micro speaker

A micro-speaker and voice coil technology, applied in the direction of sensors, electrical components, etc., can solve the problems of shortening the service life of the micro-speaker, poor electrical connection of the micro-speaker, and reducing the reliability of the micro-speaker, so as to achieve increased strength, not easy to break, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

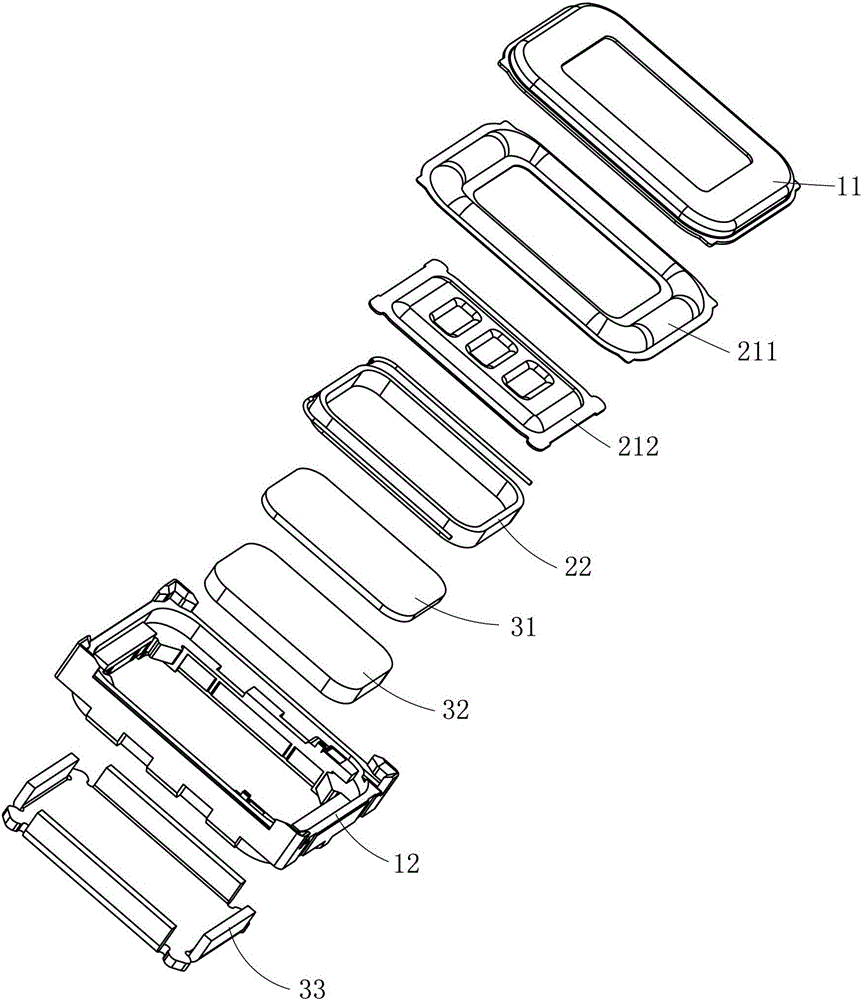

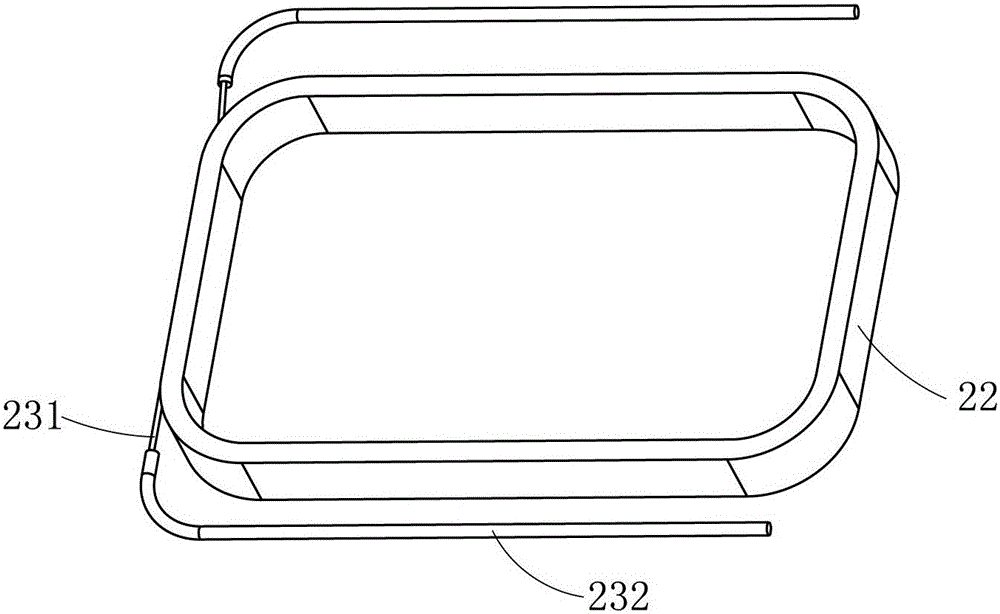

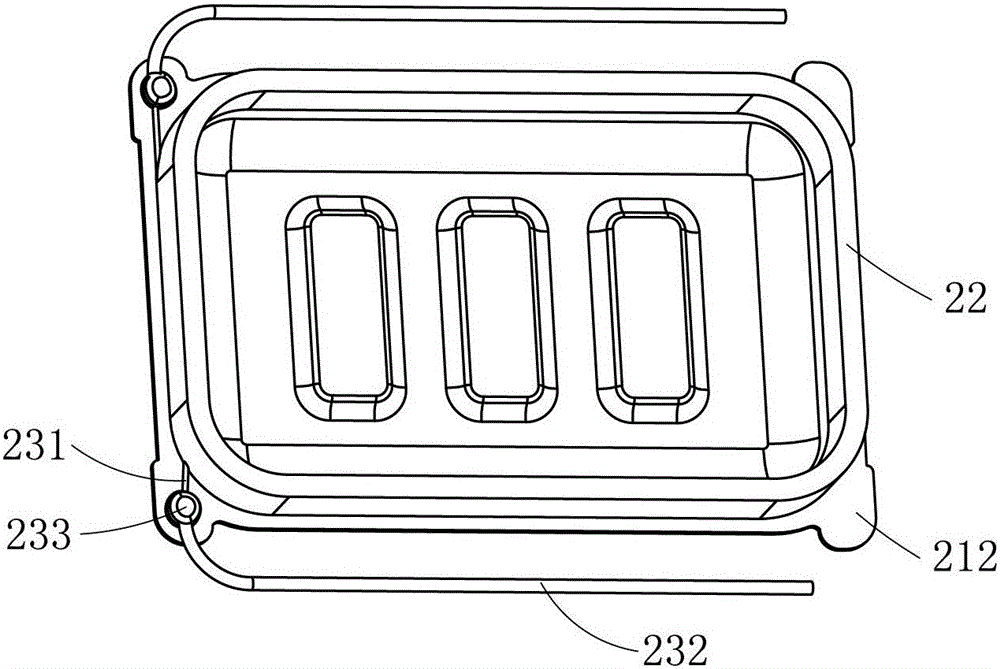

[0027] Such as figure 1 , figure 2 , image 3 and Figure 4 Commonly shown, a micro-speaker adopts a square structure, including a housing 12 and a front cover 11 combined with the housing 12. The voice coil outlet terminal 4 is provided on the housing 12, and the cavity surrounded by the housing 12 and the front cover 11 is accommodated. There are a vibration system and a magnetic circuit system. The vibration system includes a diaphragm and a voice coil 22. The leads of the voice coil 22 include a voice coil body lead 231 integrated with the voice coil 22. The voice coil body lead 231 is connected to the voice coil extension lead 232, and the voice coil extension The lead wire 232 is connected to the voice coil outlet terminal 4, and the material of the voice coil extension lead wire 232 is a conductive material with better toughness than the material of the voice coil body lead wire 231, such as brocade wire, enameled wire thicker than the voice coil body lead wire 231, ...

Embodiment 2

[0031] Such as Figure 5 , Figure 6 and Figure 7 Commonly shown, the main difference between this embodiment and Example 1 is: the micro-speaker is a circular structure, and the vibration system includes a diaphragm 21 and a voice coil 22; the magnetic circuit system includes a magnet 32 arranged in the housing 12, and a There is Washi 31.

[0032] The wire bonding portion 233 where the voice coil body lead wire 231 and the voice coil extension lead wire 232 are connected is fixed on the side wall of the voice coil 22 . It can effectively prevent the lead wire of the voice coil from breaking at the lead wire bonding portion 233 when the voice coil 22 vibrates, further improves the reliability of the micro-speaker, and further prolongs the service life of the micro-speaker.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com