Pure-phase rare-earth zirconate nanometer material and preparation method thereof

A nano-material and zirconate technology, which is applied in the field of pure-phase rare earth zirconate nano-thermal barrier coating materials and its preparation, can solve the problem of incomplete high-temperature calcination phase transition reaction, unstable high-temperature phase structure, and affecting the use of coatings Performance and other issues, to improve the effect of heat insulation, high-temperature phase structure stability, and improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a preparation method of a pure phase rare earth zirconate nano material.

[0036] The method for preparing pure phase rare earth zirconate nanomaterials provided by the present invention includes the following step: adding gadolinium oxide, yttrium oxide, ytterbium oxide, cerium nitrate, and zirconium oxychloride to 0.1:0.3:0.1:x: 1-x) is mixed to obtain a mixture, and dilute nitric acid is added to the mixture to dissolve to obtain a mixed rare earth nitrate solution, wherein said 00.2 Yb 0.2 Y 0.6 ) 2 (Zr 1-x Ce x ) 2 O 7 Slurry; the slurry is cleaned, granulated, and densified to prepare the pure phase rare earth zirconate nanomaterial.

[0037] The invention adopts a high-pressure hydrothermal synthesis method to prepare a five-element thermal barrier coating material. The invention prepares the five-element thermal barrier coating material through the method of acid dissolution, alkalization and high-pressure hydrothermal synthesis. Compared with ...

Embodiment 1

[0047] (Gd 0.2 Yb 0.2 Y 0.6 ) 2 (Zr 0.9 Ge 0.1 ) 2 O 7 Preparation of nano aggregate powder.

[0048] (1) Gd 2 O 3 , Y 2 O 3 , Yb 2 O 3 , Ce(NO 3 ) 3 , ZrOCl 2 Mix according to the molar ratio of 0.1:0.3:0.1:0.1:0.9, add the mixed powder gradually into a beaker containing dilute nitric acid, and control the temperature of the solution to 70°C to form a mixed rare earth nitrate solution.

[0049] (2) Add deionized water to the mixed solution obtained in step (1) to control the concentration of rare earth nitrate to 0.1 mol·L -1 . Drop the solution of this concentration into a glass reactor filled with dilute nitric acid solution, control the temperature at 50℃, pH=10, and stirring speed at 100r·min -1 , The reaction to obtain the hydroxide colloidal solution precursor.

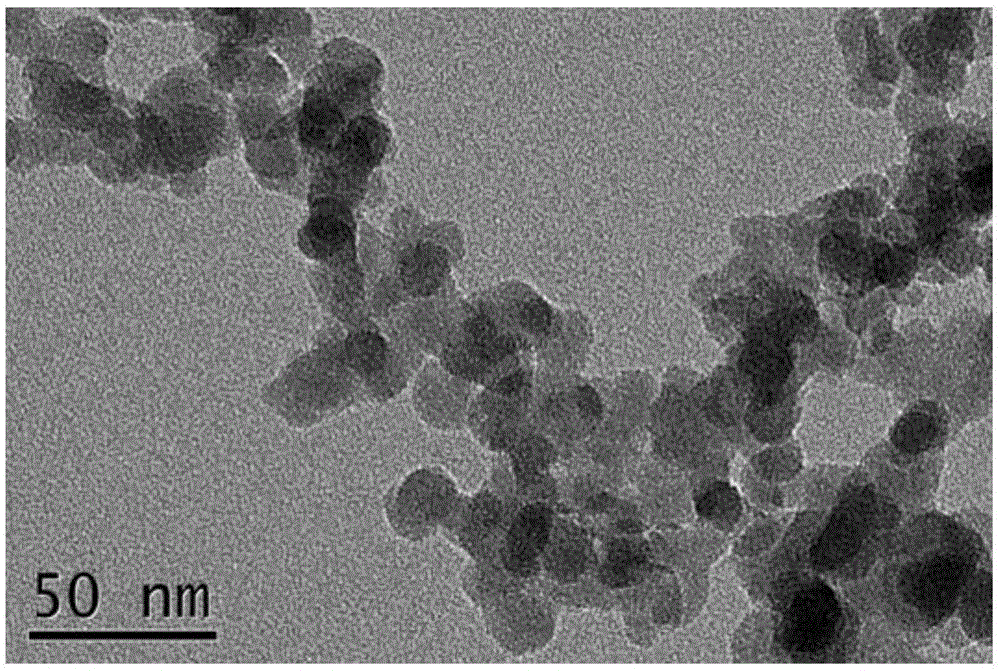

[0050] (3) Add deionized water to the colloidal solution obtained in step (2), and control the water-solid mass ratio of the precursor to 15:1. Put the colloidal solution into the high-pressure hydrothermal synthesis...

Embodiment 2

[0058] (Gd 0.2 Yb 0.2 Y 0.6 ) 2 (Zr 0.86 Ge 0.14 ) 2 O 7 Preparation of nano aggregate powder.

[0059] The difference between this embodiment mode and embodiment 1 mode is Gd 2 O 3 , Y 2 O 3 , Yb 2 O 3 , Ce(NO 3 ) 3 , ZrOCl 2 The molar ratio is 0.1:0.3:0.1:0.14:0.86. The other steps are the same as in Example 1.

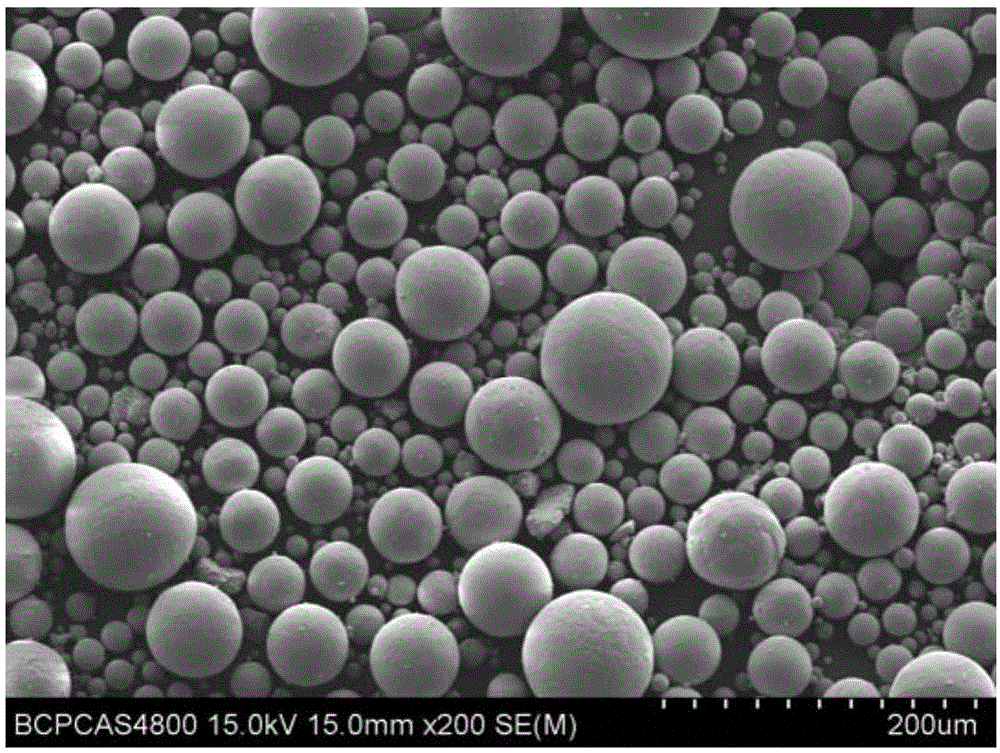

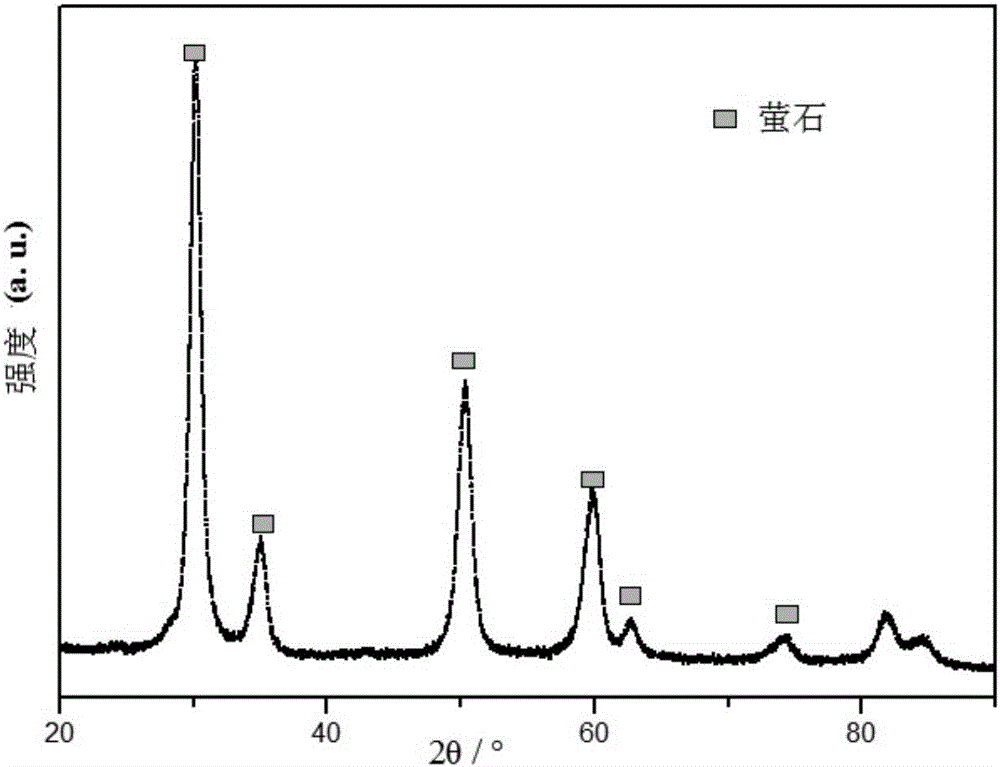

[0060] Morphology and phase analysis:

[0061] The first-level particle electron microscope test picture, the electron microscope test picture of the agglomerated powder, and the XRD pattern of the agglomerate powder prepared in this example are the same as those in Example 1.

[0062] Physical performance analysis:

[0063] The test method is the same as in Example 1, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com