Magnesium alloy integrally cast sound box and manufacturing method thereof

A kind of integral casting and magnesium alloy technology, which is applied in the components of audio equipment, magnesium alloy integral casting speakers and their manufacturing fields, can solve the problems of large overall weight of speakers, good aluminum alloy speakers, and loss of sound field energy, so as to achieve pure sound quality and preservation Good accuracy, eliminate standing wave effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

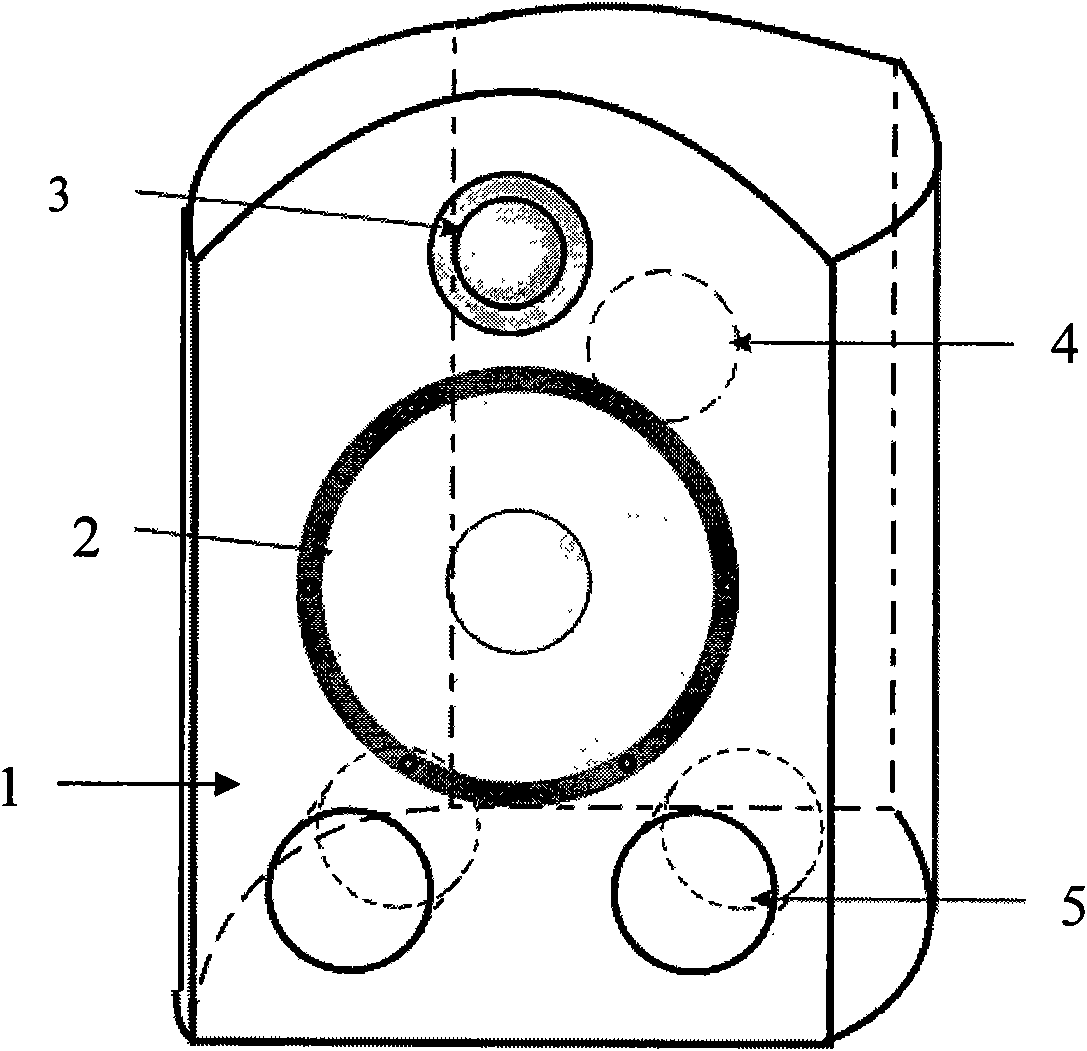

[0033] Refer to attached figure 1 , this example designs a kind of front panel wall, two side walls, the top wall are all curved surfaces, and the lower wall and the rear wall are plane magnesium alloy overall casting bookshelf sound box body. The cabinet is a double-frequency bookshelf speaker with curved side walls, and the thickness of each wall ranges from 5mm to 50mm. The thickness of the front panel wall is the largest, and the width and height of the front wall are greater than the width and height of the rear wall. frequency, the upper part is the hole for the high-frequency speaker, and the high-frequency speaker can use about 1 inch high-quality silk film, titanium metal film, or aluminum alloy thin ribbon tweeter; the middle part is the hole for the low-frequency speaker, which can be used 5-inch to 10-inch high-quality mid-low frequency speakers; the lower part is a sonic inverter tube, and the length of the inverter tube is about 1 / 2 to 2 / 3 of the depth inside the...

Embodiment 2

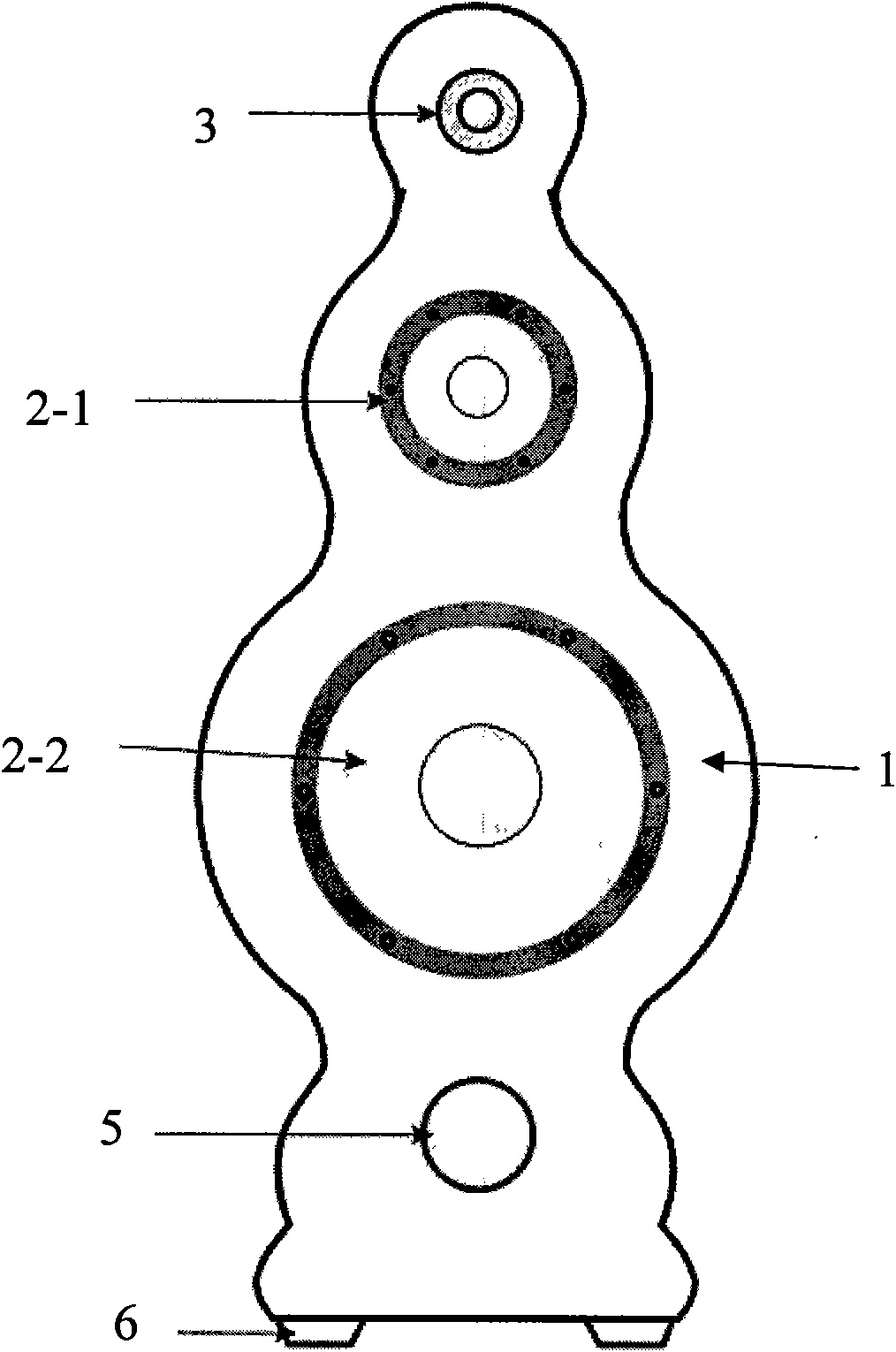

[0035] refer to figure 2 , this example designs a kind of front panel wall, two side walls, top wall and rear wall all are curved surface, and the lower wall is the magnesium alloy overall casting sound box body of plane. The speaker body adopts a circular arc transition design from top to bottom according to the size of the speaker. The speaker is three-way, the upper part is the tweeter, the middle part is the mid-range speaker, and the lower part is the low-frequency speaker. The high-frequency speaker can use about 1 inch high-quality silk film, titanium alloy film, or aluminum alloy thin ribbon tweeter; the mid-frequency speaker can use a 5-inch to 10-inch speaker; the low-frequency speaker can use an 8-inch to 18 inch speaker, with 2 sound wave ports on both sides of the lower part. The wall thickness of each part ranges from 5mm to 100mm. Four inverted trapezoidal steps can be cast on the bottom surface of the speaker as speaker feet for contact with the ground. Su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com