Multi-component alloy as-cast bainite gray cast iron cylinder jacket

A multi-element alloy and bainite technology, which is applied to cylinders, cylinder heads, engine components, etc., can solve the problems of low tensile strength, poor wear resistance, and high production cost of cylinder liners, so as to reduce production costs and improve wear resistance , cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

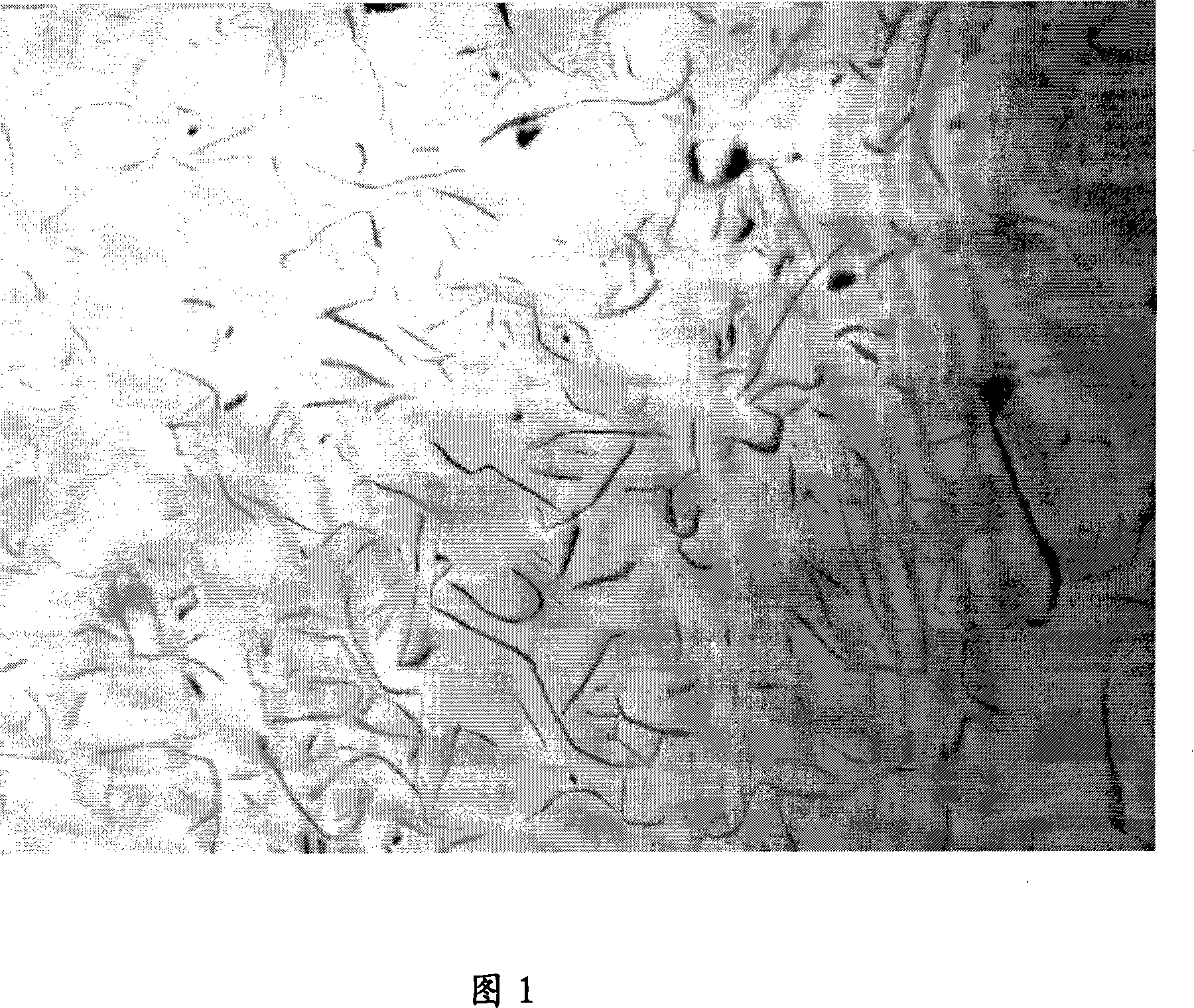

Image

Examples

Embodiment 1

[0027] According to the weight percentage of each chemical composition, it is carbon 3.2%, silicon 2.4%, manganese 0.8%, phosphorus 0.055%, sulfur 0.05%, copper 0.8%, molybdenum 0.3%, chromium 0.2%, niobium 0.07%, vanadium 0.08%, titanium 0.07%, the balance is Fe for batching. The molten iron is smelted in a frequency conversion induction furnace, and 0.6% silicon-barium-calcium inoculant is added to the molten iron before it is released from the furnace. The molten iron is controlled at a temperature of 1530°C and the molten iron is released from the furnace; the conventional process of centrifugal casting of metal mold wet paint is used to produce cylinder liner castings. Control the casting temperature at 900°C, and then quench and cool for 90s to reduce the casting temperature to 460°C. Send the castings into the incubator for slow cooling, keep warm for 90 minutes and then leave the box for air cooling. Then the casting was tempered at 450°C for 2 hours to obtain a multi...

Embodiment 2

[0029] According to the weight percentage content of each chemical composition, it is carbon 3.1, silicon 2.5, manganese 0.7, phosphorus 0.06, sulfur 0.04, copper 0.9, molybdenum 0.25, chromium 0.25, niobium 0.1, vanadium 0.1, titanium 0.08, and the balance is Fe for batching. The molten iron is smelted in a frequency conversion induction furnace, and 0.5% silicon strontium inoculant is added to the molten iron before it is released from the furnace. The molten iron is controlled at a temperature of 1520°C and the molten iron is released from the furnace. Cylinder liner castings are produced under the conventional process conditions of centrifugal casting of metal mold wet paint. The casting temperature is 880°C, and then quenched and cooled for 60s to reduce the casting temperature to 490°C; the castings are sent to an incubator for slow cooling, kept for 90 minutes, and left for air cooling. Then the casting was tempered at 440°C for 2 hours to obtain a multi-component alloye...

Embodiment 3

[0031] According to the weight percentage of each chemical composition, it is carbon 3.3, silicon 2.2, manganese 0.7, phosphorus 0.07, sulfur 0.08, copper 0.7, molybdenum 0.4, chromium 0.15, niobium 0.08, vanadium 0.08, titanium 0.07, and the balance is Fe for batching. The molten iron is smelted in a frequency conversion induction furnace, and 0.7% silicon barium inoculant is added to the molten iron before it is released from the furnace. The molten iron is controlled at a temperature of 1550°C and the molten iron is released from the furnace. Cylinder liner castings are produced under the conventional process conditions of centrifugal casting with metal mold wet coating. Control the casting temperature at 860°C, then quench and cool for 120s to lower the casting temperature to 420°C; put the castings into an incubator for slow cooling, keep them warm for 90 minutes, and leave the box for air cooling. Then the casting was tempered at 450°C for 2 hours to obtain a multi-compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com