Sheet adhered connection structure and automobile luggage rack adopting same

A technology for automotive luggage racks and connection structures, which is applied in the field of thin plate bonding connection structures, and can solve problems such as affecting appearance, exposure, and not suitable for appearance panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

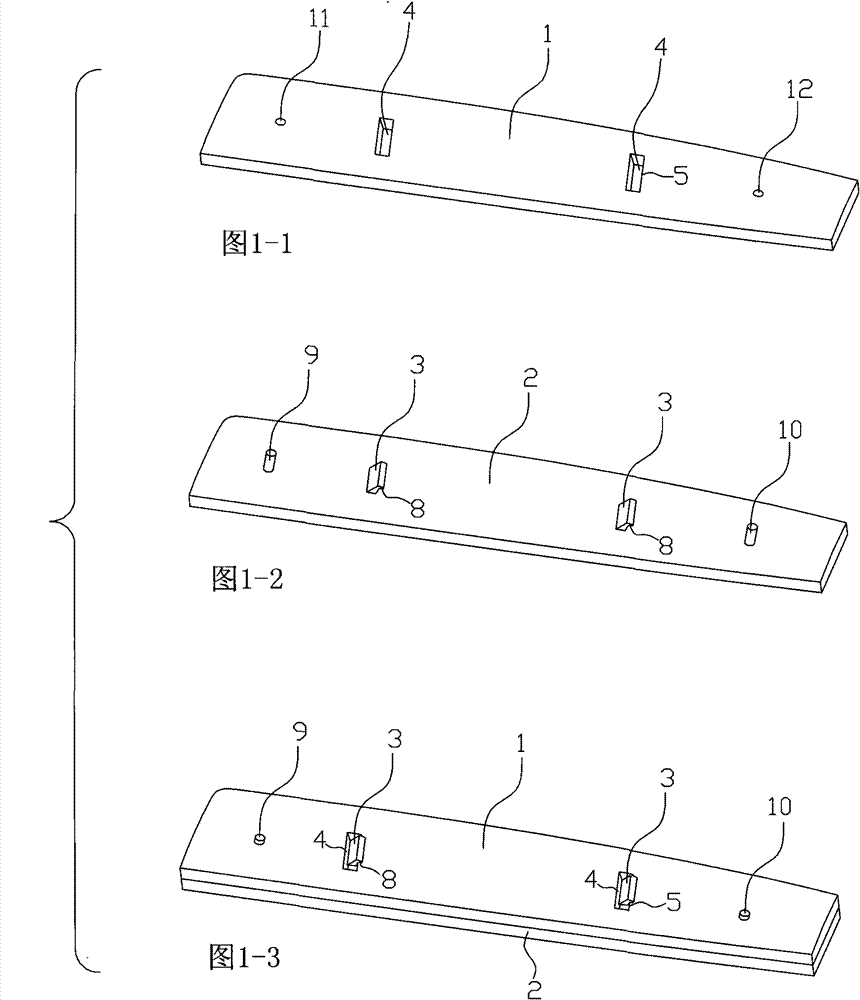

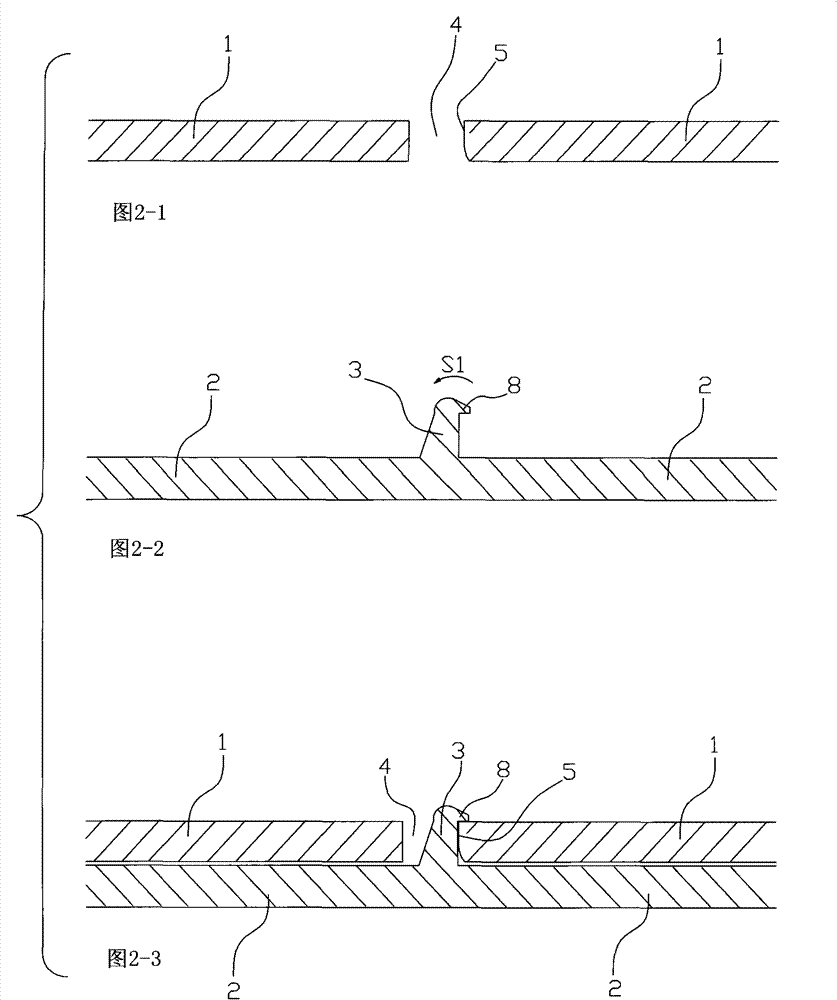

[0029] like figure 1 , figure 2 As shown, the sheet bonding connection structure includes a first sheet 1 and a second sheet 2 to be attached and connected to it. The front side of the second sheet 2 is used as the product appearance surface, and the back side used as the bonding connection surface is horizontally juxtaposed. There are two inclined protruding pieces 3 , and corresponding penetrating strip holes 4 for embedding the protruding pieces 3 are juxtaposed laterally on the adhering connecting surface of the first sheet 1 . The cross section of the protruding piece 3 is adapted to the shape of the penetration hole 4, and both are rectangular.

[0030] The top of the protruding sheet 3 is provided with a barb 8, which makes the lamination and connection of the thin plates not loosen, and the lamination connection is stable and reliable; , which is convenient for the close attachment of the two.

[0031] A leftward constraining cylindrical protrusion block 9 and a r...

Embodiment 2

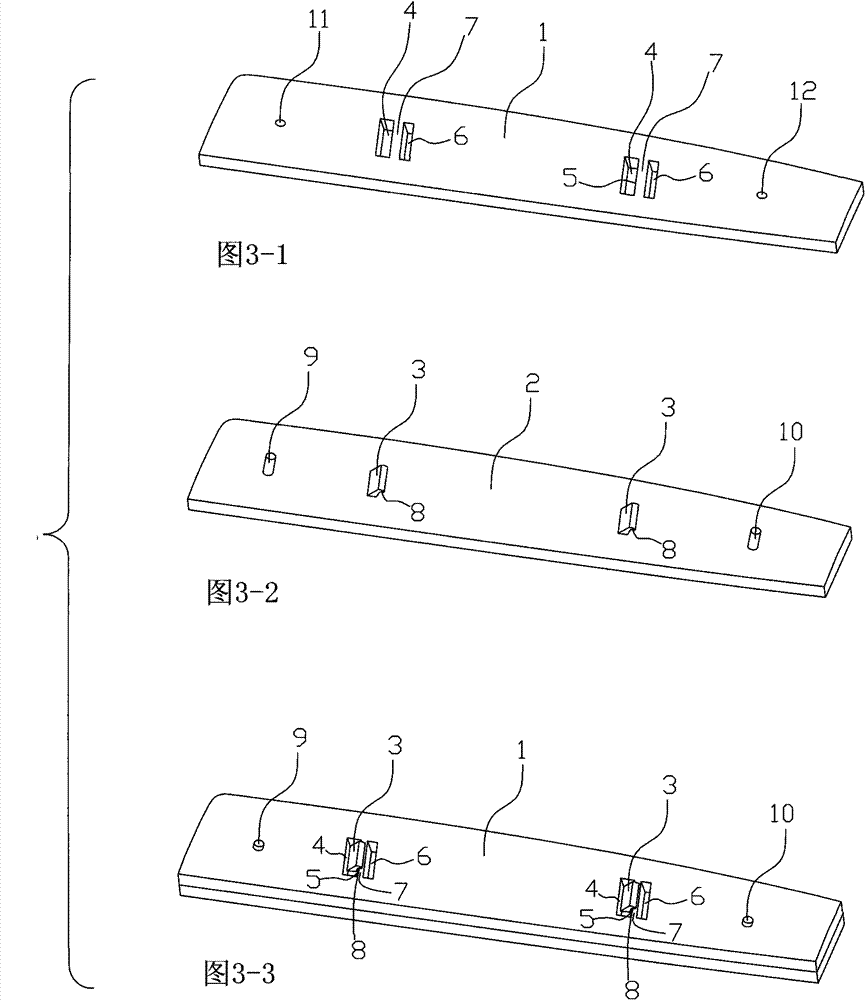

[0035] The second embodiment is an improved solution for the defect that the protruding sheet 3 is easily broken in the first embodiment, and solves this technical problem well.

[0036] like image 3 , Figure 4 As shown, the second structural scheme of the second embodiment is compared with the first embodiment, and other structures are the same as those of the first embodiment, and only the penetration holes for the embedment of the protruding sheet 3 on the bonding connection surface of the first thin plate 1 A penetrating strip hole 6 is juxtaposed in the vicinity of the compressed side 5 of the hole 4, so that a compressed narrow and long deformation bridge 7 is formed therebetween. The narrowness and length of the deformation bridge (7) must ensure that the deformation bridge (7) is deformed before the convex plate (3) when the convex plate (3) is inserted into the penetration hole (4).

[0037] When the inclined protruding piece 3 is inserted into the penetrating str...

Embodiment 3

[0040] The third embodiment is a specific application example of the improved solution described in the second embodiment of the present invention in affixing a thin sheet-like bright strip to a luggage rack of an automobile.

[0041] like Figure 7 As shown, an automobile luggage rack, mounted in pairs on the roof surface in use, comprises a tubular crossbar 20 and two support seats 21 at both ends of the crossbar to connect it with the roof of the vehicle. Each seat 21 is also equipped with a shell 22 , which is a plastic part, and a thin sheet-shaped bright strip 2 is attached and connected to the outer side of the shell 22 of the two ends of the support seat 21 or one end of the support seat 22 . The sheet-like bright strip 2 is a plastic electroplating part, and is inlaid on the outer side of the outer shell 22 of the support seat as a decorative part of the appearance of the luggage rack of the automobile.

[0042] like Figure 5 , Image 6 As shown, the sheet-like br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com