Iron-type coated-sand casting disc brake caliper body and producing method thereof

An iron mold sand-covered casting, disc brake technology, applied in casting molding equipment, brake actuators, casting molds, etc. The effect of low manufacturing cost, high production efficiency and high process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

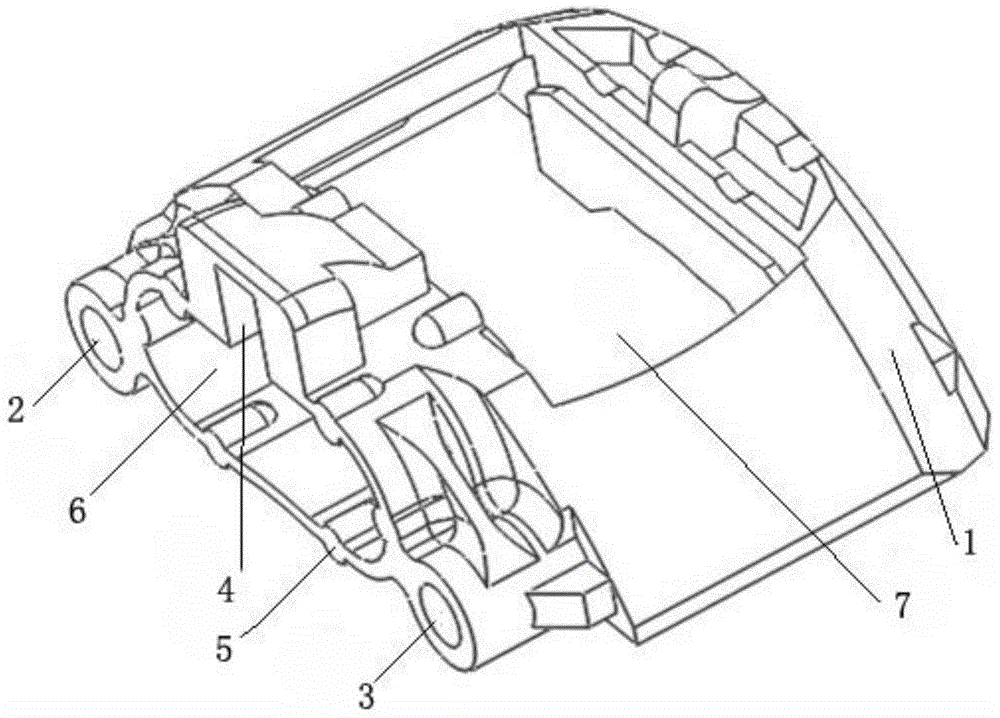

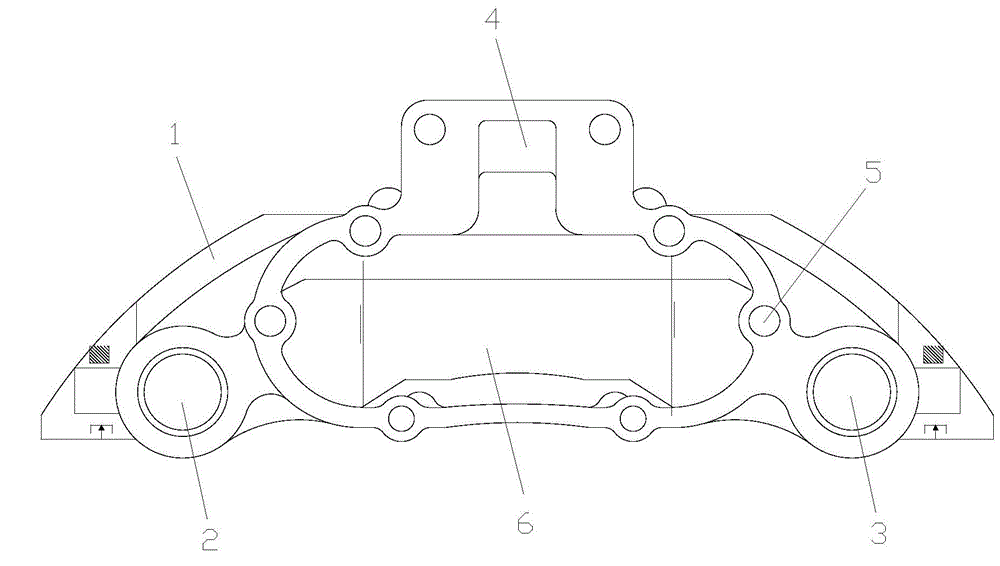

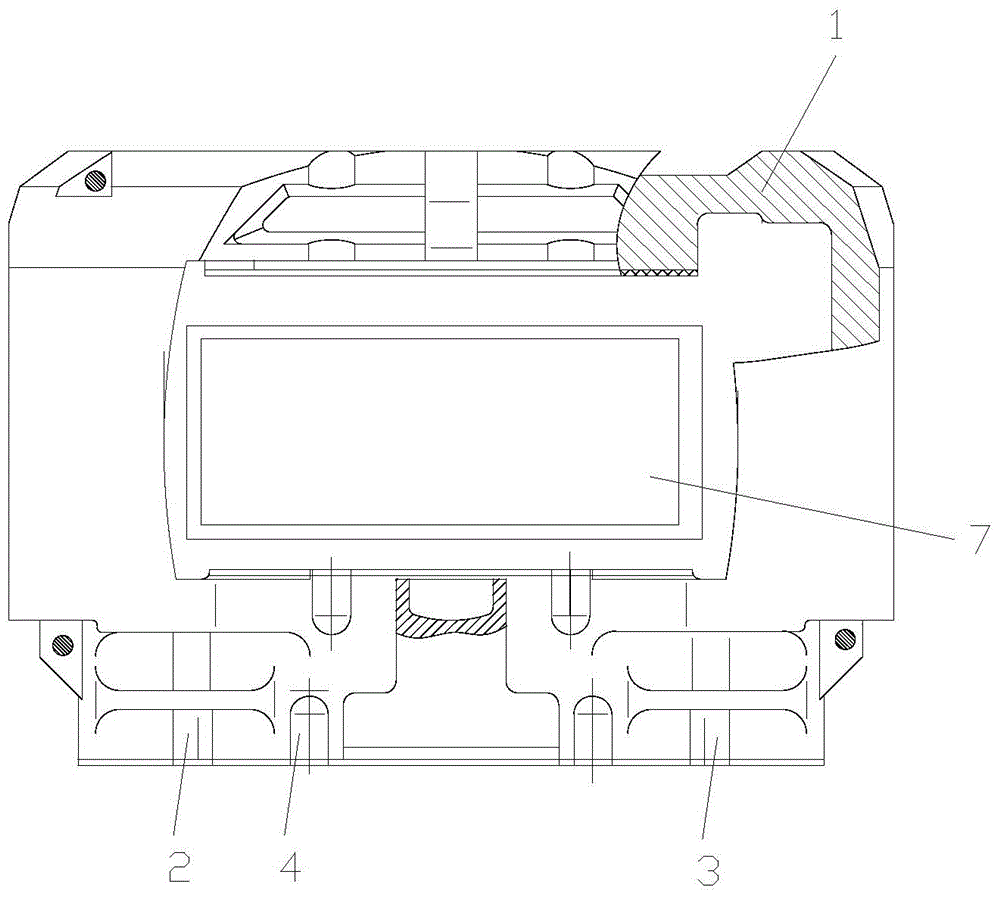

[0034] Embodiment 1 of the present invention provides a disc brake caliper body cast with iron mold sand-covered, see Figure 1 to Figure 3 , the disc brake caliper body of the iron mold sand-covered casting includes a caliper body body 1, a left end fixed support installation hole 2 and a right end fixed support installation hole 3 arranged symmetrically at both ends of the caliper body body 1, and a fixed support installation hole 3 arranged on the caliper body body 1 Brake cylinder mounting groove 4 in the middle upper part, brake mechanism cover hole 5 set on the middle side of the caliper body body 1, synchronous adjustment sprocket chamber groove 6 set in the middle of the caliper body body 1, set on the caliper body body 1 Brake disc mounting part 7 in the middle part.

Embodiment 2

[0036] Embodiment 2 of the present invention provides a production method of a disc brake caliper body cast by iron mold sand-covered casting, see Figure 4 , the production method of the disc brake caliper body of the iron mold sand-covered casting, the steps are as follows:

[0037] S101. Shape:

[0038] The outer sand box is made of iron mold, and the coated sand is resin sand. The inner cavity of the iron mold is made according to the shape of the brake caliper body, and the thickness of the sand layer is 5mm-30mm; The gate, horizontal gate and filter screen adopt closed gate; the highest perforation and core head of the upper half mold are equipped with air hole needles, and do not pass through the box surface; evenly on the parting surface of the iron mold Exhaust grooves are distributed; heating devices are installed in the middle of the upper and lower mold bottom plates of the outer mold, and the mold temperature and iron mold temperature are controlled at 180-240°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com