Ultrahigh-strength rare earth-magnesium alloy board and preparation method thereof

A technology of alloy sheet and rare earth magnesium, applied in the field of magnesium alloy sheet and its preparation, can solve the problems of coarse grain, uneven structure, poor performance, etc., and achieve the effect of fine grain and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Specific Embodiment 1: According to the mass fraction of an ultra-high-strength rare earth magnesium alloy plate in this embodiment, 2.0% to 17.0% Gd, 3.0% to 18.0% Y, 0.5% to 3.5% Zn, 0.1% to 1.5% Zr and 76.0% ~94.0% Mg, and the sum of the mass fractions of Gd and Y in the ultra-high-strength rare earth magnesium alloy plate is m, 5.0%<m<20.0%.

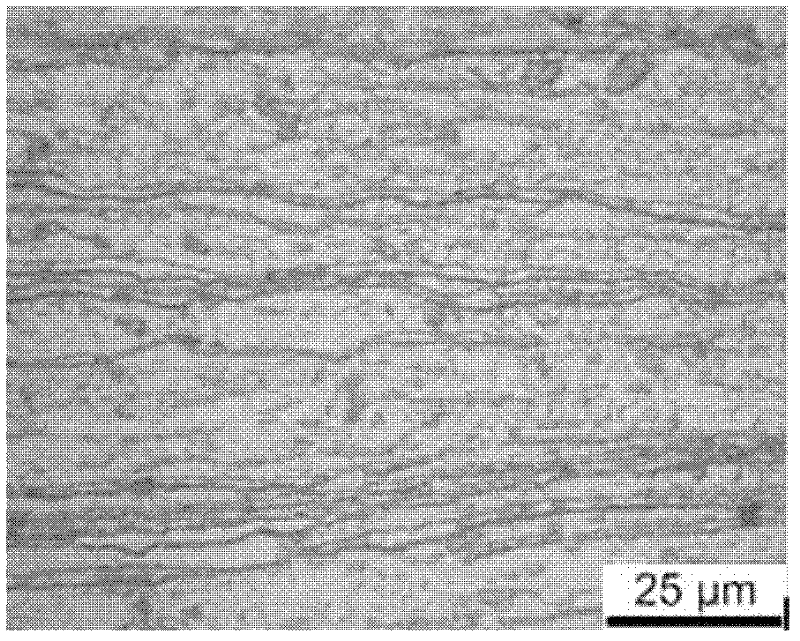

[0011] The ultra-high-strength rare-earth magnesium alloy plate prepared in this embodiment has fine grains and uniform structure.

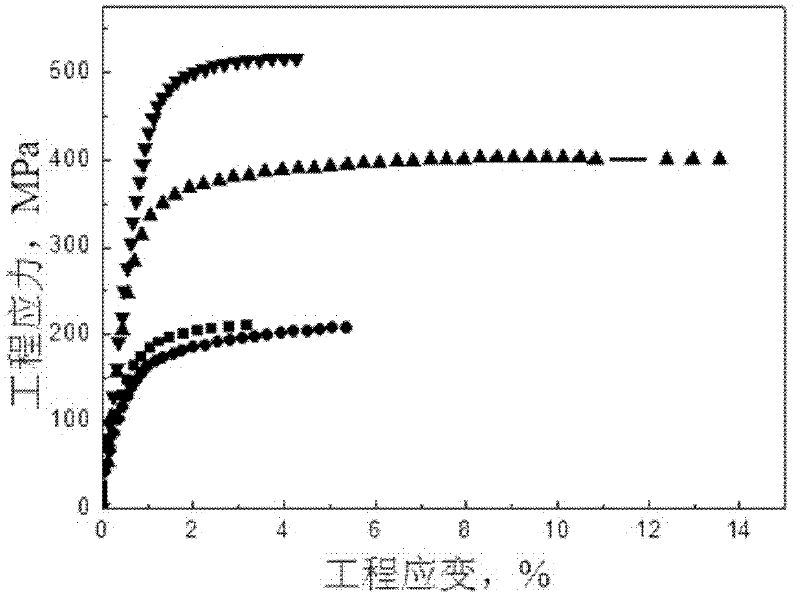

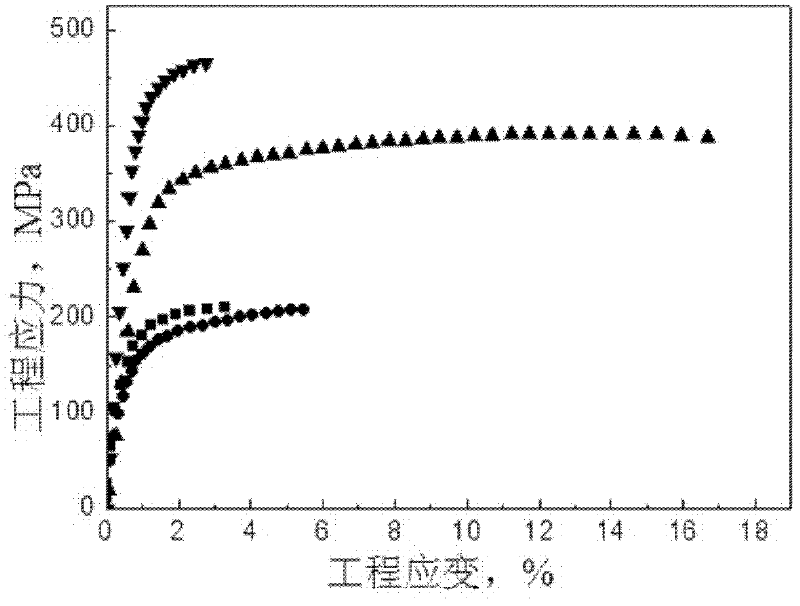

[0012] The ultra-high-strength rare-earth magnesium alloy sheet prepared in this embodiment is tested at room temperature, and it can be seen that the tensile strength is 460MPa-520MPa, the yield strength is 360MPa-430MPa, and the elongation is 4%-20%.

specific Embodiment approach 2

[0013] Specific embodiment two: In this embodiment, an ultra-high-strength rare-earth magnesium alloy plate and its preparation method are specifically completed according to the following steps:

[0014] 1. Preparation of rare earth magnesium alloy ingots: firstly, according to the mass fraction of 2.0% ~ 17.0% Gd, 3.0% ~ 18.0% Y, 0.5% ~ 3.5% Zn, 0.1% ~ 1.5% Zr and 76.0% ~ 94.0% Mg proportioning materials , and the proportioning material satisfies that the sum of the mass fractions of Gd and Y is m, 5.0%≤m≤20.0%, and then prepared into a rare earth magnesium alloy ingot by sand casting, metal mold casting or semi-continuous casting; 2. Preparation Rolling billet: the rare earth magnesium alloy ingot prepared in step 1 is subjected to homogenization annealing treatment at 400 ° C ~ 550 ° C for 6 h ~ 24 h, and then the rare earth magnesium alloy ingot after homogenization annealing treatment is cut into a thickness of 15 mm ~ 300mm, 60mm~500mm in width, and 100mm~3000mm in leng...

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the materials described in step one are pure Mg ingot, Mg-Gd master alloy, Mg-Y master alloy, pure Zn ingot, Mg-Zn intermediate alloys and Mg-Zr master alloys. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com