Intelligent storage system for casting sand cores

A storage system and casting sand technology, applied in the field of storage systems, can solve the problems of large space occupied by sand core storage, low efficiency of sand core storage and retrieval, and achieve the effect of small warehouse area, large storage scale and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

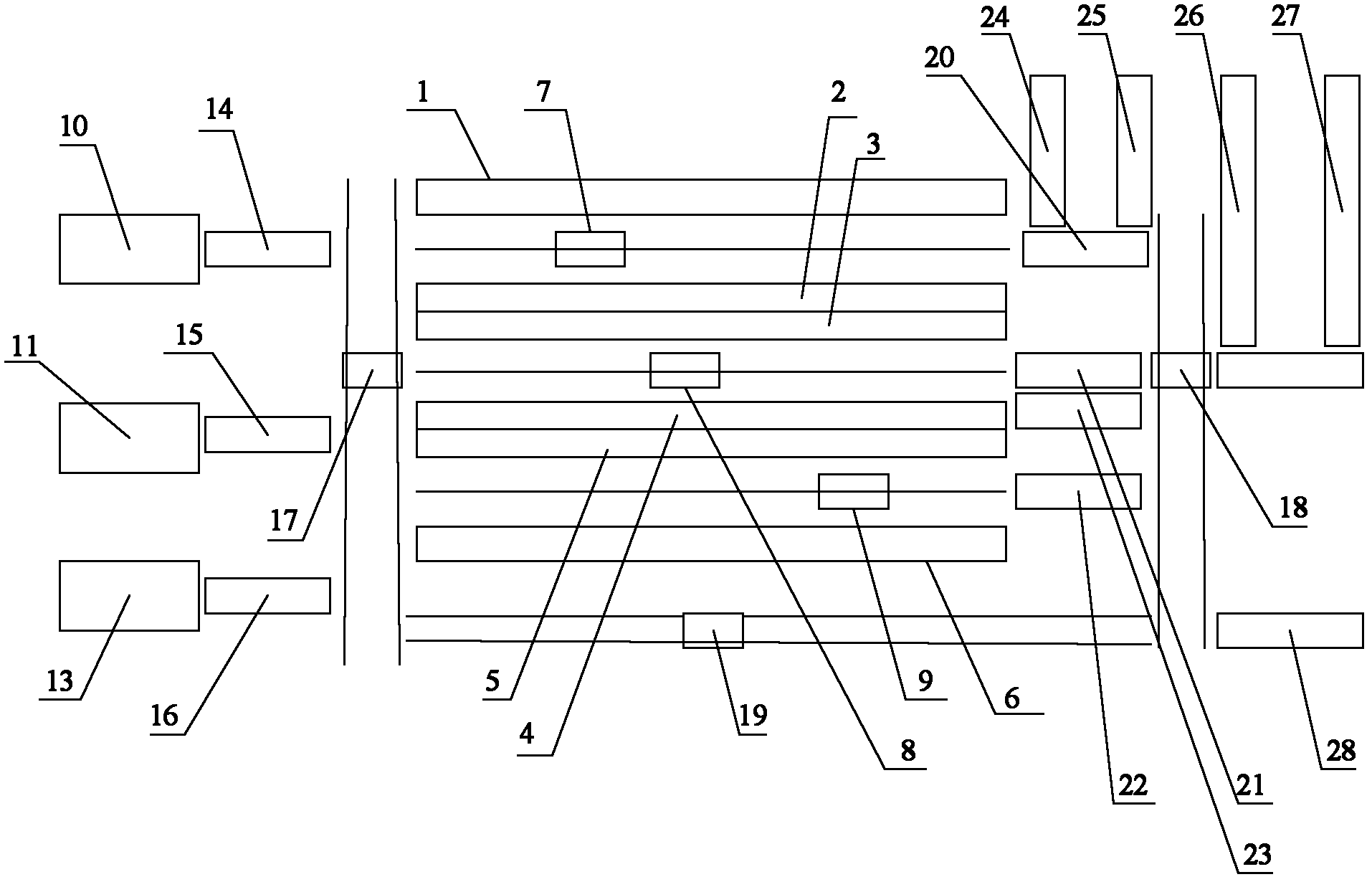

[0028] Specific embodiments of the present invention such as figure 1 As shown, the first to sixth high-rise shelves 1-6 of the three-dimensional matrix type are arranged in parallel, a stacker system 7 is provided between the high-rise shelves 1 and 2, and a stacker system 8 is provided between the high-rise shelves 3 and 4. A stacker system 9 is arranged between the upper shelves 5 and 6,

[0029] At the storage end, the first conveying systems 14, 15 are respectively connected to the surface drying furnaces 10, 11 and the entrances of the high-rise shelves, and the entrances of the high-rise shelves are connected to the first conveying systems 14, 15 through the first transition device 17, and the first The running direction of a transition device 17 is perpendicular to the arrangement direction of the high-level shelves 1-6. The third conveying system 16 connects the unqualified sand core processing room 13 and the first transition device 17 respectively.

[0030] At the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com