Water glass type magnesium alloy fusible pattern casting process

A technology of investment casting and magnesium alloys, which is used in manufacturing tools, casting equipment, metal processing equipment, etc., and can solve the problems of large castings, poor air permeability, and coarse grains of castings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

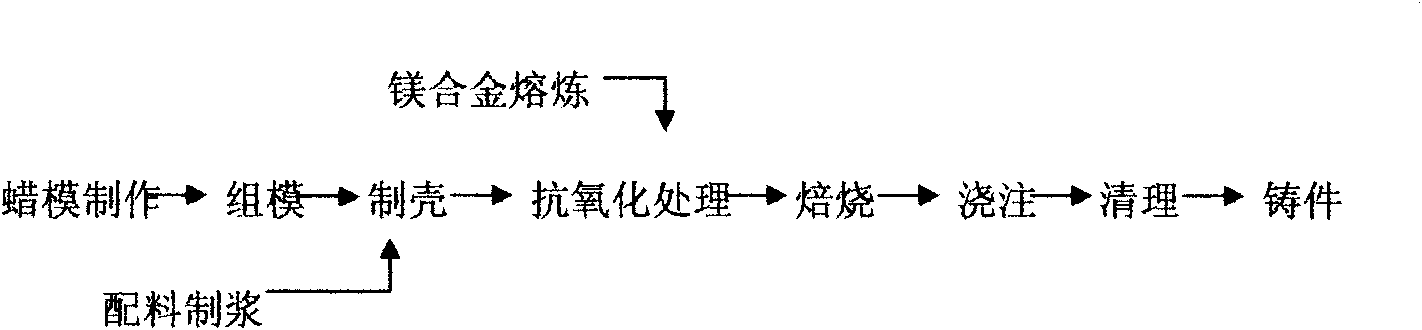

Image

Examples

Embodiment Construction

[0017] 1. Wax mold preparation

[0018] Molding material: wax-based molding material and resin-based molding material

[0019] Molding process parameters:

[0020] The injection temperature is 45-80°C; the molding temperature is 20-30°C.

[0021] Injection pressure 0.3 ~ 15Mpa; holding time 1 ~ 5 minutes

[0022] The mold-making room temperature is 18-30°C; the cooling water temperature of the wax mold is 18-28°C.

[0023] Design gating system and assemble wax patterns

[0024] 2. Shell making

[0025] Top coat ratio

[0026] Quartz glass powder: water glass: wetting agent = (1.15~1.5): 1.0: 0.05

[0027] Coating ratio of reinforcement layer

[0028] Bauxite: silica sand: water glass: wetting agent = (0.6 ~ 0.9): (0.3 ~ 0.5): 1.0: 0.05

[0029] Hardener: ammonium chloride: water = (20~30): (80~70)

[0030] Shell making process parameters:

[0031] Layers Paint Viscosity Sanding Size Hardener Temperature Hardening Time Drying Time (minutes)

[0032] / S (s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com