl alcohol to obtain a slurry; The slurry is filtered and dried to obtain a mixture powder. The dried powder is put into a high-temperature furnace for calcination. The calcination temperature is 1450°C and the calcination time is 2 hours to obtain high entropy (Y1 / 6Nd1 / 6Sm1 / 6Eu1 / 6Yb1 / 6Er1 / 6)3(Nb1 / 2Ta1 / 2)O7Ceramic powder. Put the high-entropy ceramic powder into a spark plasma sintering furnace for high temperature sintering. The atmosphere is vacuum, the sintering temperature is 1650℃, the sintering time is 4min, the sintering pressure is controlled to 40MPa, the vacuum degree is 8Pa, and the heating rate is 100℃ / min, the obtained high temperature resistant near-infrared absorption high-entropy ceramic has a purity of 100 wt%, a relative density o...

Embodiment 2

[0056]Will Y2O3, Nd2O3, Sm2O3, Eu2O3, Yb2O3, Er2O3, Nb2O5And Ta2O5Press Y2O3: Nd2O3: Sm2O3: Eu2O3: Yb2O3: Er2O3: Nb2O5: Ta2O5=1:1:1:1:1:1:1:1:1:1, and mix in a ball mill tank. The mixing time is 6 hours. The mixing medium is anhydrous ethyl alcohol to obtain a slurry; The slurry is filtered and dried to obtain a mixture powder. The dried powder is put into a high-temperature furnace for calcination. The calcination temperature is 1450°C and the calcination time is 2 hours to obtain high entropy (Y1 / 6Nd1 / 6Sm1 / 6Eu1 / 6Yb1 / 6Er1 / 6)3(Nb1 / 2Ta1 / 2)O7Ceramic powder. Put the high-entropy ceramic powder into a spark plasma sintering furnace for high temperature sintering. The atmosphere is vacuum, the sintering temperature is 1600℃, the sintering time is 10min, the sintering pressure is controlled to 40MPa, the vacuum degree is 8Pa, and the heating rate is 120℃ / min, the obtained high temperature resistant near-infrared absorption high-entropy ceramic has a purity of 100% by weight, a relative d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com