Method for producing castings by utilizing waste scrap iron and waste steel

A technology of scrap iron scraps and iron scraps, which is applied in the field of using scrap iron scraps and scrap steel to produce castings, can solve the problems of chemical composition, metallographic structure and mechanical properties, weaken the magnetic field of intermediate frequency furnaces, and high pig iron prices. Melting time, reduce production cost, enhance the effect of magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

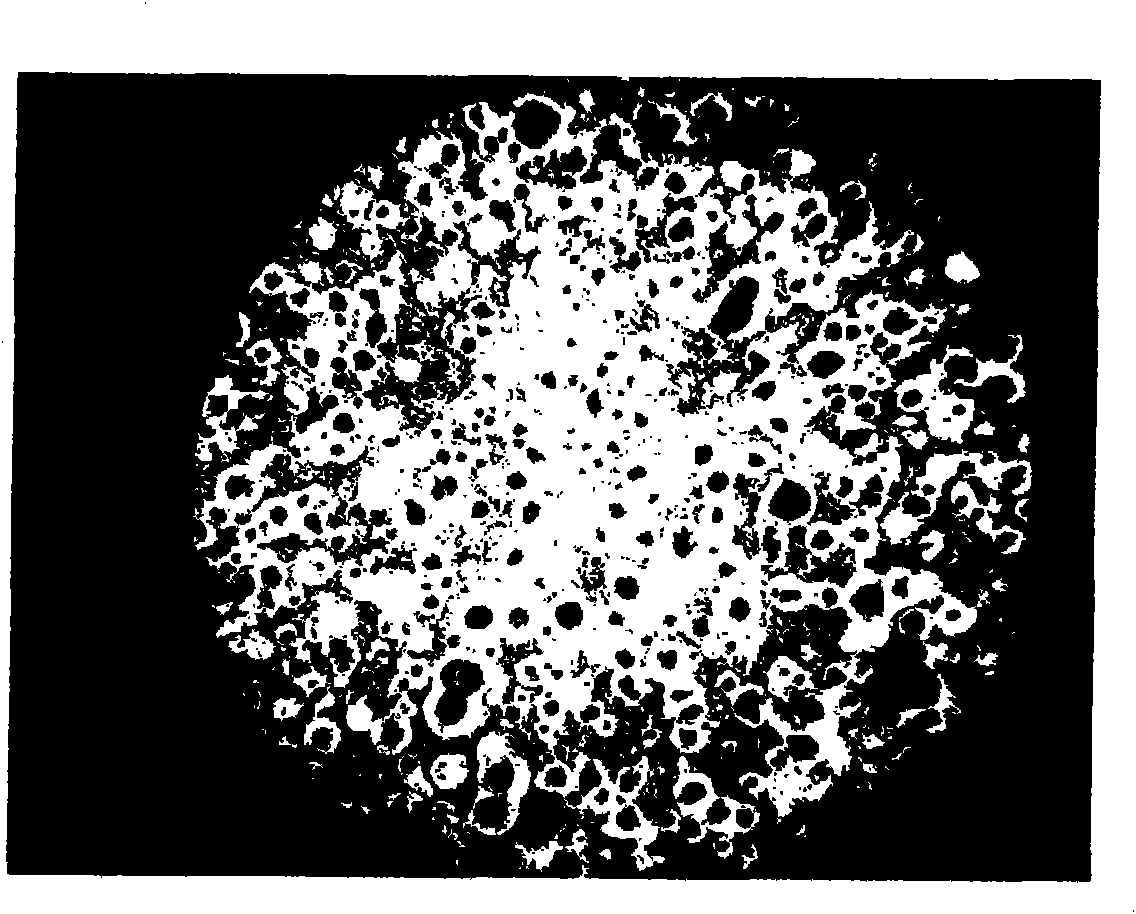

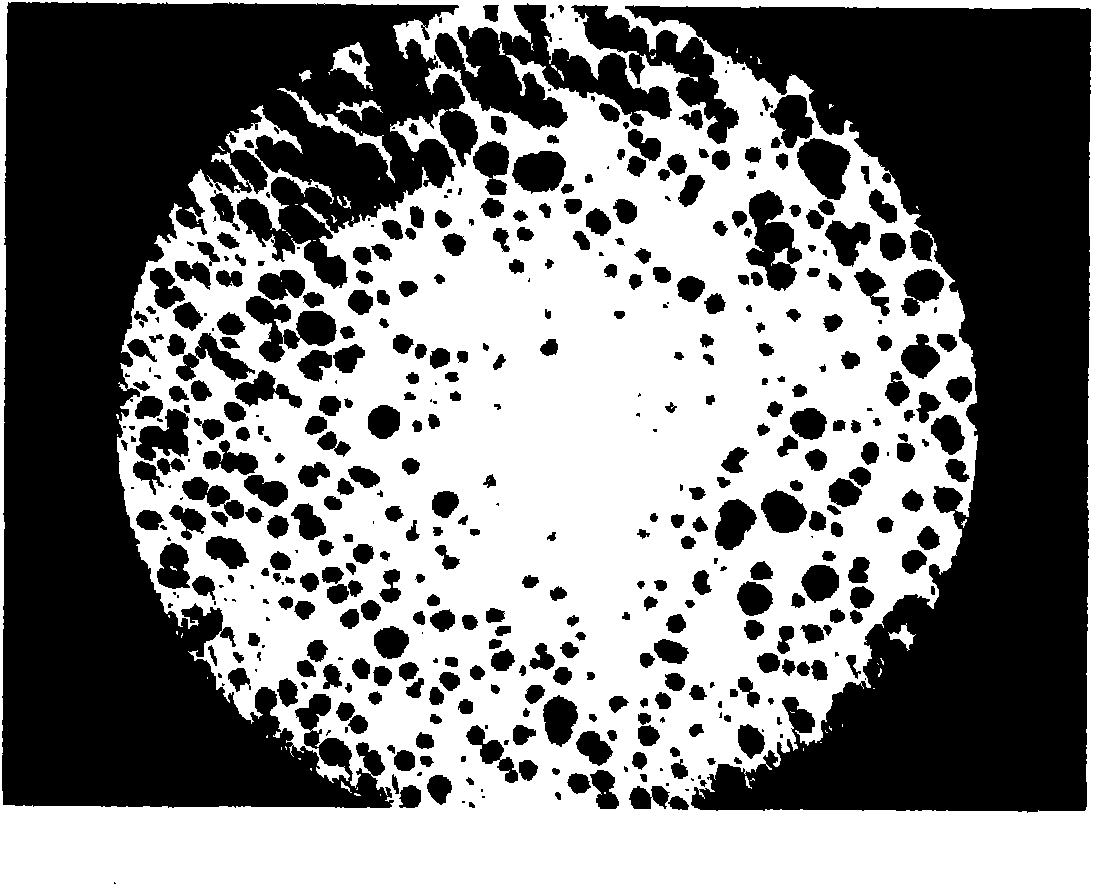

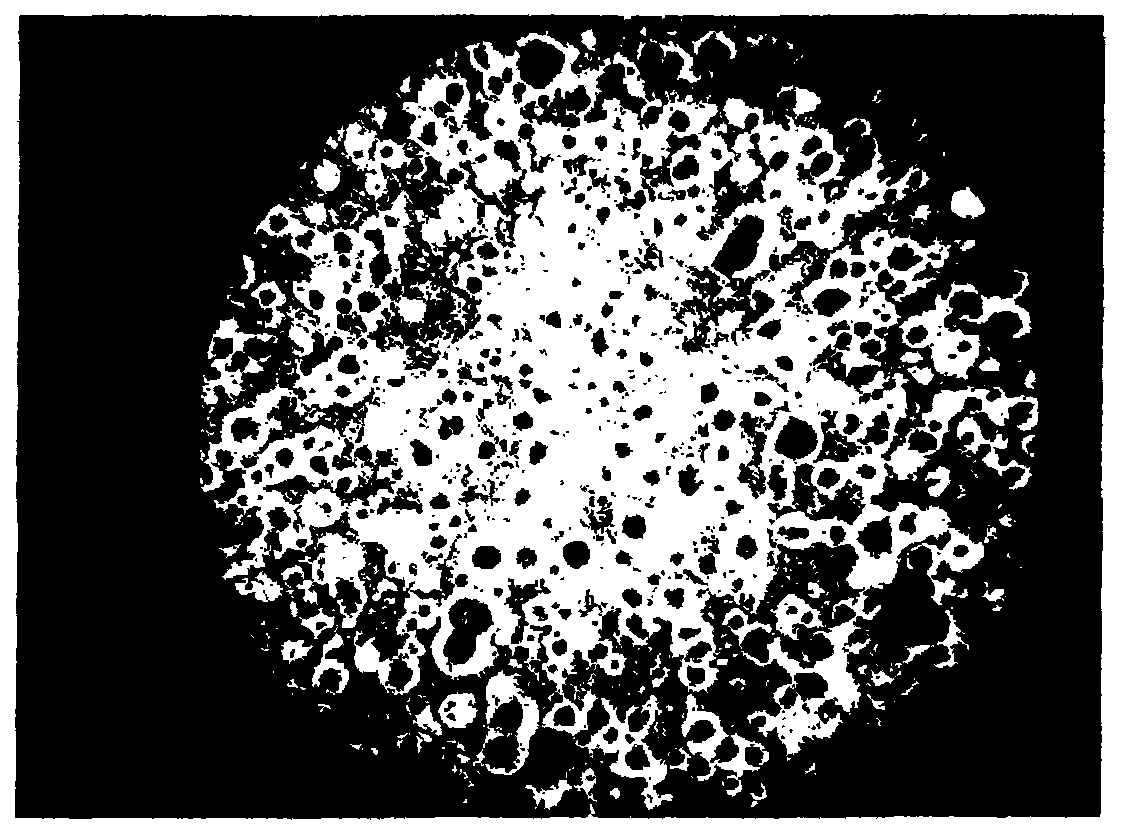

Image

Examples

Embodiment 1

[0036] According to the mass percentage, take 25% of the returned charge, 55% of the iron filings with qualified chemical composition (in line with the raw material purchase standard) and 20% of scrap steel, the sum of the mass of each component taken and the mass of the charge that the intermediate frequency furnace can accommodate Equal; lay a layer of iron filings on the bottom of the intermediate frequency furnace, the quality of the laid iron filings is 5% of the above-mentioned iron filings, and then add C with a specification of 1 to 3mm on the laid iron filings. -2 furnace bottom carburizer, the quality of the C-2 furnace bottom carburizer is 0.5% of the sum of the mass of the above-mentioned components; add a part of the recovered charge into the intermediate frequency furnace with iron filings, The quality of this part of the returned charge is 25% of the mass of the retrieved charge, and then, add a part of the iron filings taken to fill the gap between the returned ...

Embodiment 2

[0038] According to the mass percentage, take 35% of the returned charge, 35% of the iron filings with qualified chemical composition (in line with the raw material purchase standard) and 30% of scrap steel, the sum of the mass of each component taken and the mass of the charge that the intermediate frequency furnace can accommodate Equal; lay a layer of iron filings on the bottom of the intermediate frequency furnace, the quality of the laid iron filings is 10% of the above-mentioned iron filings, and then add C with a specification of 1 to 3mm on the laid iron filings. -2 Furnace bottom recarburizer, the mass of the furnace bottom recarburizer is 1% of the sum of the mass of the above-mentioned components; add part of the retrieved furnace charge into the intermediate frequency furnace with iron filings, and this part is returned to the furnace charge The quality of the reclaimed charge is 35% of the mass of the reclaimed charge, and then a part of the iron filings is added t...

Embodiment 3

[0040] According to the mass percentage, take 30% of the returned charge, 45% of the iron filings with qualified chemical composition (in line with the raw material purchase standard) and 25% of scrap steel, the sum of the mass of each component taken and the mass of the charge that the intermediate frequency furnace can accommodate Equal; lay a layer of iron filings on the bottom of the intermediate frequency furnace, the quality of the laid iron filings is 7.5% of the quality of the above-mentioned iron filings, and then add C with a specification of 1 to 3mm on the laid iron filings. -2 Furnace bottom recarburizer, the quality of the furnace bottom recarburizer is 0.75% of the mass sum of the above-mentioned components; add a part of the retrieved charge into the intermediate frequency furnace with iron filings, and this part returns The quality of the charge is 30% of the mass of the reclaimed charge, and then, add a part of the scrap iron to fill the gap between the charge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com