Methylene blue adsorption testing method of bentonite

A test method and technology of bentonite, which are applied in the direction of material analysis by chemical reaction of materials and material analysis by observing the influence on chemical indicators, can solve the problems of low measurement accuracy, prolonged test process, repeated titration, etc. Accurate results, reduced labor intensity, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

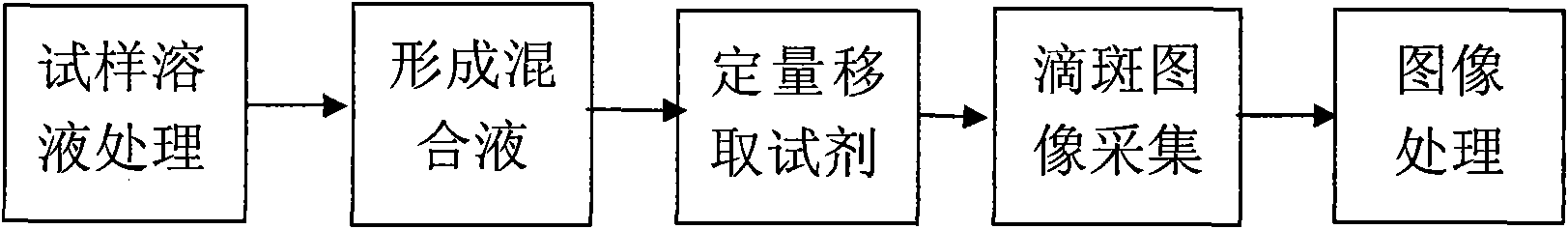

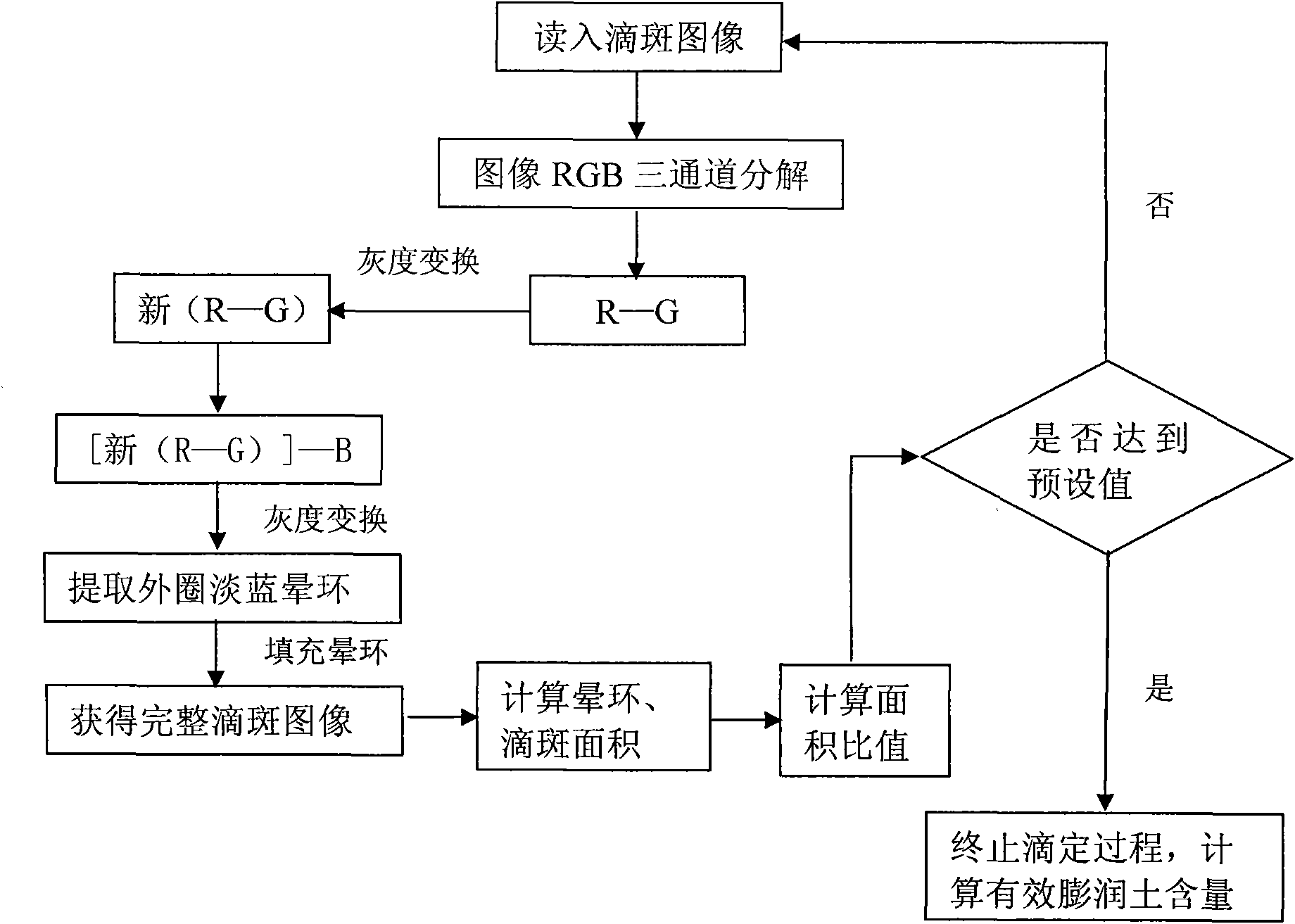

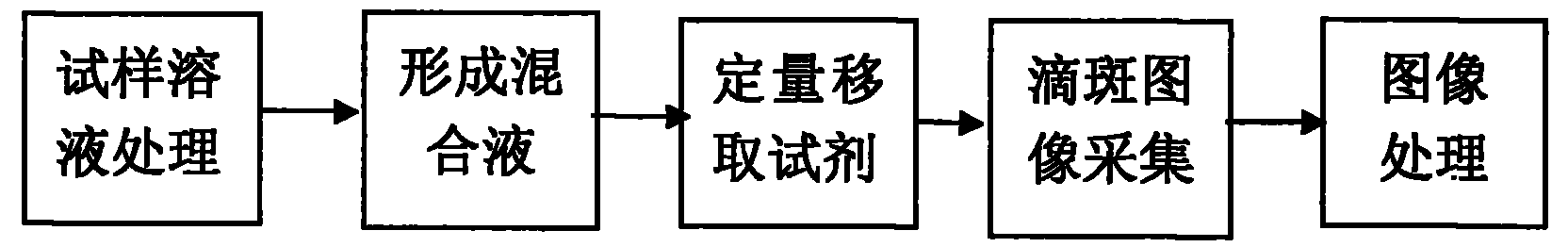

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: the determination of bentonite blue absorption

[0049] 1. Solution processing steps: heat the mixed solution of 0.2g bentonite sample, 20mL of sodium pyrophosphate solution with a mass fraction of 1%, and 50mL of distilled water, stop heating after the solution is boiled for 5 minutes, and stir until the solution is evenly dispersed;

[0050] Two. Form the mixed solution step: the daily bentonite blue amount test value is 38mL, and the first methylene blue titration is estimated to be 30mL, quantitatively pipetting 30mL of pure methylene blue solution with a mass percentage concentration of 0.2% in the processed bentonite sample solution and Stir to form a mixture, go to step 4;

[0051] 3. Quantitative pipetting reagent step: quantitatively pipette the pure methylene blue solution with a mass percentage concentration of 0.2% in the treated bentonite sample solution and stir to form a mixed solution; control the methylene blue according to the area ratio ...

Embodiment 2

[0055] Embodiment 2: Determination of effective bentonite content in clay old sand

[0056] 1. Solution processing step: heat the mixed solution of 5 g of clay old sand, 20 mL of sodium pyrophosphate solution with a mass fraction of 1%, and 50 mL of distilled water, and stop heating after the solution is boiled for 5 minutes, and stir until the solution is evenly dispersed;

[0057] 2. The step of forming a mixed solution: the daily test value of the blue absorption amount of old sand is 85mL, and the first methylene blue titration is estimated to be 70mL, quantitatively pipette 70mL of pure methylene blue solution with a mass percentage concentration of 0.2% into the treated old sand solution And stir to form a mixture, go to step 4;

[0058] 3. Quantitative pipetting reagent step: quantitatively pipette the pure methylene blue solution with a mass percentage concentration of 0.2% in the treated old sand solution and stir to form a mixed solution, and control the area ratio T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mana absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com