Bidirectional clamping mechanism

A technology of two-way clamping and power mechanism, which is applied in the direction of clamping, metal processing machinery parts, support, etc., can solve the problems of machining accuracy deviation, inconsistent centerline deviation, etc., and achieve the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

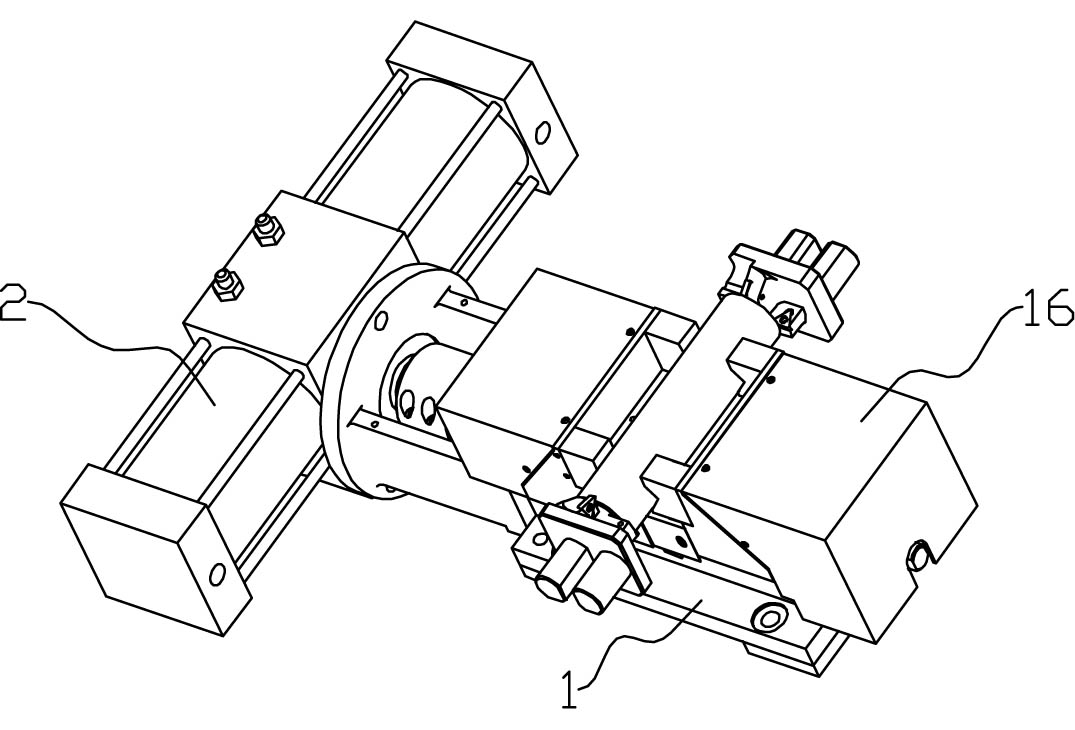

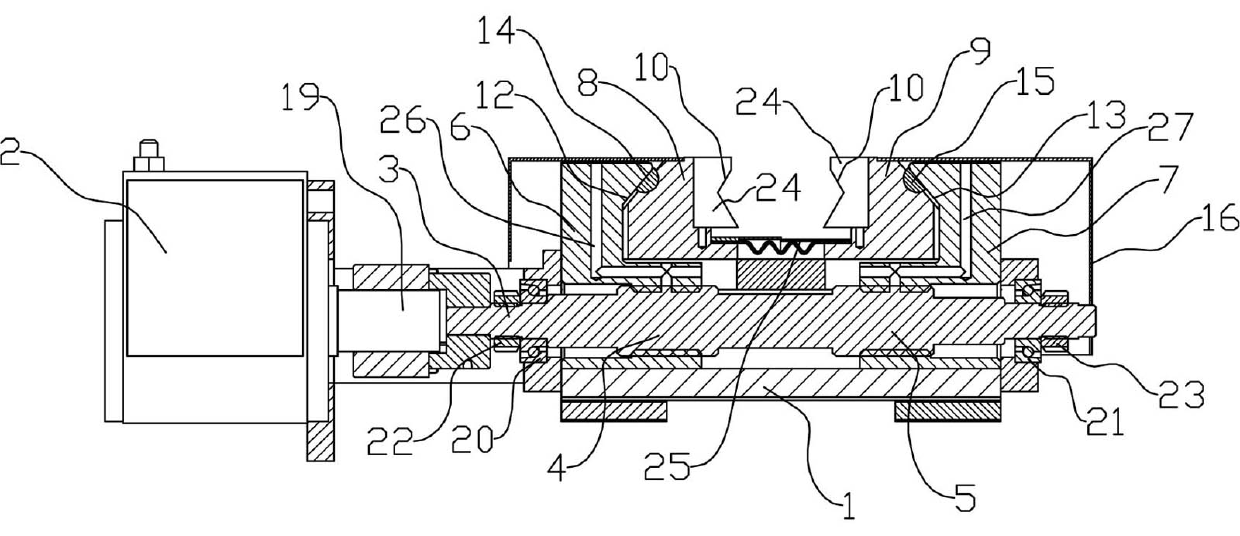

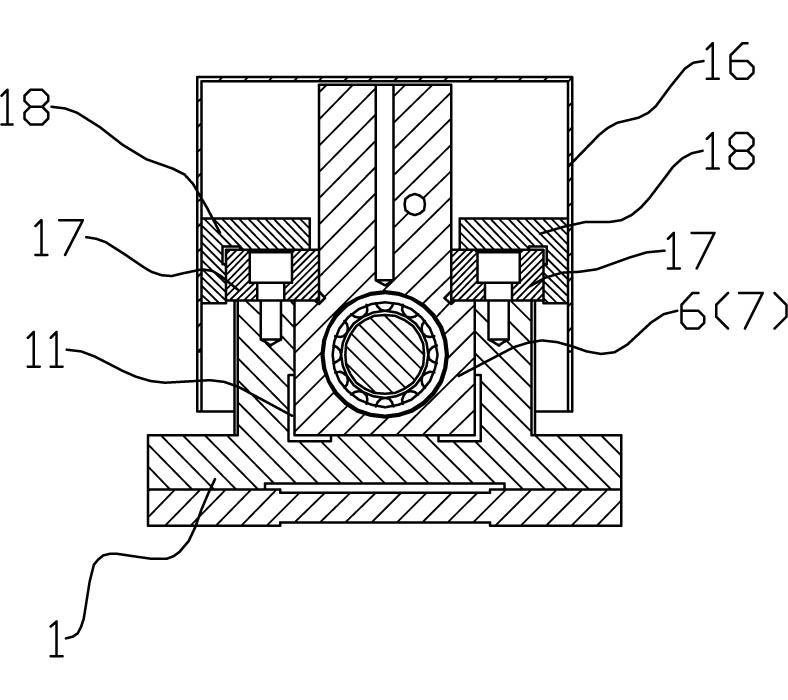

[0016] refer to Figure 1 to Figure 3 , a two-way clamping mechanism of the present invention, comprising a base 1 and a power mechanism 2, the rotating shaft 19 of the power mechanism 2 is connected with a screw 3, and the screw 3 is respectively provided with first and second threaded parts 4, 5 at intervals, The pitches of the first and second threaded parts 4 and 5 are equal and the direction of rotation is opposite. The outer parts of the first and second threaded parts 4 and 5 are fitted with first and second nuts 6 and 7. The first and second nuts 6 The first and second sliders 8 and 9 are installed on the first and second sliders 7 and 7 respectively, and the first and second sliders 8 and 9 are respectively provided with jaws 10 with opposite openings. Wherein, the power mechanism 2 is one of a rotary cylinder, an oil cylinder or a motor. Due to the adoption of the above-mentioned structure in this bidirectional clamping mechanism, the first and second nuts 6 and 7 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com