Method for preparing austenitic-bainitic high- strength alloy gray iron

A technology of high-strength alloy and austenite is applied in the field of preparation of austenitic alloy gray iron, which can solve the problems of low strength, low hardness and poor toughness of gray iron, reduce the fluidity of molten iron and achieve stable performance. , the effect of dense tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

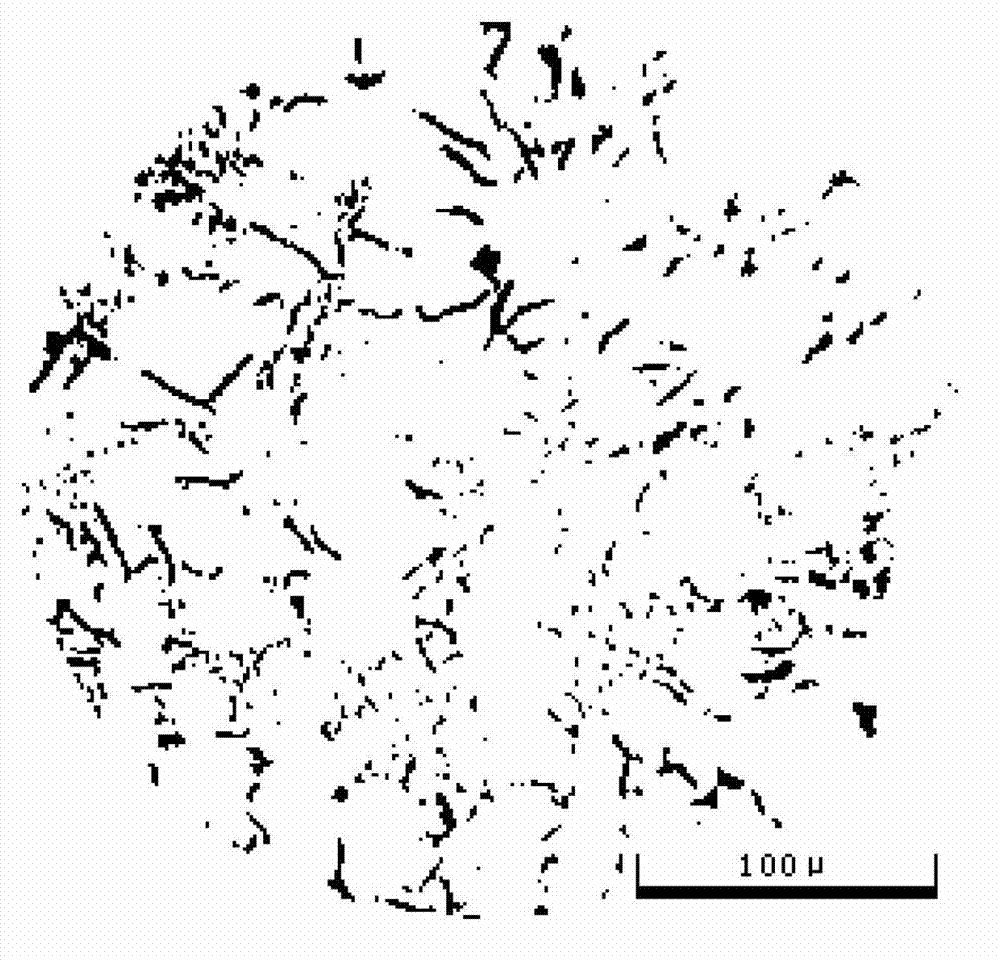

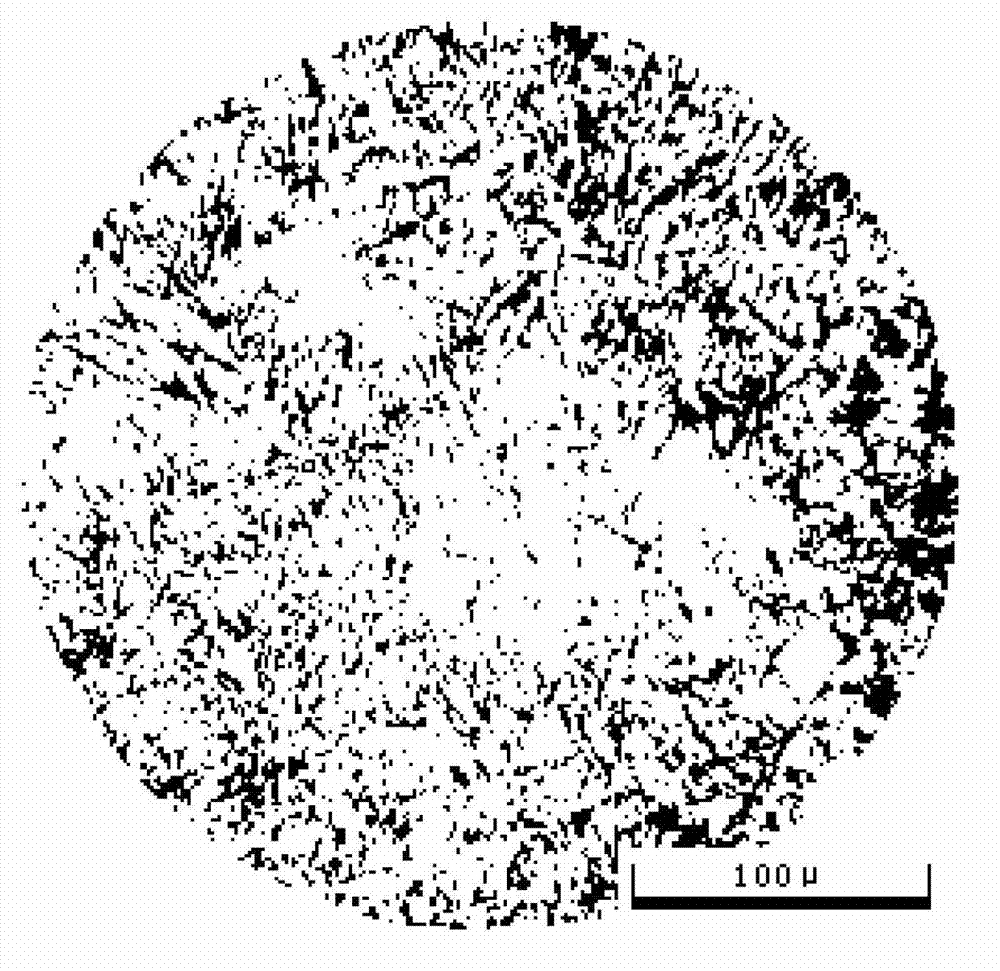

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: the preparation method of a kind of austeric high-strength alloy gray iron of this embodiment is carried out according to the following steps:

[0015] 1. According to the mass parts of Q10 pig iron, ductile iron return charge and steel scrap, respectively 60~70, 10~20 and 10~20, weigh Q10 pig iron, ductile iron return charge and scrap steel, and then weigh the ferromolybdenum mass and Q10 pig iron , The ratio of the total mass of ductile iron recycled materials to scrap steel is (1.5~1.8): 100, and the ratio of the total mass of electrolytic copper to Q10 pig iron, ductile iron recycled materials and scrap steel is (2~2.2): 100, according to The ratio of the mass of silicon-barium inoculant to the total mass of Q10 pig iron, nodular iron return charge and steel scrap is (0.9~1.1): 100, according to CaO-Al 2 o 3 The ratio of the quality of the base molten steel purifying agent to the total mass of Q10 pig iron, ductile iron return materials and...

specific Embodiment approach 2

[0020] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the components contained in the steel scrap in step 1 and the mass fractions of each component are: C: 0.15%~0.25%, S: 0.012%~0.016%, P: 0.014%~0.034%, Mn: 0.10%~0.30%, Si: 0.20%~0.40%, other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the mass fractions of Q10 pig iron, nodular iron return charge and steel scrap in step one are 60, 20 and 20 respectively, other steps and parameters and specific implementation Method 1 or 2 are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com