Gravity casting process of all-metal mould of coupler aluminum part

A gravity casting and all-metal technology, which is applied in metal processing equipment, manufacturing tools, casting molding equipment, etc., can solve the problems of uneconomical, unenvironmental protection, high modeling requirements, etc., and achieve the effect of saving time and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

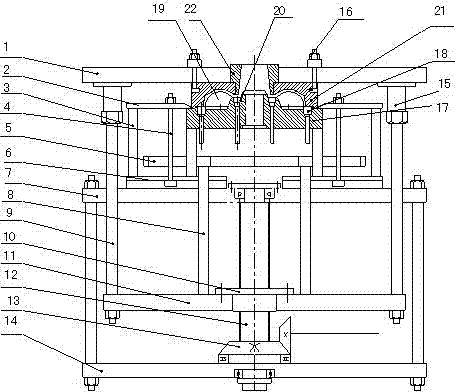

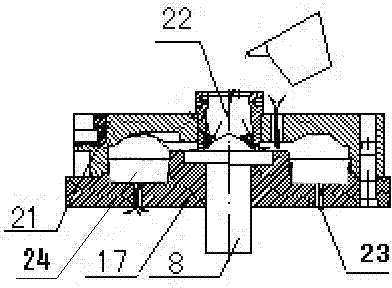

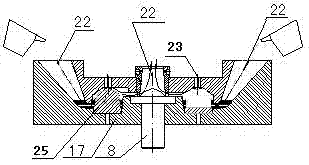

[0014] Embodiment: Take the YOXII400 turbine as an example to illustrate the all-metal mold gravity casting process. as the picture shows:

[0015] (1) The mold is preheated and closed. First, clean the dirt and residue on the surface of the YOX400 hydraulic coupling turbine mold, fix the inner core of the all-metal mold on the lower mold and integrate it, remove the inner and outer ejector pins on the mold, and put the mold and related components Put it into a baking oven, raise the temperature of the baking oven to 100-150°C, keep the temperature at a constant temperature for 30-60 minutes, and then raise the mold temperature evenly to 250°C. Take out the mold and spray release paint on the surface of the cavity and the components, and then put it in the furnace to keep the temperature for about 10 minutes. Pay attention to the inner and outer diameters of the inner and outer top rings of the mold to leave a thermal expansion gap of 0.5mm. Then fix the lower mold 17 taken ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com