Electrical bearing ground device

A coaxial, electric charge technology used in connection with grounding devices, bearing assembly, electromechanical devices, etc., to solve problems such as melting, dent formation, heating of conductive materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

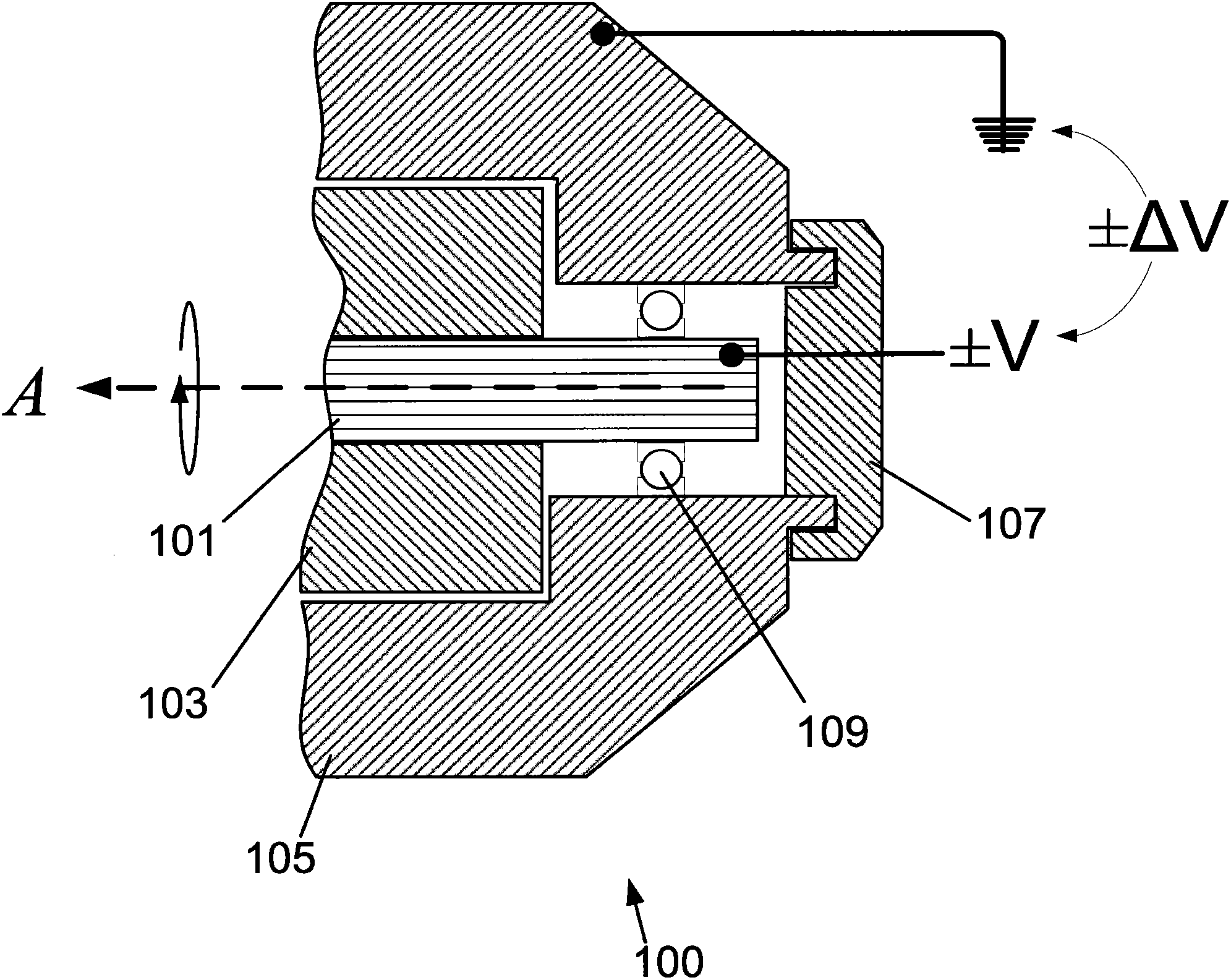

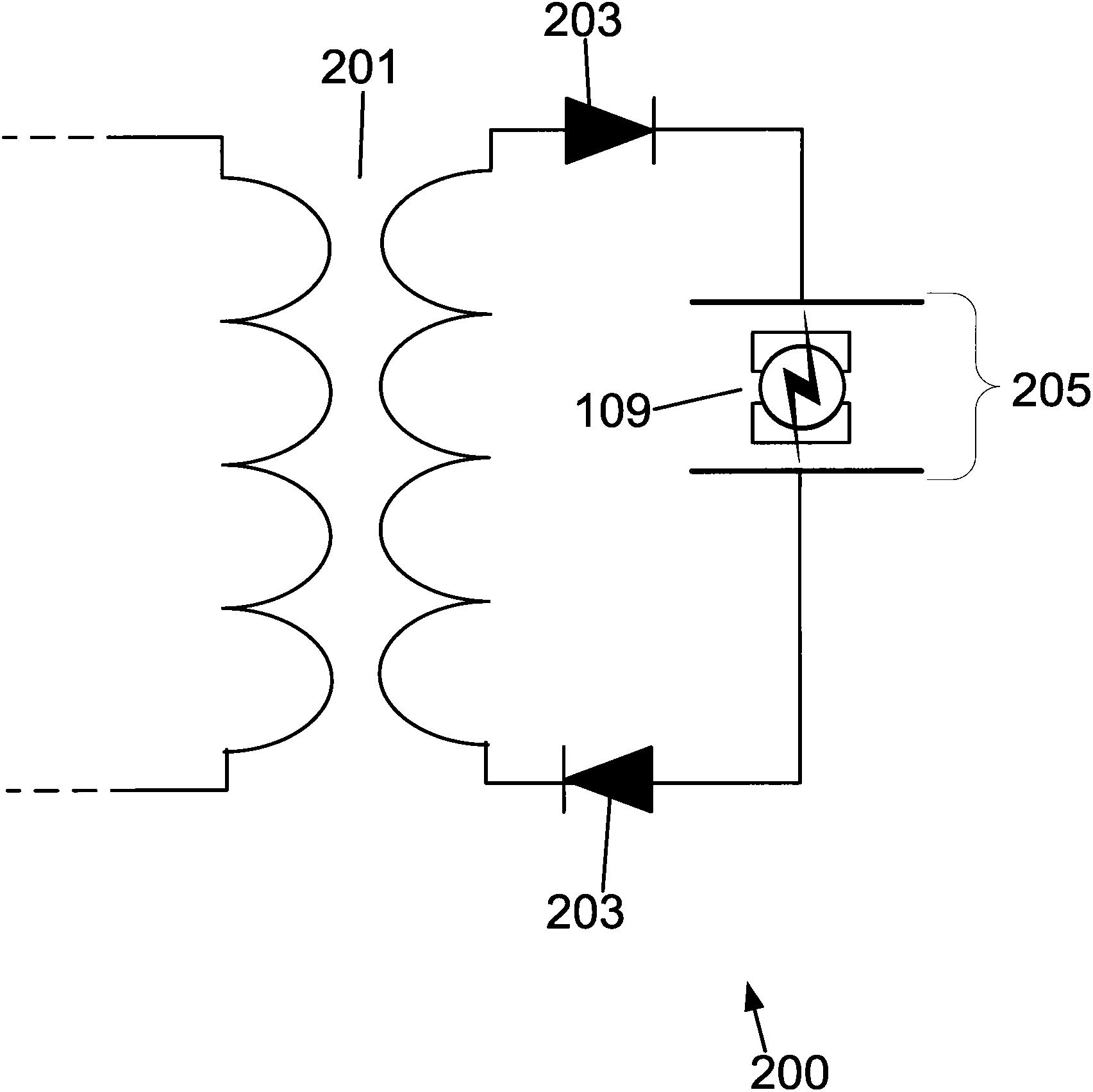

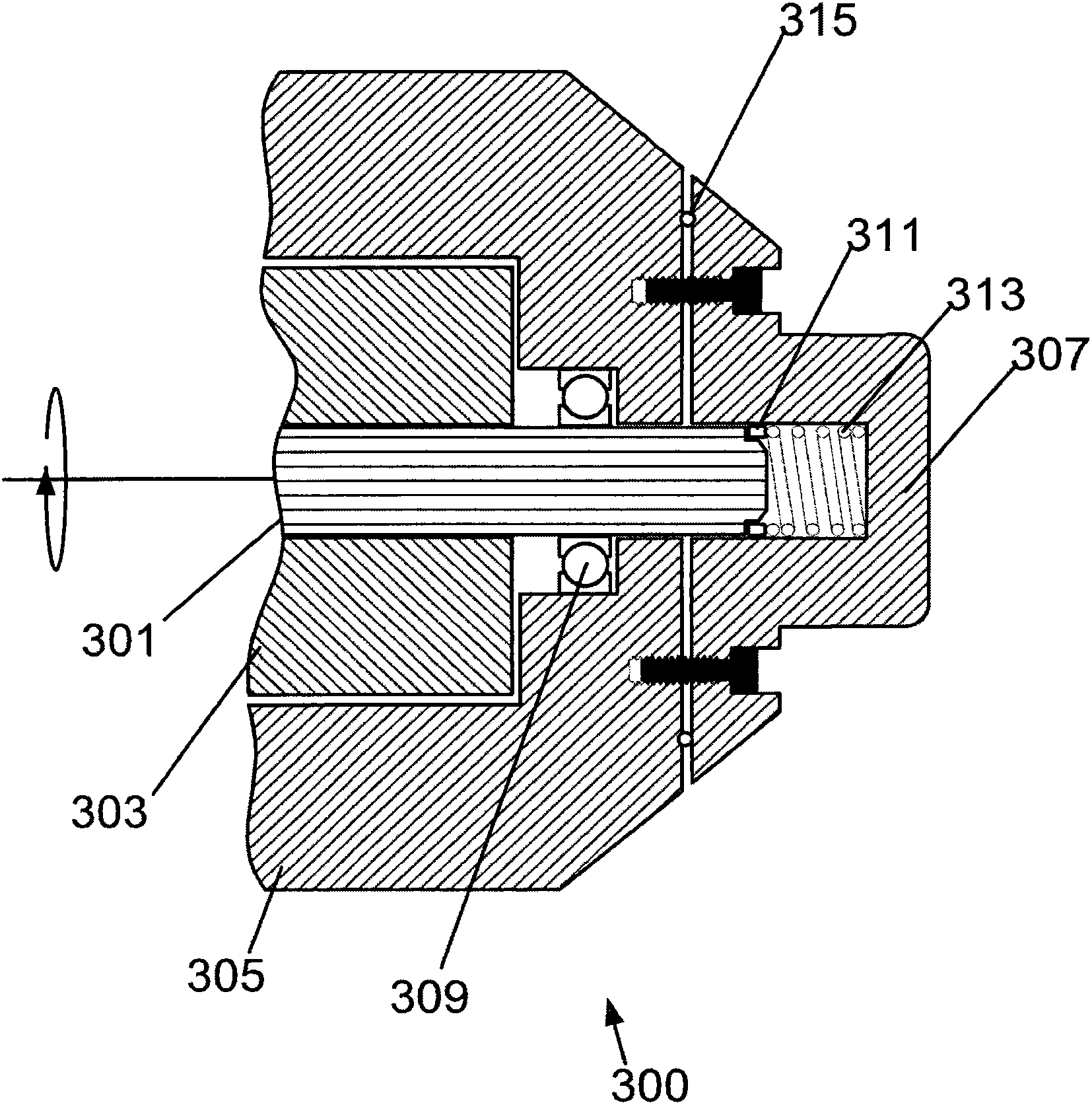

[0016] The present invention is concerned with electrical energy usage and generation, and the principles of the invention allow for an efficient and economical solution to charging / discharging bearings in a form that is easy to install and easy to maintain. The systems and devices of the present invention can be used in a wide range of applications including locomotive, industrial and construction energy use and generation applications, etc., without substantial supply or retrofit costs. Specific, non-limiting examples include industrial and consumer grade generators, such as stand-alone generators and generators that are part of larger machines or structures.

[0017] Furthermore, while the principles of the present invention are described by way of example with respect to conductive bearing arrangements, it will be appreciated that the principles of the present invention can also be used in other environments, including those using more expensive ceramic or other insulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com