Multi-point directional extrusion casting method applicable to nonuniform wall thickness complex casting

A squeeze casting, non-uniform technology, applied in the field of multi-point directional squeeze casting, can solve the problems of limited range of casting shapes and sizes, high requirements for equipment and molds, easy to form shrinkage and shrinkage cavities, etc., to achieve flexible design, equipment The effect of low mold requirements and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

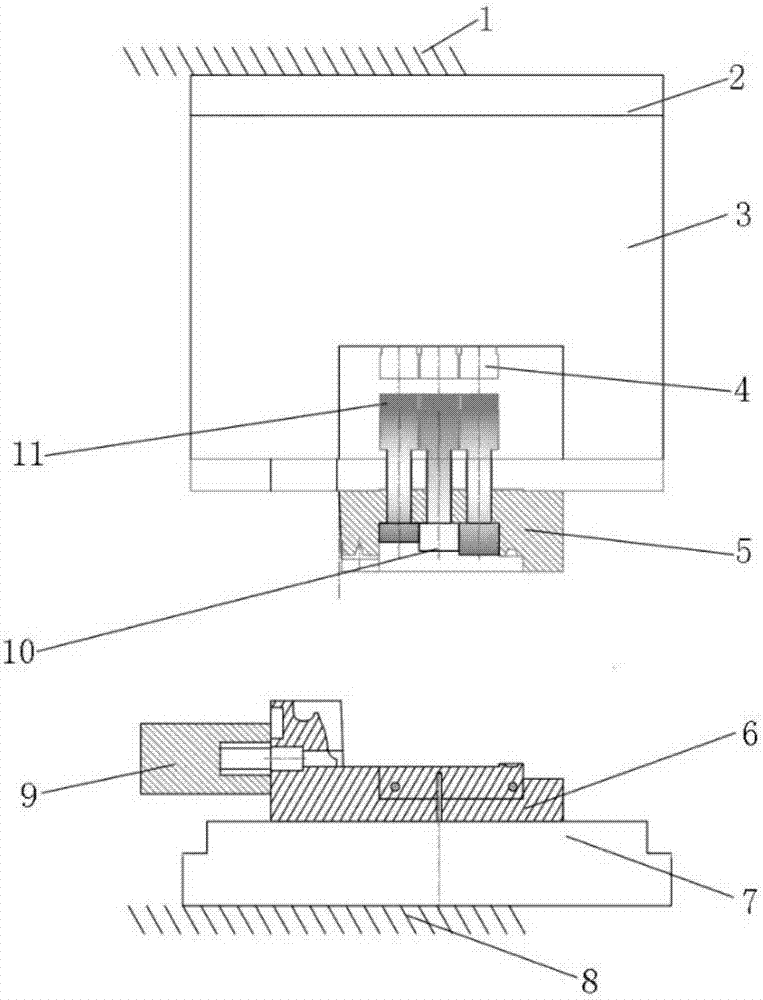

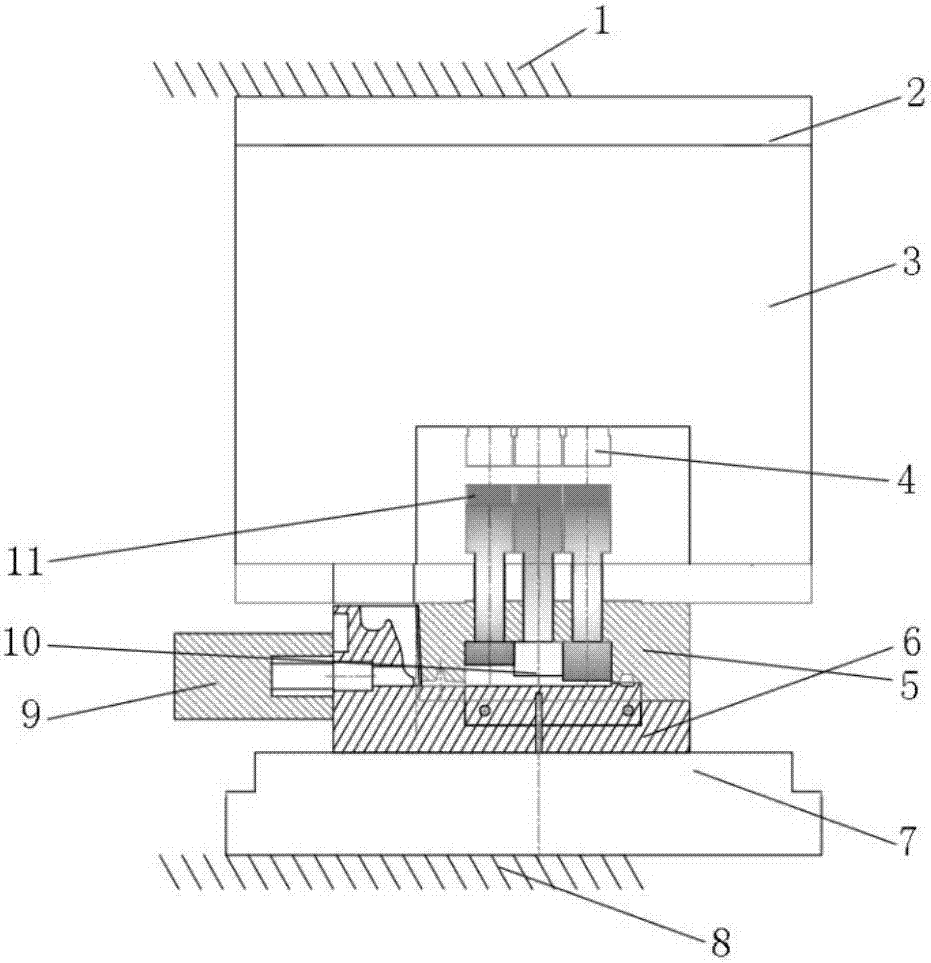

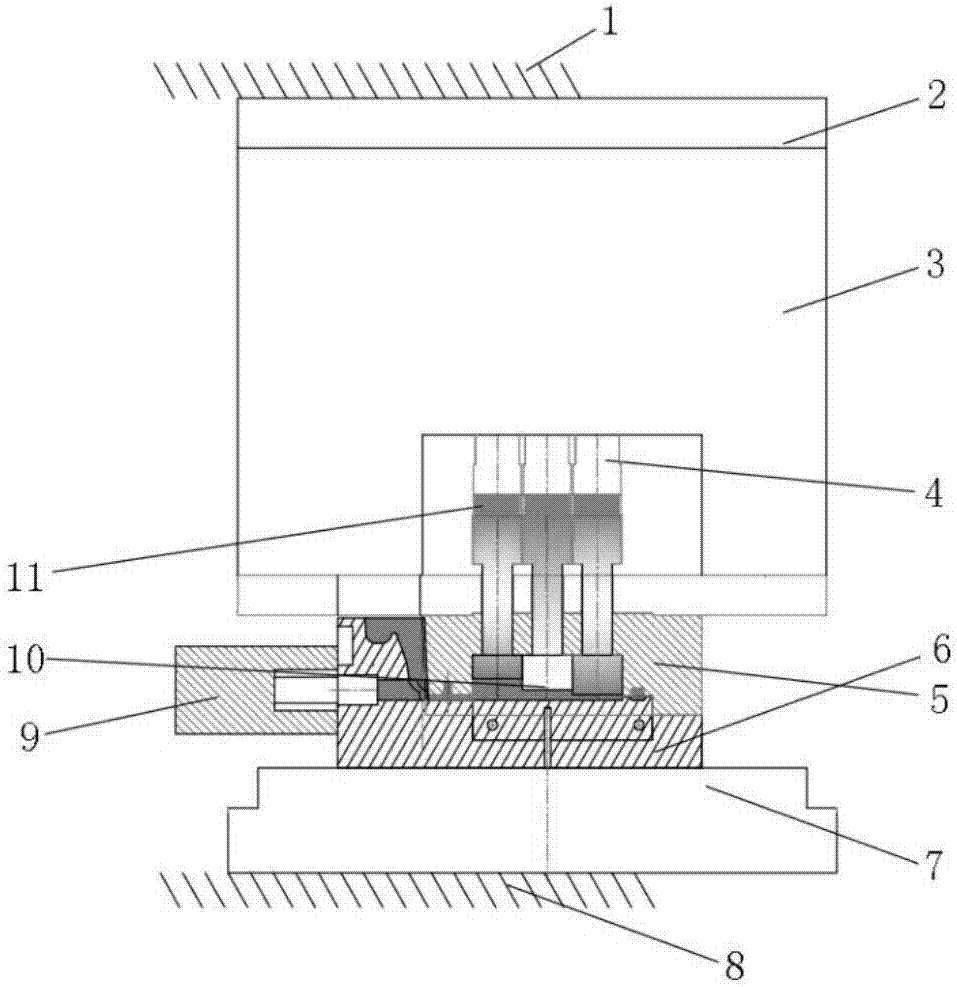

[0049] This embodiment provides a multi-point directional squeeze casting mold suitable for complex castings with non-uniform wall thickness, such as Figure 1-Figure 3 As shown, the mold includes: a movable mold structure 5, a fixed mold structure 6, and a pressure applying structure 3, the movable mold structure 5 is arranged above the fixed mold structure 6, and the pressure applying structure 3 is arranged above the movable mold structure 5;

[0050] The movable mold structure 5 includes a movable mold base plate and a plurality of pressure applying punches 10, and the lower bottom surface of the pressure applying punches 10 is connected with the movable mold base plate to form an upper cavity;

[0051]The fixed mold structure 6 includes a fixed mold base plate and a fixed mold cavity plate, and the fixed mold cavity plate is arranged on the top of the fixed mold base plate, and can be connected with the movable mold structure 5 to form a closed casting cavity;

[0052] A ...

Embodiment 2

[0066] This embodiment provides a multi-point directional squeeze casting method suitable for complex castings with non-uniform wall thickness, including using the mold described in Embodiment 1 to apply multi-point directional pressure to the complex casting with non-uniform wall thickness to be solidified Step; the range of the directional pressure is 0-100MPa. The pressure time is 0-100s.

[0067] In this embodiment, since the casting to be formed has three wall thicknesses, three pressure-applying punches corresponding to the wall thicknesses are provided in the mold filling and solidification device used. When applying directional pressure, the pressure punch corresponding to the maximum wall thickness applies a pressure of 50MPa; the pressure punch corresponding to the middle wall thickness value applies a pressure of 20MPa; the pressure punch corresponding to the minimum wall thickness applies a pressure of 0MPa ; The pressure time is 50s.

[0068] Analytical methods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com