micro speaker

A technology of micro-speaker and voice coil, applied in the direction of sensors, electrical components, etc., can solve the problems of shortening the service life of micro-speakers, reducing the reliability of micro-speakers, poor electrical connection of micro-speakers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

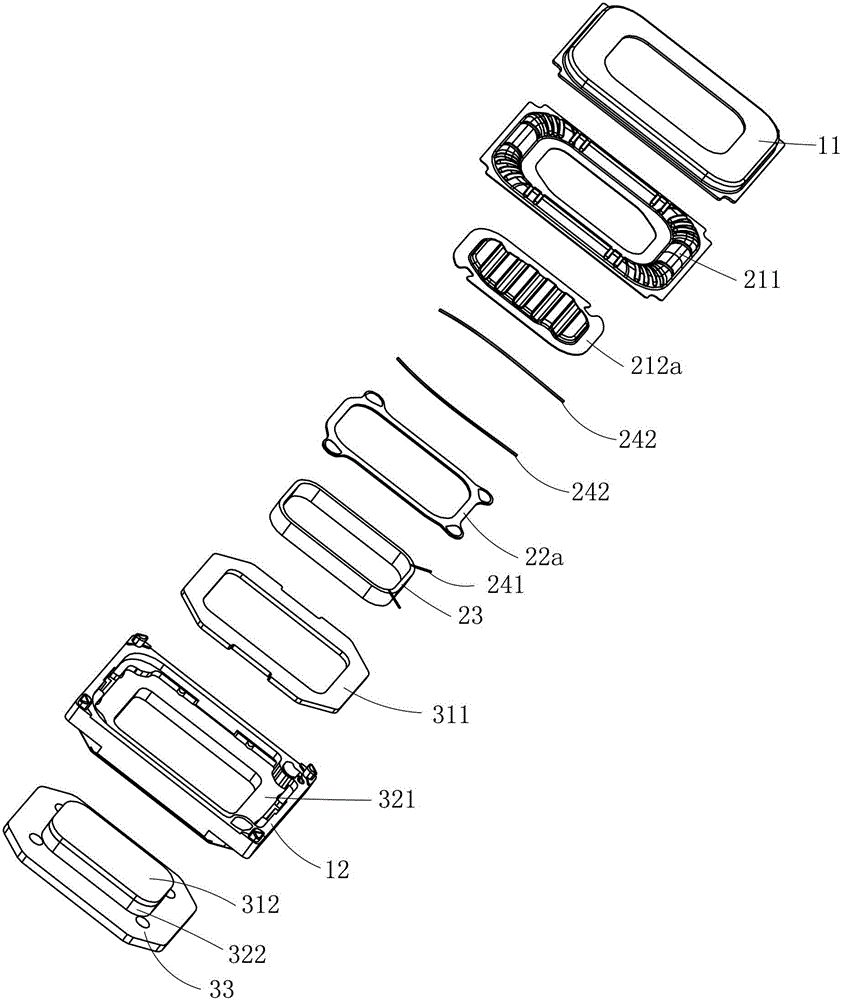

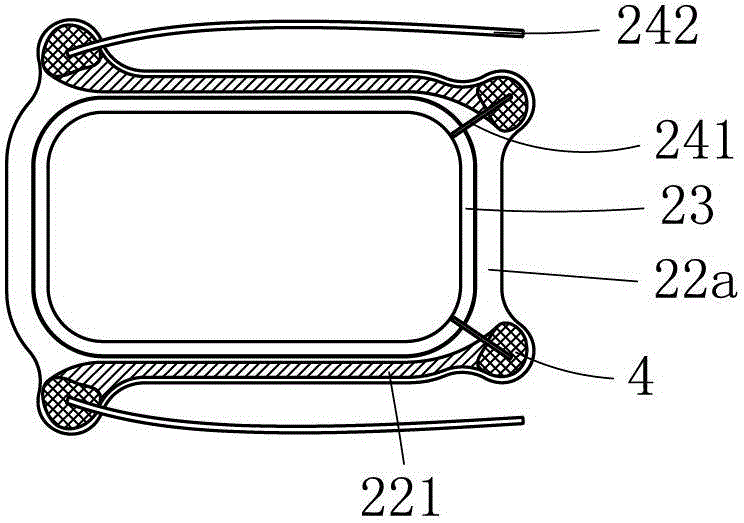

[0030] Such as figure 1 , figure 2 and image 3 Commonly shown, a micro-speaker includes a housing 12 and a front cover 11 that is buckled together with the housing 12. The voice coil outlet terminal 5 is provided on the housing 12, and the cavity surrounded by the housing 12 and the front cover 11 accommodates The vibration system and the magnetic circuit system, the vibration system includes a diaphragm and a voice coil 23, the diaphragm includes a ring-shaped outer diaphragm 211 and an inner diaphragm 212a located inside the outer diaphragm 211, the lead wire of the voice coil 23 includes an integral body with the voice coil 23 The voice coil body lead wire 241, the voice coil body lead wire 241 is connected to the voice coil extension lead wire 242 through a conductive component, and the material of the voice coil extension lead wire 242 is a conductive material with better toughness than the material of the voice coil body lead wire 241, such as brocade wire, The voice...

Embodiment 2

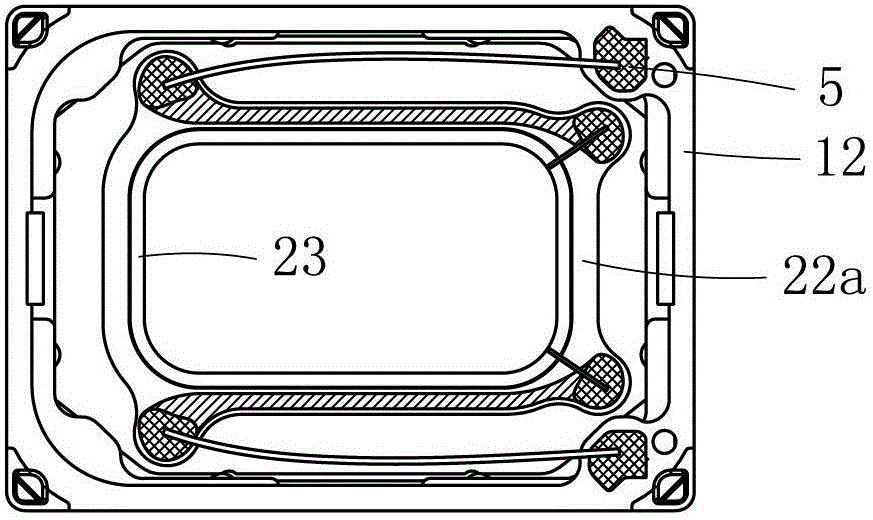

[0035] Such as Figure 4 , Figure 5 and Figure 6 Commonly shown, the main difference between this embodiment and Example 1 is that the connecting piece 22b is a hard plastic sheet, and the four corners of the connecting piece 22b are all formed into pads 4 through conductive treatment, and the conductive treatment can be used on the connecting piece 22b. The corners of the connecting piece 22b are plated with conductive material to form a pad 4, or a metal sheet is bonded to the corner of the connecting piece 22b as the pad 4, and the lead wire 241 of the voice coil body and the extended lead wire 242 of the voice coil are connected to the same pad at the same time. 4.

[0036] In this embodiment, the four corners of the connecting piece 22b are all provided with the structure of the pads 4, and only two corners on the same short side of the connecting piece 22b may be provided with the welding pads 4. Coil body lead wire 241 and voice coil extension lead wire 242 are con...

Embodiment 3

[0039] Such as Figure 5 As shown, the main difference between this embodiment and the above-mentioned embodiments is that the conductive component includes a pad 4 disposed on the edge of the inner diaphragm 212b for electrically connecting the voice coil body lead 241 and the voice coil extension lead 242.

[0040] The inner diaphragm 212b is rectangular and made of hard plastic. The edges of the four corners of the inner diaphragm 212b are all formed with conductive pads 4. The conductive treatment can be done by coating the corners of the inner diaphragm 212b with conductive coating. The material is used to form the pad 4, or a metal sheet is bonded to the corner of the inner diaphragm 212b as the pad 4, and the lead wire 241 of the voice coil body and the extended lead wire 242 of the voice coil are connected to the same pad 4 at the same time.

[0041] In this embodiment, the four corners of the inner diaphragm 212b are all provided with pads 4, and only the two corners ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com